Patents

Literature

32results about How to "Elevation is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

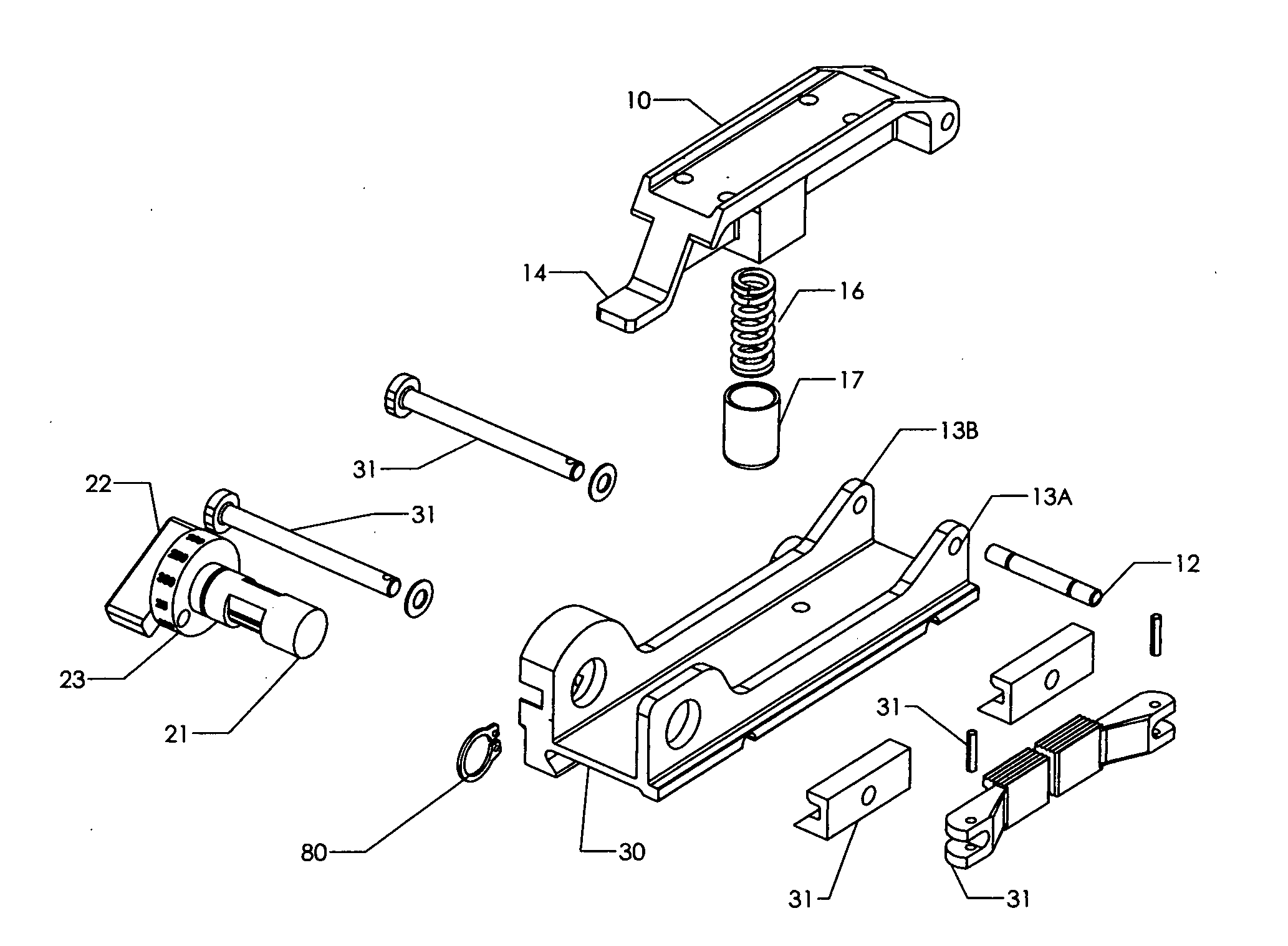

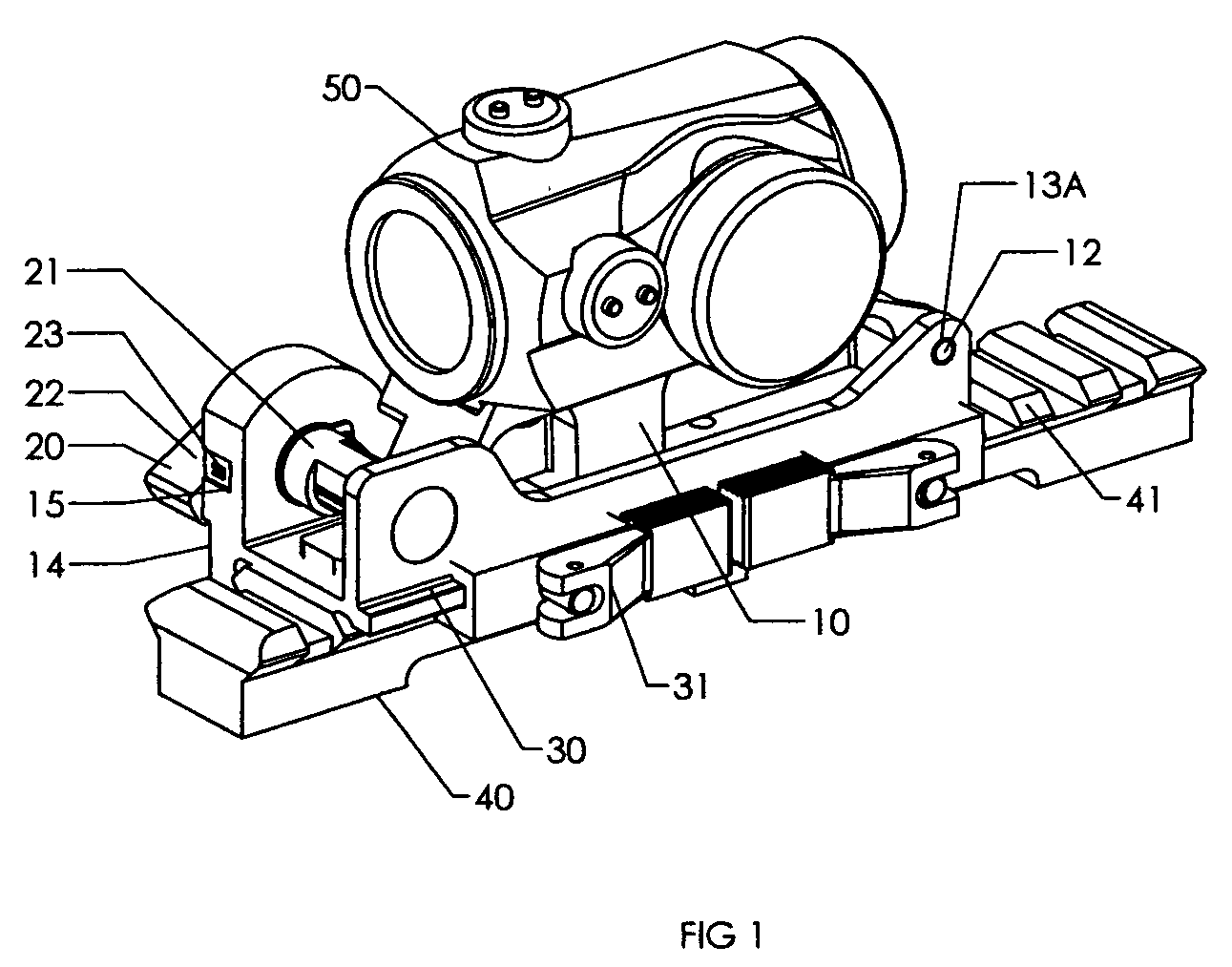

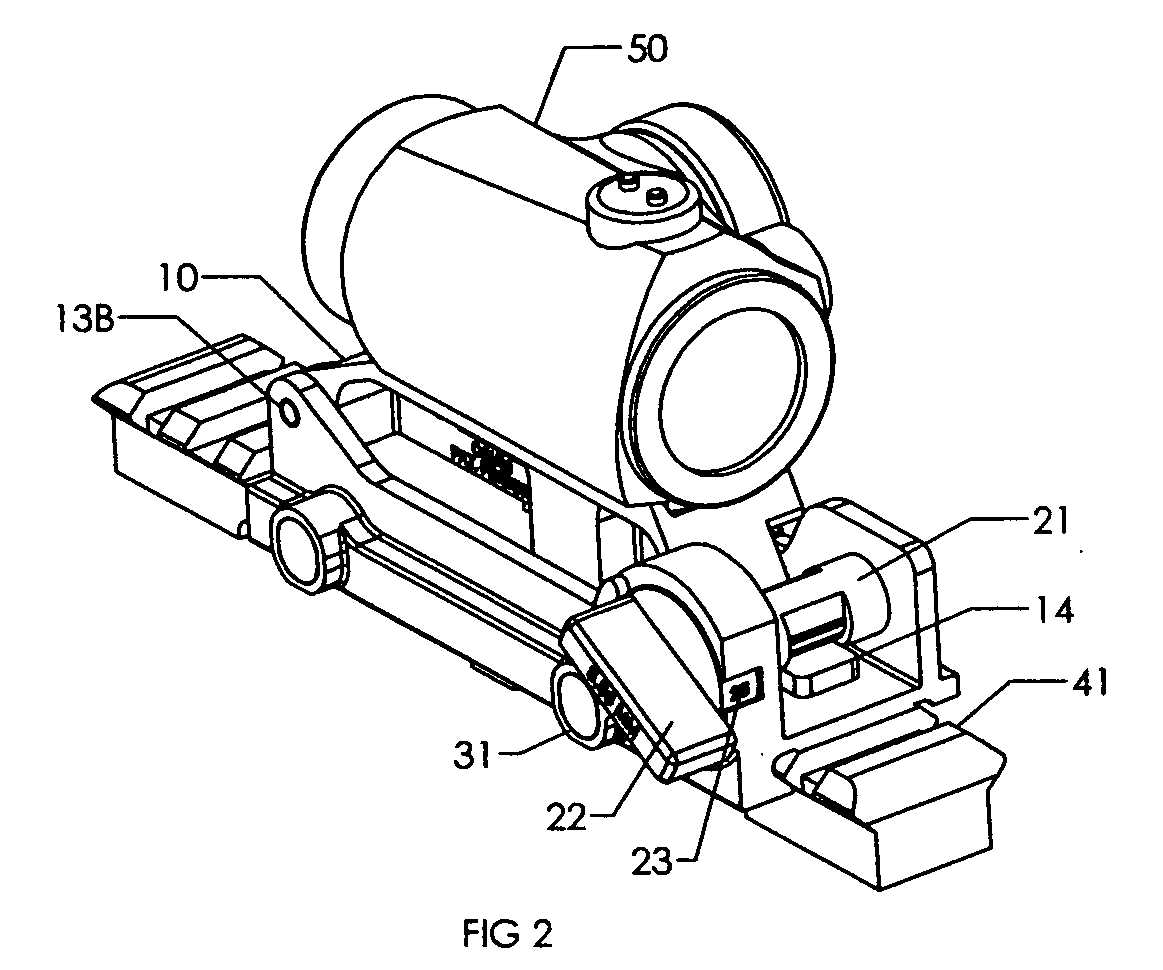

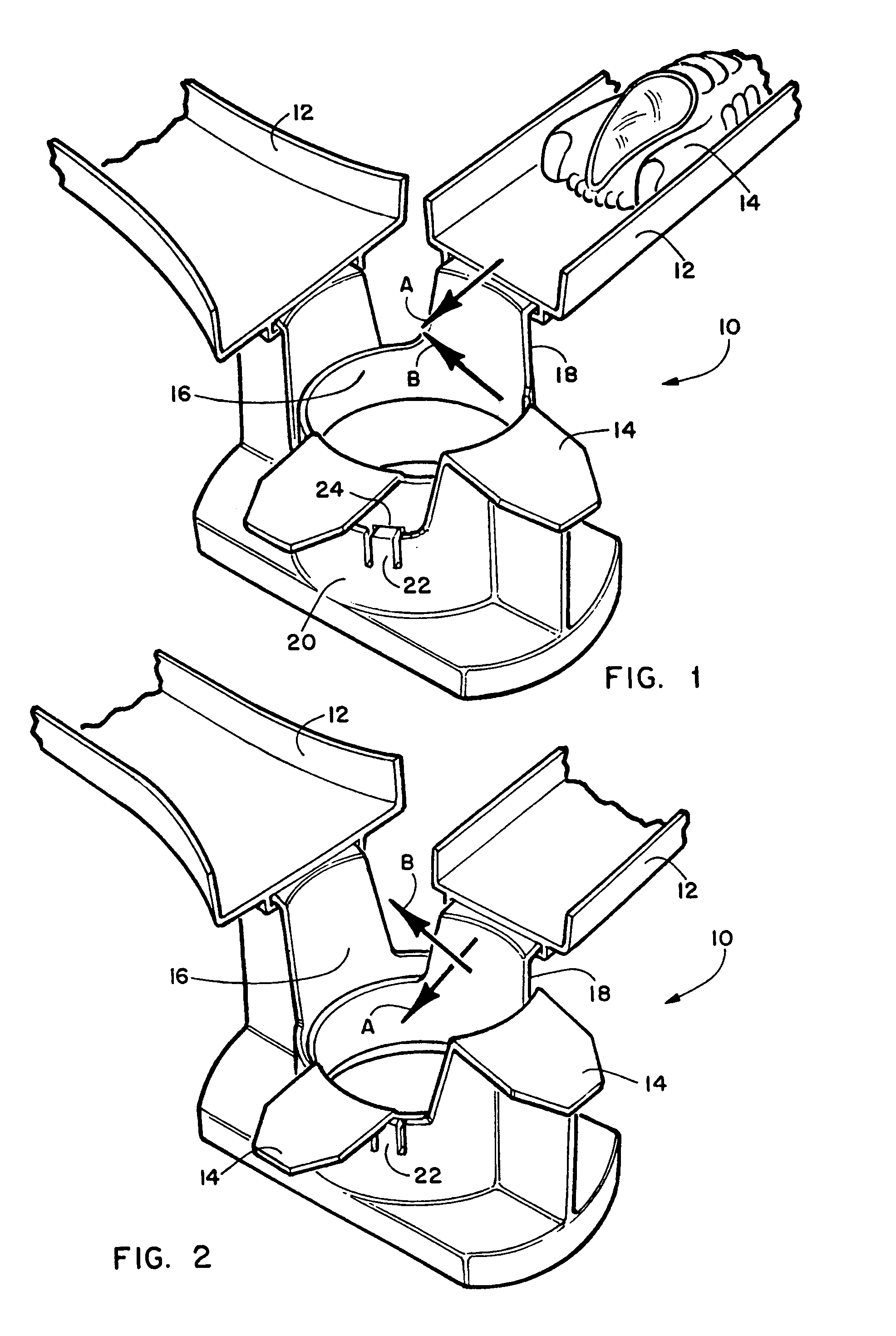

Adjustable base for an optic

InactiveUS20100162611A1Easy to adjustElevation is accurateSighting devicesEngineeringTrajectory of a projectile

A gun sight base which is designed to allow the user to quickly adjust the elevation of the attached gun sight as a means to affect the trajectory of a projectile discharged from the host firearm. Provided is a removable, pre-calibrated adjustment cam which is in operational contact with the attached gun sight. A distance indicator is visible to the user to allow for rapid elevation adjustments without the need for tools.

Owner:LWRC INTERNATIONAL

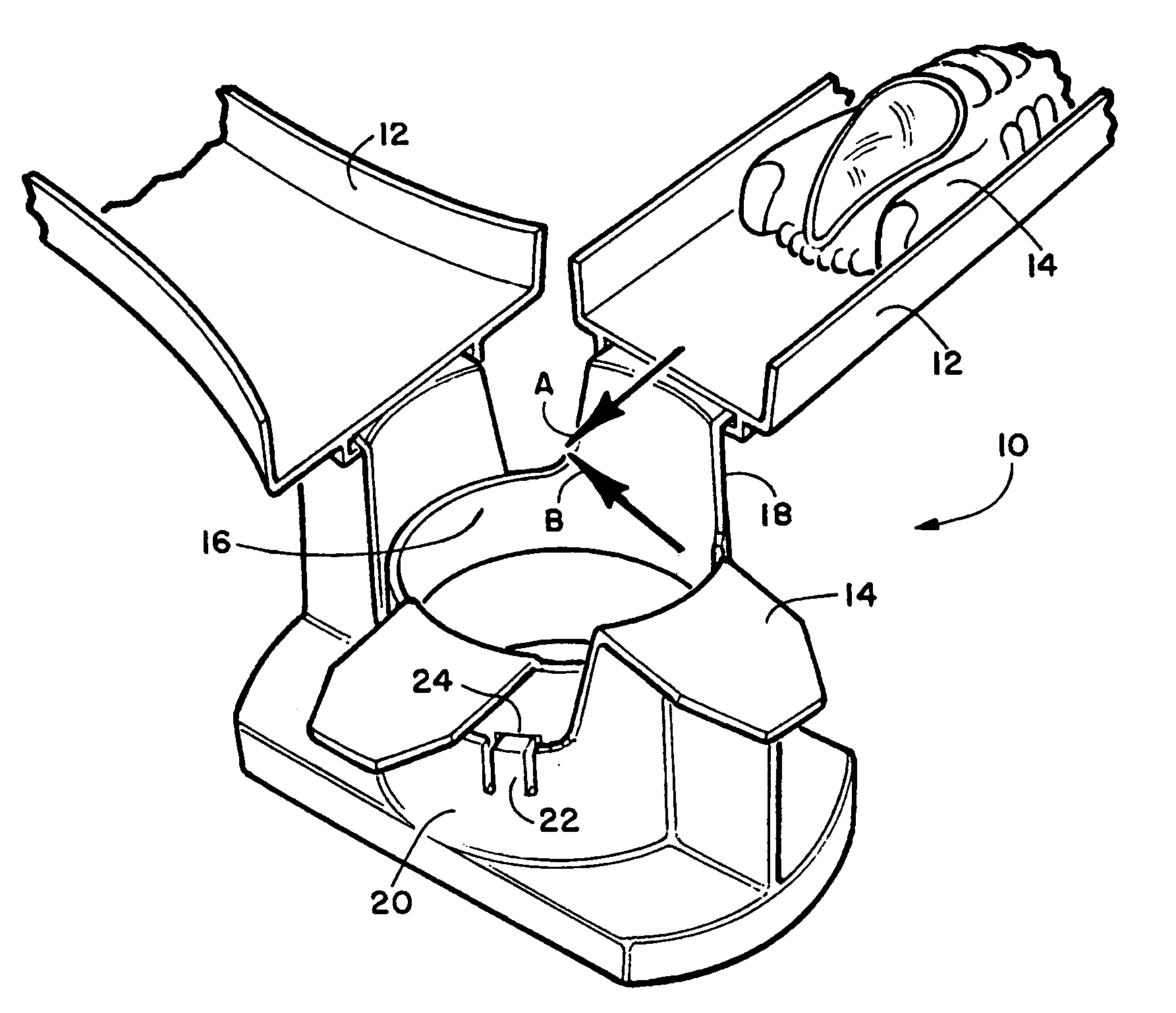

Toy vehicle intersection with elevational adjustment

An intersection adapted for engagement with a toy racetrack to provide an combination jump and overcrossing intersection for vehicles traversing the racetrack. The device features first and second supports engageable with inline pairs of track thereby forming two pathways across a jump formed by a gap in the middle of the device. The first support is in a translatable engagement with the second support between a first position where vehicles crossing the gap at the same time would collide and a second position forming a second path where vehicles jumping the gap are on different trajectories.

Owner:MAISTO INT

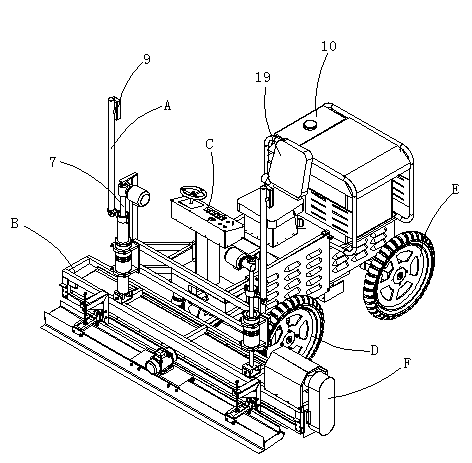

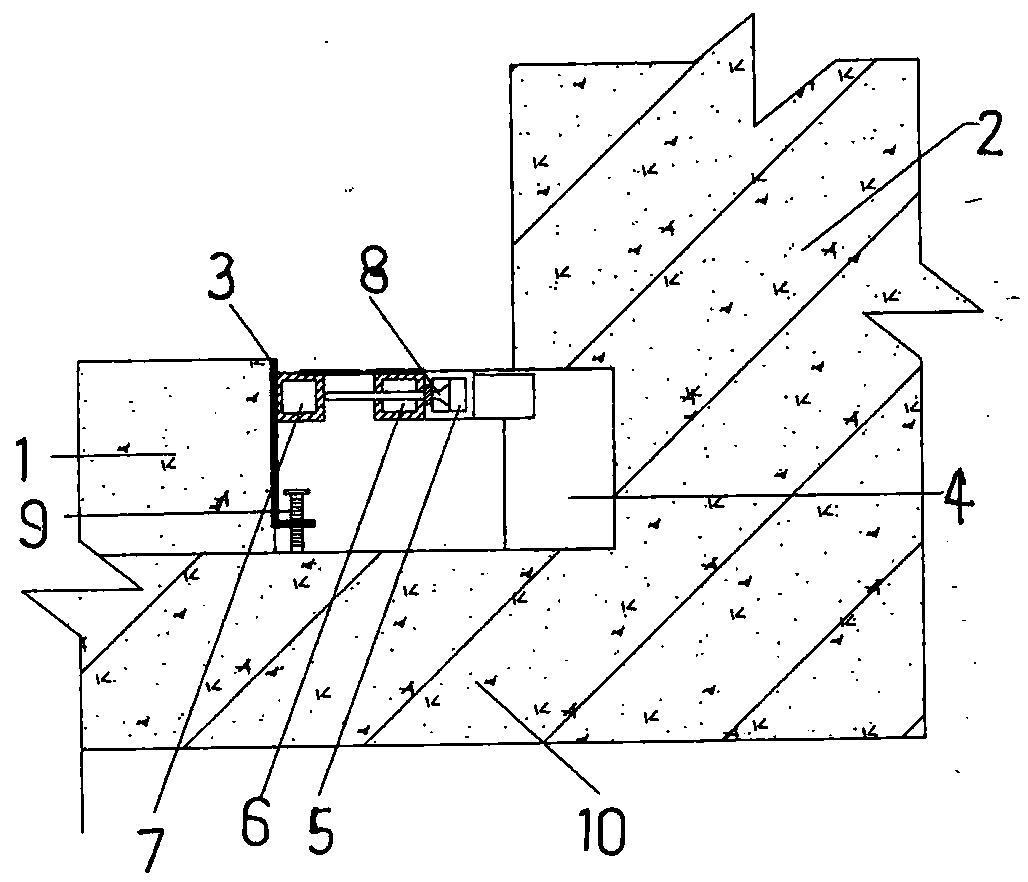

Concrete laser leveling machine driven by driving type pure electric power

ActiveCN103276655ASimple and lightweight structureReduce resistanceRoads maintainenceControl systemElectric machine

The invention relates to a concrete laser leveling machine driven by driving type pure electric power. The laser leveling machine comprises a machine skeleton, a machine power system, a control system, a laser measuring and controlling system and a leveling head capable of feeding automatically, wherein the leveling head can be connected and matched with the front end of the machine skeleton through an electric pusher capable of ascending or descending; the leveling head comprises a vibration plate, a vibration plate installation seat, a vibration motor installation seat, a vibration motor, a connection assembly, a steel rope and a spiral feeding mechanism, wherein the vibration motor is mounted on the vibration motor installation seat and is connected and matched with the vibration plate; the vibration plate is mounted on the vibration plate installation seat; the connection assembly is fixed on the side surface of the spiral feeding mechanism; and the vibration plate installation seat is suspended on the connection assembly through the steel rope and is movably matched with the spiral feeding mechanism through the connection assembly. The spiral feeding mechanism of the machine can automatically clear concrete accumulated in front of a scraper, thereby reducing working resistance; and at the same time, the spiral feeding mechanism is provided with the scraper, thereby keeping the accuracy of the surface elevation of the concrete.

