Finite element modeling method for self-aligning roller bearing

A technology of self-aligning roller bearings and modeling methods, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as changes in stress transmission paths, affecting finite element strength analysis results, and loss of self-aligning effects , to achieve the effect of good model convergence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

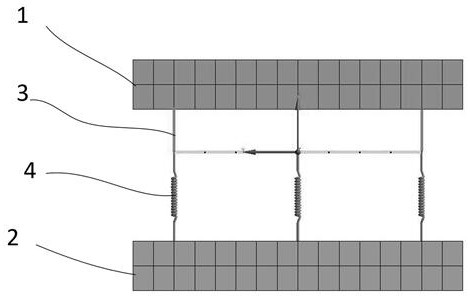

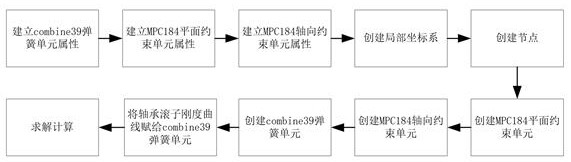

[0020] see Figure 1~2 As shown, the present invention provides a spherical roller bearing finite element modeling method, including the following steps:

[0021] S1. Create the structure and unit type of the finite element three-dimensional model of the bearing, establish the finite element analysis model of the inner and outer rings of the bearing, and ensure that the corresponding joint lines of the inner and outer rings of the bearing pass through the bearing center;

[0022] S11. Establish spring unit properties, plane constrained unit properties and axial constrained unit properties, create a local three-dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com