An insulation layer laying device for prefabricated wall brick processing

A technology of thermal insulation layer and wall brick, which is applied in the field of laying device for thermal insulation layer for prefabricated wall brick processing, which can solve the problems of inability to apply glue to prefabricated sandwich thermal insulation wall bricks and automatic prefabricated sandwich thermal insulation wall brick processing, etc., to achieve enhanced adhesion , enhance firmness, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

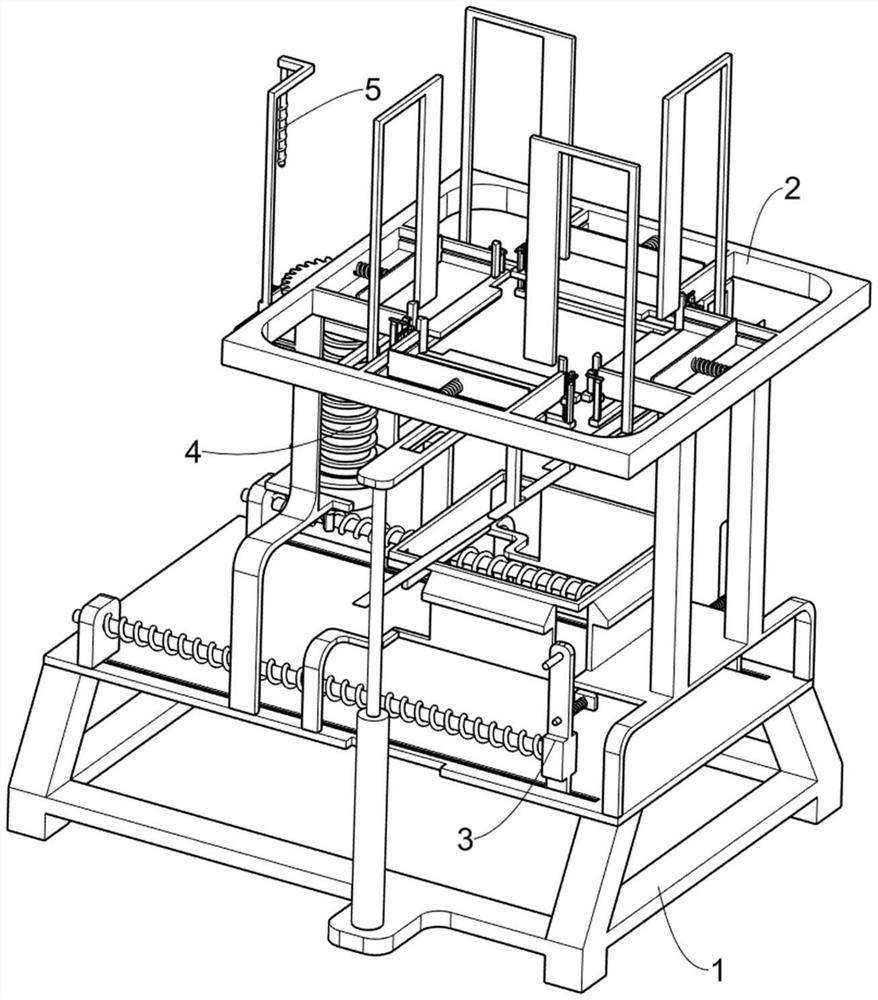

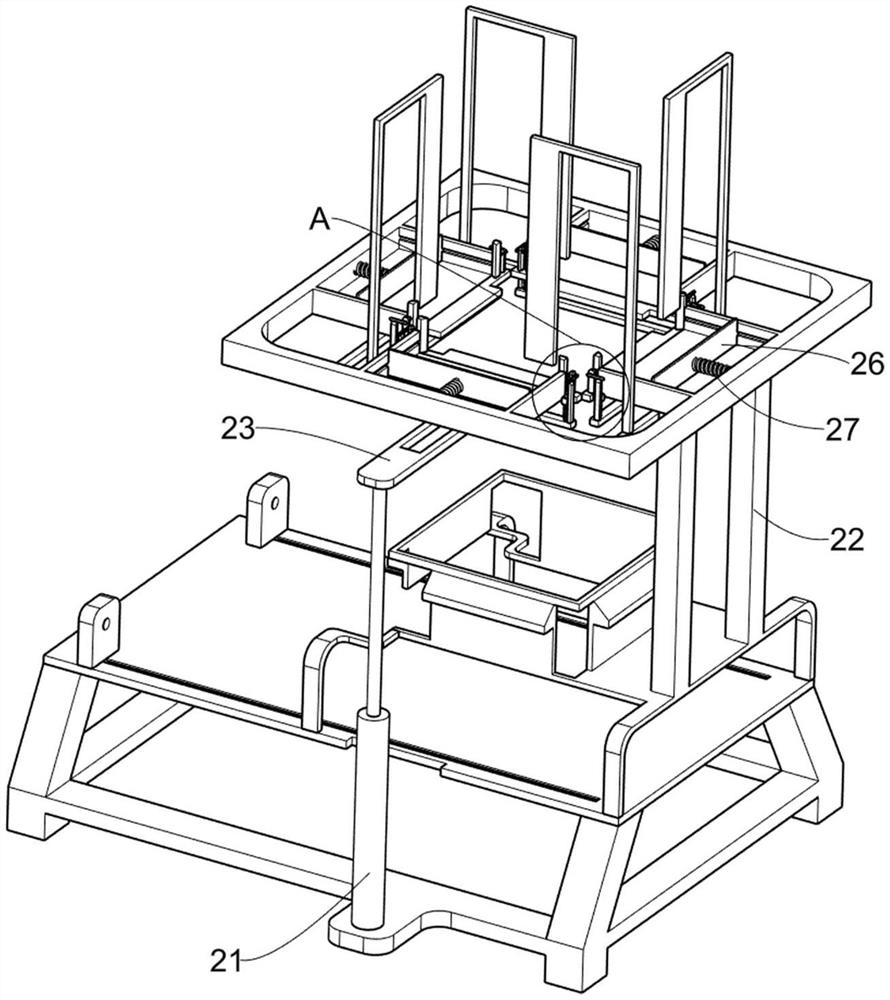

[0028] A thermal insulation layer laying device for processing prefabricated wall tiles, such as Figure 1-11 As shown, it includes a first fixing frame 1, a steel bar placing mechanism 2 and a pushing mechanism 3, the first fixing frame 1 is provided with a steel bar placing mechanism 2, and the steel bar placing mechanism 2 is used for arranging steel bars around the insulation board, and the pushing mechanism 3 is provided with on the rebar placement mechanism 2.

[0029] The rebar placement mechanism 2 includes a cylinder 21 , a guide frame 22 , a second fixed frame 23 , a first sliding frame 24 , a first return spring 25 , a sliding plate 26 , a second return spring 27 , a wedge bar 28 , and a first fixed rod 29 , the second sliding frame 211, the third restoring spring 212, the third sliding frame 213, the fixing bar 214 and the fourth restoring spring 215, the cylinder 21 is installed on the first fixing frame 1, and the cylinder 21 is used to drive the second fixing fr...