Owner:上海捷舟工程机械有限公司

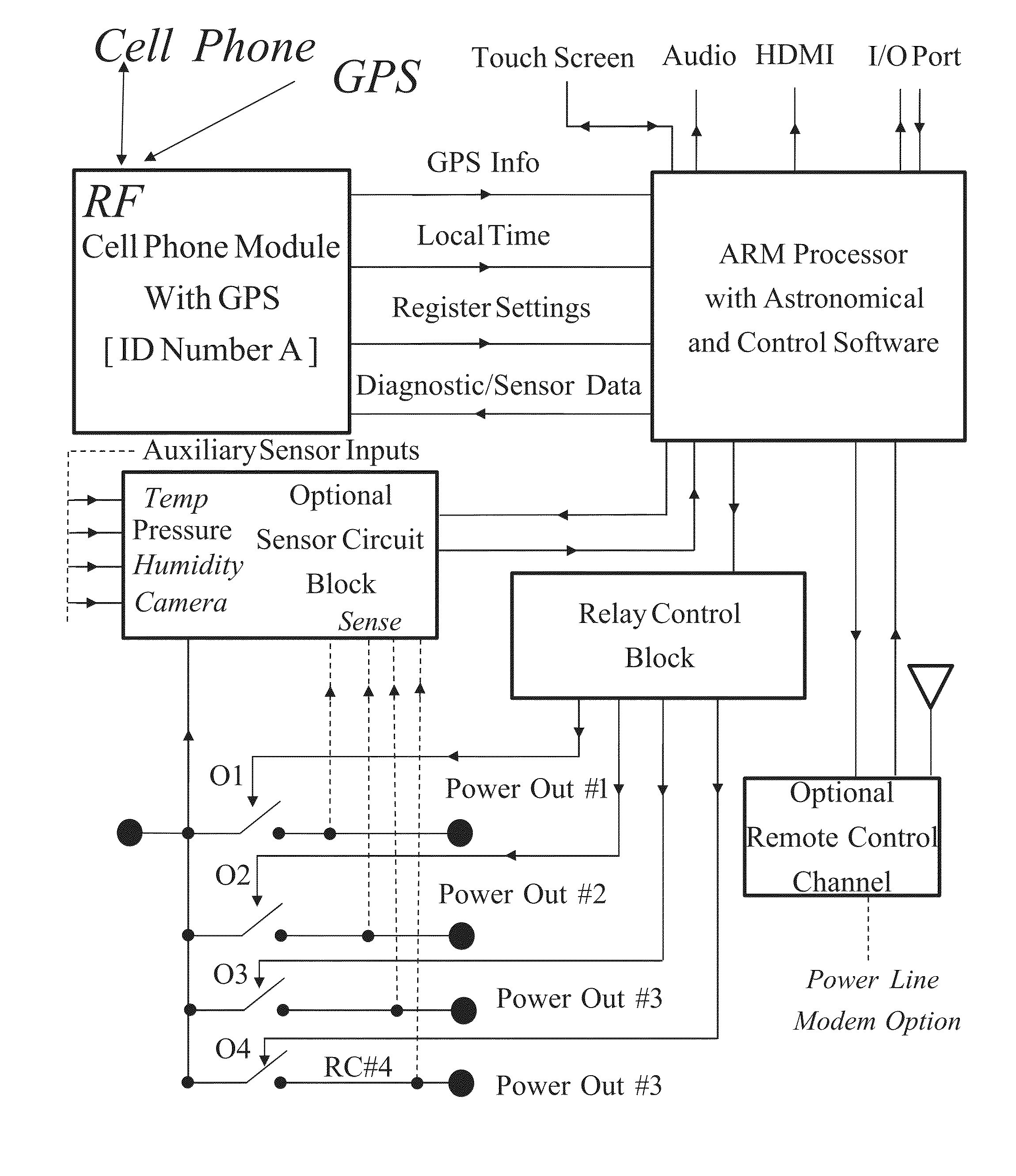

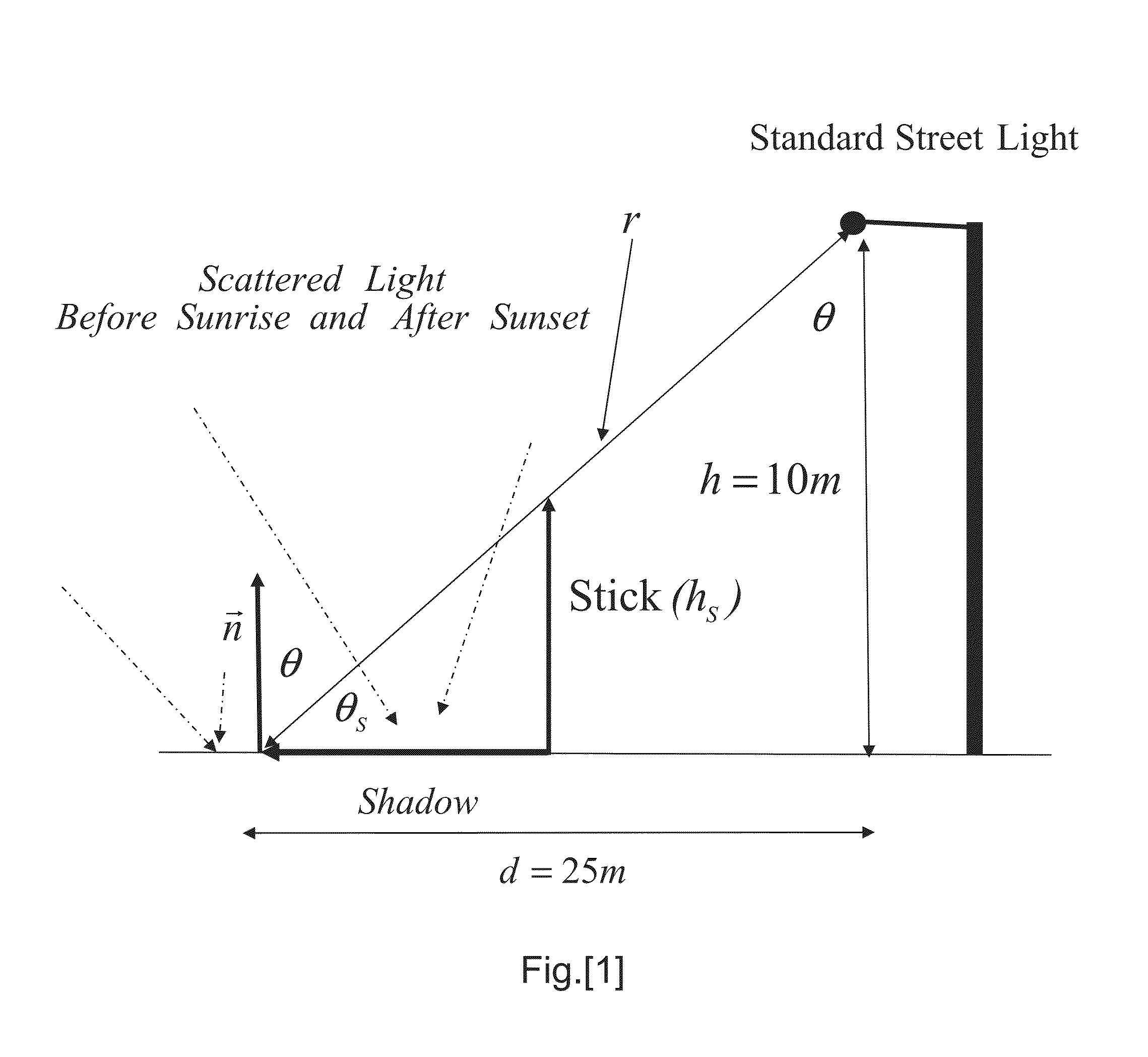

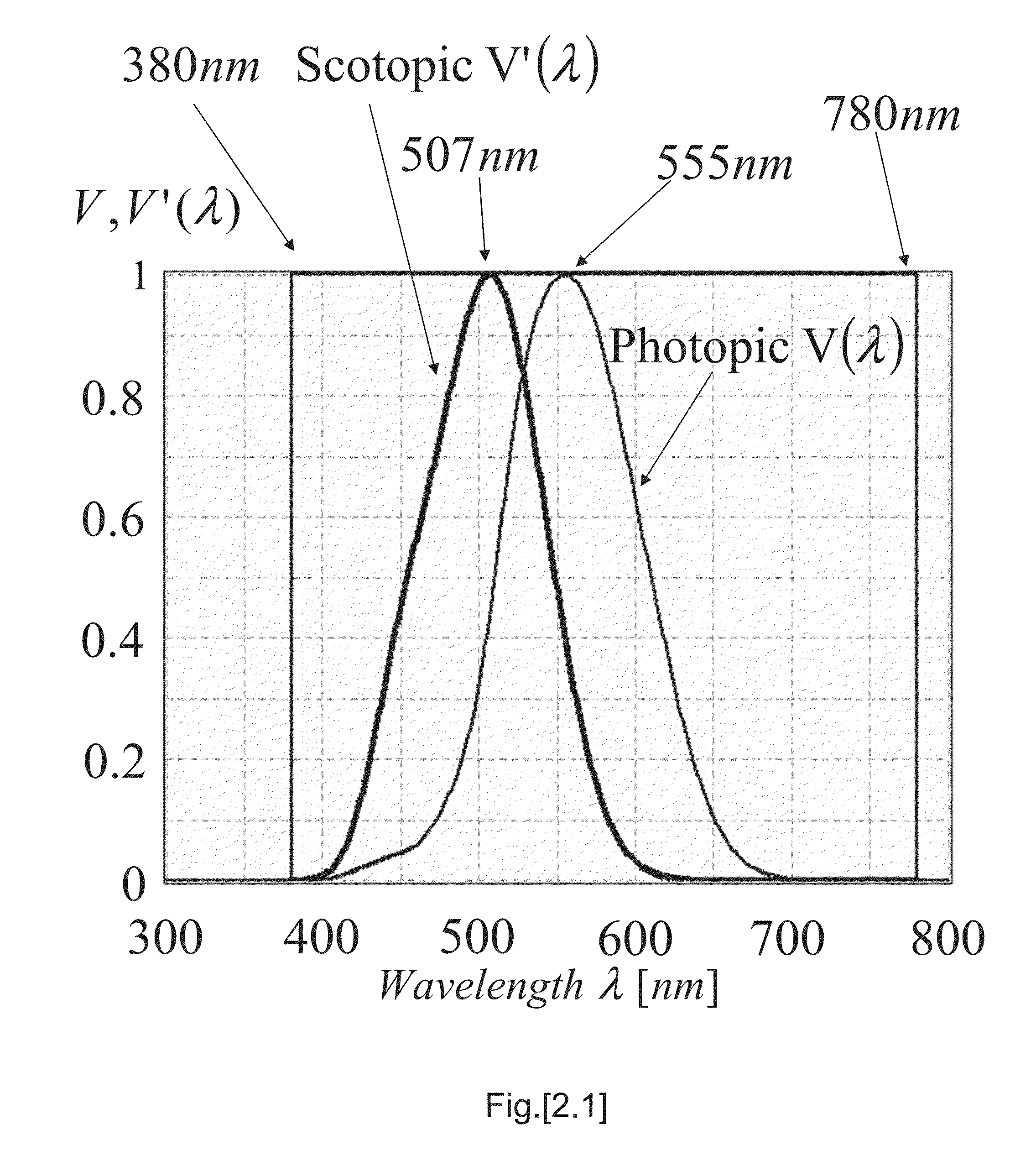

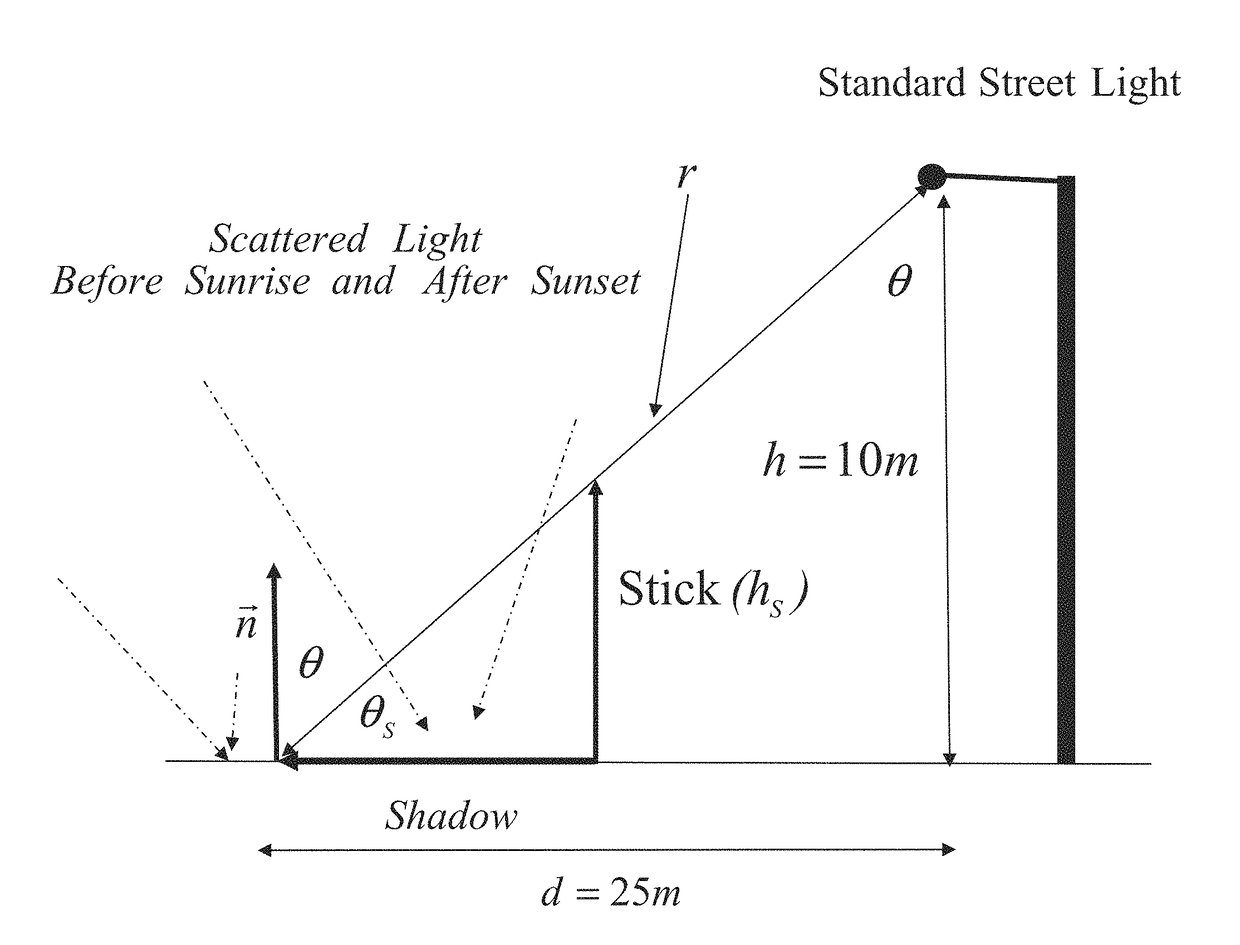

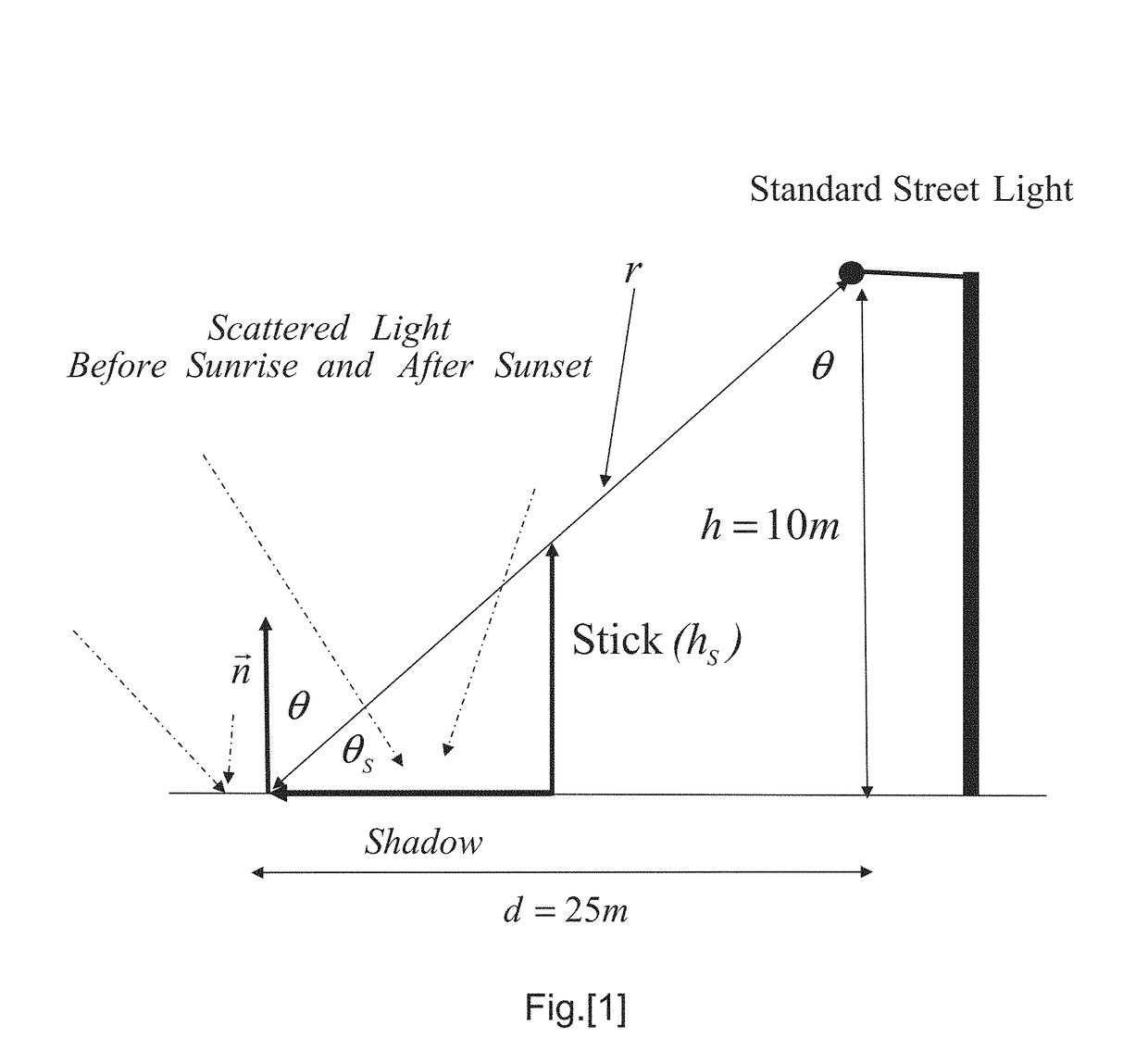

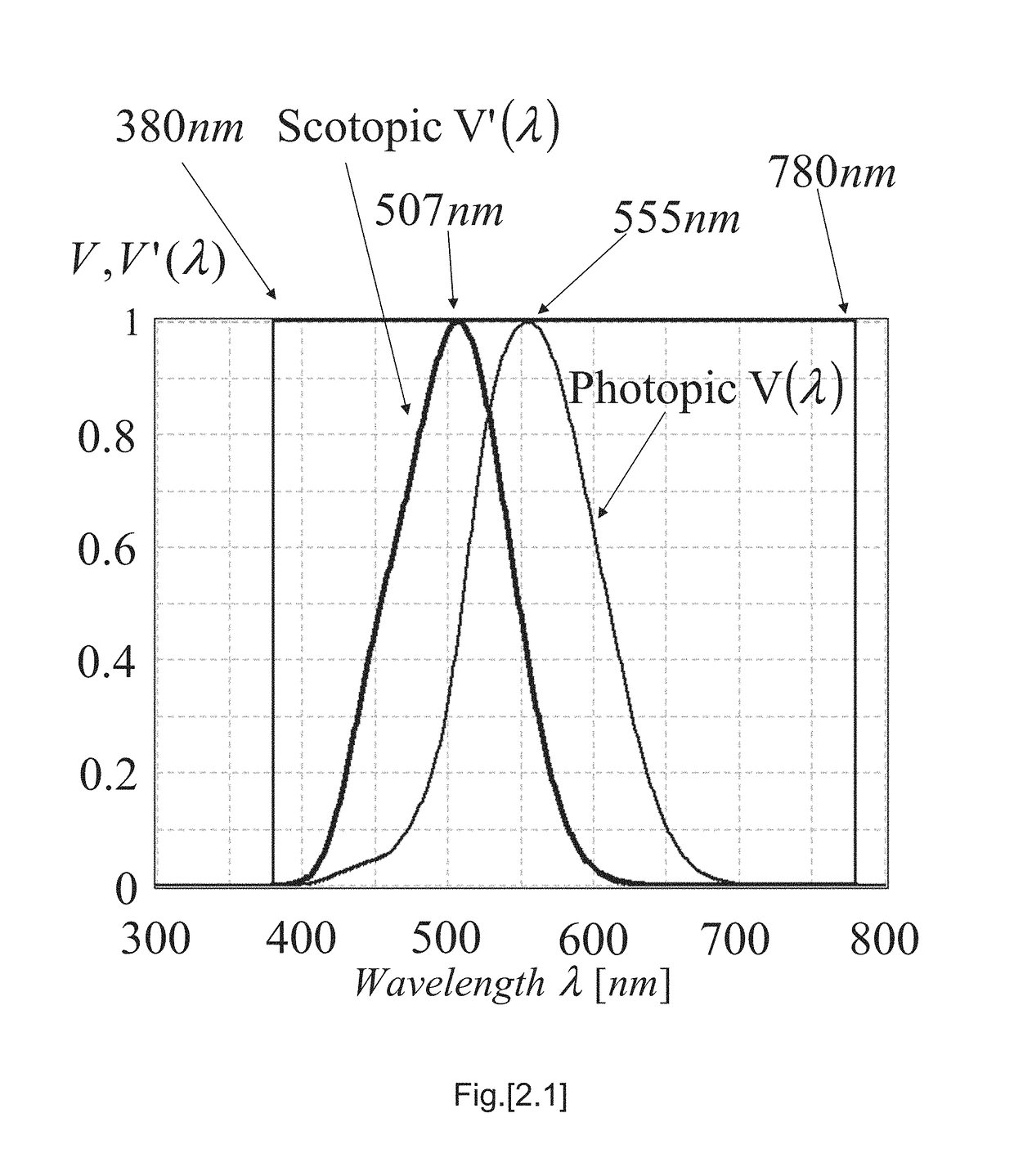

Method and apparatus for controlling electrical power usage based on exact sun elevation angle and measured geographical location

ActiveUS20150342005A1Easy to controlSmooth transitionElectrical apparatusElectric light circuit arrangementLongitudePower usage

A method and apparatus are provided to control artificial lighting using accurate geographical location, date and time, in order to activate such electrical activity only during needed periods of actual terrestrial darkness related to sun elevation. Accurate, real-time calculation of sun elevation relative to geographical location and date / time allow natural lighting characteristics such as natural light spectrum and intensity to be matched to artificial lighting, in order to provide a smooth transition in ambient lighting and to save energy. An apparatus according to the invention comprises a global positioning system (GPS) element for determining latitude, longitude, altitude, date and time and a calculation element for determining sun elevation angle accurately. A specific embodiment requires only desired sun elevation angle inputs from the user for controlling electrical switches in a control system.

Owner:LONESTAR INVENTIONS LP

Integral construction method of sealing and curing agent wear resistant floor

The invention discloses an integral construction method of sealing and curing agent wear resistant floor, including toolings mold design, construction preparation, cleaning of the concrete base, positioning and laying out, installation of elevation control of bolt angle steel, installation of construction joint template in the reserved area around the column, elevation survey, base wetting, layingwire mesh, pouring concrete with fine stones and leveling, mechanical plastering and pressing, removal of angle steel, concrete pouring for filling silos, maintenance, removal of peri-column formwork, dismantling line, slitting, round angle aluminum bars, manufacture of crack resistant reinforcement bar installation, installing, secondary concrete pouring at column edge, trowel light, floor cleaning, fine grinding process at the base, a first seal curing agent operation, water mill operation and cleaning the floor to dry, a second seal curing agent operation, water mill operation and cleaningthe floor to dry, secondary water grinding and polishing, the late maintenance and other steps. The integral construction method of the sealing and curing agent wear resistant floor has the advantages of convenient construction and good effect.

Owner:启东建筑集团有限公司

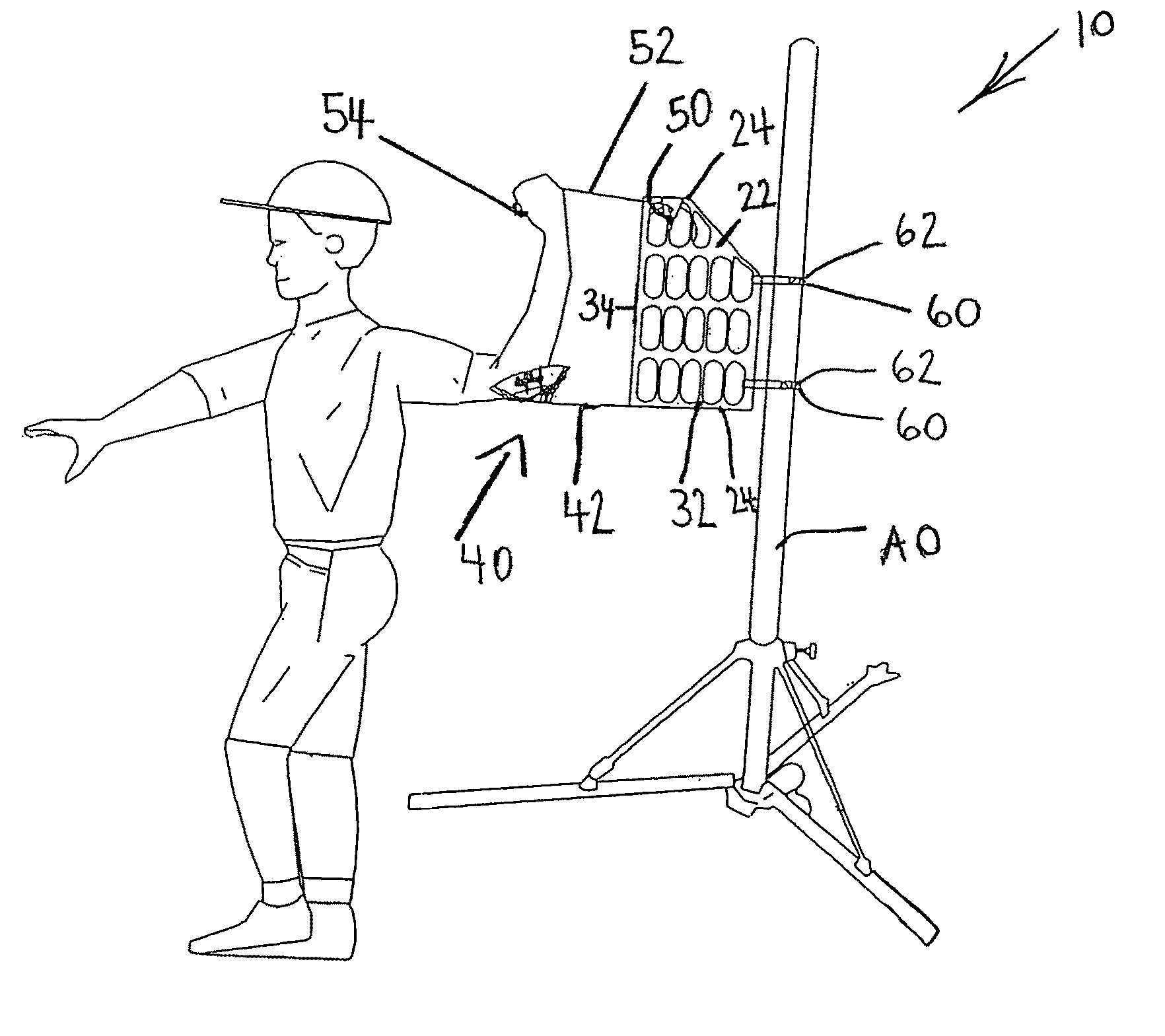

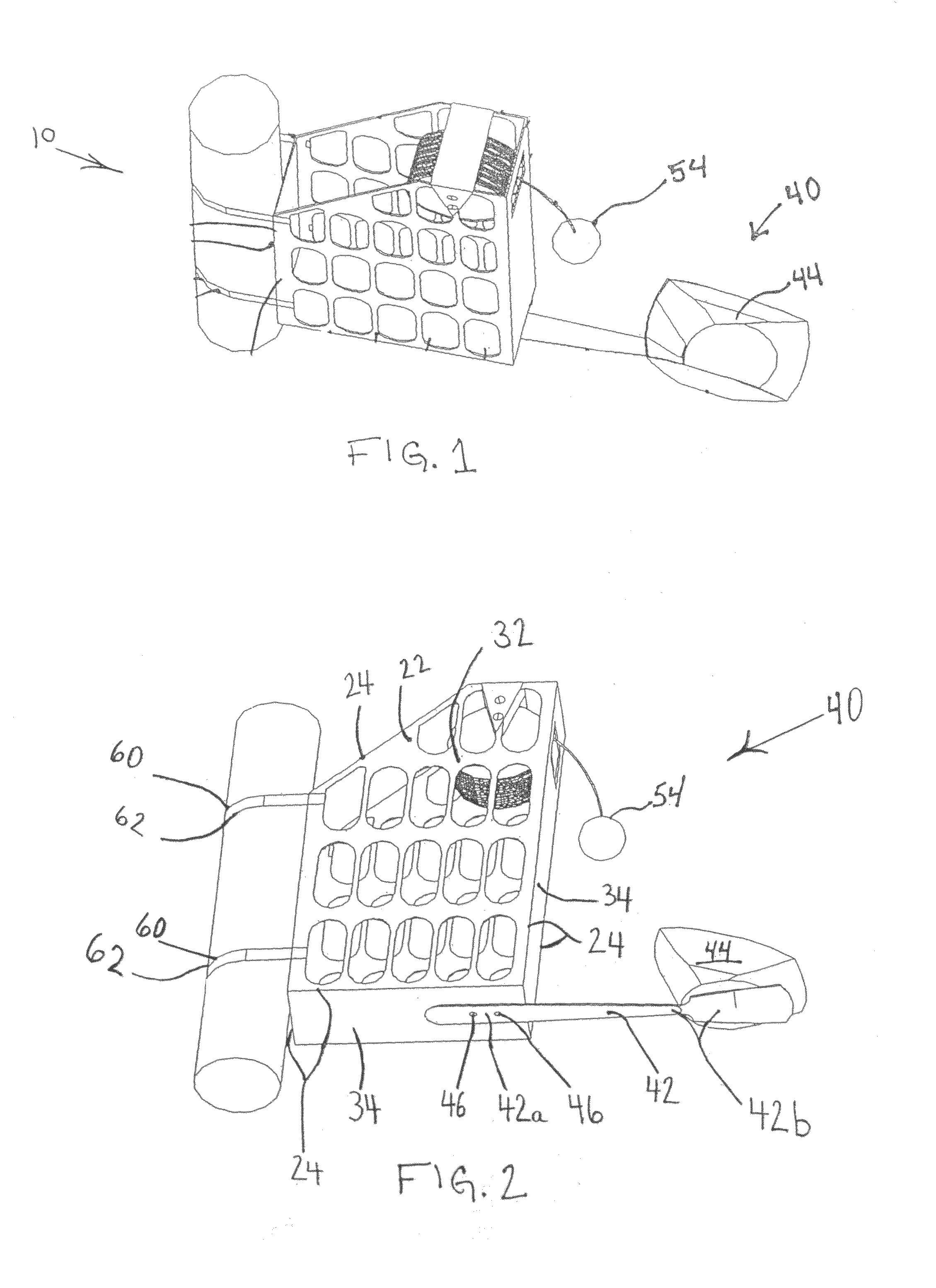

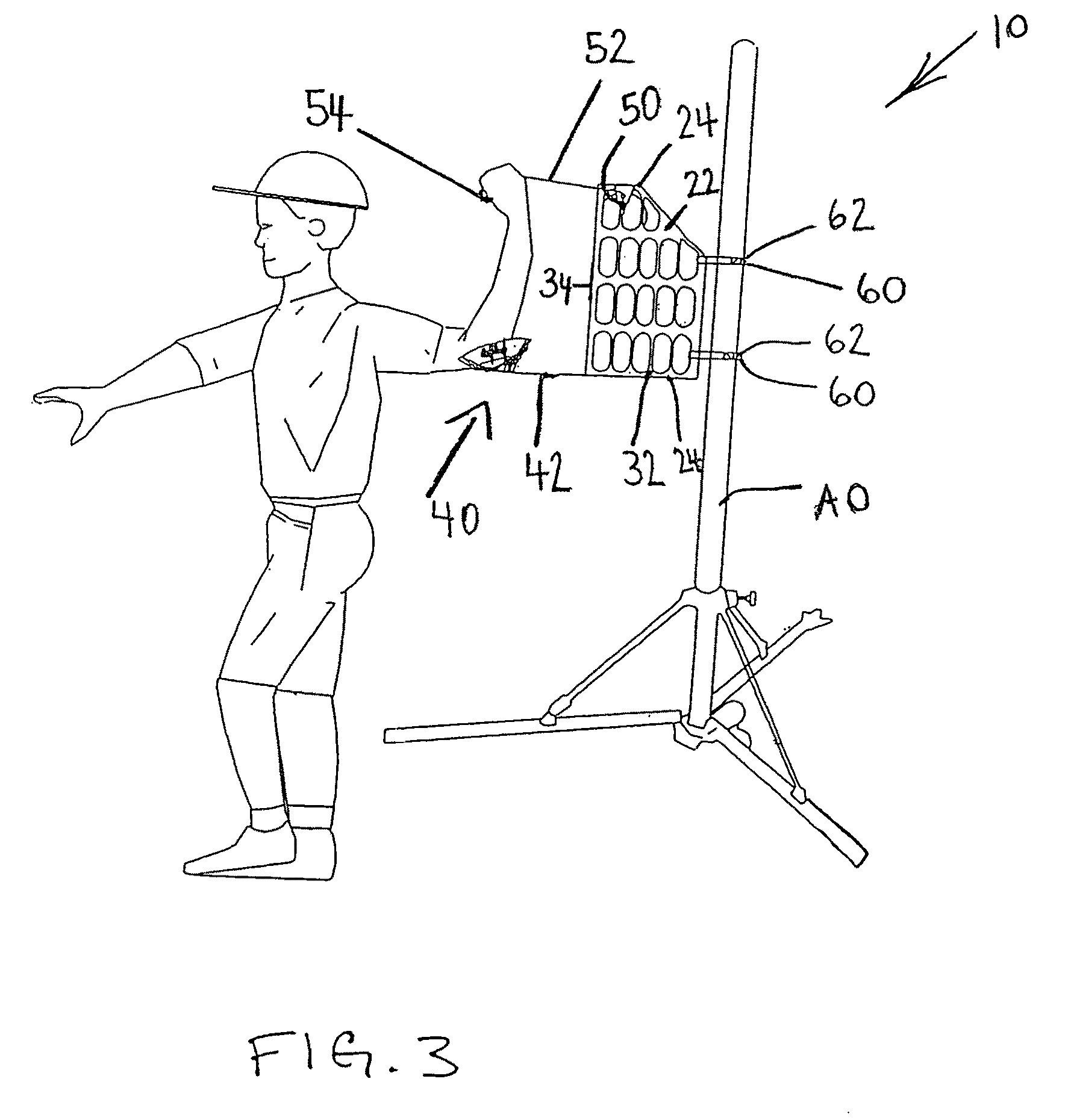

Ball throwing muscle training apparatus

A muscle memory training apparatus for training a ball player in proper elbow elevation at the beginning of a throw includes a frame; an elbow support cup assembly mounted to and projecting forwardly from the frame; a spring-loaded reel mounted to the frame a distance above the support cup assembly and having a retracting line secured to a ball mounted to the frame; and a fastening mechanism connected to the frame for fastening the apparatus to an anchoring object at a suitable elevation. A method of using the muscle memory training apparatus includes the steps of: securing the apparatus to a selected anchoring structure such that the elbow support cup is substantially at the user shoulder level; placing the user elbow in the elbow support cup; grasping the ball; and throwing the ball forwardly from the apparatus, so that the ball is subsequently retracted by the spring-loaded reel.

