Method for correcting influence of blade end rounding on flow

A blade and flow technology, which is applied in the field of axial flow turbines, can solve the problems such as the rounding flow change at the end of the blade that cannot be solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

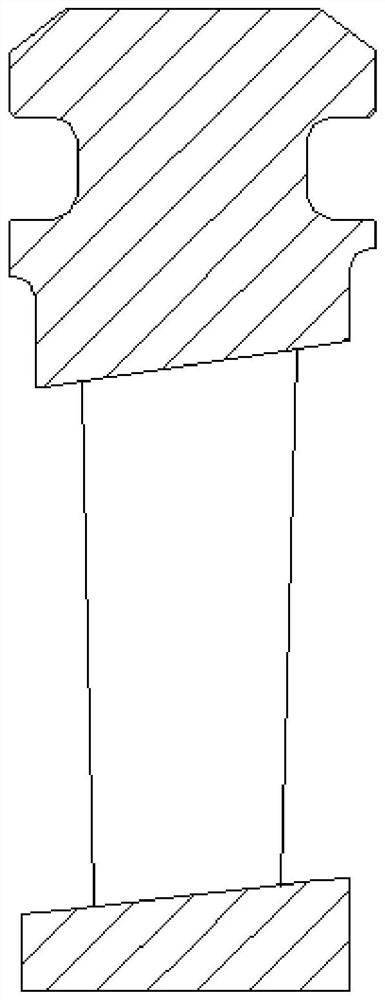

[0062] Specific implementation mode one: combine Figure 1 to Figure 16 Describe this embodiment, a method for correcting the influence of blade end rounding on flow in this embodiment, which includes the following steps:

[0063] Step 1. According to the relative size of the throat width O of the blade end and the radius R of the blade rounding, determine the calculation formula used for the correction:

[0064] When the airfoil throat width O at the end of the blade is greater than or equal to 2R, this is the case A, and the calculation formula used for the correction is

[0065] A 01 =2(R 2 -πR 2 / 4) = 0.4292R 2 (1);

[0066] When the airfoil throat width O at the end of the blade is less than 2R, this is case B, and the calculation formula used for correction is

[0067]

[0068] Step 2. Calculate the reduction value A of the flow area b :

[0069] Since the blade rounding is relatively small in value relative to the height of the working part of the blade, it ...

specific Embodiment approach 2

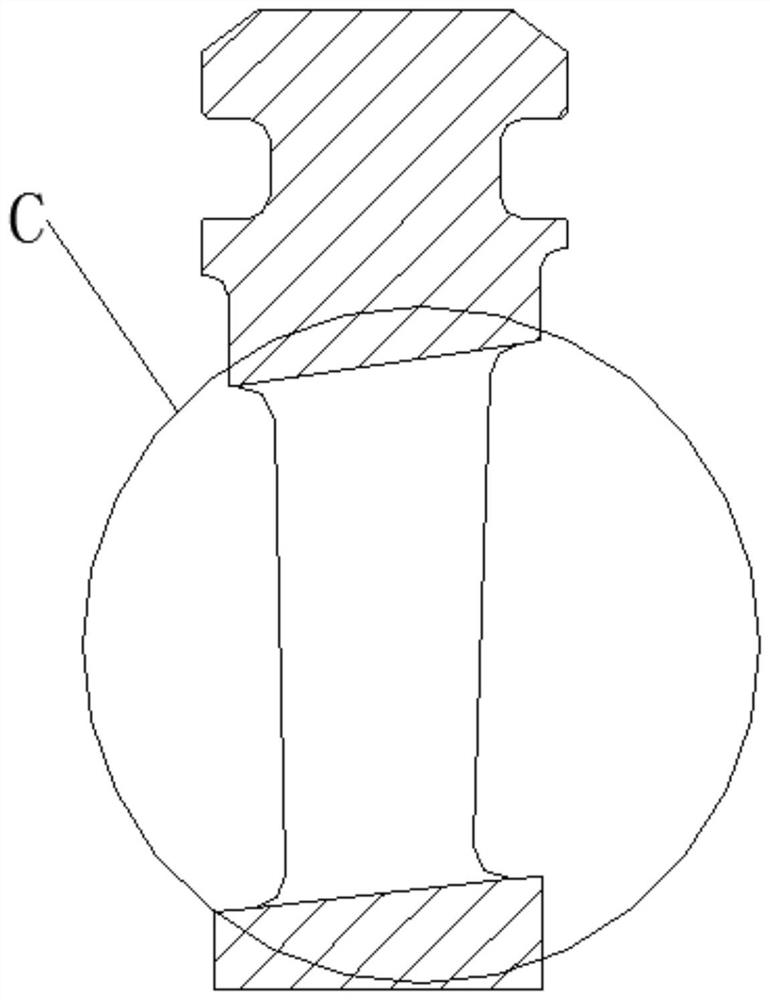

[0095] Specific implementation mode two: combination Figure 4 to Figure 6 Describe this embodiment. In step 2 of this embodiment, when the root rounding area is case A, the area is A 1 The formula for calculating is,