Embodiment 2

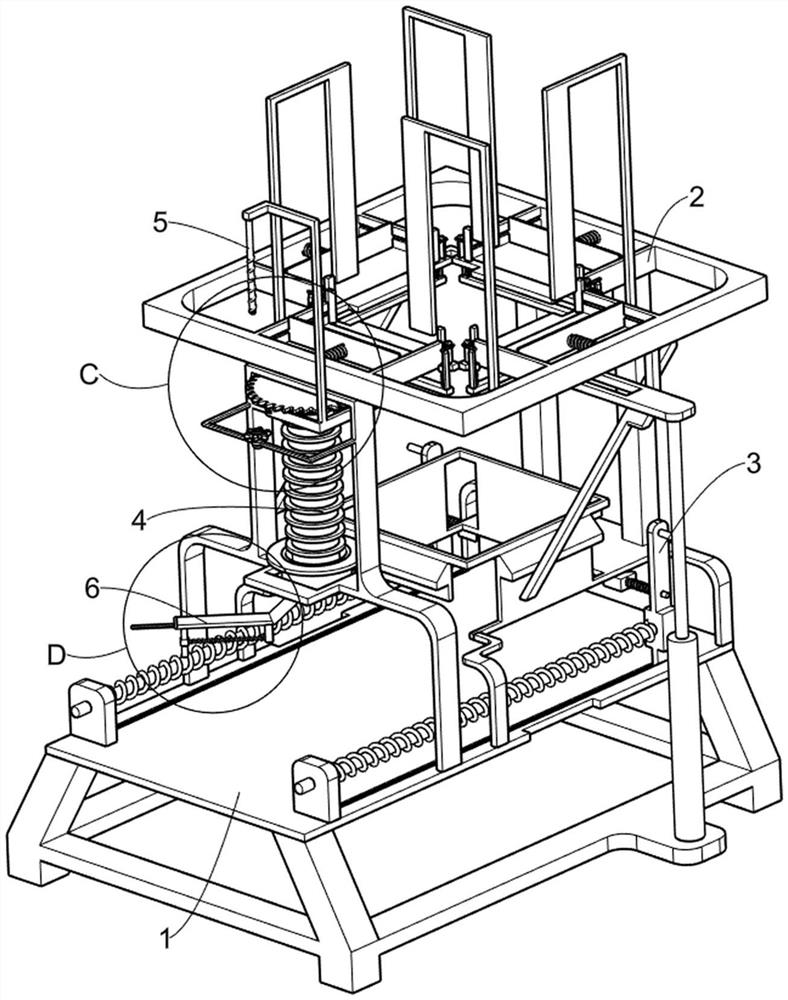

[0038] On the basis of Example 1, as Figure 8-9 As shown, it also includes a lifting mechanism 4, the lifting mechanism 4 is arranged on the first fixing frame 1, the lifting mechanism 4 is used to assist the sixth sliding frame 65 to eject glue, and the lifting mechanism 4 includes a third fixing frame 41, a third fixing frame The rod 42 , the first gear 43 , the gluing cylinder 44 , the fourth fixing frame 45 , the second wedge block 46 and the seventh return spring 47 , the third fixing frame 41 is connected to the top of the first fixing frame 1 , and the third fixing rod 42 The third fixing rod 42 is slidably connected to the first gear 43 , the bottom of the first gear 43 is connected to a glue filling cylinder 44 , and the fourth fixing frame 45 is connected to the second fixing frame 23 . On the fourth fixing frame 45, a second wedge-shaped block 46 is slidably connected. The second wedge-shaped block 46 is used to push the glue filling cylinder 44 and its upper devic...

Embodiment 3

[0042] On the basis of Example 2, as Figure 10-11 As shown, it also includes a glue injection mechanism 6, the glue injection mechanism 6 is arranged on the glue filling cylinder 44, the glue injection mechanism 6 is used for applying glue to the prefabricated sandwich thermal insulation wall tiles, and the glue injection mechanism 6 includes an eighth return spring 61, The fifth sliding frame 62 , the sliding tube 63 , the fixing block 64 , the sixth sliding frame 65 and the ninth return spring 66 . Eight return springs 61, the other end of the eighth return spring 61 is connected with the fifth sliding frame 62, the bottom of the glue filling cylinder 44 is slidably connected with a sliding tube 63, the sliding tube 63 is used for conveying glue, and the sliding tube 63 is provided with a rectangular groove, The sliding pipe 63 is fixedly connected to the fifth sliding frame 62, the fixing block 64 is connected to the sliding pipe 63, the sixth sliding frame 65 is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com