Owner:DERISSE ROUDY

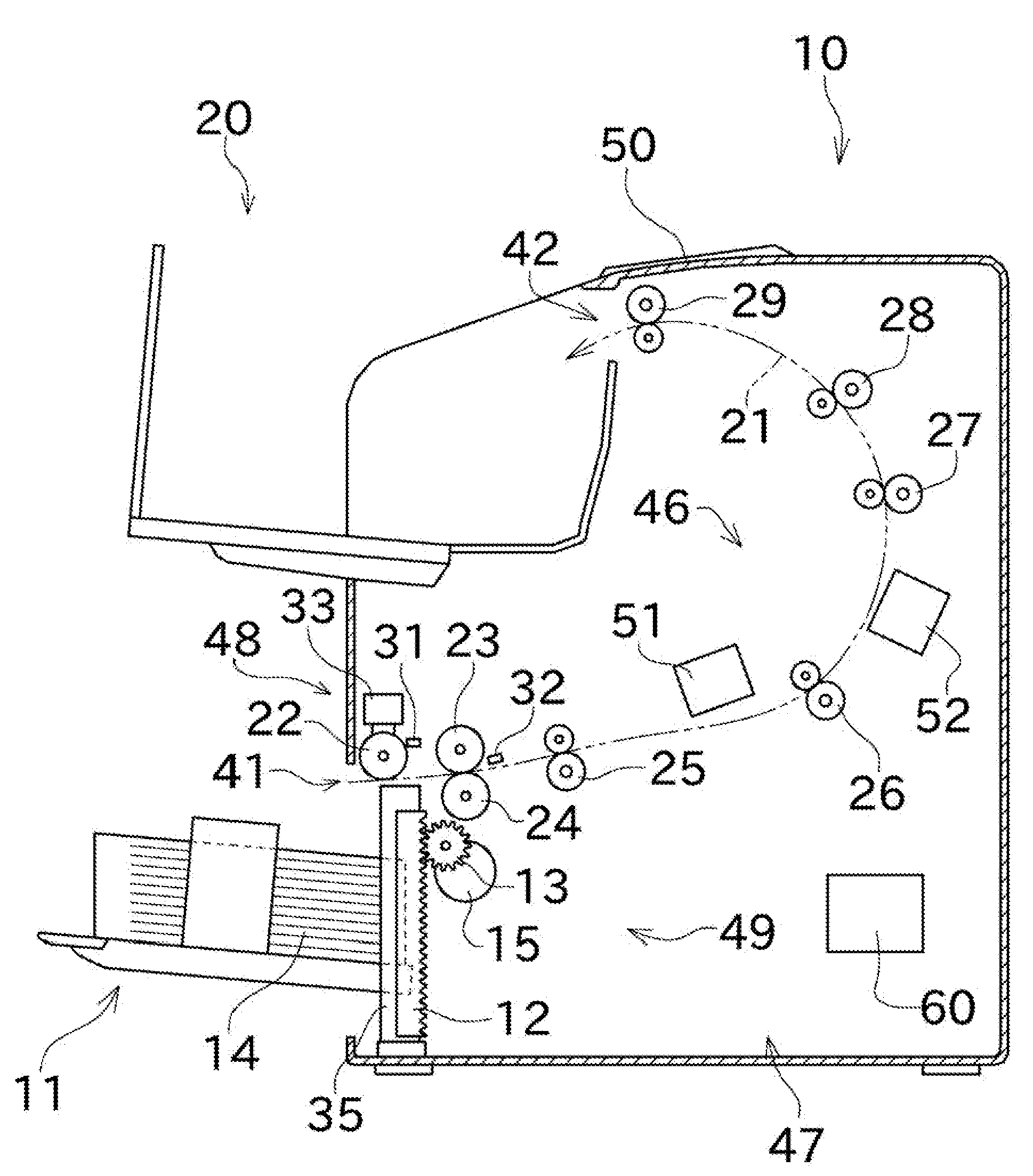

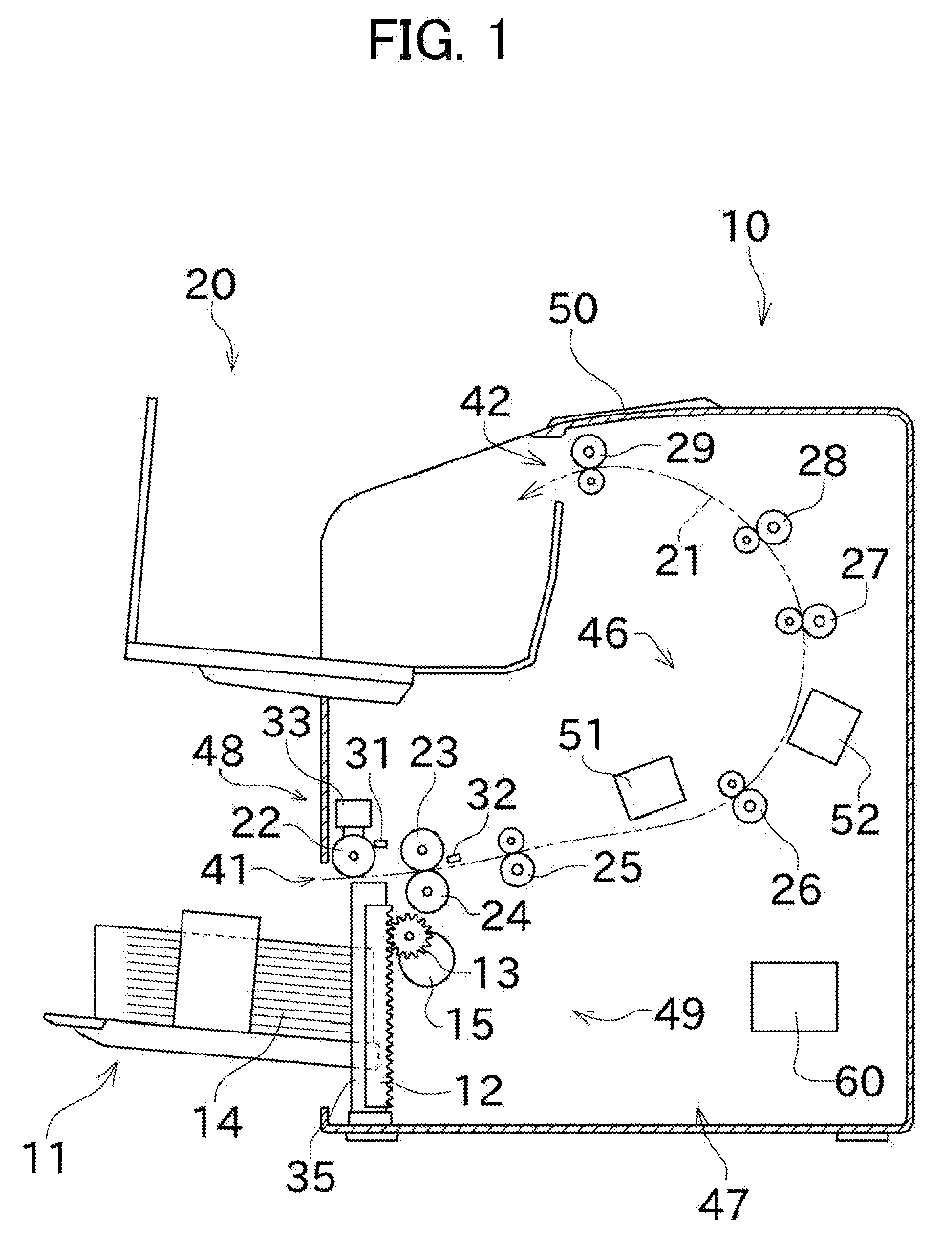

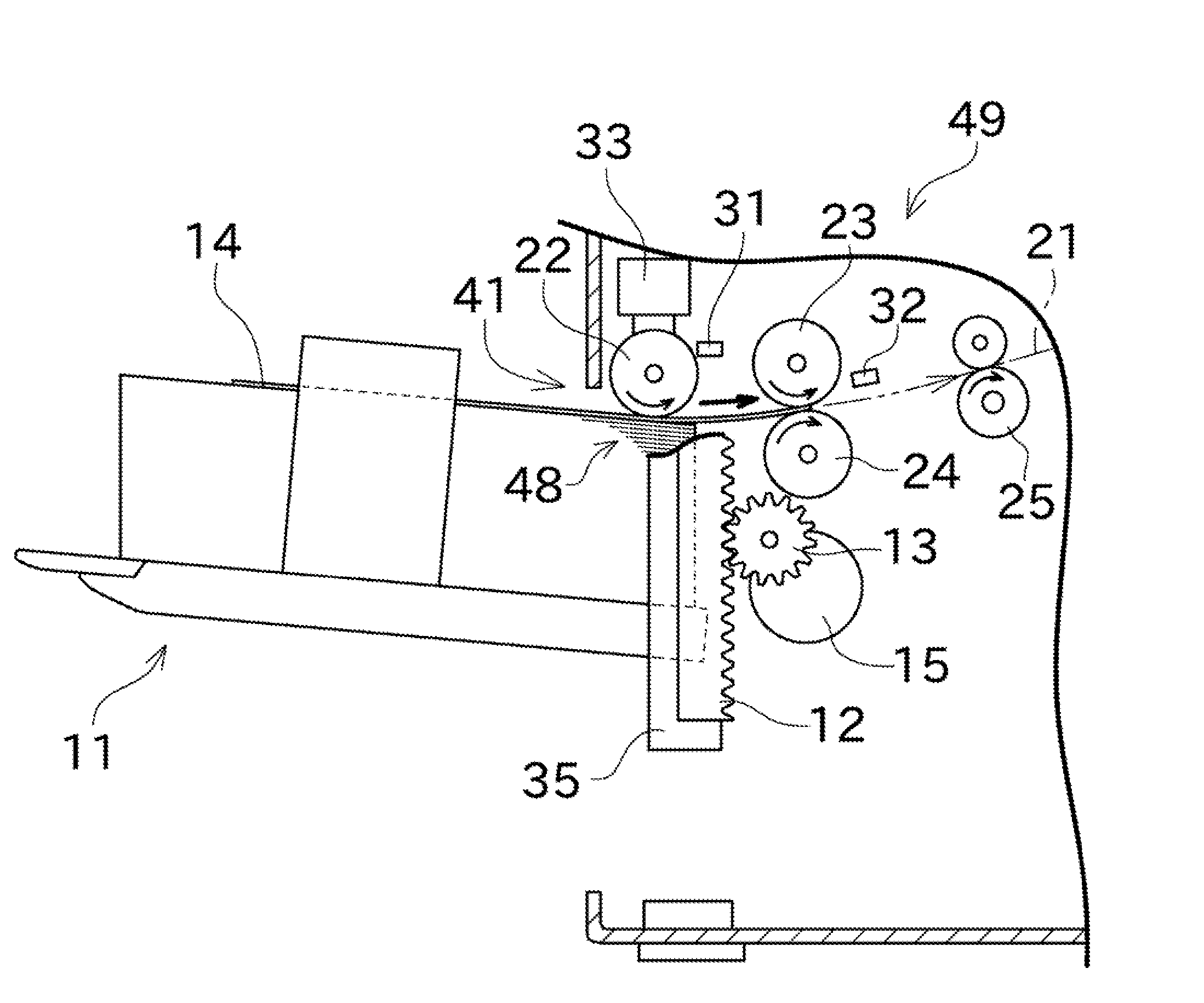

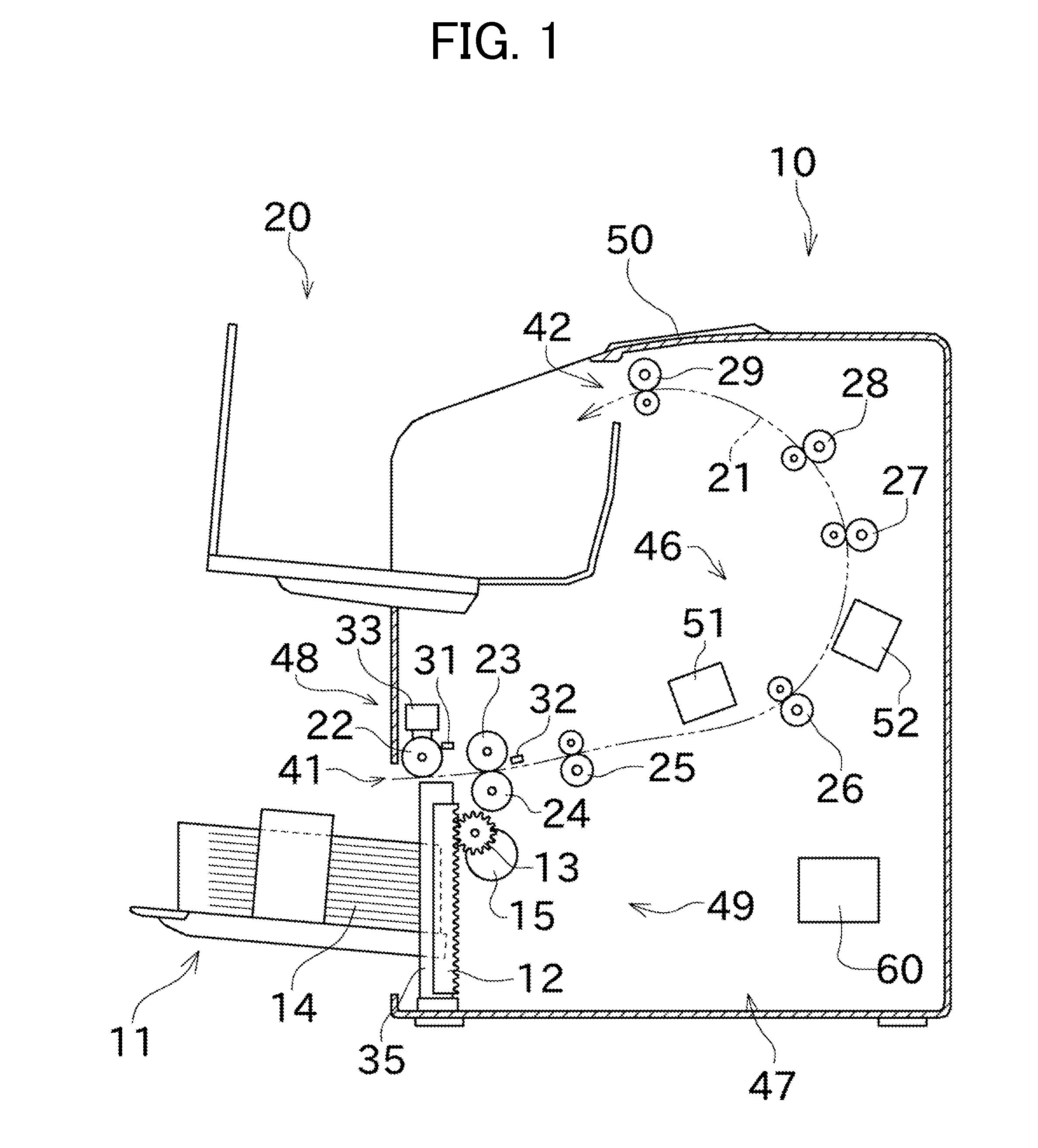

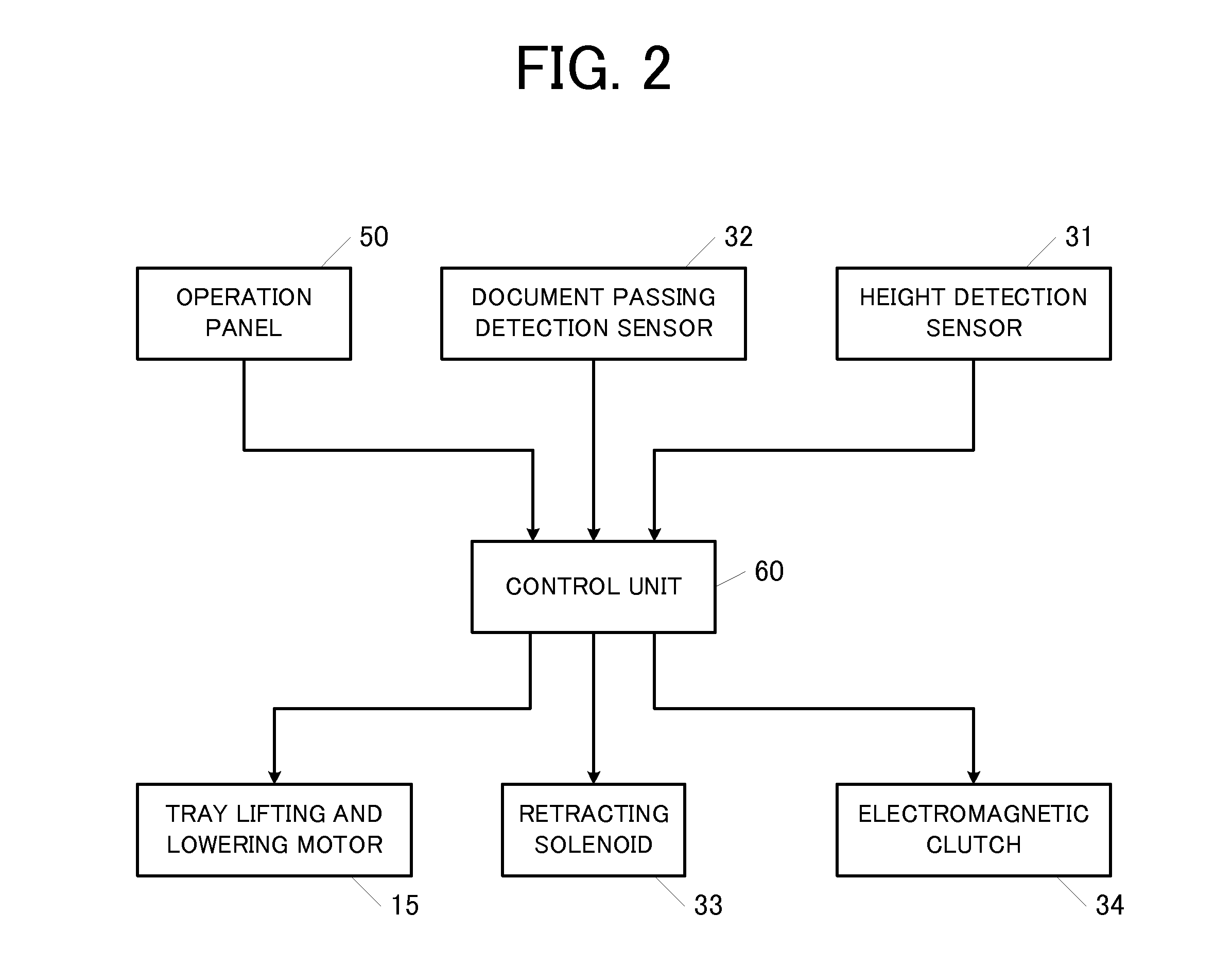

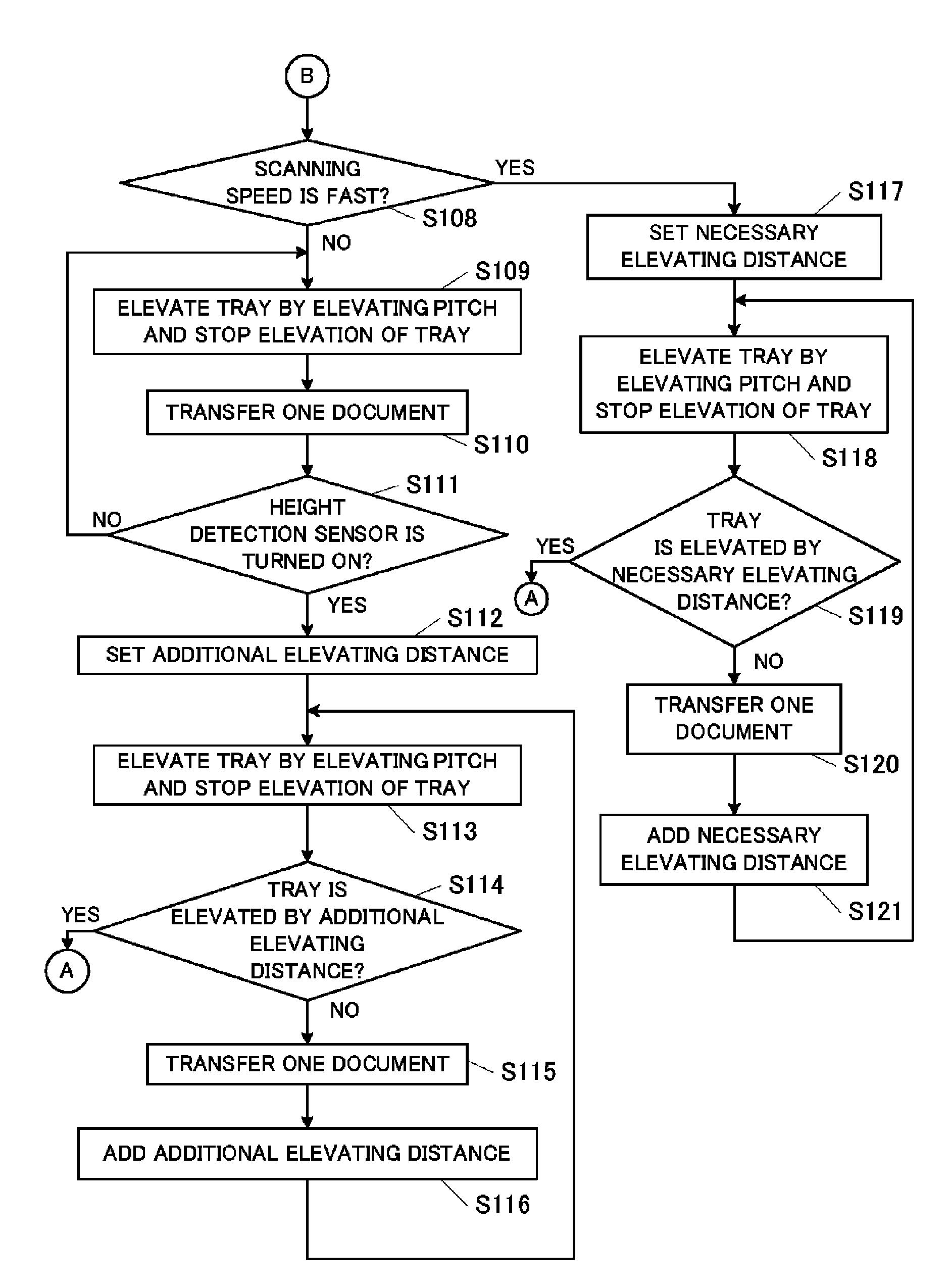

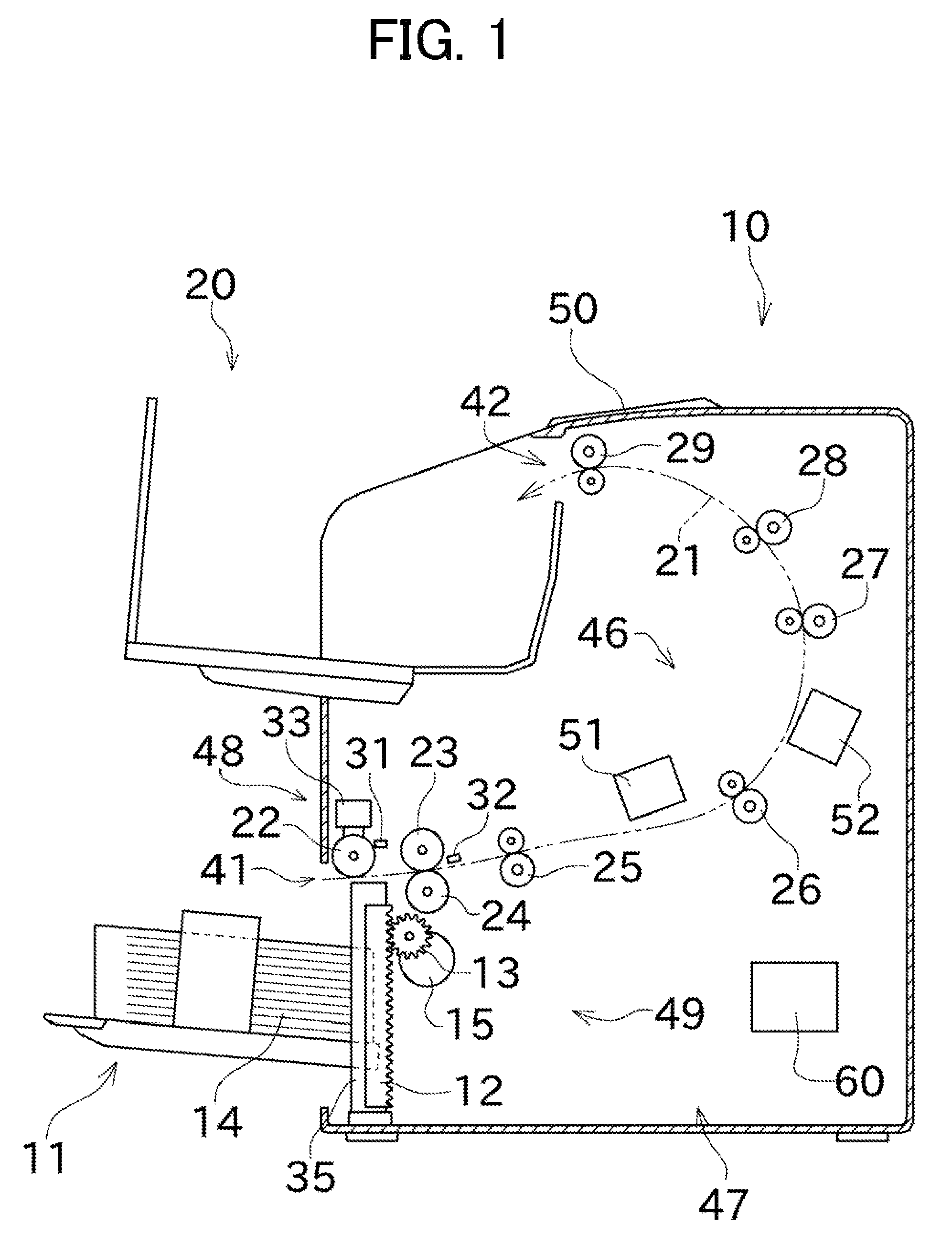

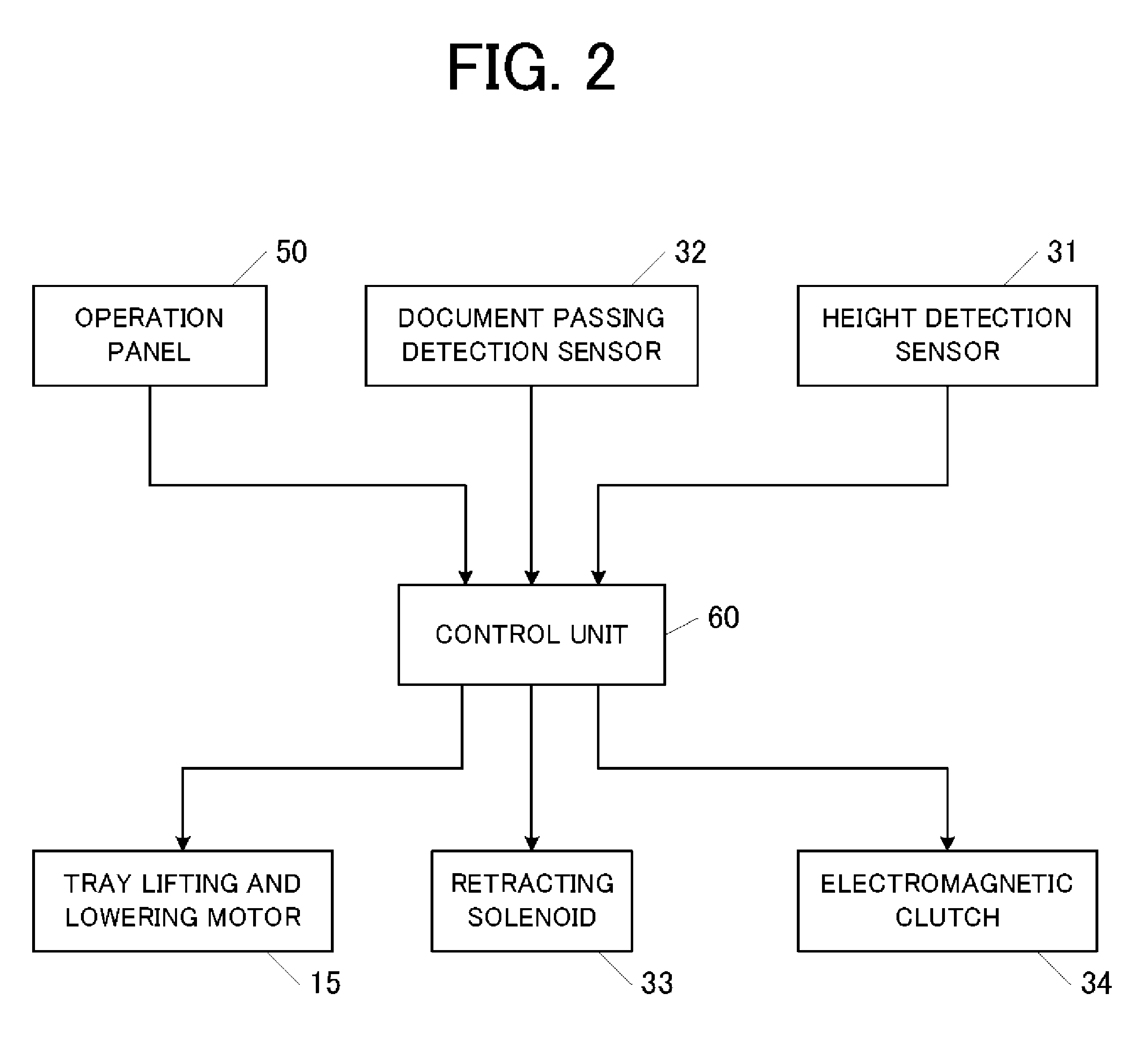

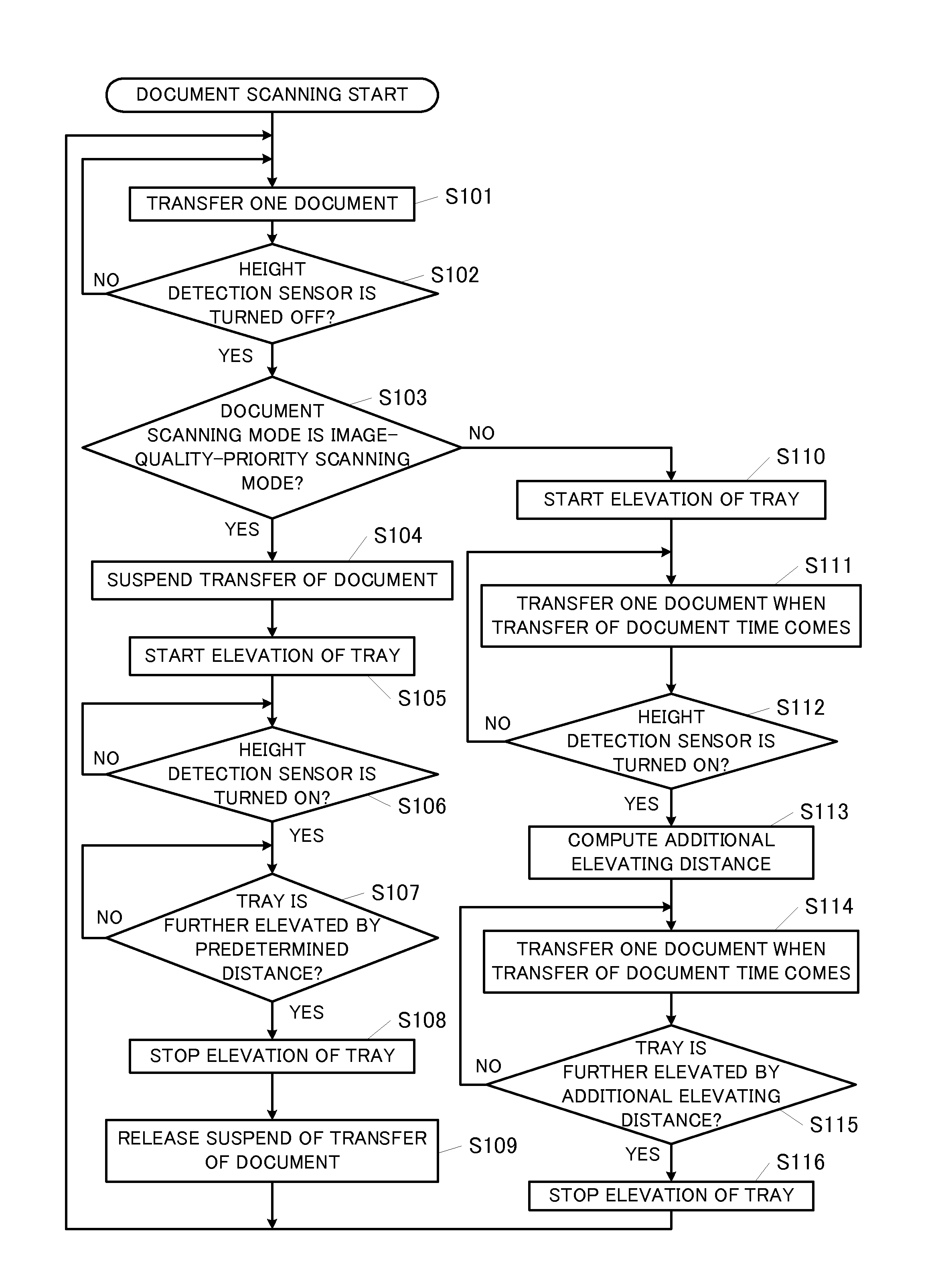

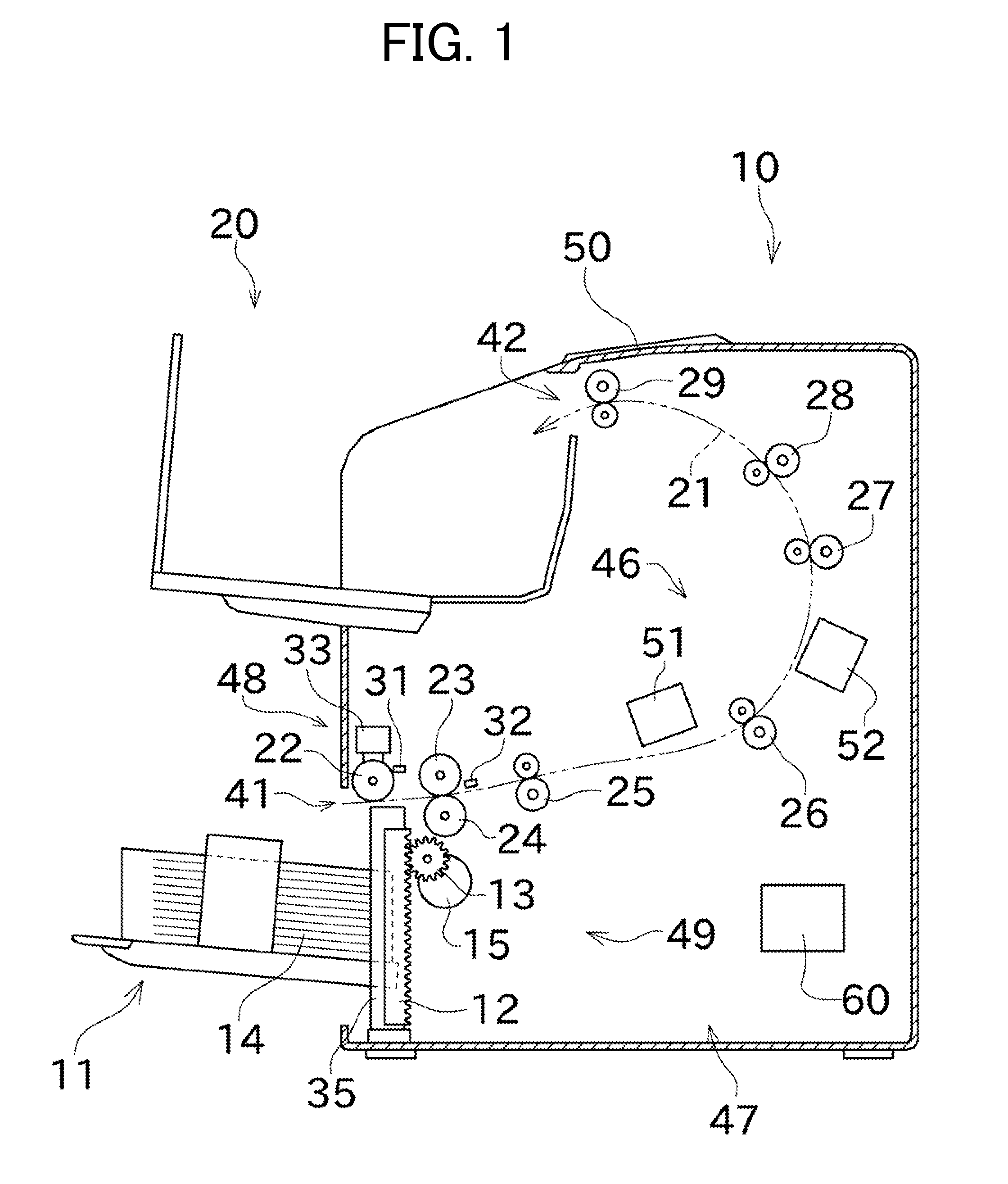

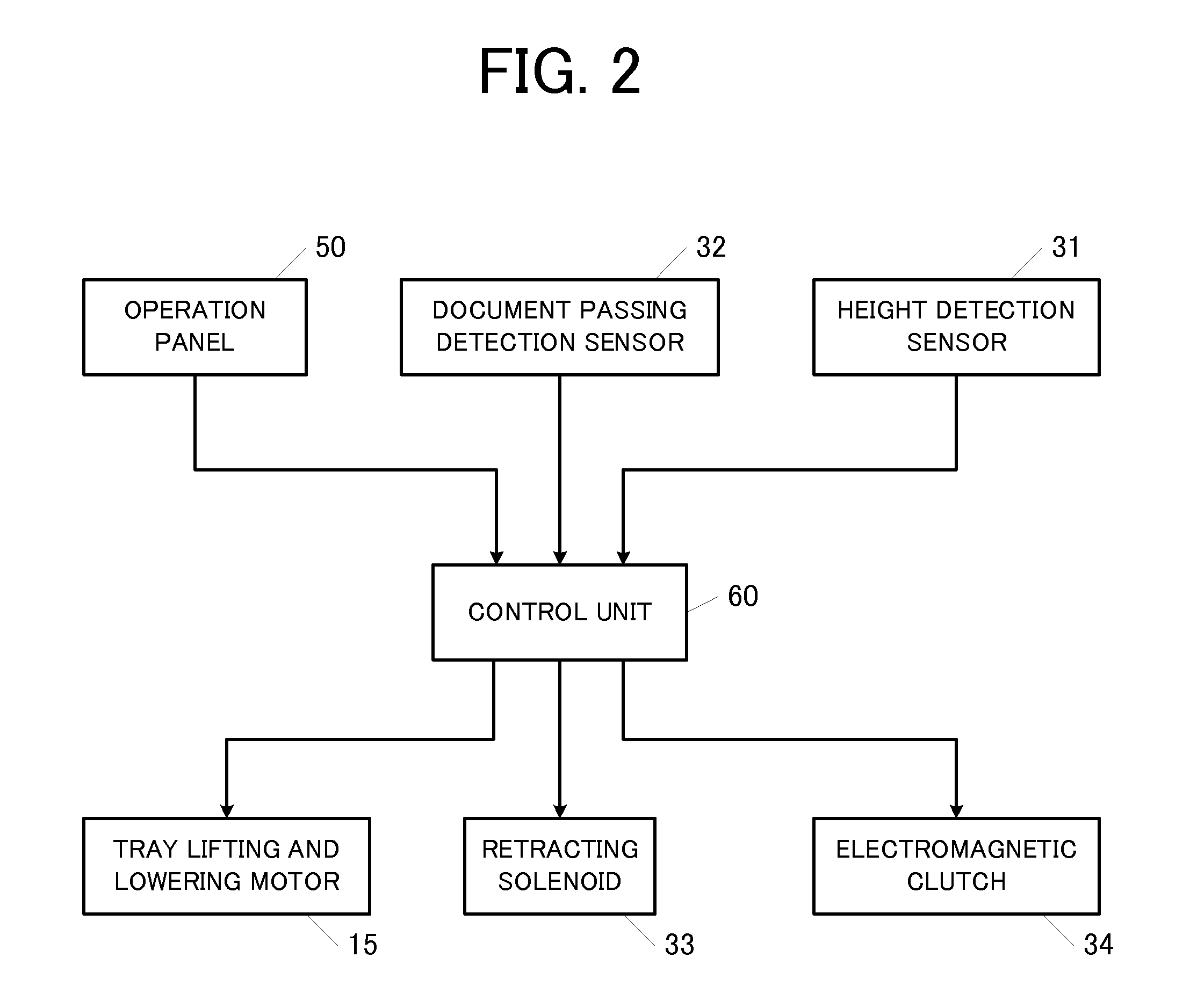

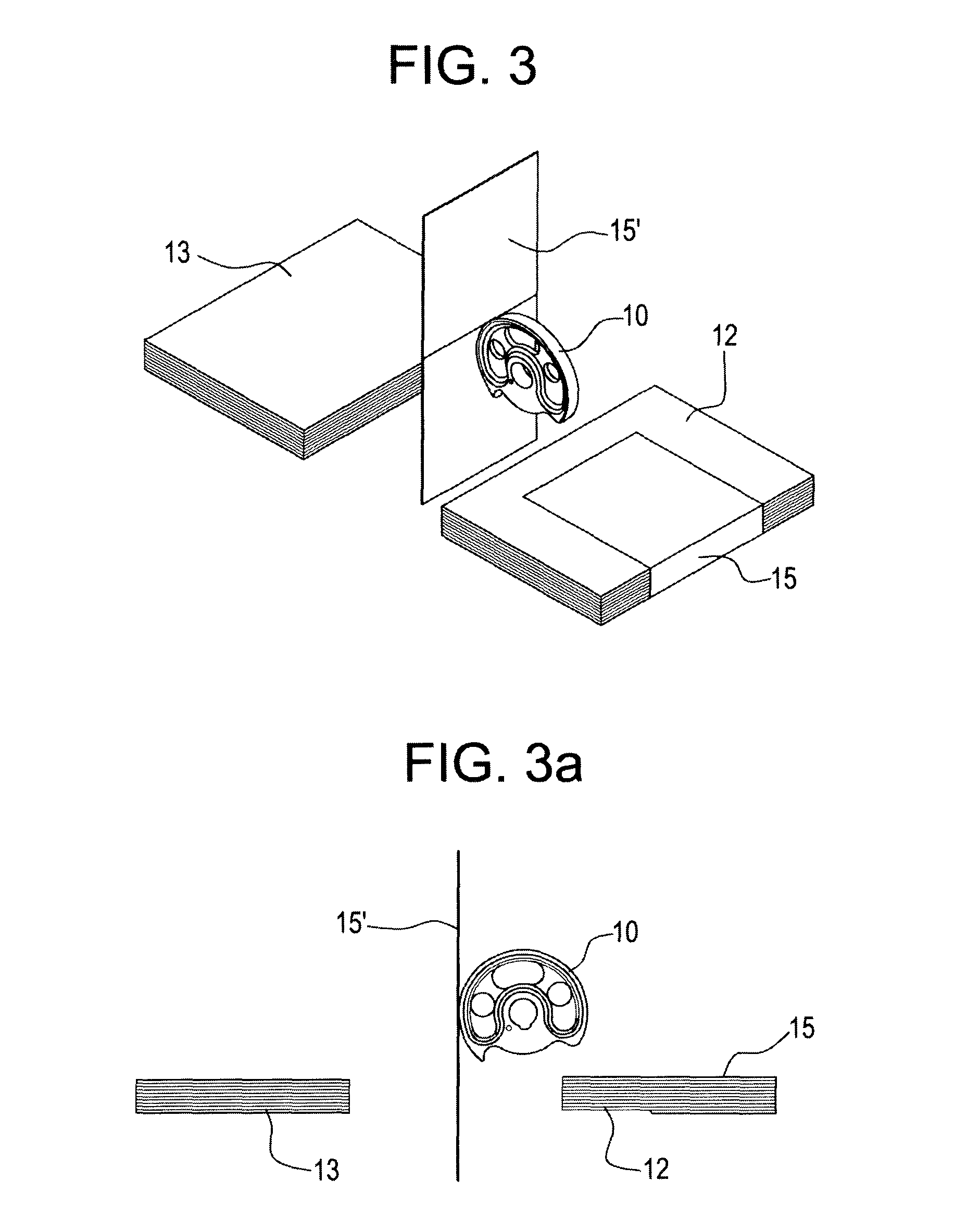

Image scanning apparatus and image scanner

InactiveUS20080224391A1Inhibit deteriorationIncrease speedFunction indicatorsArticle feedersComputer scienceControl mode

In an image scanning apparatus, when documents on a document tray are sequentially transferred, different control steps are performed according to a scanning speed when an upper surface height of the documents is lowered thereby turning off a height detection sensor. In a first control mode, which is not a high speed scanning, the document tray is elevated little by little during an inter-transfer time between each time one document is transferred until the upper surface height reaches a target height that is higher by a predetermined distance since the height detection sensor is turned on. In a second control mode, in which high speed scanning is performed, the document tray is elevated little by little during the inter-transfer time each time the one document is transferred until the upper surface height reaches a height that is higher by a predetermined distance than a height at a time when the height detection sensor is turned off.

Owner:MURATA MASCH LTD

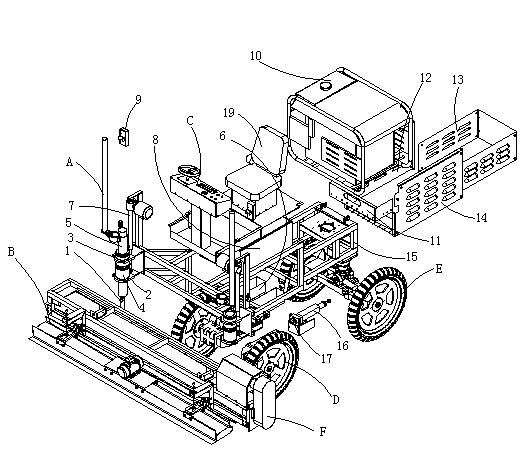

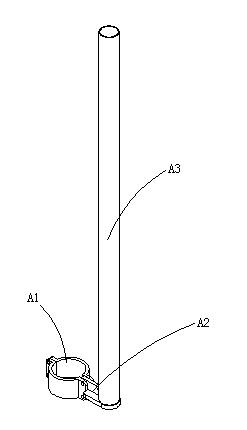

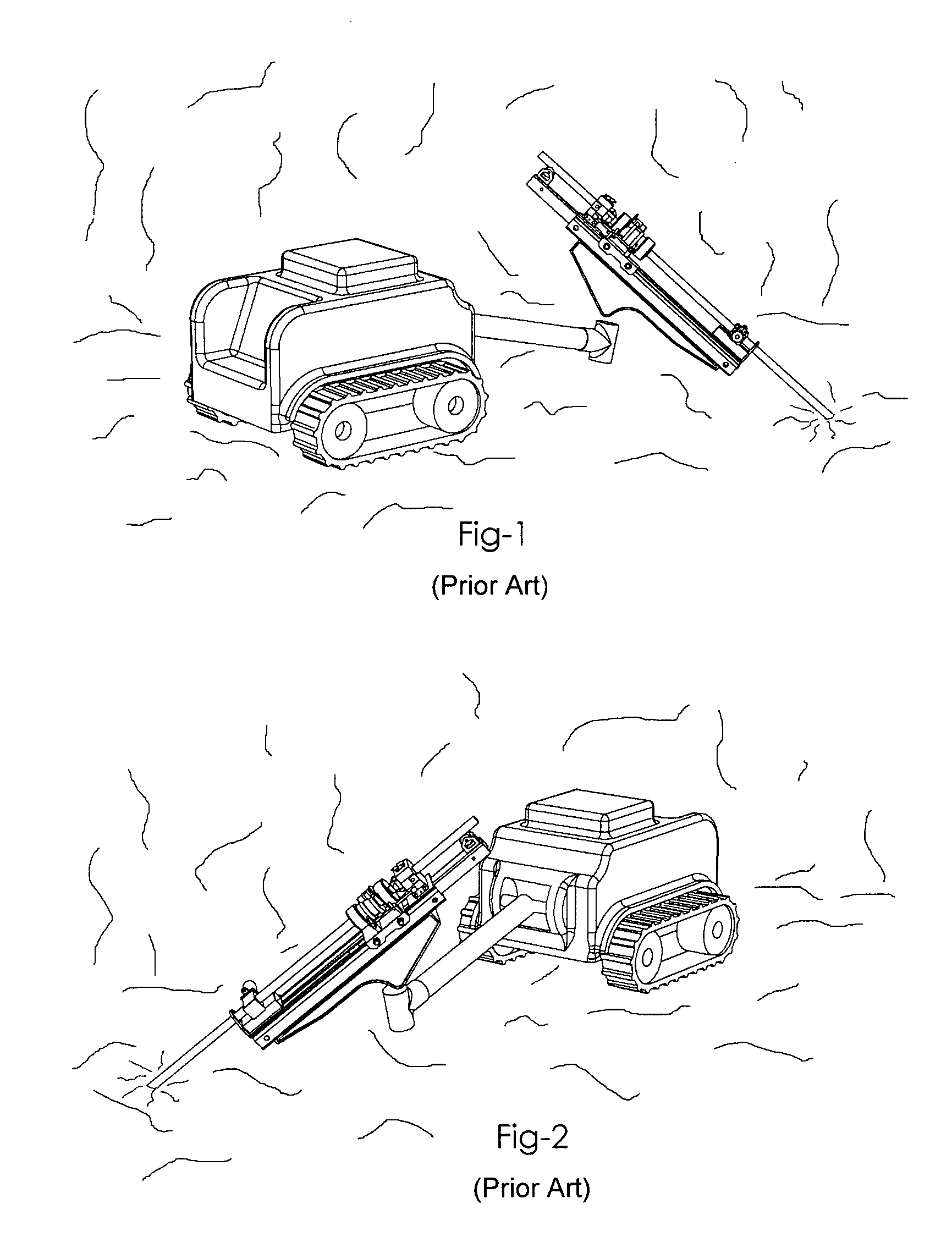

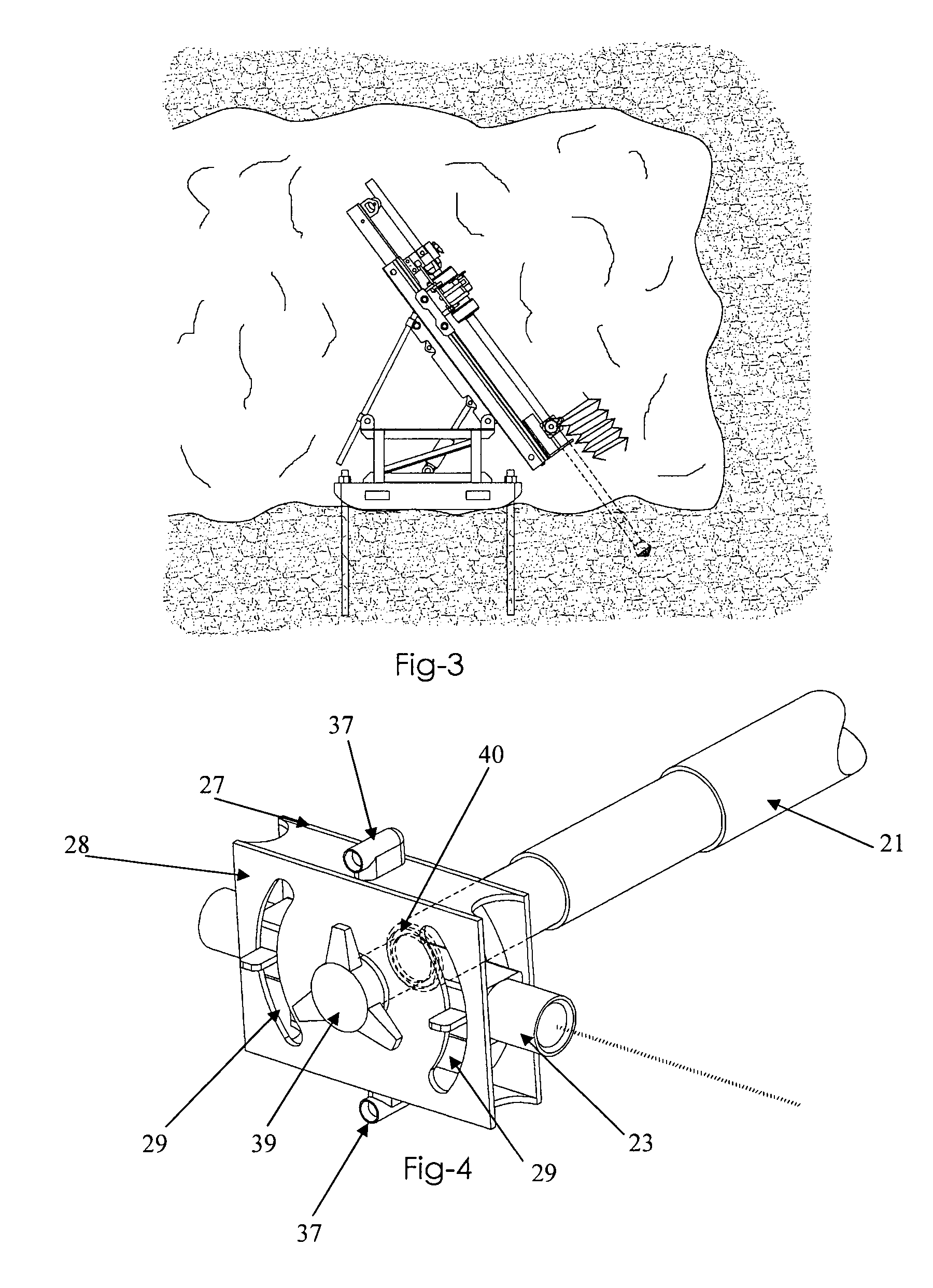

