Cooling device for high-temperature wind tunnel model

A cooling device and wind tunnel technology, which is applied in household refrigeration devices, measuring devices, applications, etc., can solve problems such as affecting the accuracy of wind tunnel tests, introducing additional error sources to test data, and adversely affecting the development of wind tunnel tests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

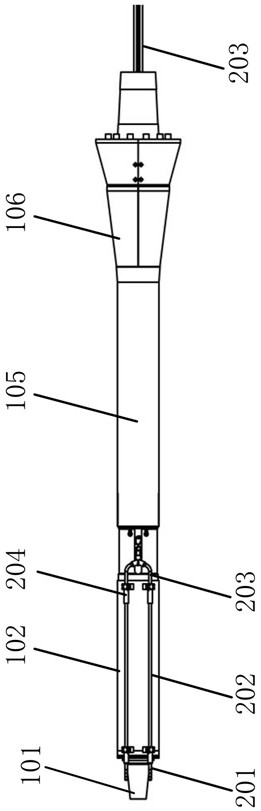

[0031] With the incoming flow of the wind tunnel as the front, the model of the cooling device used for the high temperature wind tunnel model of the present invention is fixed on the middle bracket of the high temperature wind tunnel in the form of a rod balance and a tail support. The cooling device includes a balance rod protection assembly, and Includes a cold spray assembly that fits inside the model to cool it down;

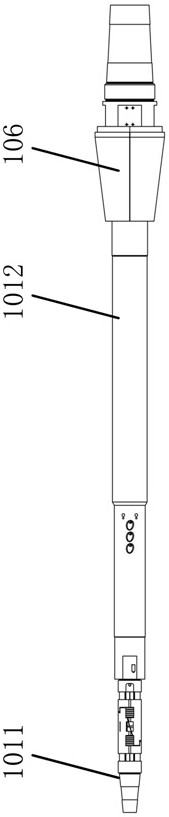

[0032] Such as figure 1 As shown, the pole-type balance assembly 101 includes a pole-type balance 1011 and a balance pole 1012 fixedly connected from front to back. A channel is arranged on the top, and an air-cooled intake pipe 203 connected with an external high-pressure air source is installed in the channel;

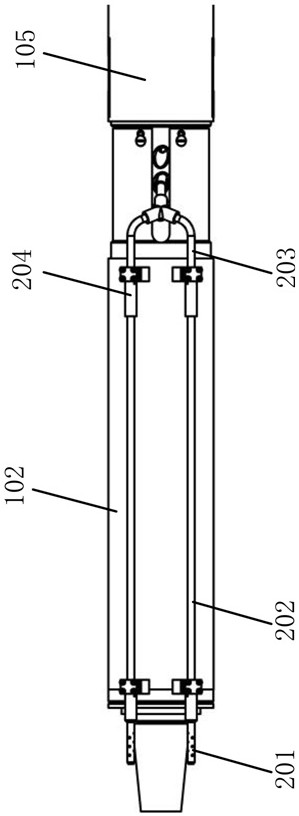

[0033] Such as figure 2 As shown, the balance pole protection assembly includes a balance heat shield 102 and a pole heat shield 105; the balance heat shield 102 is set on the pole balance 1011 in the pole balance assembly 101, and the pole hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com