Bolt safety coefficient checking simulation method

A technology of safety factor and simulation method, which is applied in the direction of design optimization/simulation, electrical digital data processing, special data processing applications, etc., and can solve problems such as too large or too small bolt selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

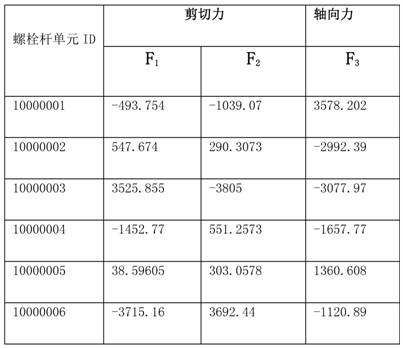

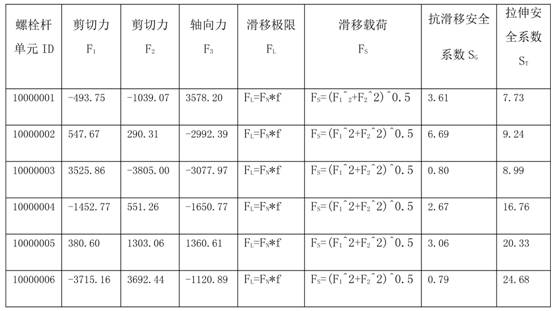

[0032] The invention discloses a bolt safety factor check simulation method, which mainly uses finite element simulation software to digitally and accurately analyze and extract the three-way force of each bolt under different working conditions, and calculate the anti-slip of each bolt Safety factor and tensile safety factor mainly relate to the safety factor checking of bolts. What this embodiment adopts is nastran software, and its implementation process is as follows:

[0033] S1. Bolt modeling: Each connection point of two sheet metal parts is rigidly connected through a bolt and a pair of bolt holes. Through the finite element simulation software, each bolt hole is simulated within a certain range using a rigid element. Rigid bolt rods are established between the two rigid units corresponding to each pair of bolt holes, that is, the modeling of a bolt unit is completed, and each bolt unit includes a bolt rod and two bolt holes; select the bolts that need to be checked, C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com