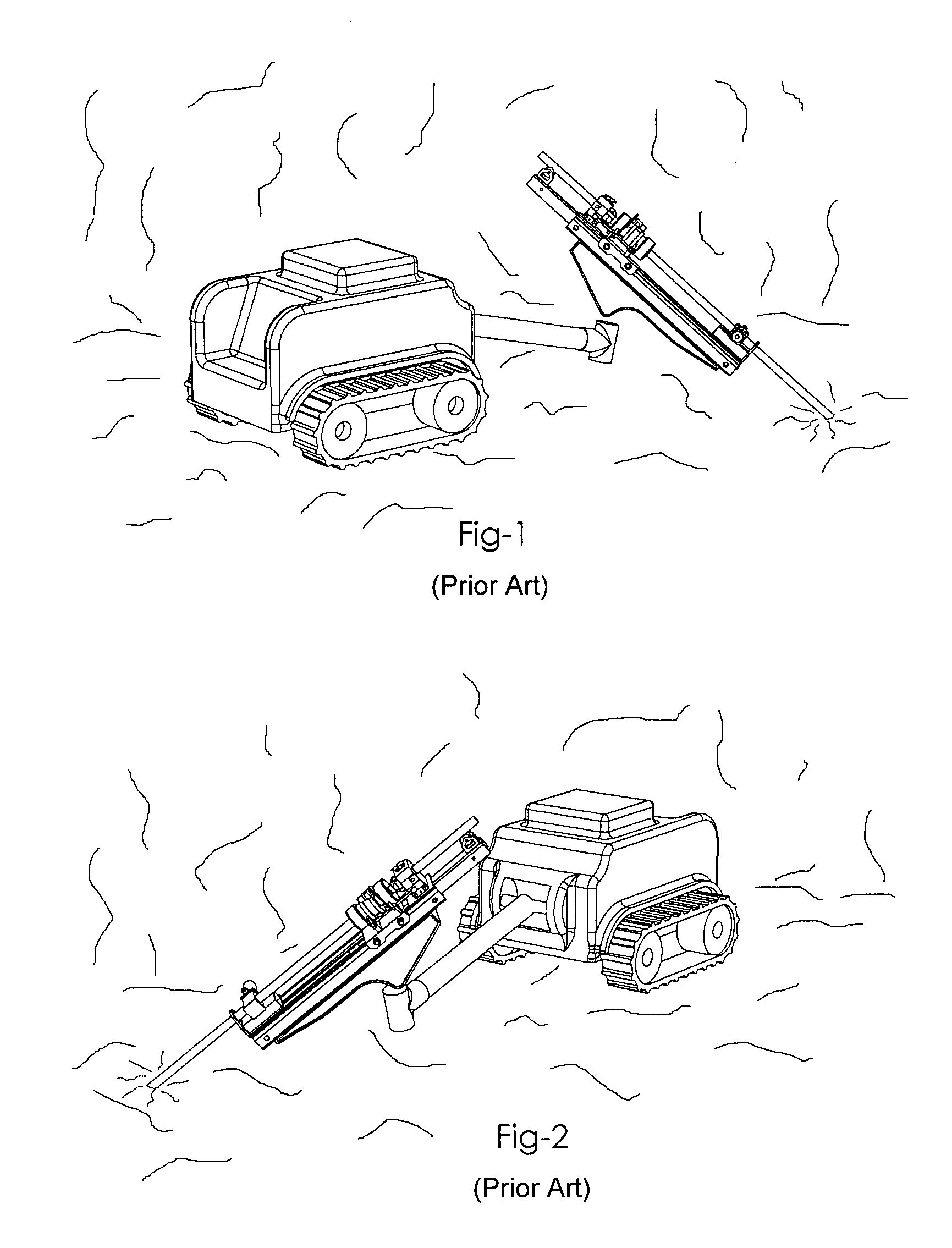

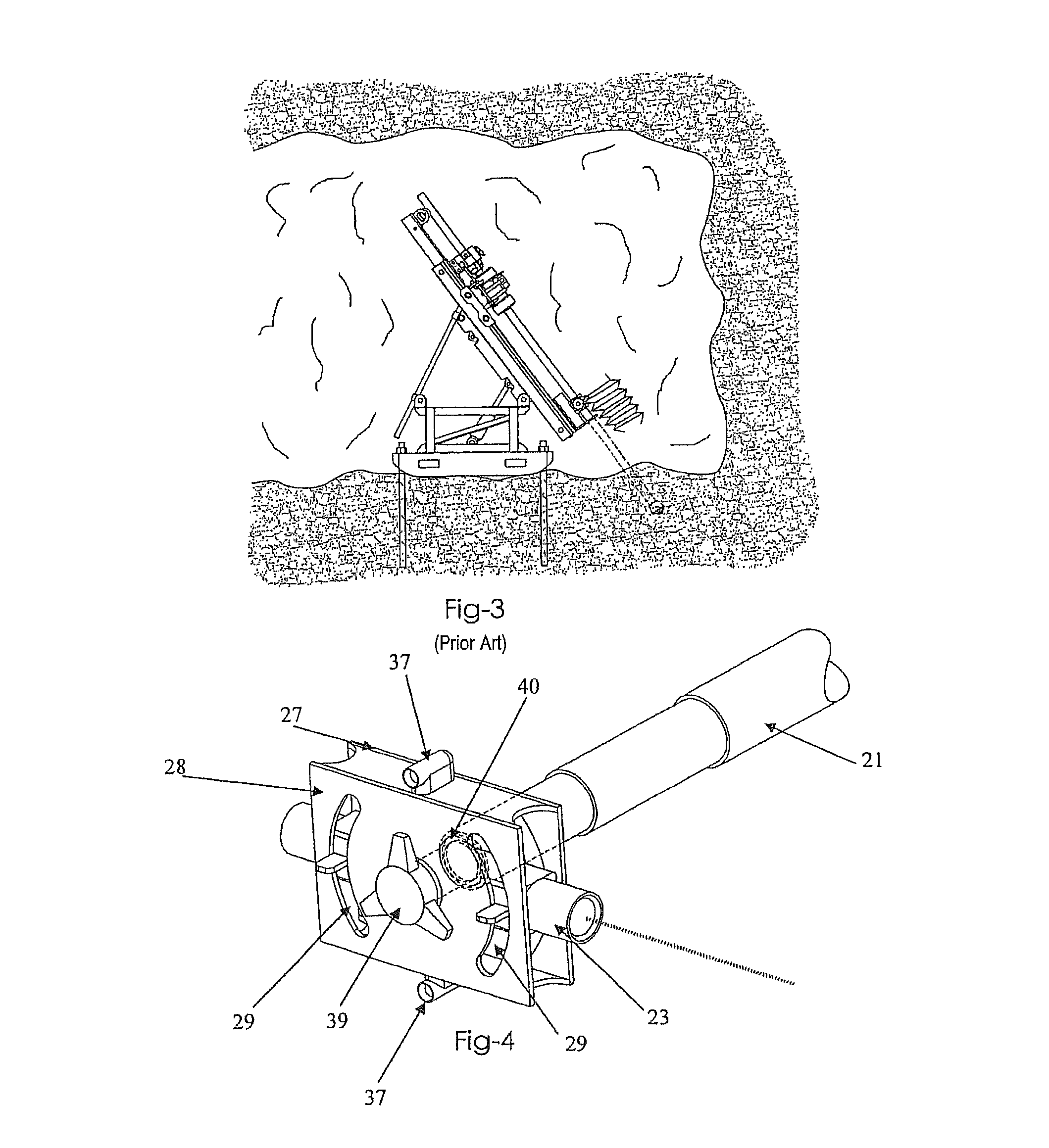

Laser alignment device for use with a drill rig

ActiveUS20120279782A1Improve accuracyImprove precisionSurveyDerricks/mastsBiomedical engineeringAzimuth

A laser alignment device for a drill rig having an elongate drill rod, the laser alignment device including a head unit having at least a pair of laser emitting devices mounted independently to one another thereon, each of the laser devices movable in one plane only and oriented in substantially opposite directions to one another, an attachment means to attach the head unit to a drill rig and a length adjustable assembly to adjust the separation distance between the head unit and the drill rod, wherein the alignment device is used to align at least the azimuth of the drill rod relative to survey marks.

Owner:PRECISION ALIGNMENT HLDG

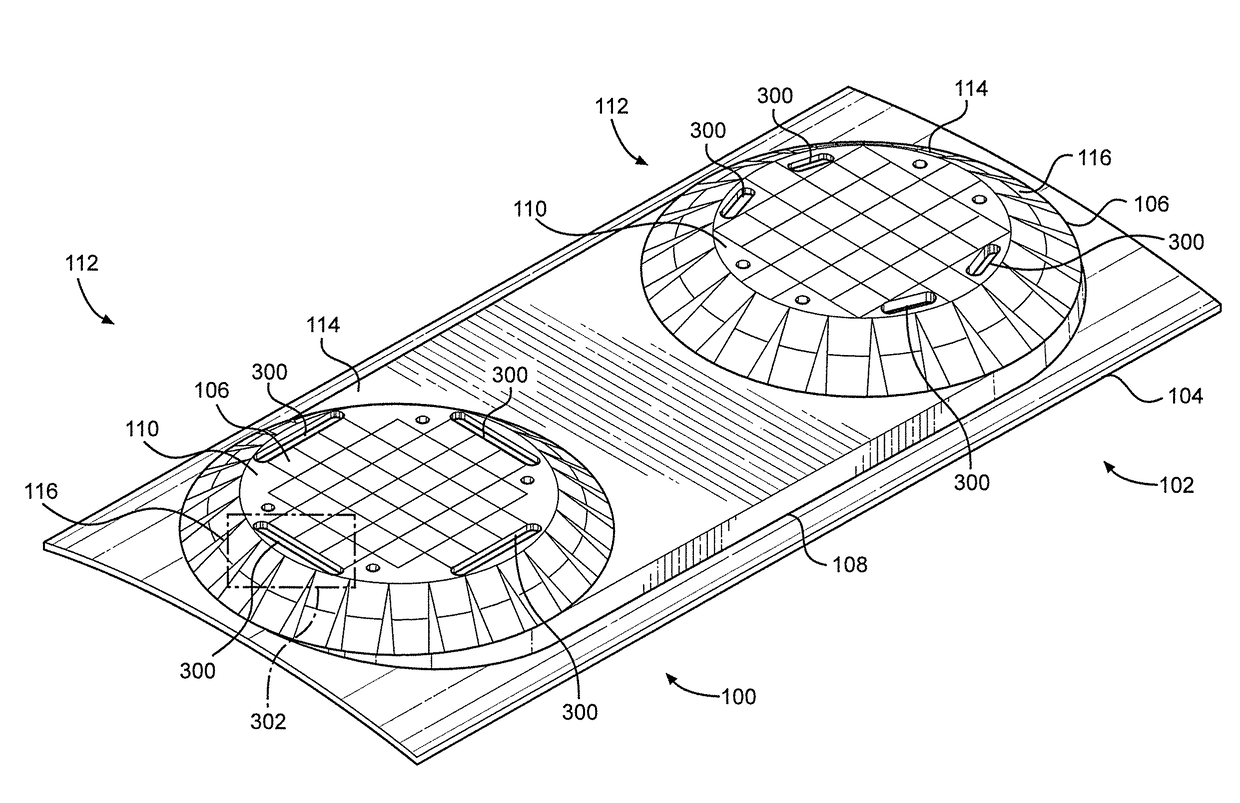

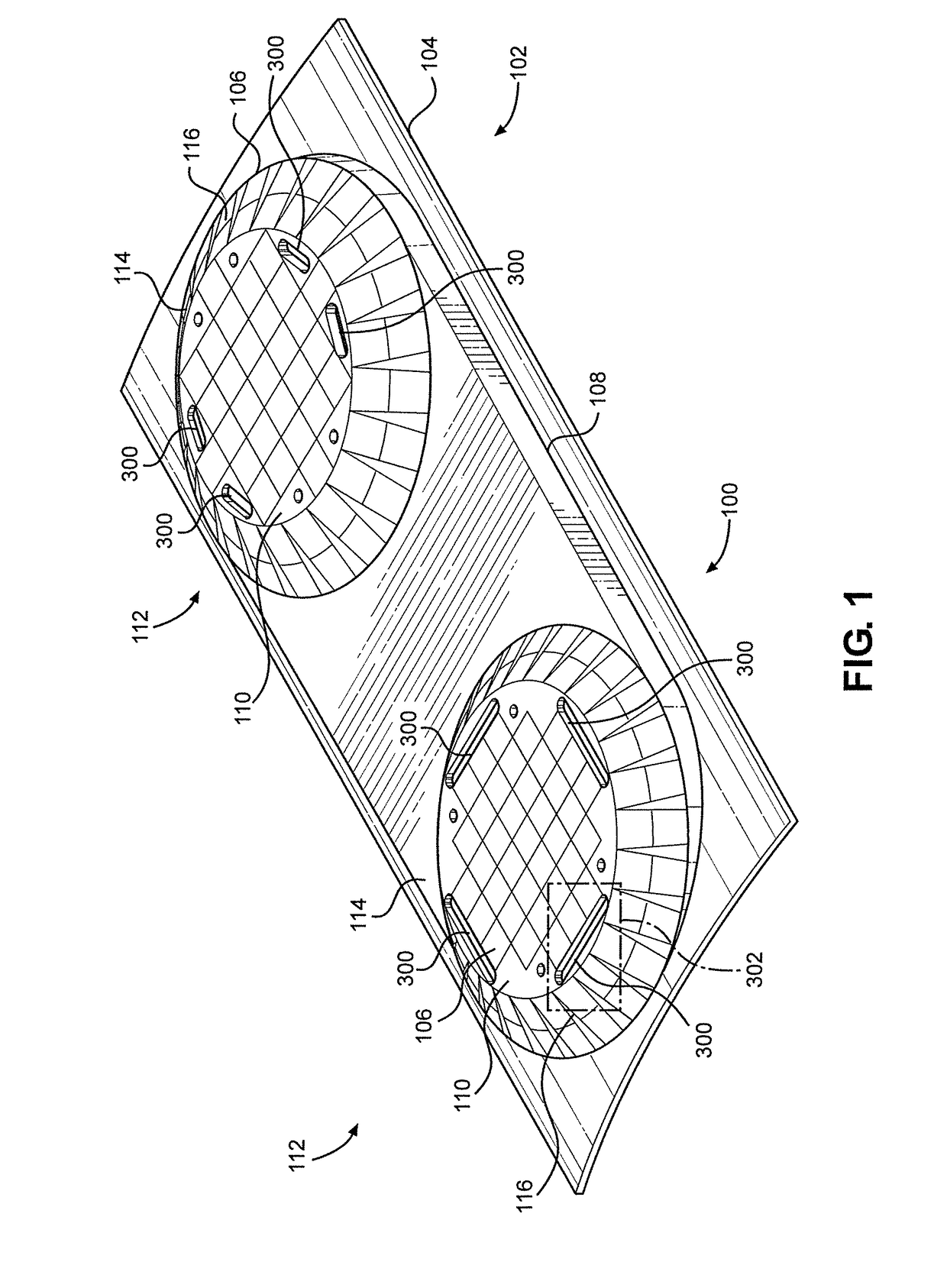

Antenna assembly

ActiveUS20170331176A1Elevation is accurateAntenna adaptation in movable bodiesRadiating elements structural formsEngineeringPlanar array

An antenna assembly including a support and antenna tiles disposed in the support. The antenna tiles form an external surface corresponding substantially in shape to lateral faces of a frustum. The frustum includes a central axis with the antenna tiles disposed around the central axis of the frustum and sloping away therefrom. Each antenna tile includes opposite ends, with one end narrower than the other end. A planar array of antenna elements is disposed on each antenna tile in which the antenna elements of each array are configured to operate as a phased array. A control system connects to the planar arrays of antenna elements in which the control system is configured to selectively activate and deactivate each of the planar arrays.

