RH refining system and production method of ultra-low carbon steel

An ultra-low carbon steel and a production method technology, applied in the field of iron and steel smelting, can solve the problems such as the inability to timely and accurately predict the degree of decarburization and the content of carbon elements in molten steel, the decrease in the detection accuracy of the exhaust gas analyzer, and the lag in the detection of CO value, etc. Achieve scientific and effective decarburization time, optimized decarburization time, and the best effect of qualified carbon elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

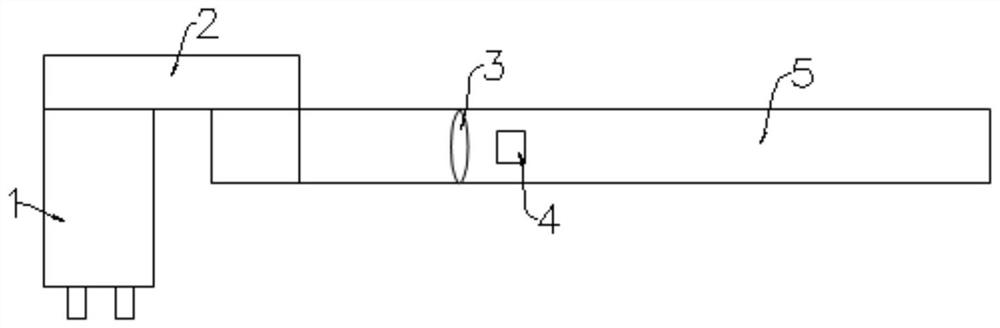

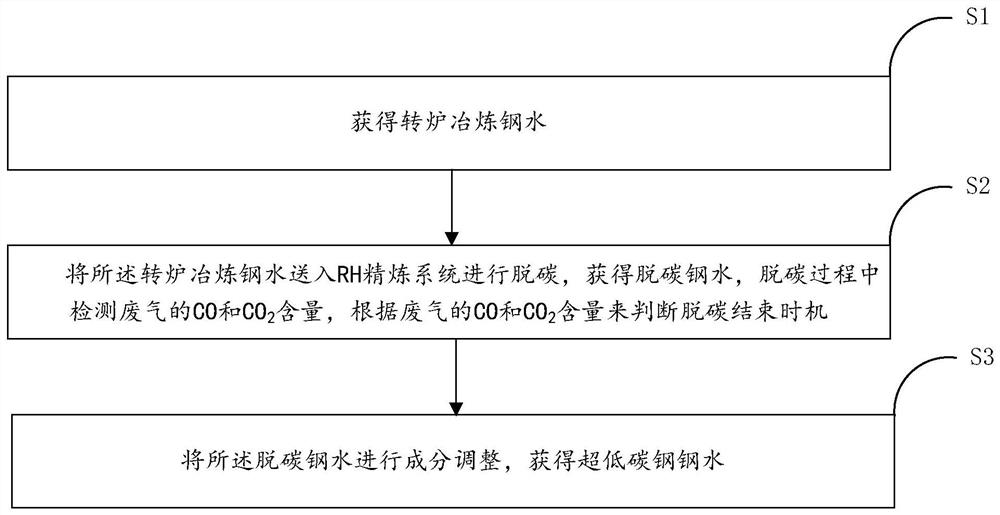

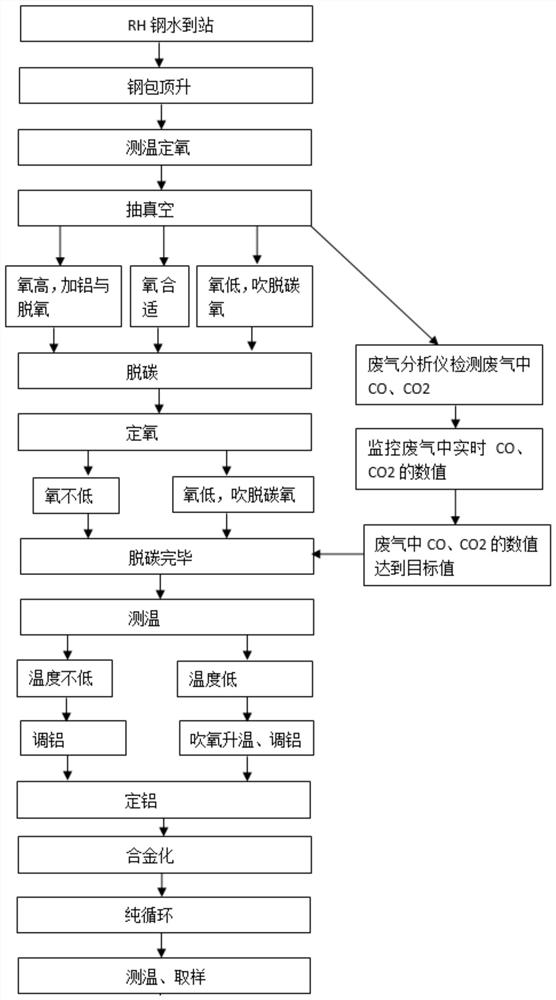

[0072] A production method of ultra-low carbon steel, the method includes: adopting a RH refining system, the system includes a refining furnace, a vacuum tank and a vacuum pipeline connected in sequence, and the vacuum pipeline is provided with a vacuum main valve and an exhaust gas analyzer. The exhaust gas analyzer is located near the rear end of the vacuum main valve to detect CO and CO in the exhaust gas during the decarburization of molten steel. 2 content.

[0073] S1: The converter is tapped according to the ultra-low carbon steel non-killing mode, and aluminum slag balls are added after tapping to carry out slag modification;

[0074] S2: After the ultra-low carbon steel enters the RH refining station, the ladle is lifted up, temperature measurement, oxygen determination, sampling, and vacuuming for decarburization;

[0075] S3: According to the carbon content after the furnace and the fixed oxygen value at the station, it is judged whether to carry out supplementary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com