[0096] A 1 =2(R 1 2 -πR 1 2 / 4) = 0.4292R 1 2 (8);

[0097] In step 2, when the root rounding area is case B, the area is A 2 ;

[0098]

[0099] Others are the same as the first embodiment.

specific Embodiment approach 3

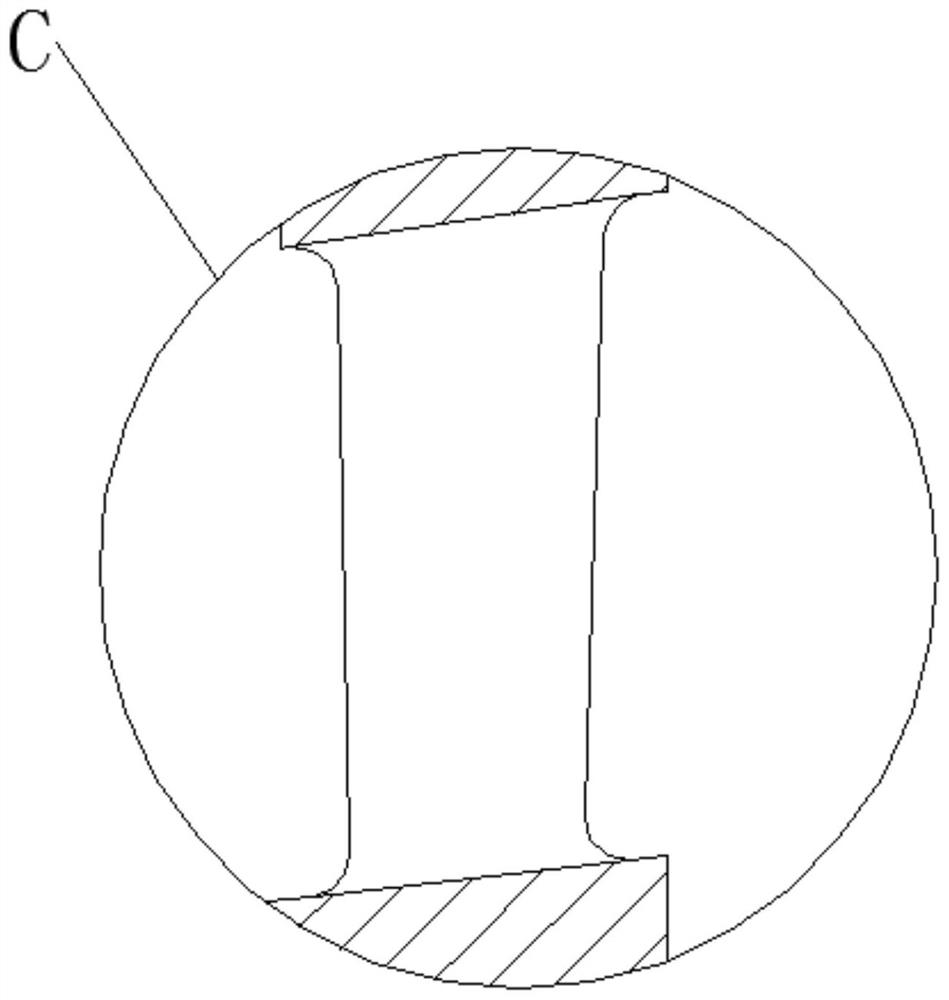

[0100] Specific implementation mode three: combination Figure 8 to Figure 10 Describe this embodiment. In step 2 of this embodiment, when the top rounded area is case A, the area is A 3 ;

[0101] A 3 =2(R 3 2 -πR 3 2 / 4) = 0.4292R 3 2 (10);

[0102] In step 2, when the top rounded area is case B, the area is A 4 :

[0103]

[0104] Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com