Owner:PANASONIC AVIONICS CORP

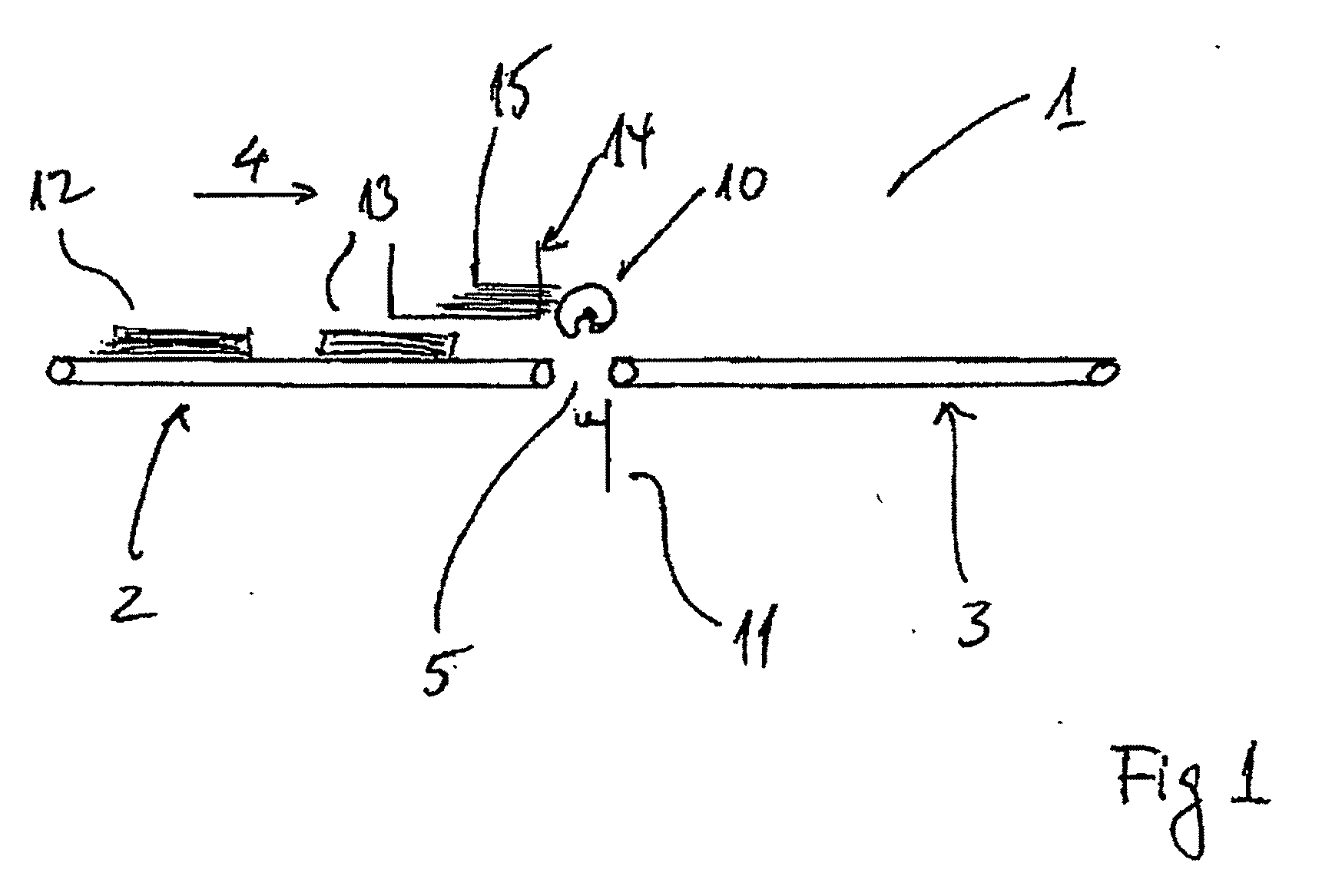

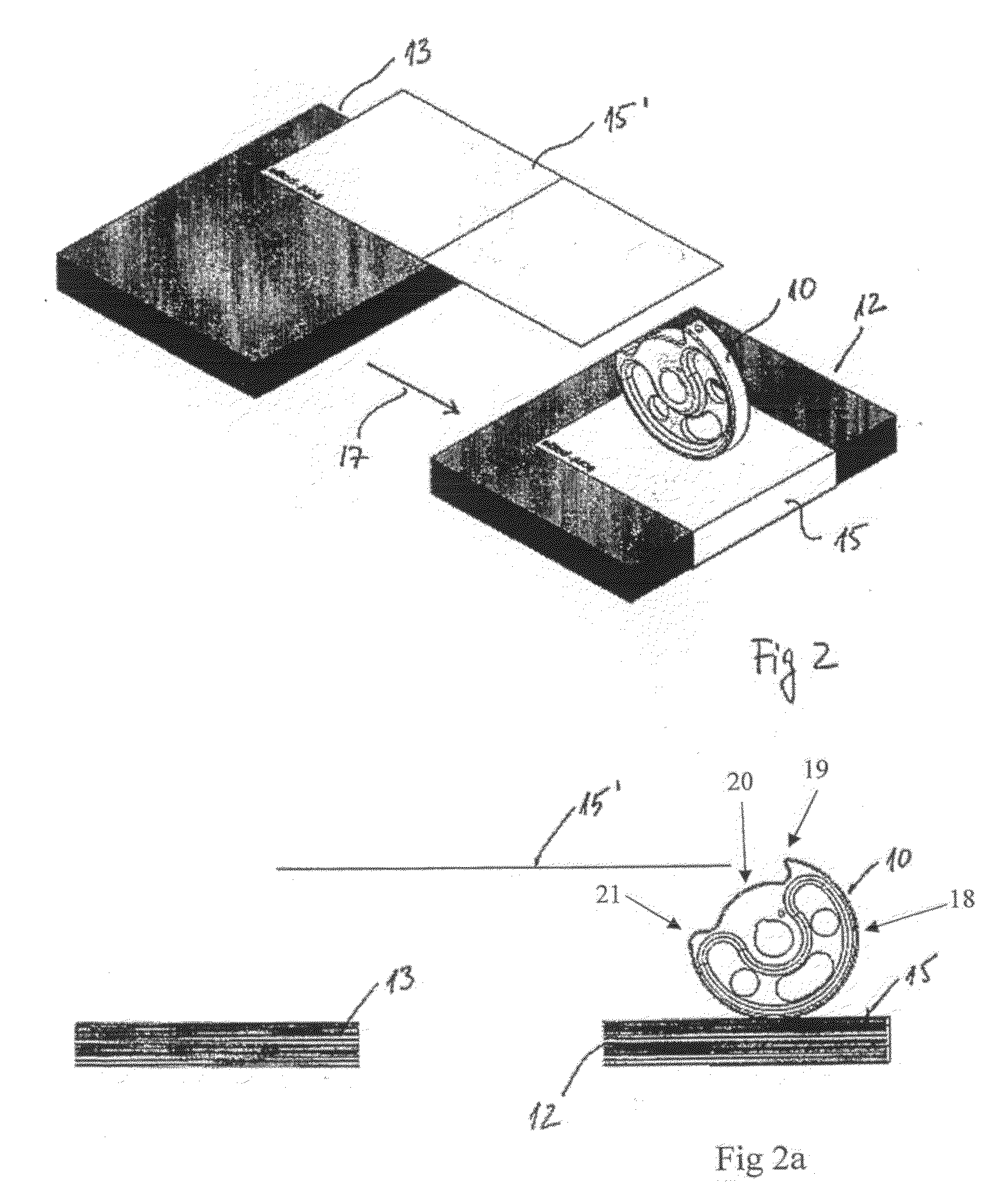

Image scanning apparatus and image scanner

ActiveUS20080226371A1Addressing slow performanceElevation is accurateFunction indicatorsElectrographic process apparatusImaging qualityDocumentation

In an image scanning apparatus, documents on a document tray are transferred one by one, and an upper surface height of the documents is lowered to turn off a height detection sensor. Different kinds of control modes are performed according to a document scanning mode. In an image-quality-priority scanning mode, a transfer unit suspends transfer of the document, the document tray is elevated until the upper surface height reaches a target height that is higher by a predetermined distance after the height detection sensor is turned on, and the transfer unit resumes the transfer of the document. In a speed-priority scanning mode, while the transfer of the document is continued by the transfer unit, the document tray is elevated until the document tray reaches the target height.

Owner:MURATA MASCH LTD

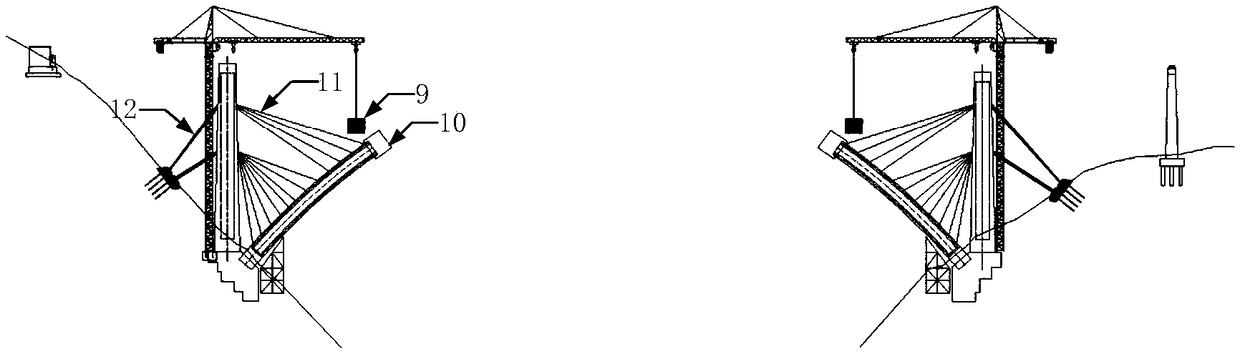

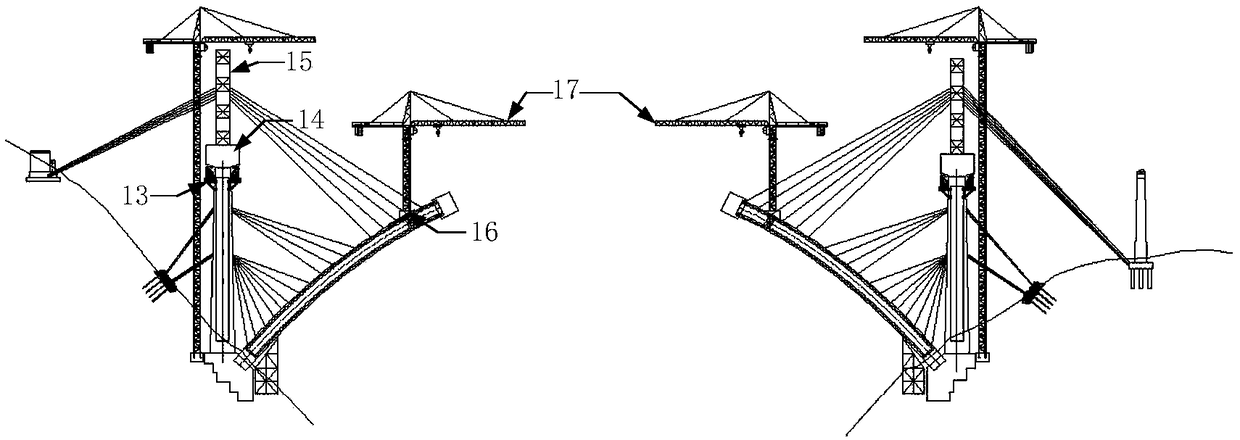

Cantilever pouring system and construction method of long-span railway reinforced concrete arch bridge

PendingCN109235285AImprove construction efficiencySave cable costsBridge erection/assemblyReinforced concreteAbutment

The invention discloses a cantilever pouring system of a long-span railway reinforced concrete arch bridge. The system is characterized in that the embedded structure comprises a main arch abutment foundation (1), an approach bridge abutment (2) and a side pier foundation (3), and the large-temporary engineering structure comprises a back cable anchor spindle (4), a support (6) and a buckling tower (15); The buckle cable structure comprises a temporary buckle cable (11) and a back cable (12). The auxiliary tower crane assembly comprises a first tower crane (5) and a second tower crane (17), wherein the auxiliary tower crane assembly relays reinforcement cages (9) of each segment to be in place, thereby effectively solving the technical problem of constructing a long-span railway concrete arch bridge under the site condition that temporary supports cannot be installed. A long-span railway reinforce concrete arch bridge cantilever pouring construction method is also provide, which greatly increases construction efficiency compared with that traditional construction method and saves cable and part of ground anchor cost. The invention also provides a large-span railway reinforced concrete arch bridge cantilever pouring construction method.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

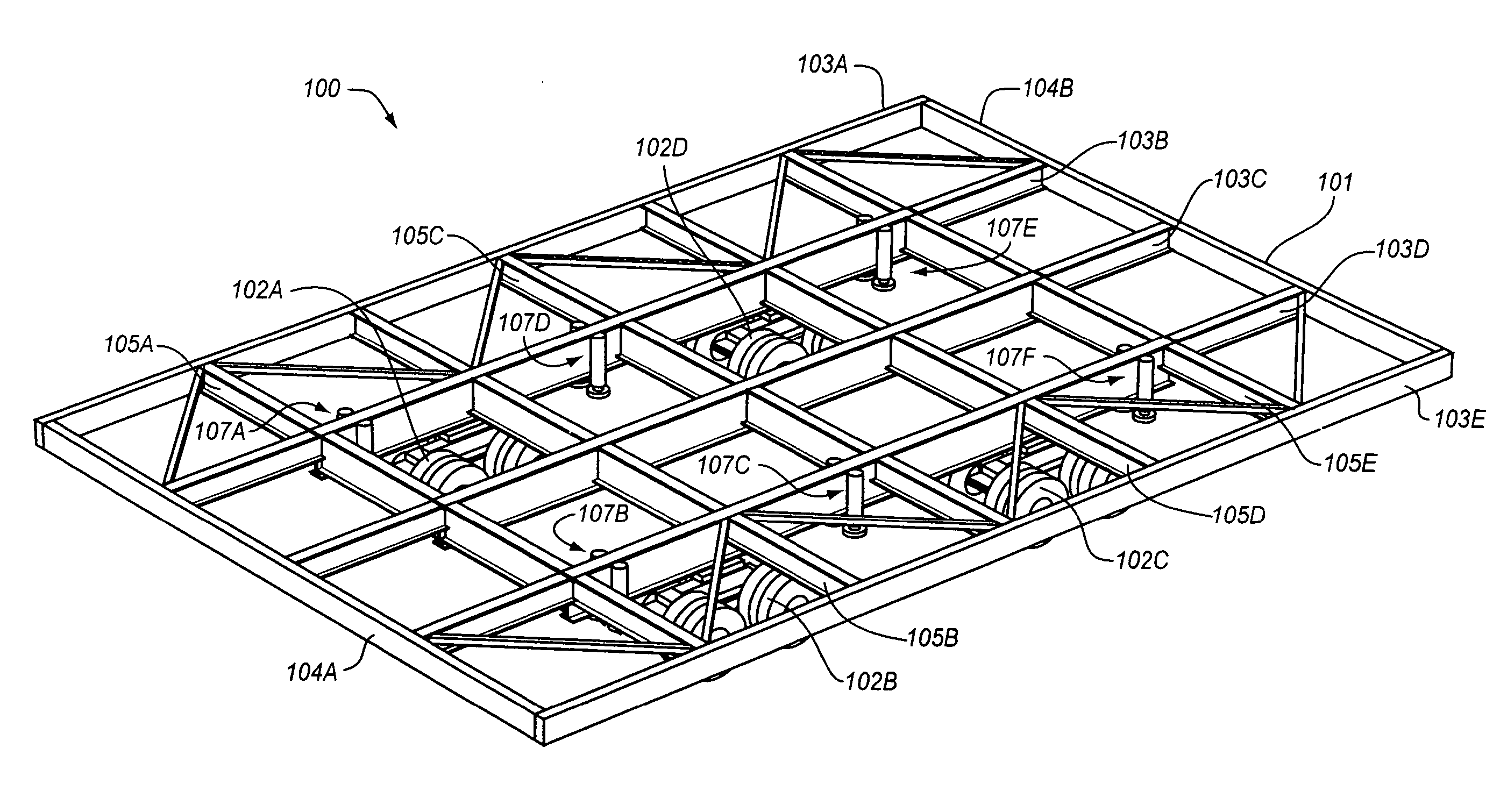

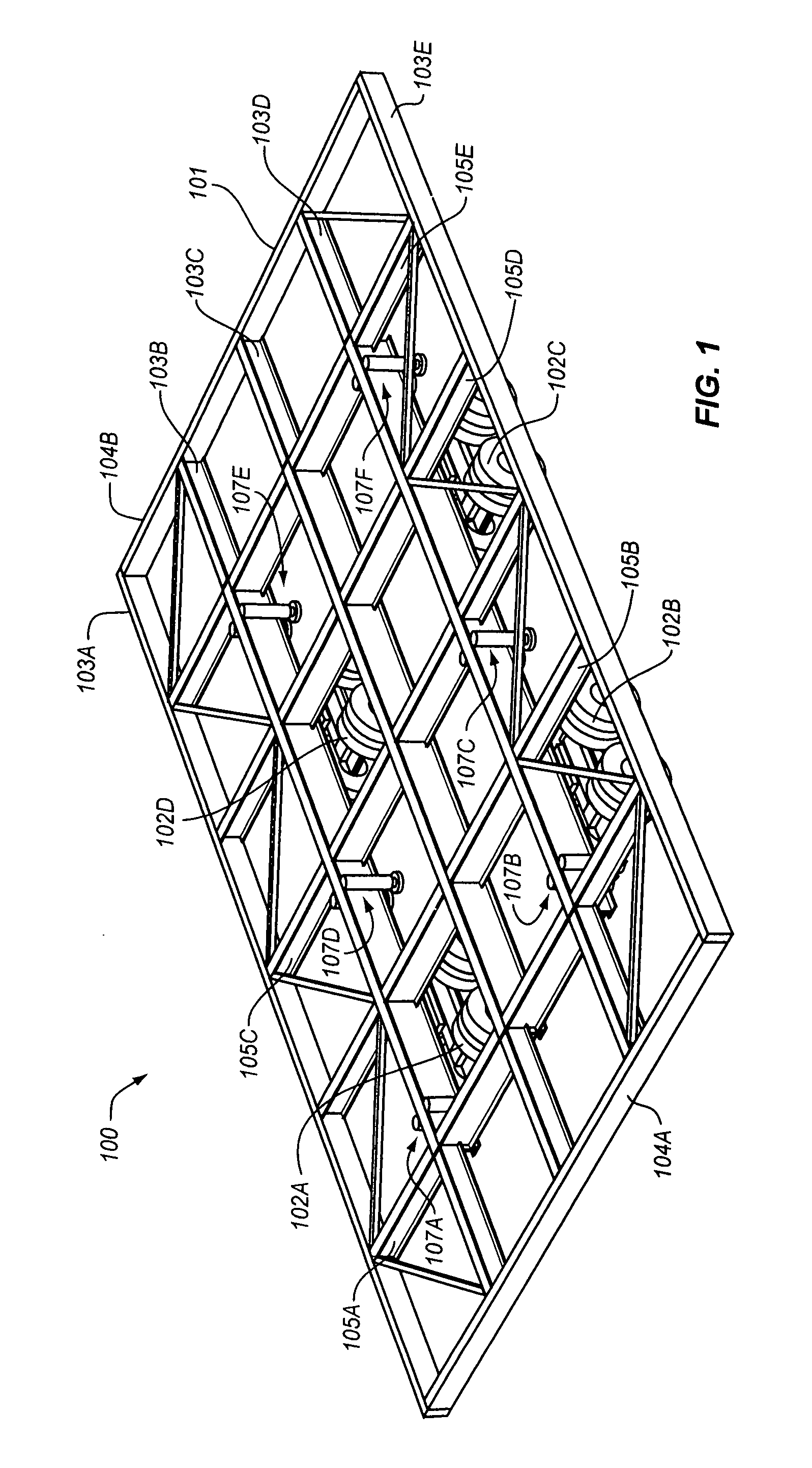

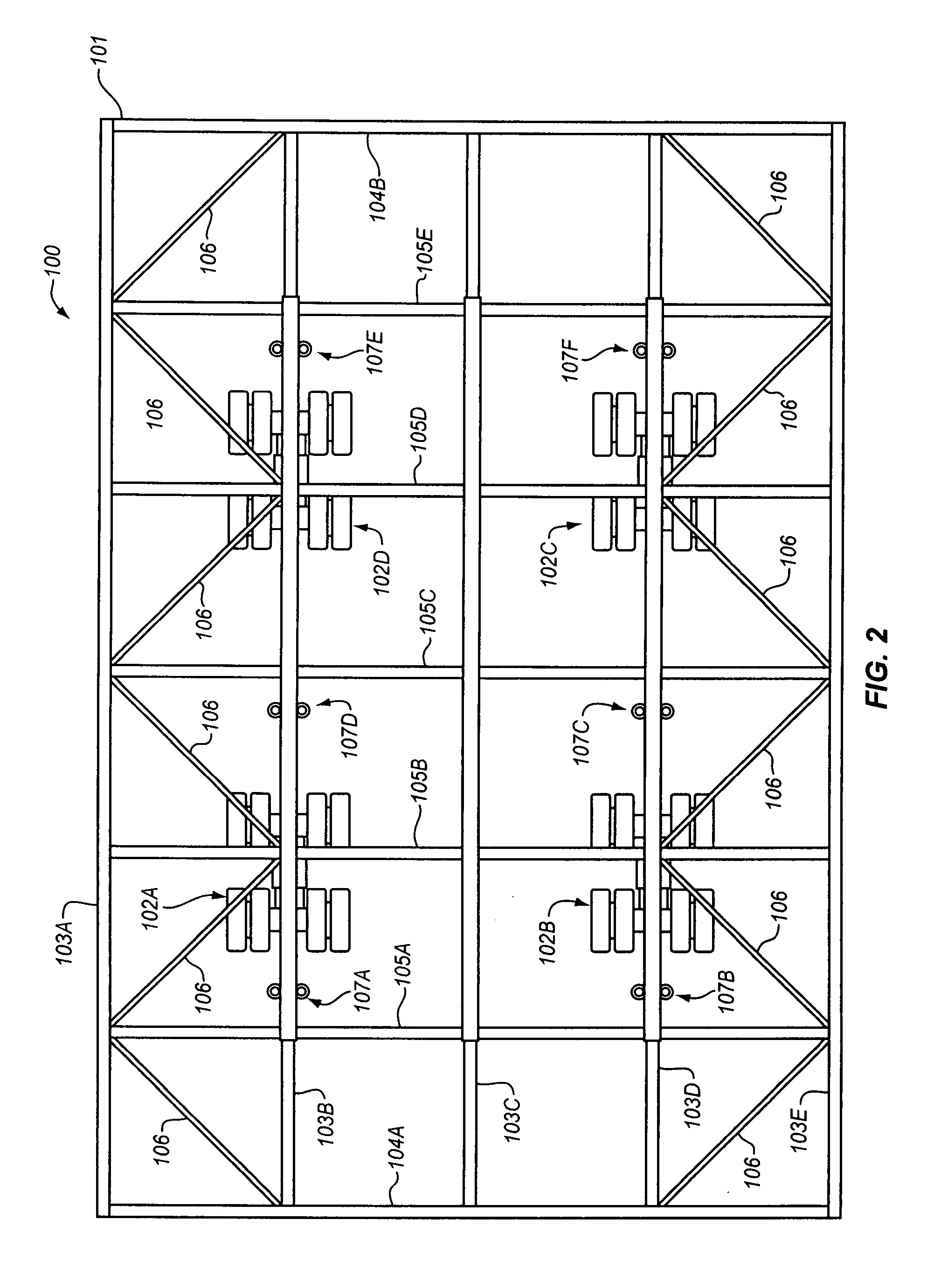

Whole house conveyance machine

InactiveUS20070266650A1Efficient mechanismSufficient structural integrityUnderstructuresSpecial buildingSupporting systemEngineering

The invention comprises a plurality of steel framing members that are permanently or semi-permanently affixed to one another to create an integral frame that does not have to be completely recreated to perform successive home movements on different sized homes and has sufficient structural integrity and dynamic load support systems to transport a house without causing cracking and breakage of brittle finishes. Multi-tire transportation assemblies support the frame on its bottom side. An integral system of hydraulic jacks that have bending moment capability are affixed to the integral frame to allow the integral frame to be elevated and lowered while remaining stable so that the multi-tire transportation assemblies can either be spun or removed, the integral frame can be leveled, or the integral frame can be elevated and lowered to the required elevation of a foundation or the dock of the manufacturing facility that produces standard size houses.

