Pre-levelled tower footing foundation and leveling construction method therefor

A construction method and tower foundation technology, which are applied in basic structure engineering, architecture, building construction, etc., can solve the problems of affecting the stability of the support surface, cumbersome leveling of tower foundations, etc., and achieve the overall elevation that is easier to control, easy to operate, and simplified to operate. effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

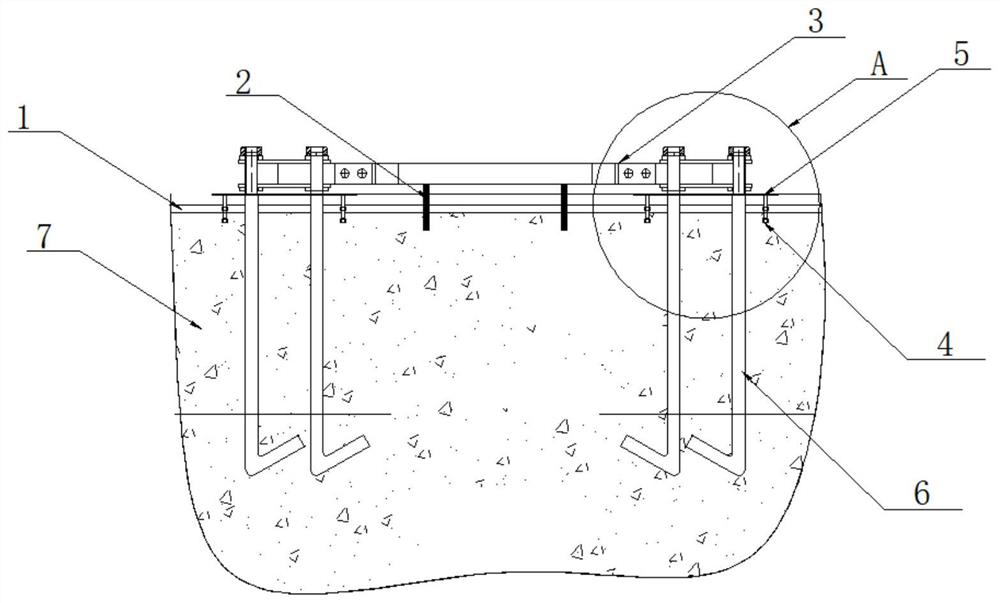

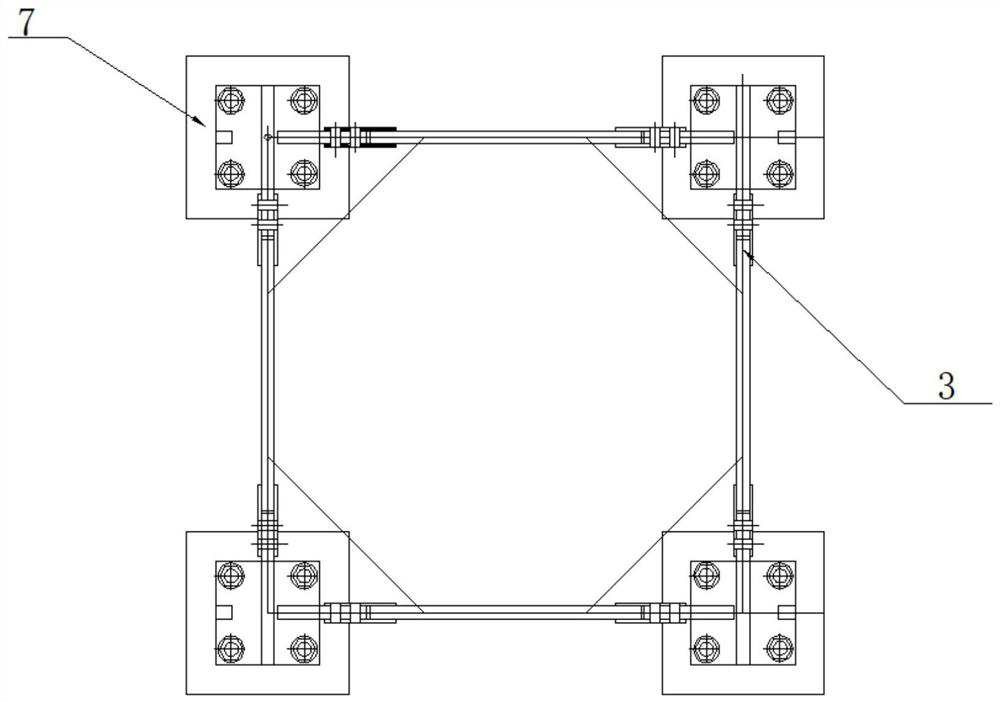

[0053] Such as Figure 1-4 As shown, the embodiment of the present application discloses a pre-leveled tower foundation, including:

[0054] Reinforcement cage 1, the reinforcement cage 1 is bound by a plurality of steel bars. When binding, it is necessary to ensure that the reinforcement cage 1 has sufficient stability and has a working space inside;

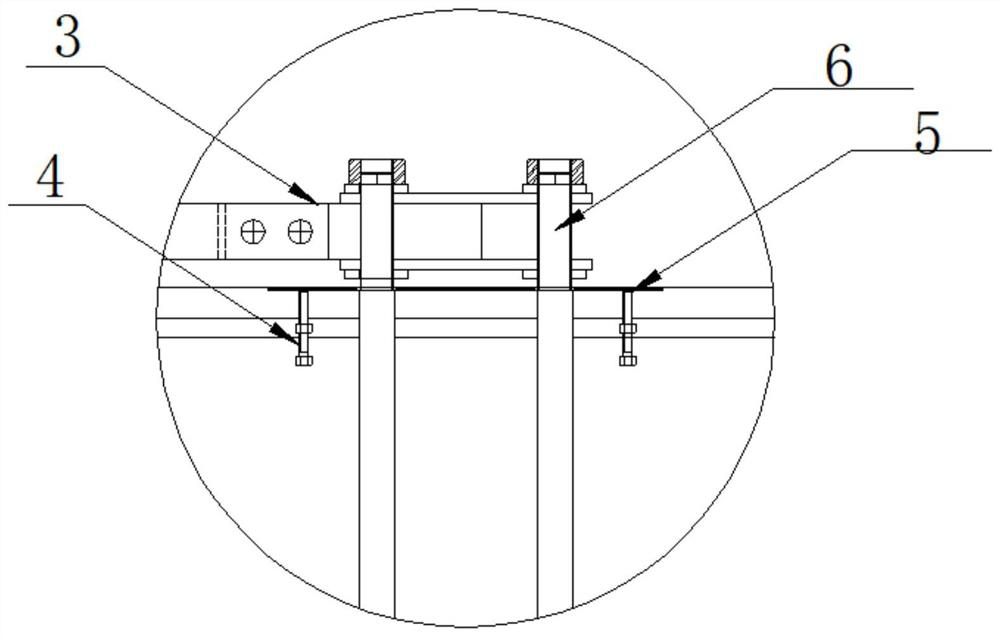

[0055] A plurality of support bars 2 are installed on the reinforcement cage 1 at intervals, and the upper surfaces of the support bars 2 are at the same level, and the support bars 2 are used to support the subsequent fixed mold;

[0056] The fixed form 3 is assembled on the upper side of the steel cage, and the lower surface of the fixed form 3 is in contact with the upper surface of the supporting steel bar 2. The fixed form 8 in the embodiment of the present application is convenient for the subsequent assembly of the tower crane.

[0057] A plurality of adjusting bolts 4 are installed on the reinforcement cage 1 at interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com