Green and environment-friendly printing method

A green and environmentally friendly printing method technology, applied in the printing field, can solve the problems of equipment oil pollution, lack of ink collection structure, and more splashed ink, etc., and achieve the effect of convenient pulling out and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

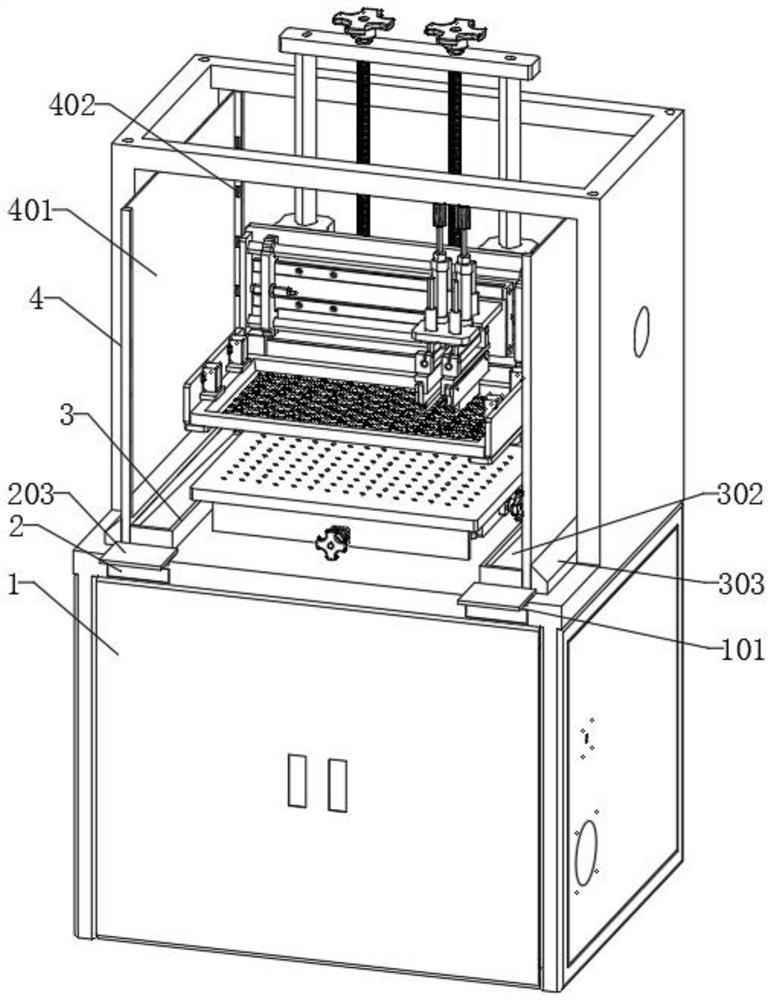

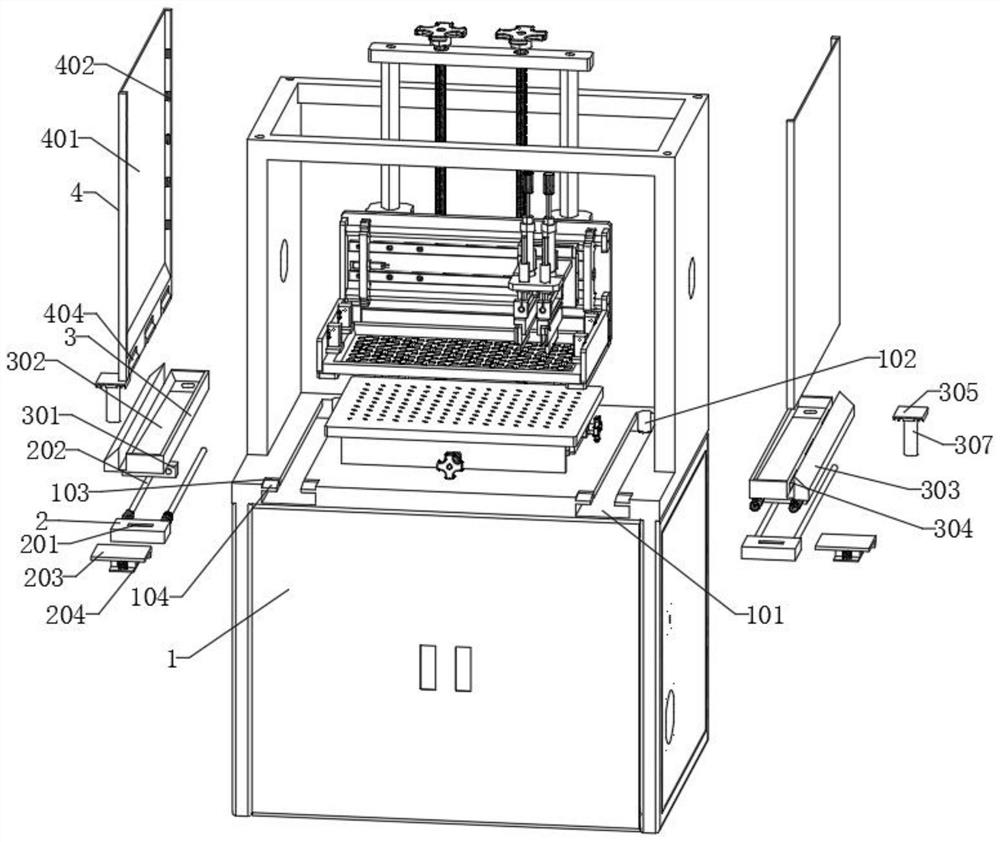

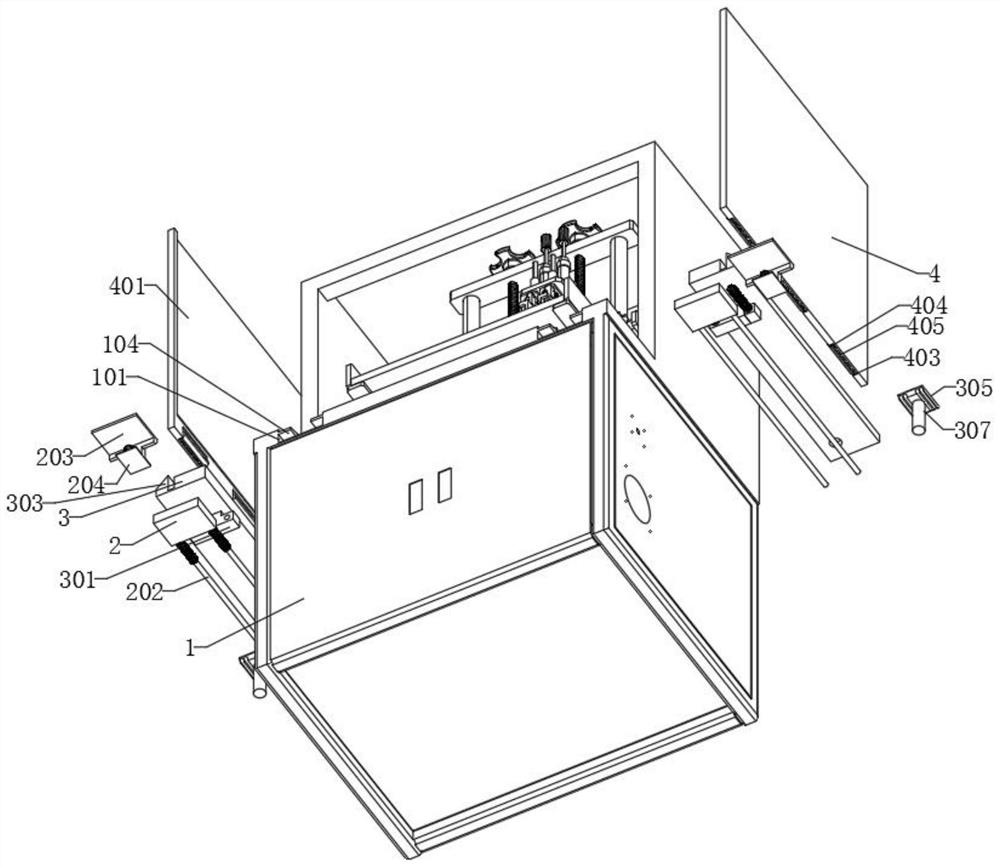

[0057] as attached figure 1 to attach Figure 8 Shown:

[0058] The present invention provides a green printing method. The green printing method is realized by using green printing equipment, thereby completing efficient green printing: the green printing equipment includes: a main body 1; the main body 1 is the main body of the environmental printing equipment , and the main body 1 is a rectangular structure, two fixed parts 2 are installed inside the two slots 101 of the main body 1, and two moving parts 3 are installed at both ends of the main body 1; the fixed part 2, the fixed part 2 includes a limit mechanism , the top of the fixed part 2 is equipped with a limit mechanism, the fixed part 2 is a rectangular structure; the moving part 3, the moving part 3 is a rectangular plate structure, and the moving part 3 is made of alloy material, and the outer side of the moving part 3 is equipped with a side plate 4; The side plate 4, the side plate 4 is a rectangular plate struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com