Owner:INTPROP LLC

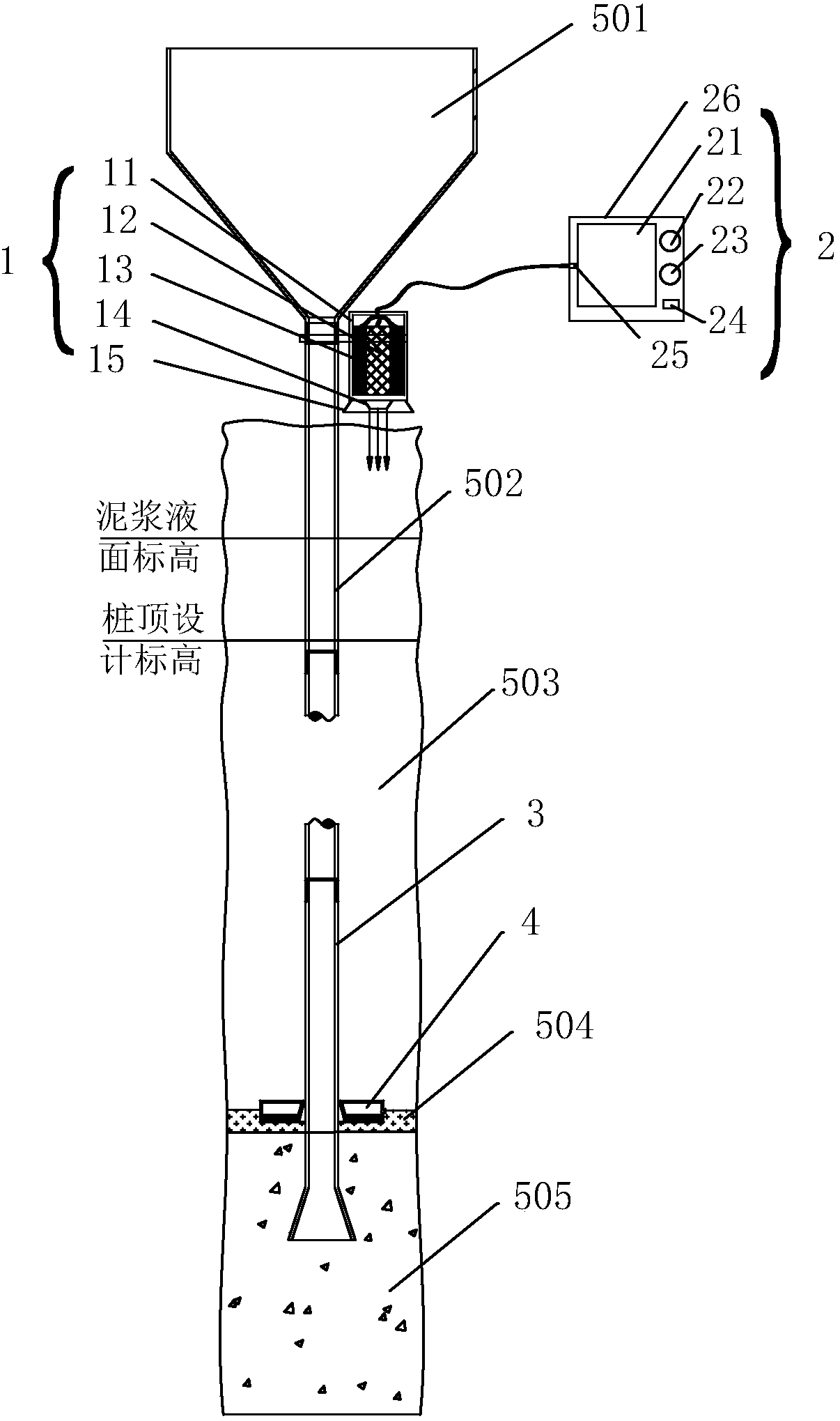

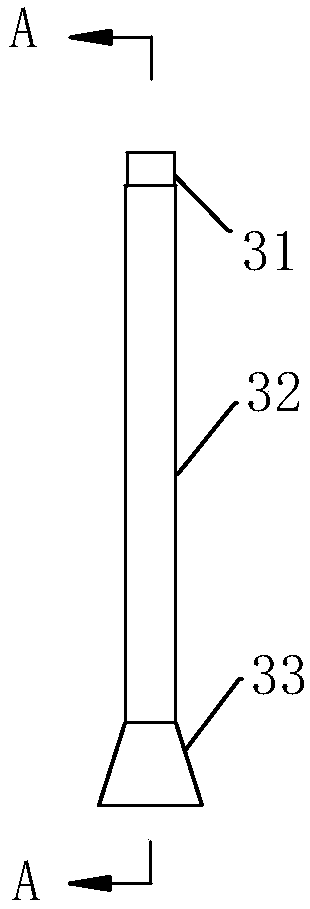

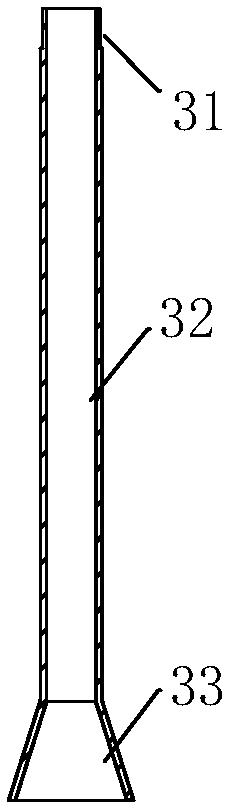

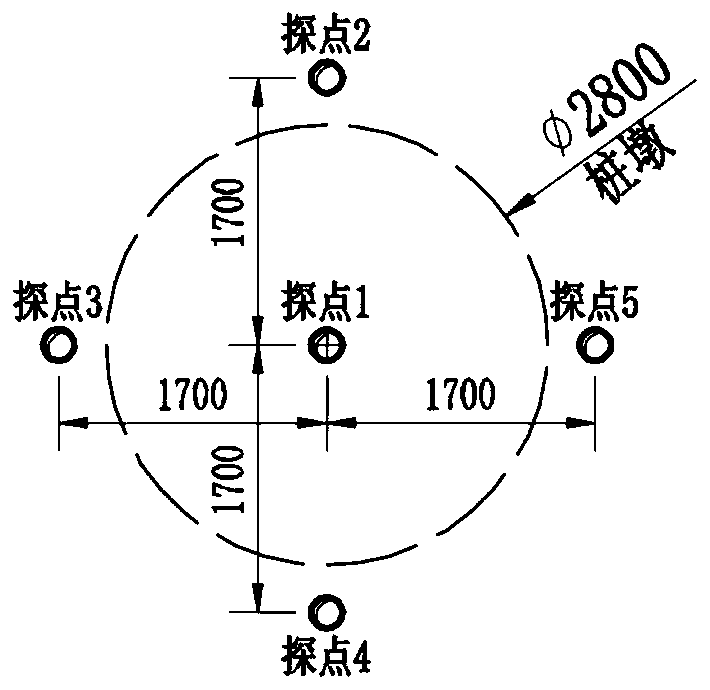

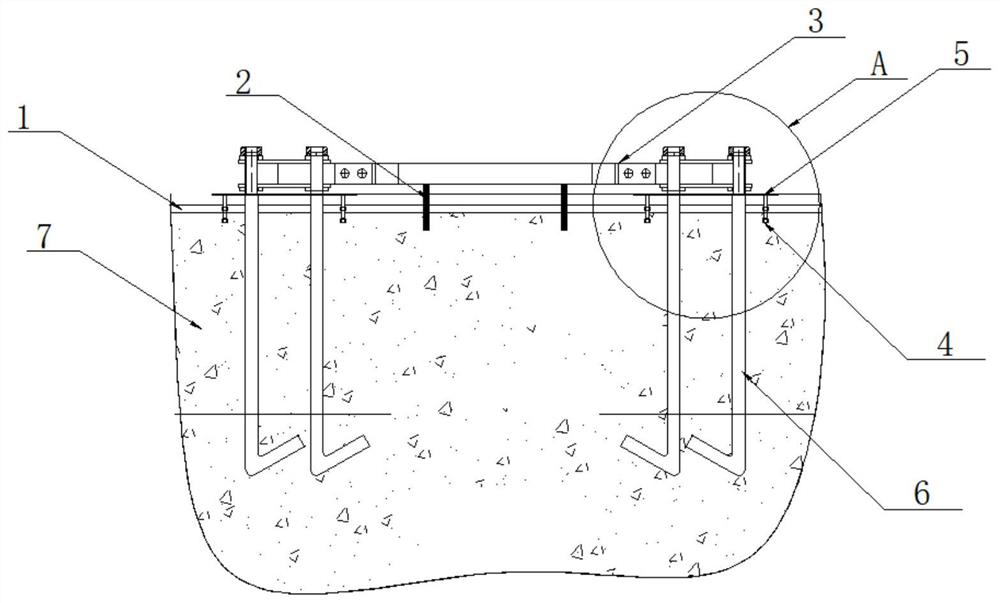

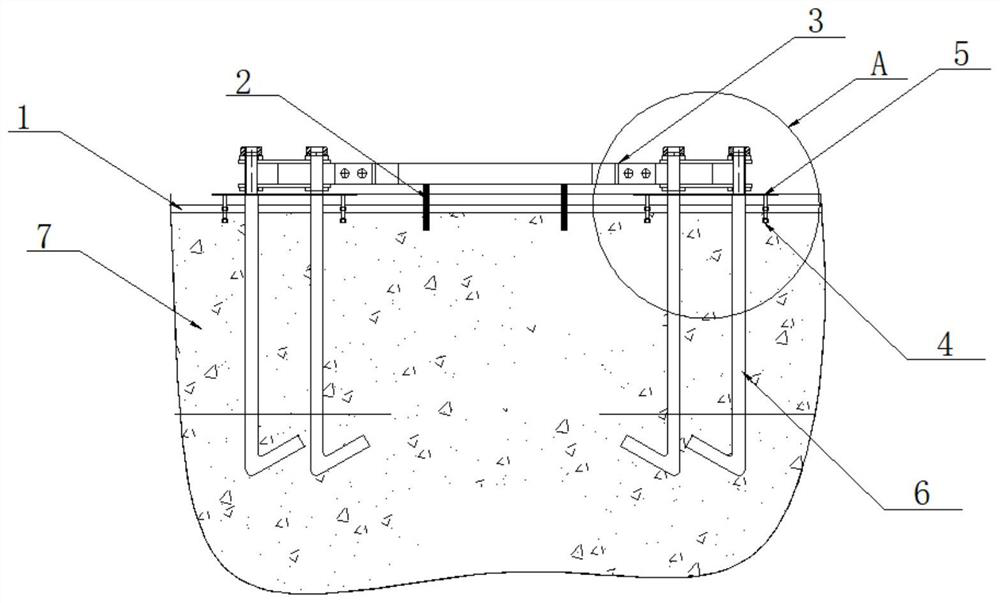

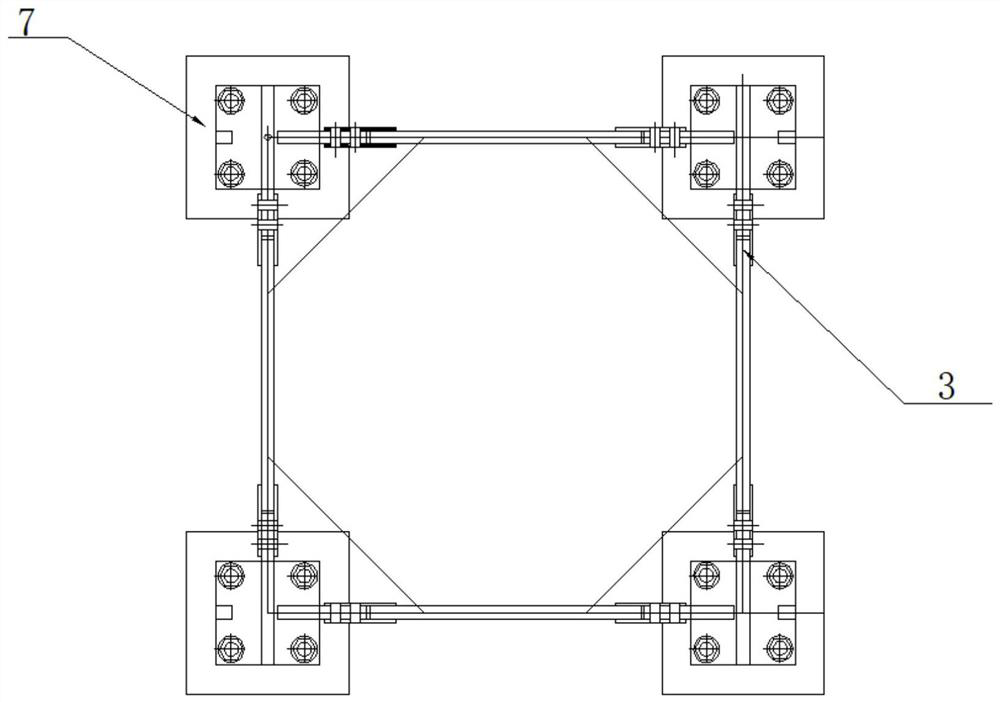

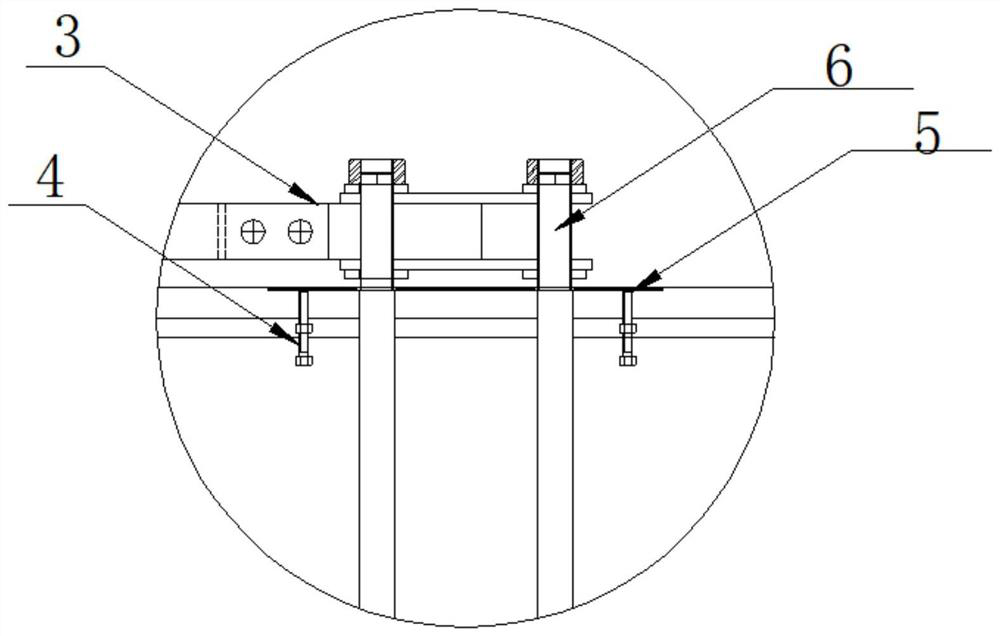

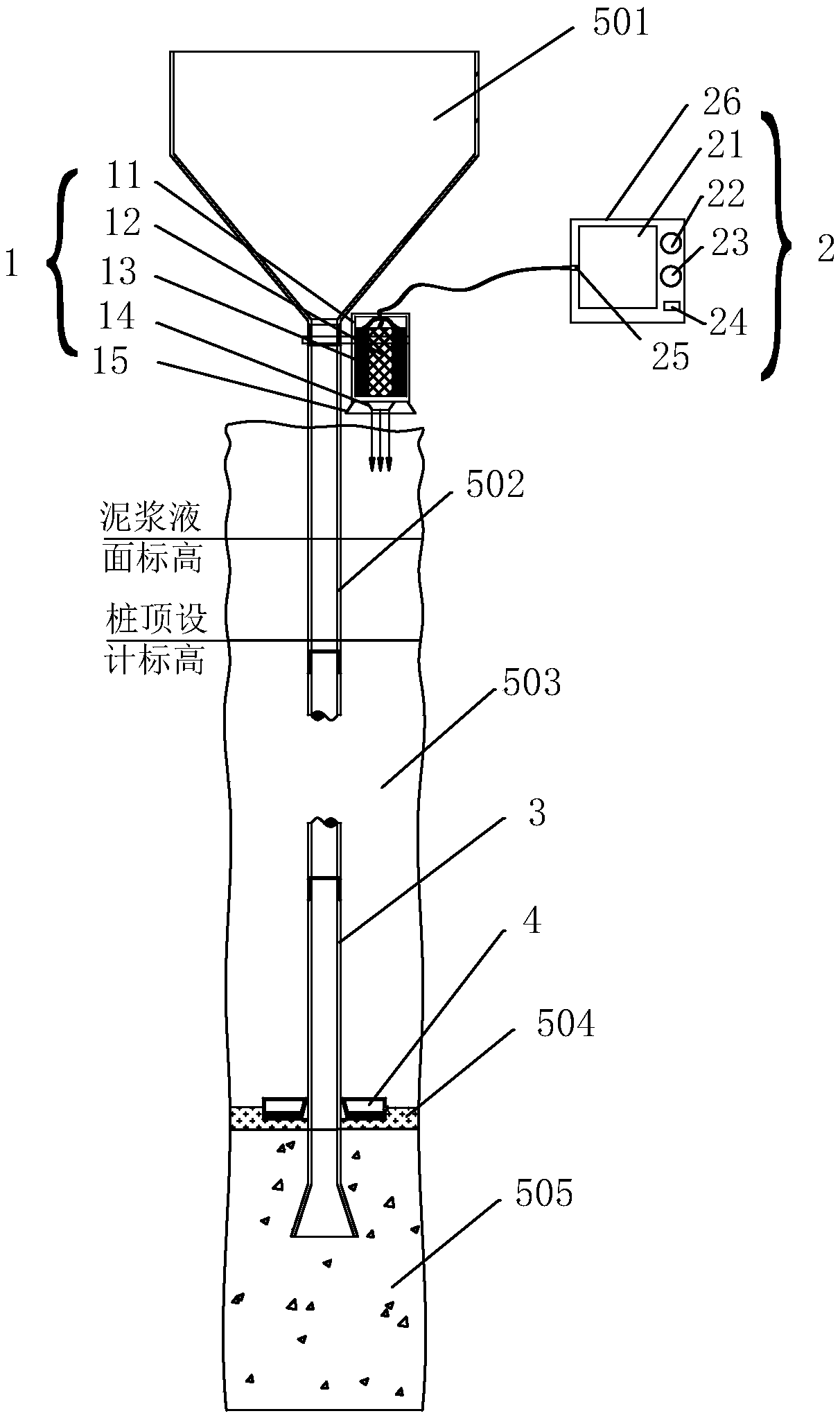

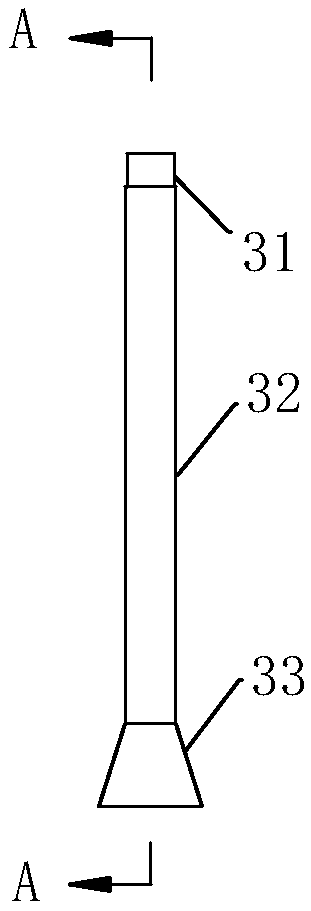

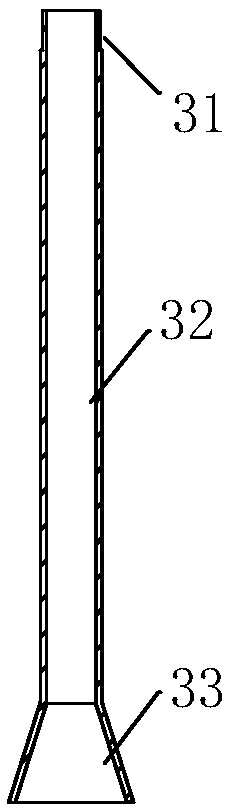

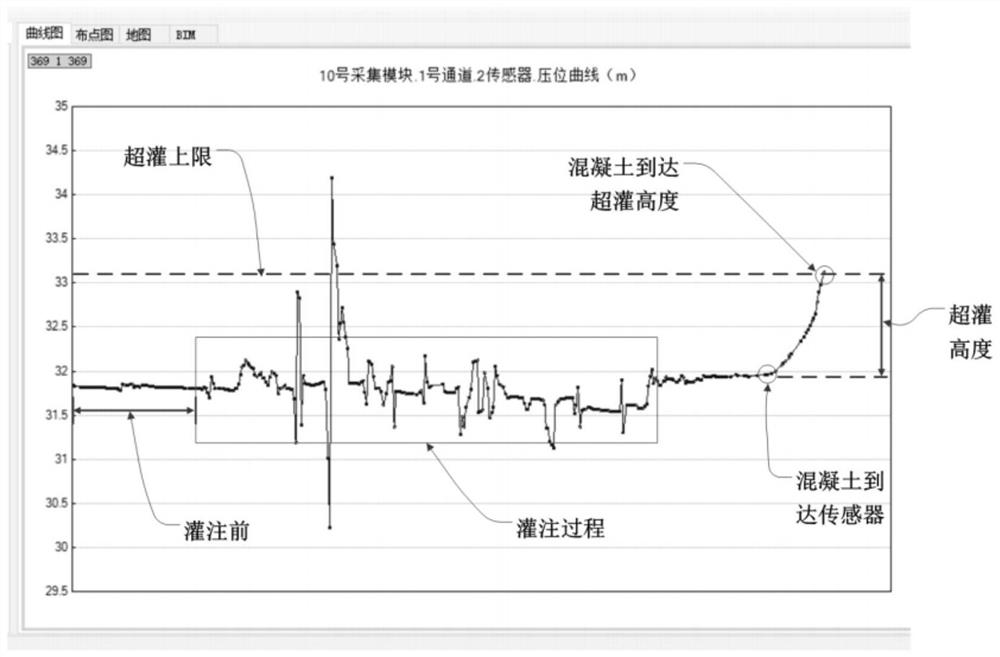

Detecting system and detecting method for real-time detecting of elevation of super-long hole bored grouting pile

ActiveCN108253933AImprove reflectivityElevation is accurateHeight/levelling measurementLevel indicators by floatsEmissivityEngineering

The invention discloses a detecting system and a detecting method for real-time detecting of elevation of a super-long hole bored grouting pile. The detecting system comprises an extension guiding pipe installed at the bottom of a grouting pile guiding pipe, a buoy sleeving the outer side of the extension guiding pipe, a plurality of ultrasonic probes, and a data reader, the plurality of ultrasonic probes are installed at the lower end of the outer side of a material hopper, and are configured to detect the height of the buoy, the plurality of ultrasonic probes are connected with the data reader, and the top surface of the buoy is a polished surface. The emissivity of ultrasonic waves in an intersurface between concrete and a floating layer can be increased by setting of the buoy during anunderwater concrete pouring process, the ultrasonic probes receive reflected ultrasonic waves exceeding a threshold value, on the one hand the emissivity of the ultrasonic waves can be increased, theelevation of a concrete pouring surface is more precise, the occurrence of over-grouting can be reduced, the amount of the concrete is reduced, and engineering cost is reduced; on the other hand, theelevation of the hole bored grouting pile can be accurately controlled, the probability of the occurrence of over-grouting can be reduced, and the over-grouting amount of each time of over-grouting can be reduced.

Owner:SHANGHAI CONSTRUCTION GROUP

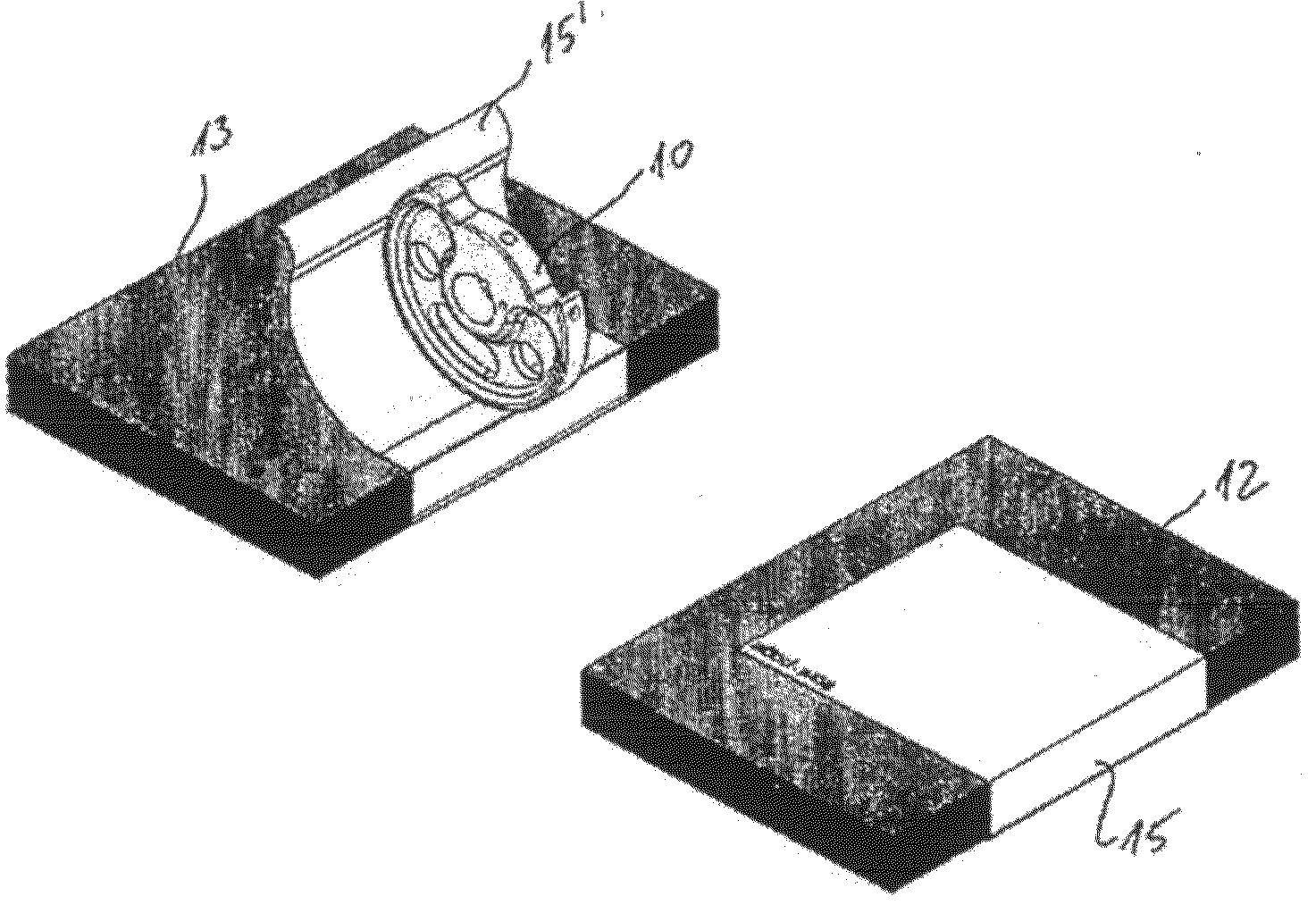

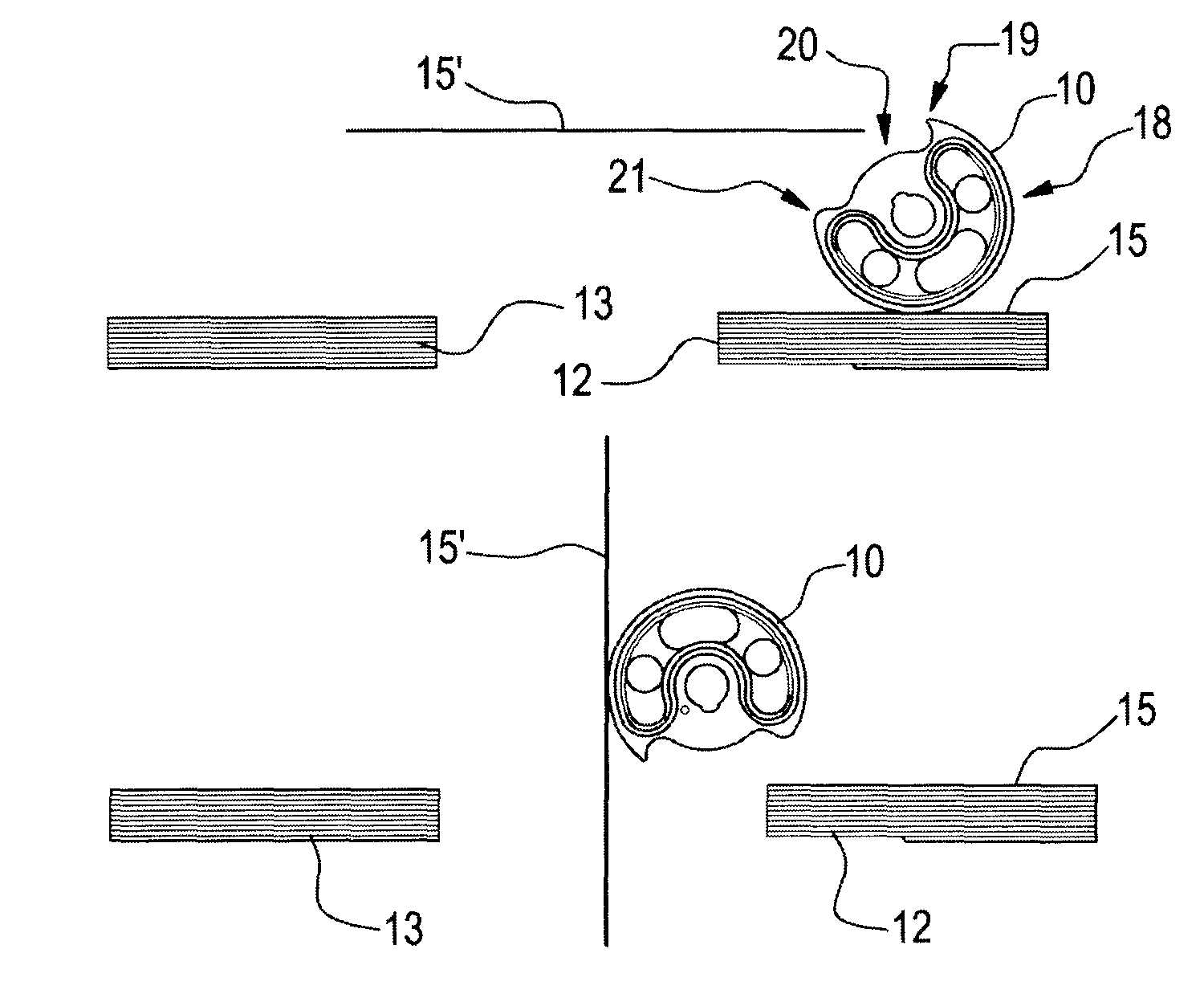

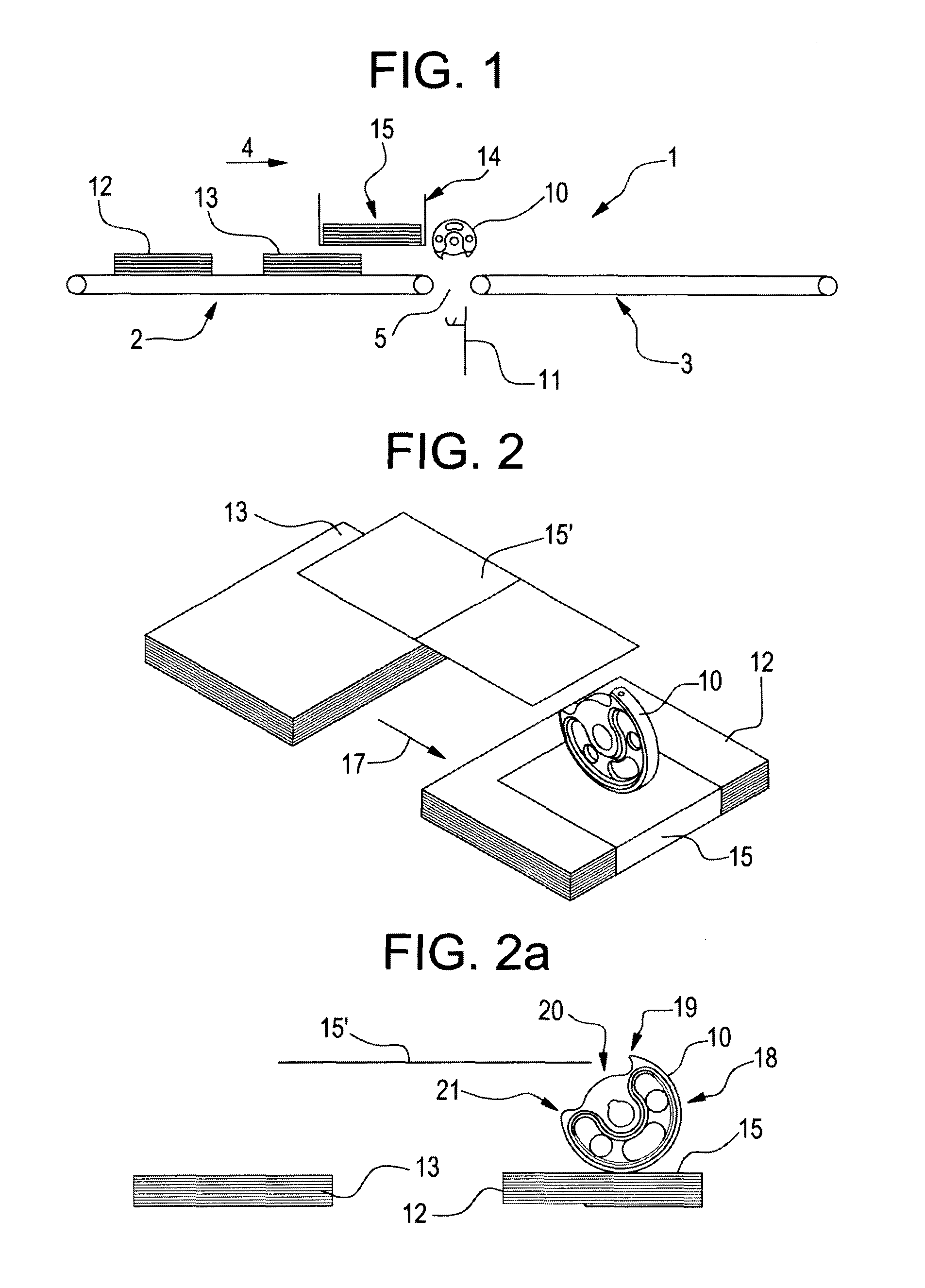

Method and apparatus for wrapping a stack with a wrapping sheet

InactiveUS20100139218A1Easy to controlPrecise arrangementPaper article packagingWrapping material feeding apparatusStructural engineeringIndustrial engineering

Owner:SCHUR PACKAGING SYST

Image scanning apparatus and image scanner

InactiveUS7753365B2Inhibit deteriorationIncrease speedFunction indicatorsPictoral communicationPaper documentSurface level

Owner:MURATA MASCH LTD

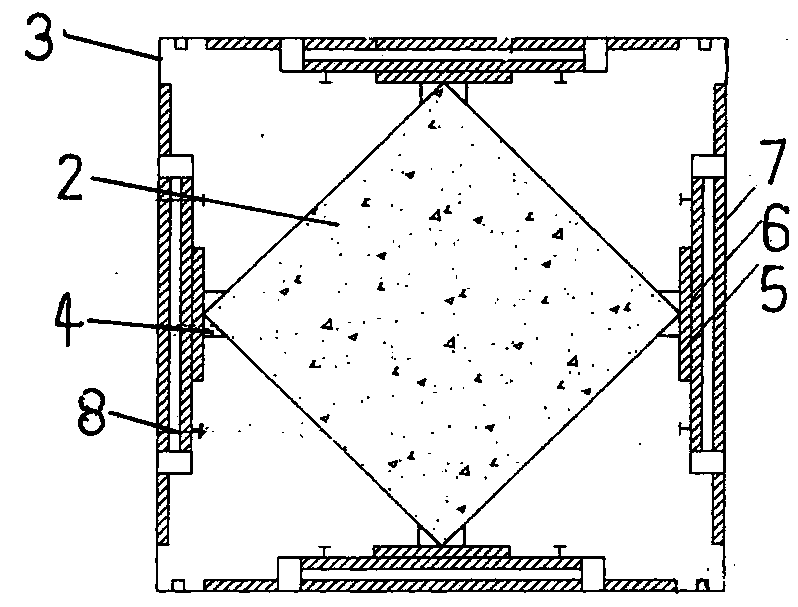

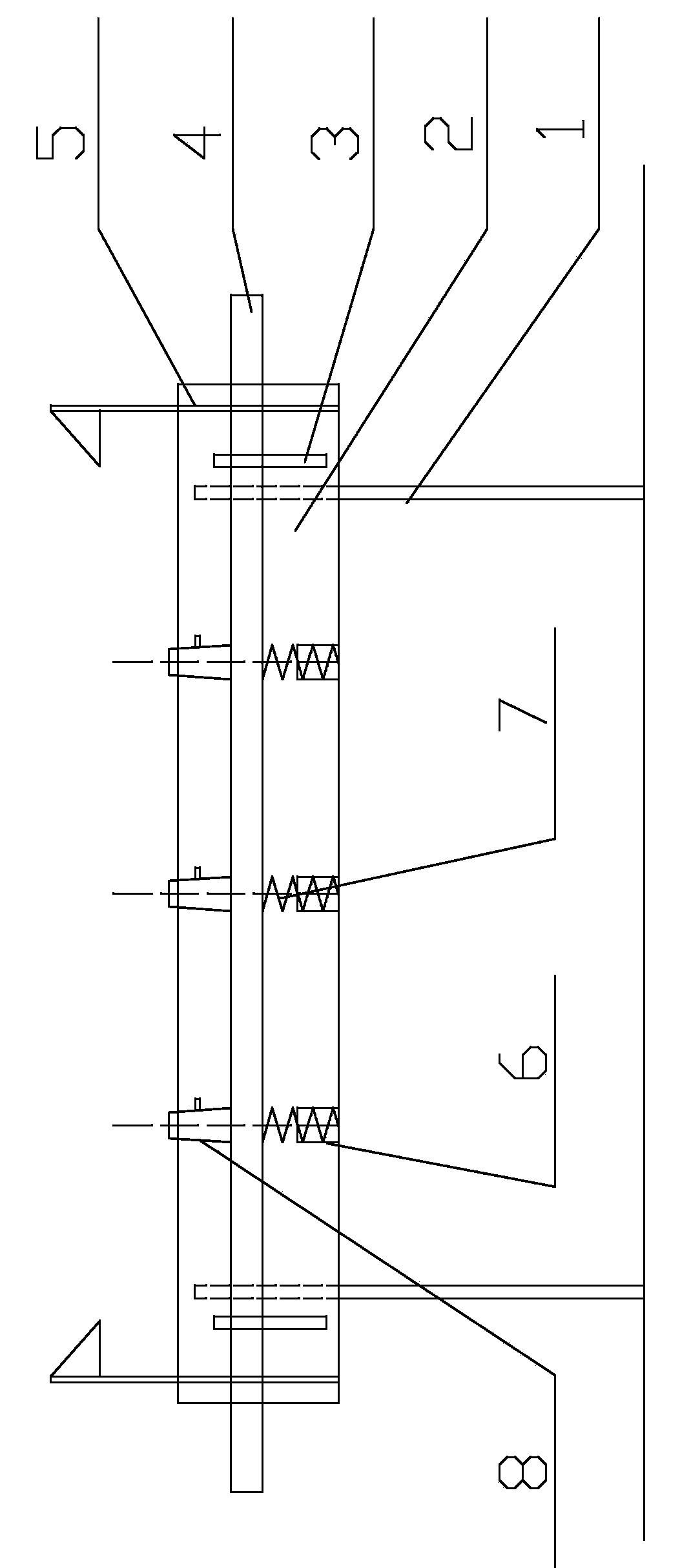

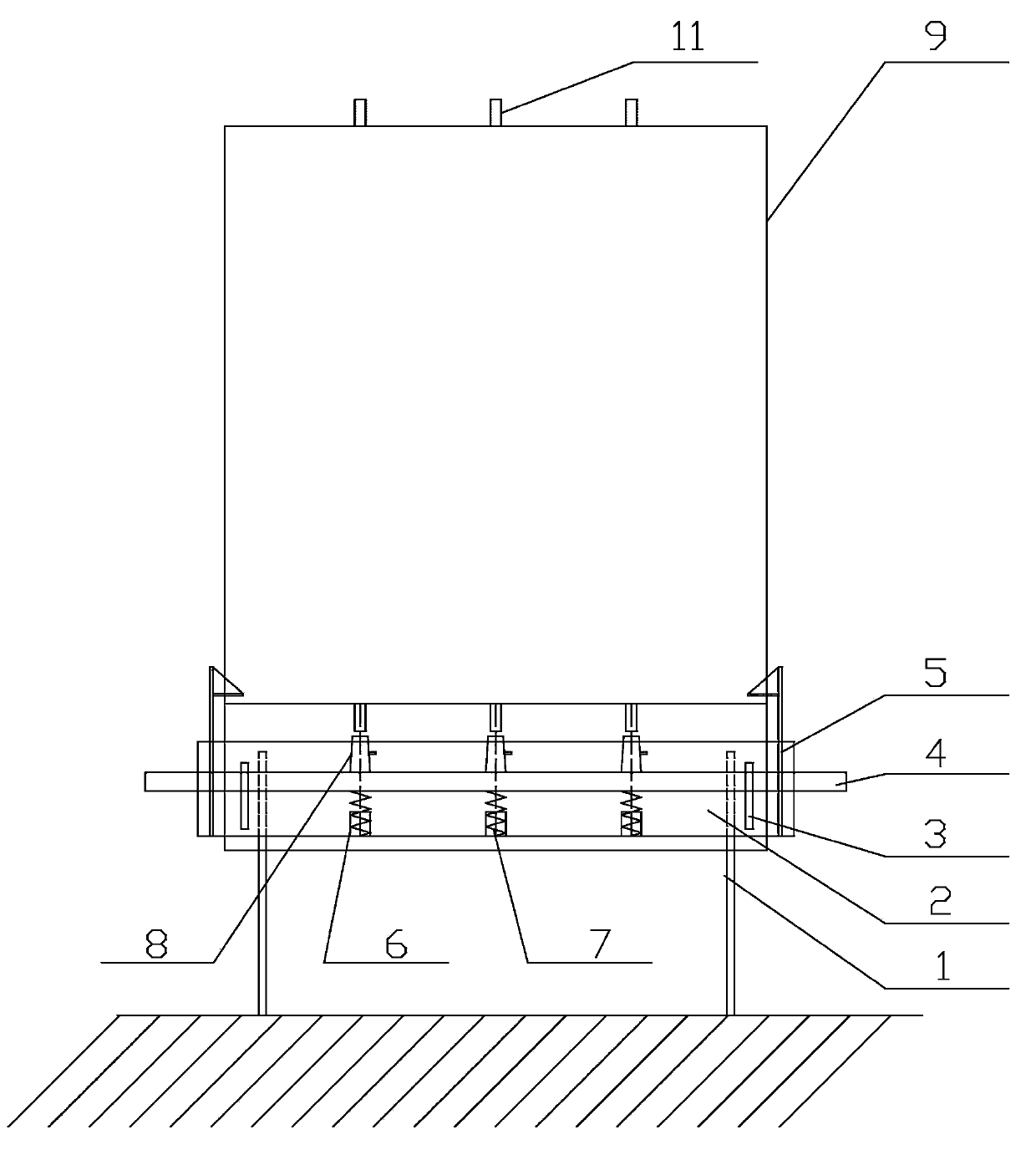

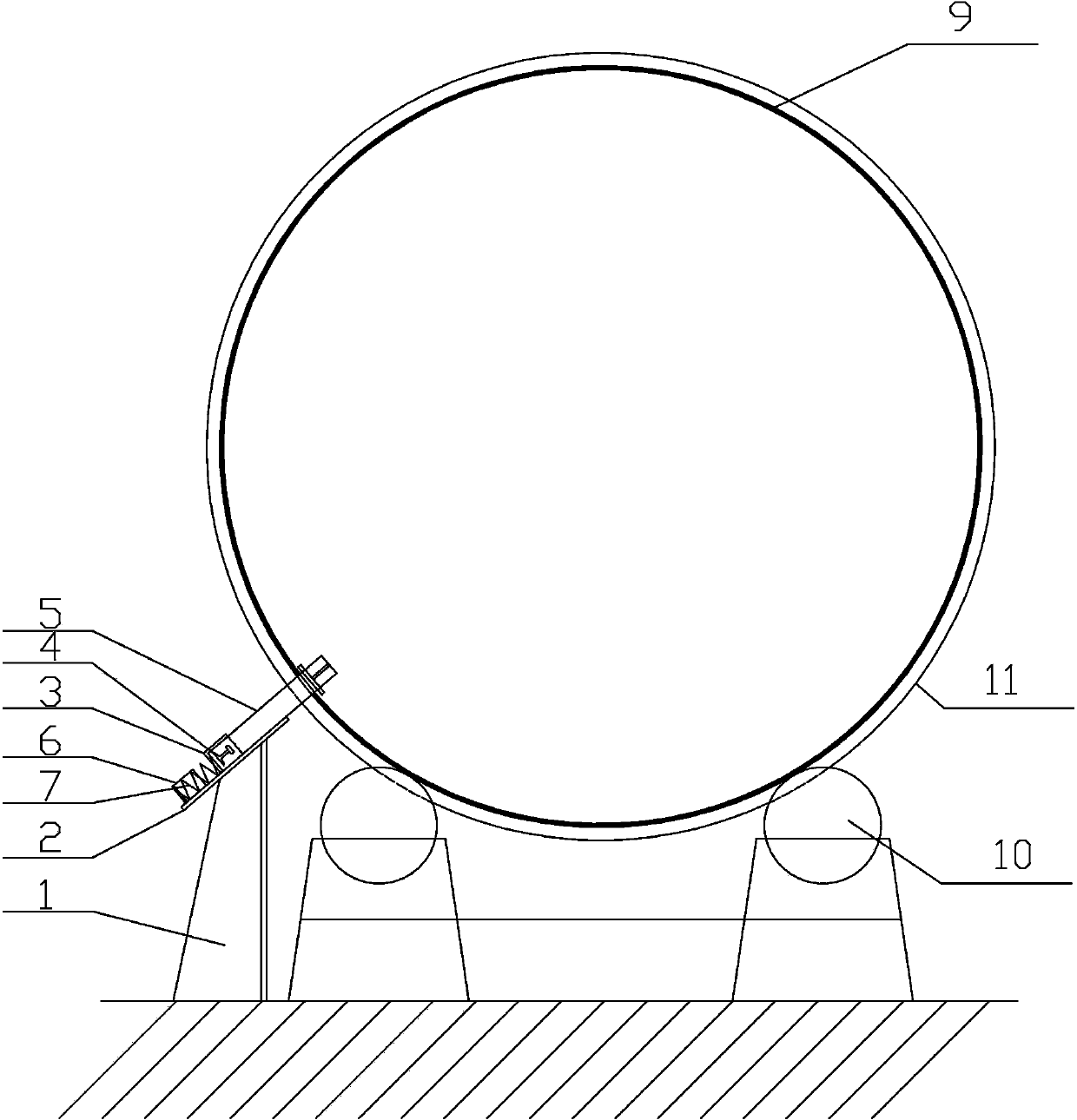

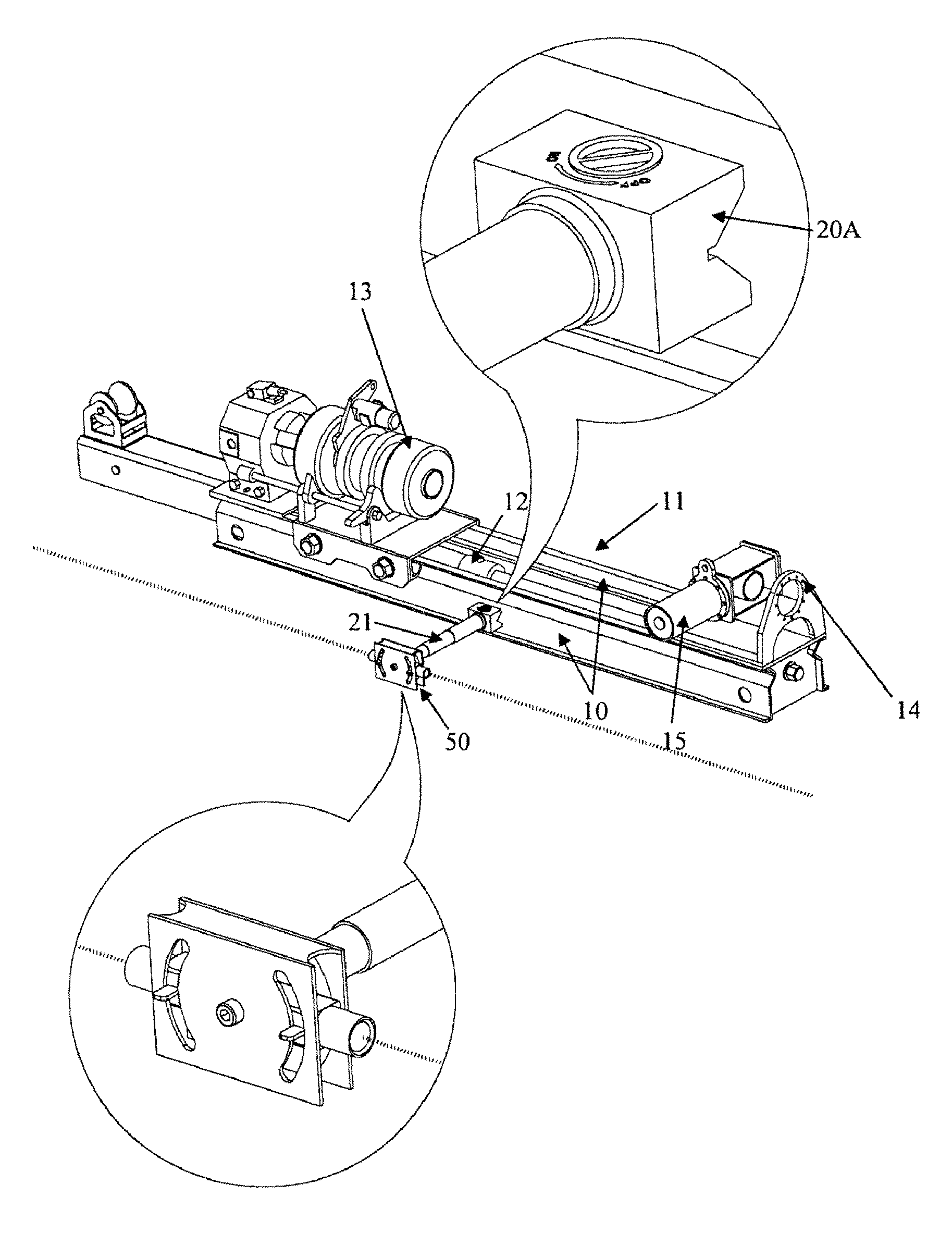

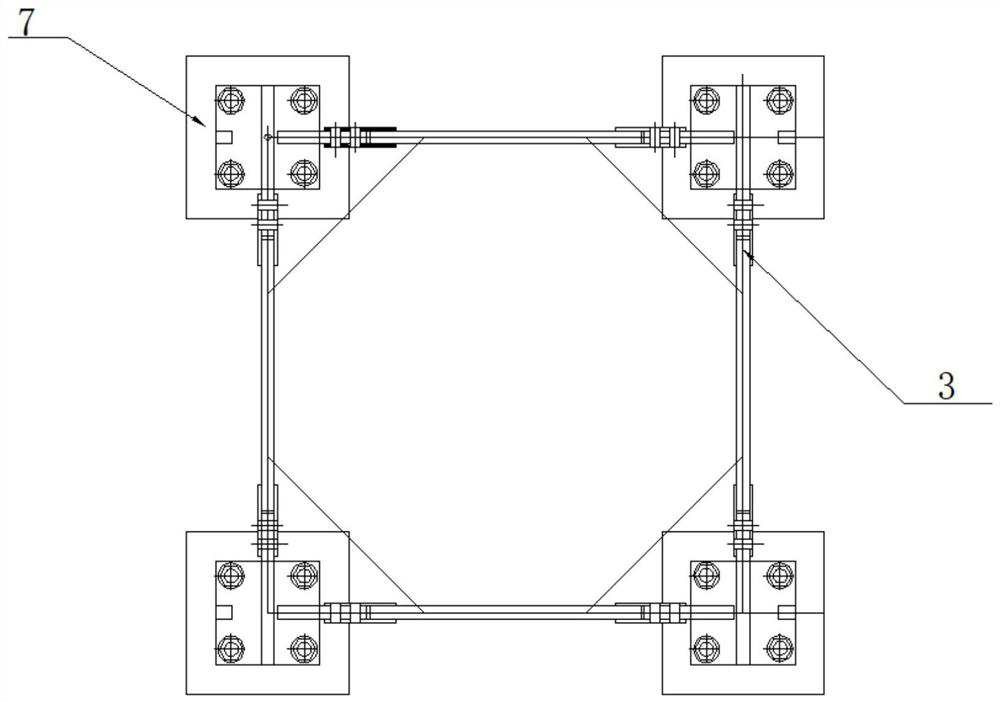

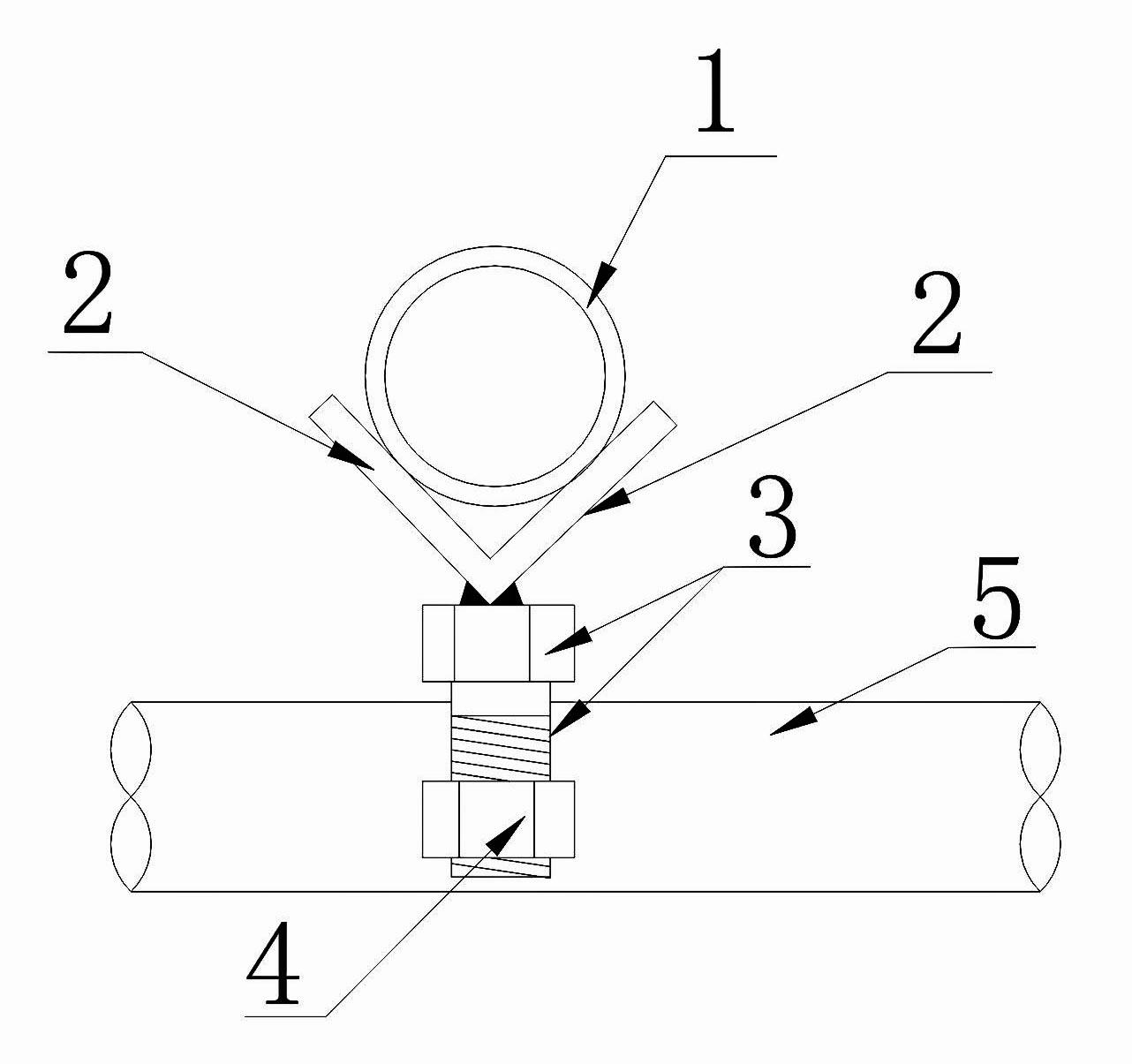

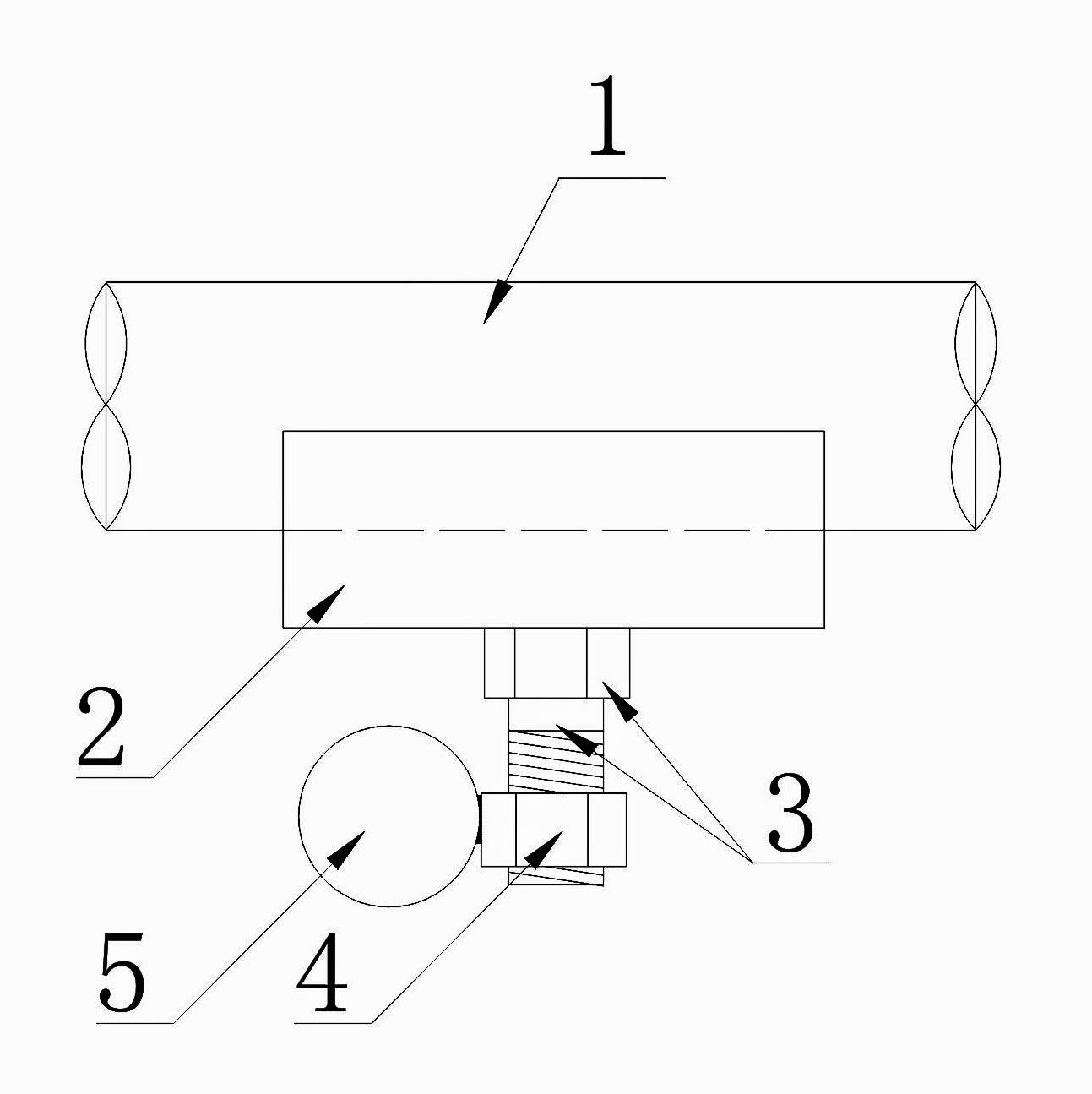

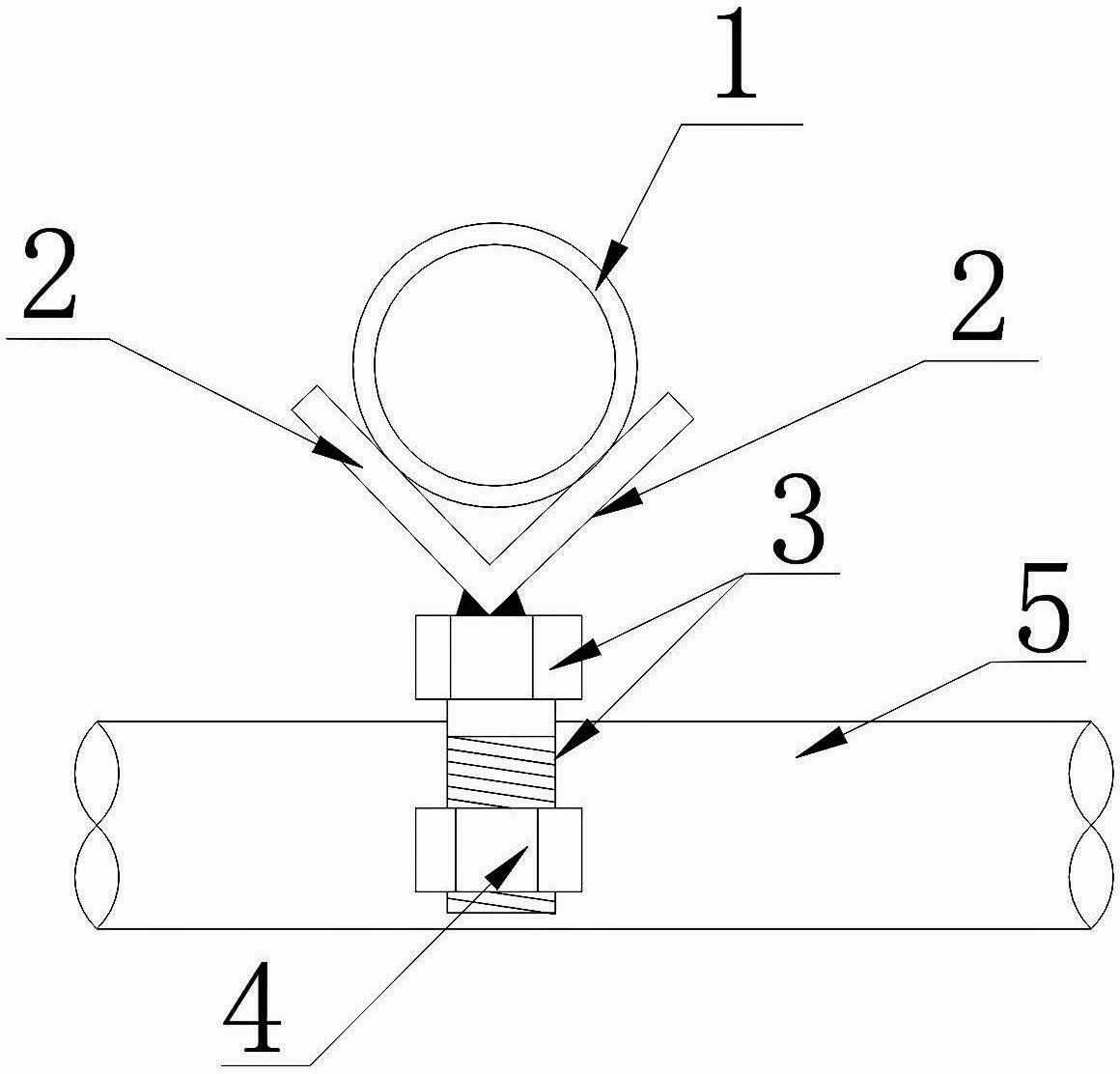

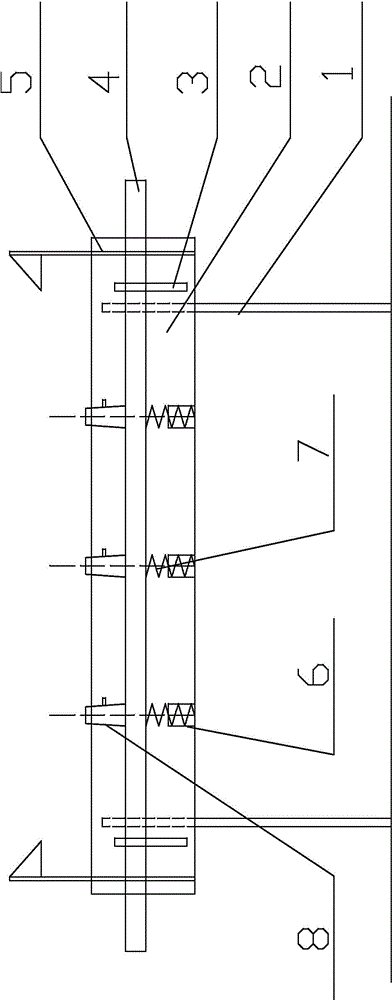

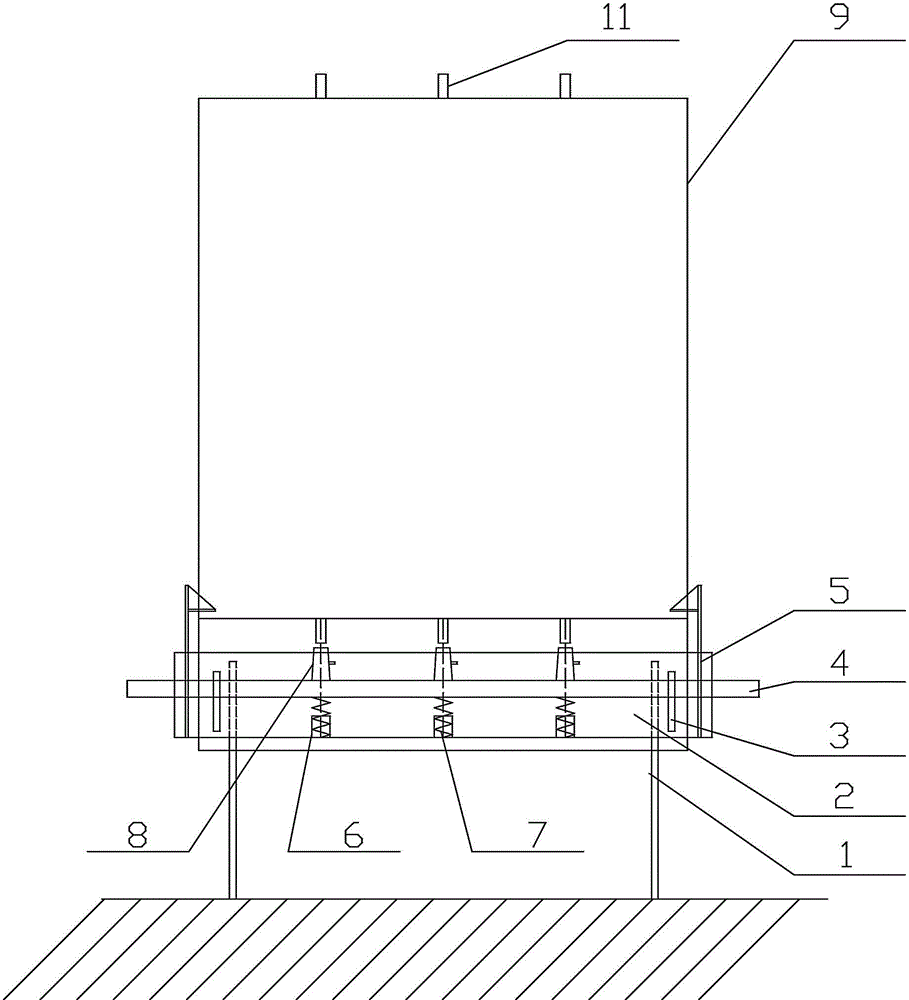

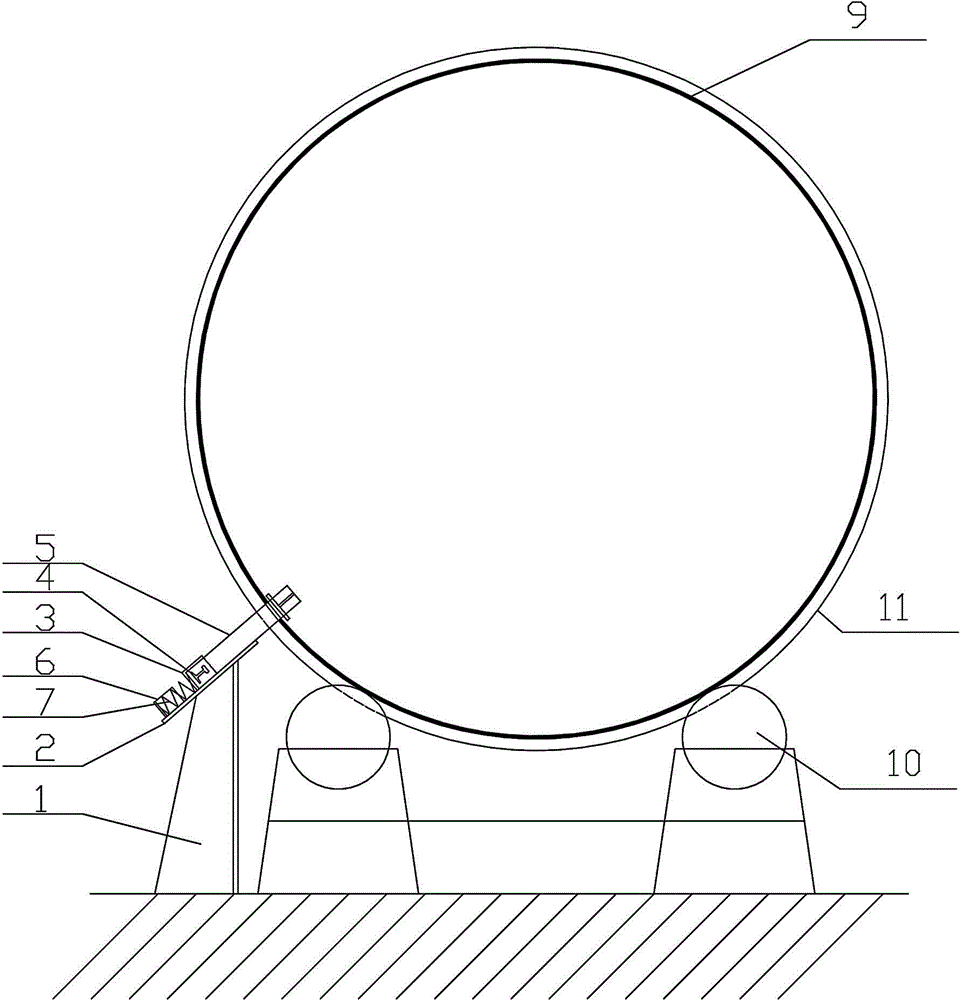

Simple device for assembling pressure steel pipe stiffening ring

ActiveCN103386579AReduce auxiliary workloadAvoid quality defectsWelding/cutting auxillary devicesAuxillary welding devicesFixed frameArchitectural engineering

The invention relates to a simple device for assembling a pressure steel pipe stiffening ring. An upright and a supporting panel are welded together; the supporting panel and a rail fixed frame are connected into a whole in a welding manner; rails are fixed on the supporting panel by the rail fixed frame; one ends of lateral pull plates are sleeved on the rails; the other ends of the lateral pull plates are pressed against the inner wall of a steel pipe body in the working process; sleeves and the supporting panel are connected into a whole in a welding manner; springs are placed in the sleeves to take a supporting effect on the rails; and jacks are placed on the rails and are not connected with the rails. The device is simple to install and is convenient to use; assembling quality of the steel pipe stiffening ring and quality of the surface of the pipe wall are effectively controlled; auxiliary workload of steel pipe manufacturing is greatly reduced; production efficiency is improved; cost is reduced; the simple device is easy to disassemble; elevation and flatness are accurate to control; and the simple device can be repeatedly used.

Owner:SINOHYDRO BUREAU 6 CO LTD

Laser alignment device for use with a drill rig

InactiveUS9045950B2Improve accuracyImprove precisionSurveyDerricks/mastsEngineeringBiomedical engineering

A laser alignment device for a drill rig having an elongate drill rod, the laser alignment device including a head unit having at least a pair of laser emitting devices mounted independently to one another thereon, each of the laser devices movable in one plane only and oriented in substantially opposite directions to one another, an attachment means to attach the head unit to a drill rig and a length adjustable assembly to adjust the separation distance between the head unit and the drill rod, wherein the alignment device is used to align at least the azimuth of the drill rod relative to survey marks.

Owner:PRECISION ALIGNMENT HLDG

Image scanning apparatus and image scanner

InactiveUS8056896B2Addressing slow performanceElevation is accurateFunction indicatorsElectrographic process apparatusPaper documentComputer science

In an image scanning apparatus, documents on a document tray are transferred one by one, and an upper surface height of the documents is lowered to turn off a height detection sensor. Different kinds of control modes are performed according to a document scanning mode. In an image-quality-priority scanning mode, a transfer unit suspends transfer of the document, the document tray is elevated until the upper surface height reaches a target height that is higher by a predetermined distance after the height detection sensor is turned on, and the transfer unit resumes the transfer of the document. In a speed-priority scanning mode, while the transfer of the document is continued by the transfer unit, the document tray is elevated until the document tray reaches the target height.

Owner:MURATA MASCH LTD

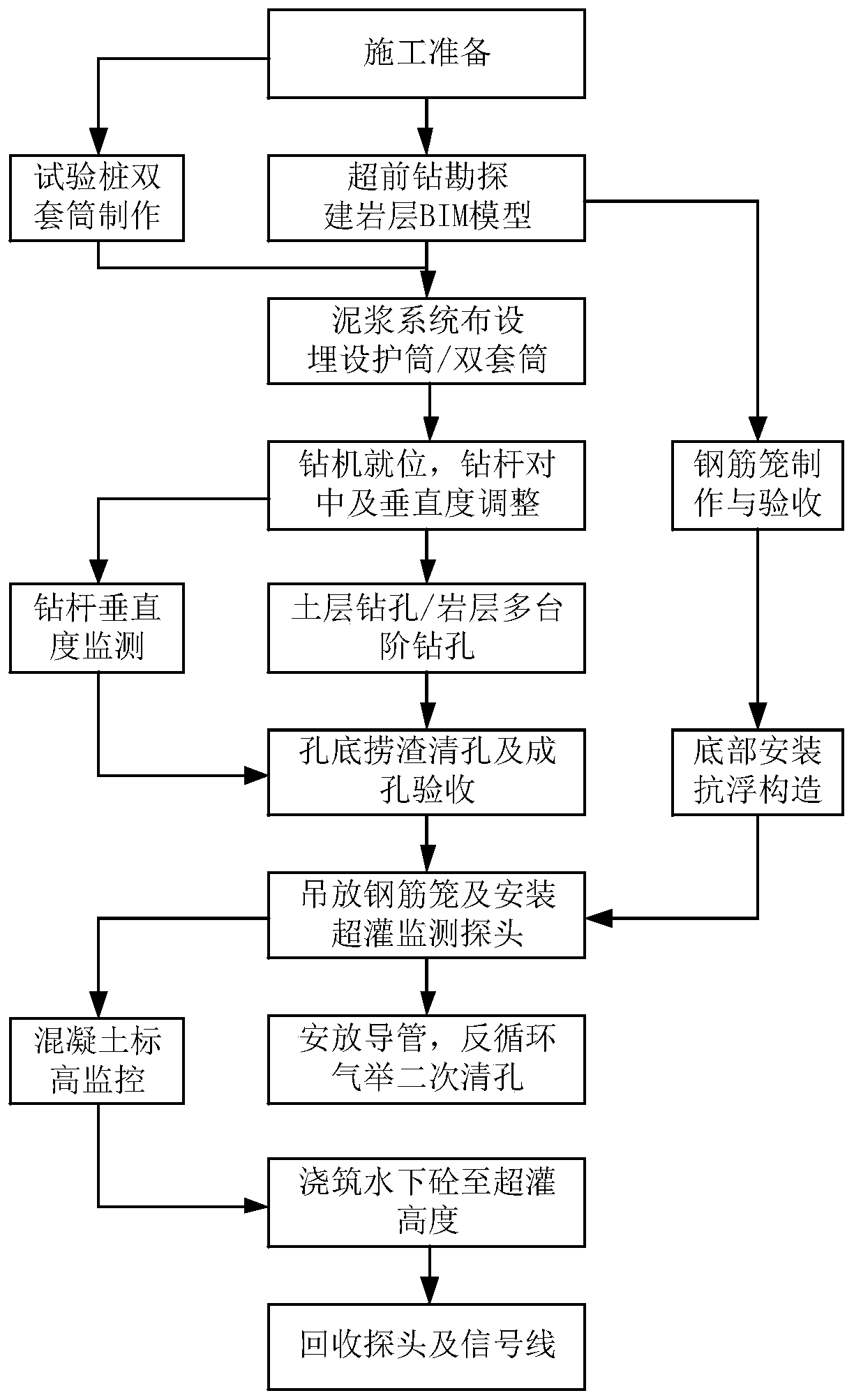

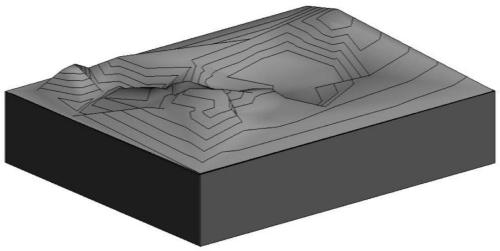

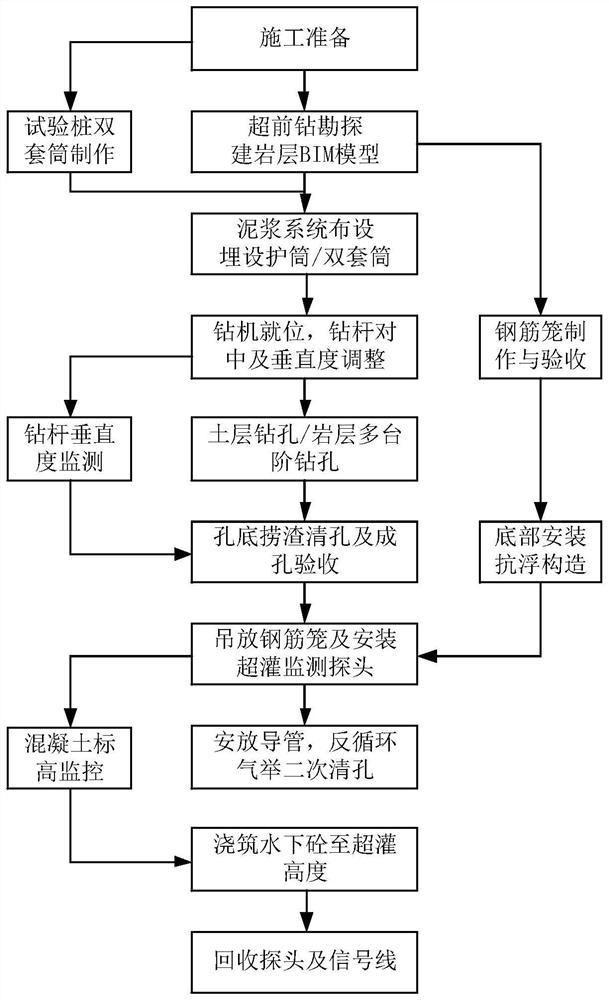

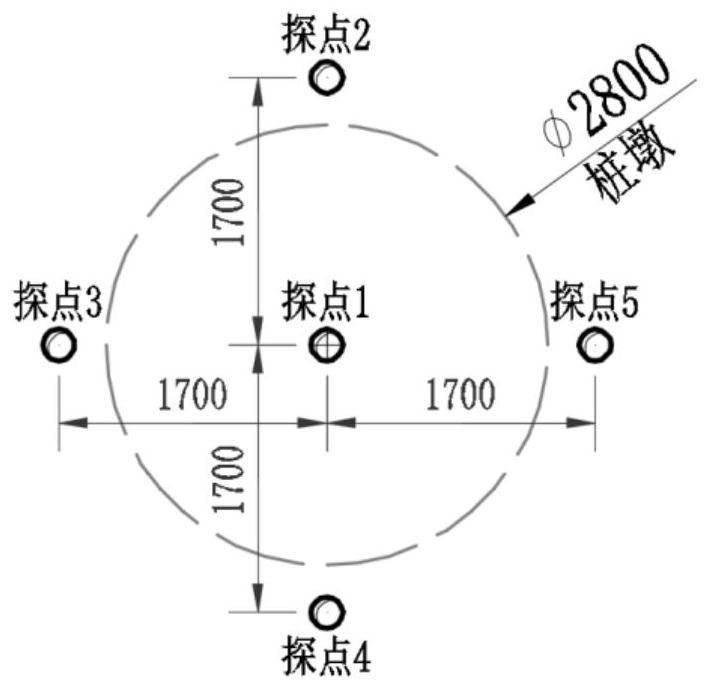

Construction method for test pile with ultra-buried depth in rock stratum

ActiveCN111519613AGuaranteed accuracyImprove the quality of test pilesGeometric CADEarth drilling toolsRebarGas lift

The invention discloses a construction method for a test pile with ultra-buried depth in a rock stratum, and belongs to the field of test pile construction. The technical problems that holes in a complex rock stratum are difficult to form, the underwater concrete ultra-pouring elevation cannot be accurately controlled, the static load detection operation conditions of the bottom of an ultra-deep foundation pit are limited, and the bearing detection is influenced by the control friction resistance for a cast-in-place pile are solved. According to the technical scheme, the method comprises the following steps that S1, construction preparation is carried out; S2, advanced drilling exploration is carried out, and a rock surface BIM model is established; S3, a protective cylinder is positionedand buried, and manufacturing and placing of double sleeves of the test pile are carried out; S4, a drilling machine is in place, and the centering and perpendicularity adjustment of a drill rod are carried out; S5, soil layer drilling, wall protection and rock stratum multi-stage step type drilling are carried out; S6, the perpendicularity of the drill rod is monitored by utilizing an internal and external double-control method; S7, a steel reinforcement cage is manufactured and an anti-floating structure is installed according to the step 2, the steel reinforcement cage is hoisted and placed, and an ultra-pouring monitoring probe is installed; S8, a guide pipe is placed, and secondary hole cleaning is carried out by adopting a gas lift reverse circulation method; and S9, underwater concrete pouring and ultra-pouring height monitoring are carried out.

Owner:CHINA CONSTR EIGHTH ENG DIV

Pre-levelled tower footing foundation and leveling construction method therefor

ActiveCN113293790AHas a flat areaElevation is easy to controlFoundation engineeringBuilding constructionsArchitectural engineeringRebar

The invention discloses a pre-levelled tower footing foundation. The foundation comprises a reinforcement cage, a plurality of supporting steel bars, a fixed form, a plurality of adjusting bolts, a plurality of leveling steel plates, a plurality of foundation bolts and a concrete layer; the supporting steel bars are arranged on the steel reinforcement cage at intervals, and the upper surfaces of the supporting steel bars are located on the same horizontal plane; the fixed form is assembled above the reinforcement cage, and the lower surface of the fixed form is in contact with the upper surfaces of the supporting steel bars; the adjusting bolts are arranged on the reinforcement cage at intervals; the leveling steel plates are arranged at the tops of the adjusting bolts at intervals, the leveling steel plates are located below the fixed form, and the upper surfaces of the leveling steel plates are located on the same horizontal plane; the foundation bolts sequentially penetrate through the leveling steel plates and the fixed form from bottom to top; and the concrete layer is poured on the reinforcement cage, and the upper surface of the concrete layer is flush with the upper surfaces of the leveling steel plates. The invention further discloses a leveling construction method for the supporting surface. The technical problems that in the prior art, follow-up leveling of a tower footing is tedious, and the stability of the supporting surface is affected are solved.

Owner:江苏扬建集团有限公司

Intelligent monitoring support convenient to adjust height

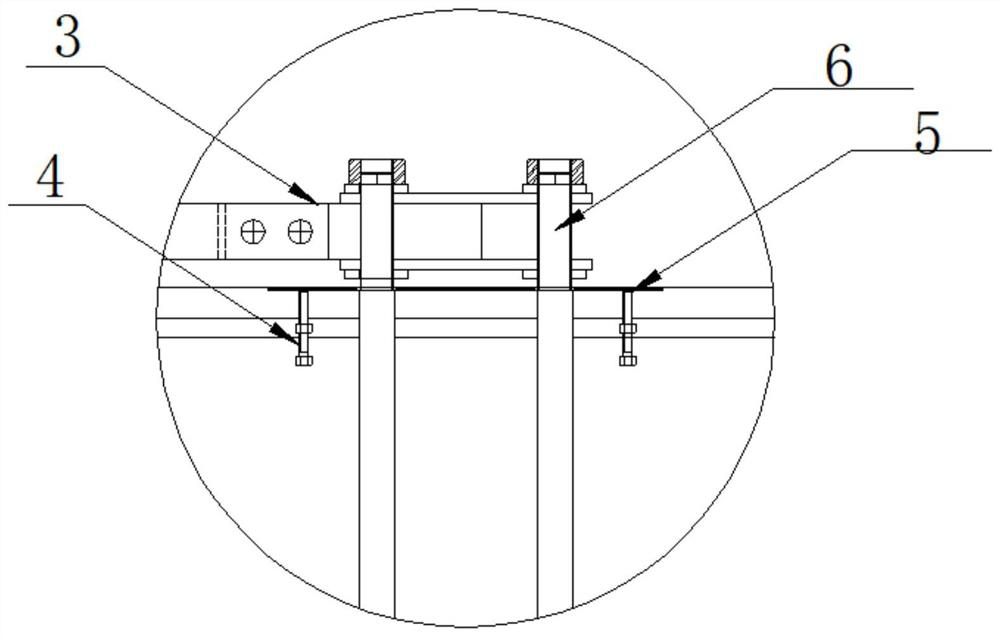

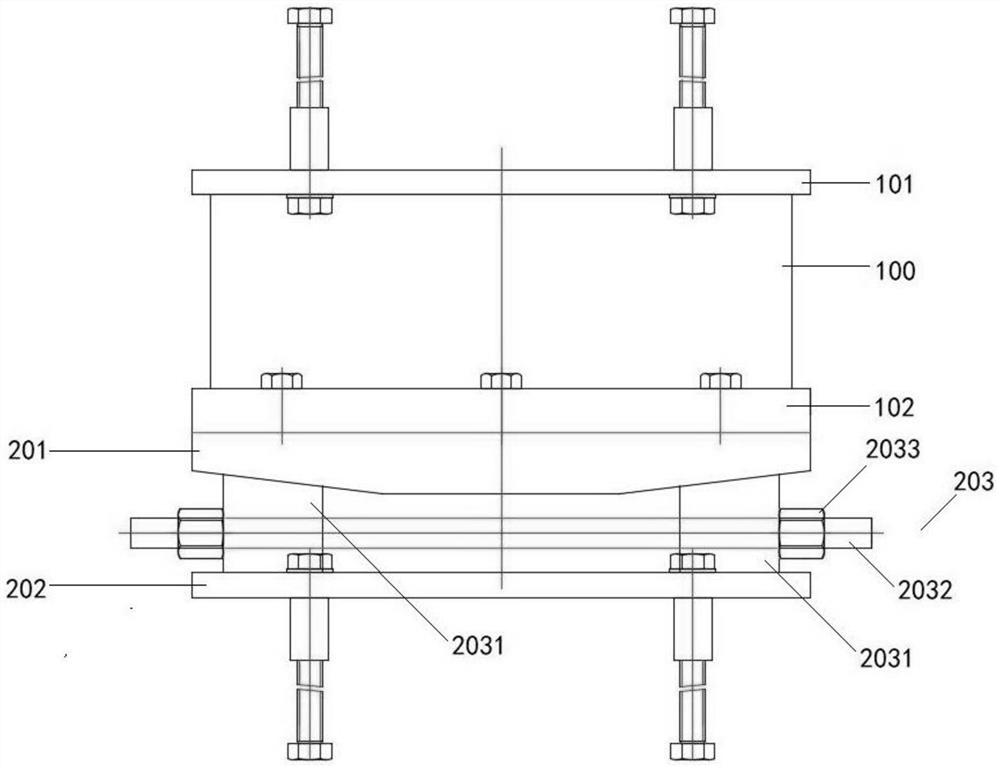

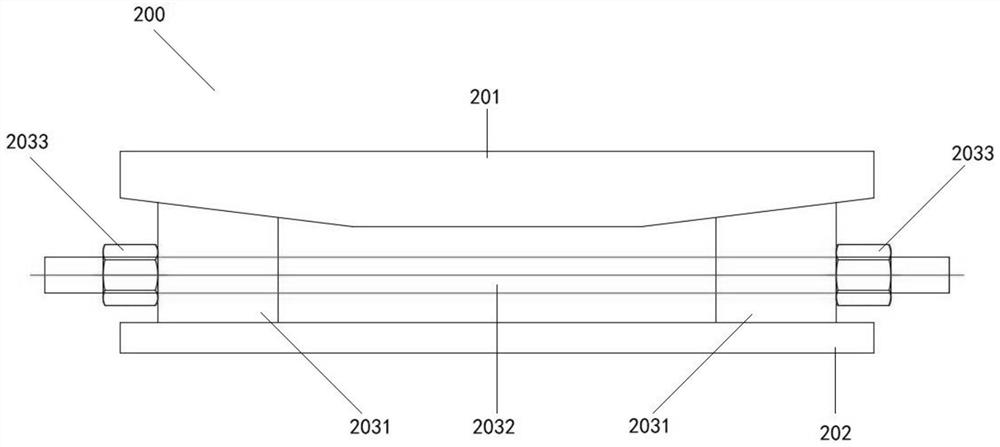

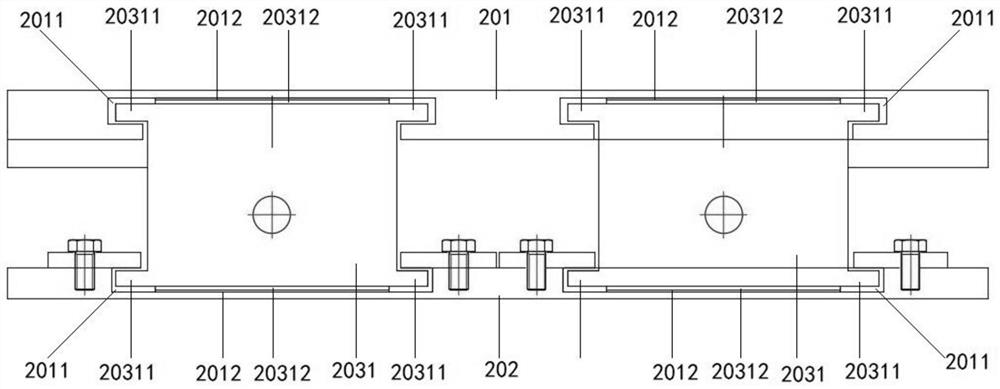

PendingCN114481820AEasy to install elevationEasy to replaceBridge structural detailsApparatus for force/torque/work measurementBridge engineeringData acquisition

The invention belongs to the technical field of bridge engineering, and particularly relates to a convenient height-adjusting intelligent monitoring support which comprises a support body, a support upper steel plate arranged at the top and a support lower steel plate arranged at the bottom. The adjusting piece is located below the support body; the adjusting part comprises an upper adjusting steel plate and a lower adjusting steel plate which are arranged at intervals up and down, and a wedge-shaped part positioned between the upper adjusting steel plate and the lower adjusting steel plate; the wedge-shaped piece comprises two wedge-shaped adjusting blocks which are symmetrically arranged, an adjusting pull rod and a locking nut; the intelligent monitoring piece comprises a force measuring device, a data acquisition instrument and a computer terminal. According to the bridge height adjusting support, the problems existing in an existing bridge height adjusting support are solved, a plurality of components such as the support body, the adjusting piece and the intelligent monitoring piece are designed, and the multiple components are matched with one another, so that the height of a bridge can be conveniently adjusted, and the bridge can be remotely monitored in real time on line.

Owner:柳州东方工程橡胶制品有限公司

A pre-leveled tower foundation and its leveling construction method

ActiveCN113293790BHas a flat areaElevation is easy to controlFoundation engineeringBuilding constructionsArchitectural engineeringRebar

Owner:江苏扬建集团有限公司

Method and apparatus for controlling electrical power usage based on exact sun elevation angle and measured geographical location

ActiveUS9949339B2Easy to controlSmooth transitionElectrical apparatusElectric light circuit arrangementLongitudeEffect light

A method and apparatus are provided to control artificial lighting using accurate geographical location, date and time, in order to activate such electrical activity only during needed periods of actual terrestrial darkness related to sun elevation. Accurate, real-time calculation of sun elevation relative to geographical location and date / time allow natural lighting characteristics such as natural light spectrum and intensity to be matched to artificial lighting, in order to provide a smooth transition in ambient lighting and to save energy. An apparatus according to the invention comprises a global positioning system (GPS) element for determining latitude, longitude, altitude, date and time and a calculation element for determining sun elevation angle accurately. A specific embodiment requires only desired sun elevation angle inputs from the user for controlling electrical switches in a control system.

Owner:LONESTAR INVENTIONS LP

Method and apparatus for wrapping a stack with a wrapping sheet

InactiveUS8156717B2Easy to controlPrecise arrangementPaper article packagingWrapping material feeding apparatusMechanical engineering

Owner:SCHUR PACKAGING SYST

Plastering slide track device for surface finishing when pouring concrete bottom plate in hole

InactiveCN102605802AControl flatnessEasy to removeArtificial islandsUnderground chambersSurface finishRebar

A plastering slide track device for surface finishing when pouring a concrete bottom plate in a hole consists of steel pipe slide track, an angle steel support, screw stems, nuts and bottom plate top reinforcements. The steel pipe slide track is placed on the angle steel support, the lower end of the angle steel support is welded with the screw stems, the nuts are welded on the bottom plate top reinforcements, and the screw stems are screwed into the nuts. After the plastering slide track device is fixedly mounted on a concrete bottom plate to be poured, pouring elevation and surface evenness of the concrete bottom plate can be conveniently and accurately controlled by means of adjusting the heights of the screw stems, and an operator utilizes the device to primarily level out the surface of the concrete bottom plate. Before concrete is set initially, surface finishing and artificial pressure polishing of the concrete bottom plate are finished via a compacting machine. The plastering slide track device is simple in installation, convenient in use, easy in detachment and accurate in elevation and evenness control, and can be reused.

Owner:SINOHYDRO BUREAU 6 CO LTD

Real-time detection system and detection method for super-long bored pile elevation

ActiveCN108253933BImprove reflectivityElevation is accurateHeight/levelling measurementLevel indicators by floatsEmissivityEngineering

The invention discloses a detecting system and a detecting method for real-time detecting of elevation of a super-long hole bored grouting pile. The detecting system comprises an extension guiding pipe installed at the bottom of a grouting pile guiding pipe, a buoy sleeving the outer side of the extension guiding pipe, a plurality of ultrasonic probes, and a data reader, the plurality of ultrasonic probes are installed at the lower end of the outer side of a material hopper, and are configured to detect the height of the buoy, the plurality of ultrasonic probes are connected with the data reader, and the top surface of the buoy is a polished surface. The emissivity of ultrasonic waves in an intersurface between concrete and a floating layer can be increased by setting of the buoy during anunderwater concrete pouring process, the ultrasonic probes receive reflected ultrasonic waves exceeding a threshold value, on the one hand the emissivity of the ultrasonic waves can be increased, theelevation of a concrete pouring surface is more precise, the occurrence of over-grouting can be reduced, the amount of the concrete is reduced, and engineering cost is reduced; on the other hand, theelevation of the hole bored grouting pile can be accurately controlled, the probability of the occurrence of over-grouting can be reduced, and the over-grouting amount of each time of over-grouting can be reduced.

Owner:SHANGHAI CONSTRUCTION GROUP

Simple device for assembling pressure steel pipe stiffening ring

ActiveCN103386579BReduce auxiliary workloadAvoid quality defectsWelding/cutting auxillary devicesAuxillary welding devicesFixed frameArchitectural engineering

The invention relates to a simple device for assembling a pressure steel pipe stiffening ring. An upright and a supporting panel are welded together; the supporting panel and a rail fixed frame are connected into a whole in a welding manner; rails are fixed on the supporting panel by the rail fixed frame; one ends of lateral pull plates are sleeved on the rails; the other ends of the lateral pull plates are pressed against the inner wall of a steel pipe body in the working process; sleeves and the supporting panel are connected into a whole in a welding manner; springs are placed in the sleeves to take a supporting effect on the rails; and jacks are placed on the rails and are not connected with the rails. The device is simple to install and is convenient to use; assembling quality of the steel pipe stiffening ring and quality of the surface of the pipe wall are effectively controlled; auxiliary workload of steel pipe manufacturing is greatly reduced; production efficiency is improved; cost is reduced; the simple device is easy to disassemble; elevation and flatness are accurate to control; and the simple device can be repeatedly used.

Owner:SINOHYDRO BUREAU 6 CO LTD

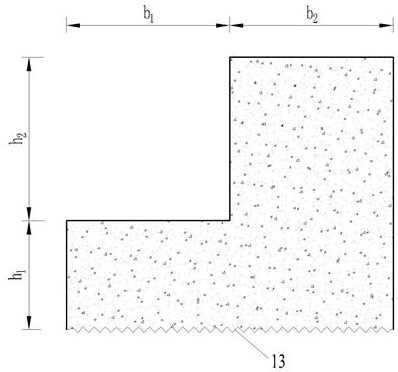

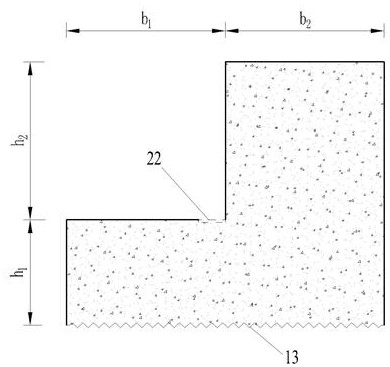

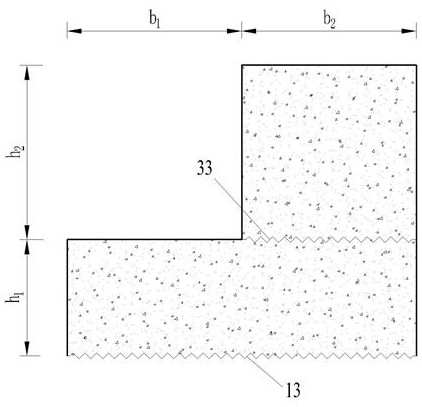

A kind of in-situ construction method of stepped concrete

ActiveCN109083404BGuaranteed integrityGuaranteed compactnessTreadsForms/shuttering/falseworksSocial benefitsDesign standard

The invention discloses a step-shaped concrete casting mold assembly and a cast-in-situ construction method, comprising: cleaning the base surface → supporting the side form → pouring the concrete at the lower part of the step → laying a movable die and clamping → pouring the upper part of the step Concrete→Remove the movable die→Tighten the surface of the lower part of the steps→Tighten the surface of the upper part→Conservation→Remove the side formwork and continue the maintenance. Since the present invention adopts the dynamic operation process of "installation later and removal first" of the movable die and the form support method that the 45° contact surface between the movable die and the upper inner mold can be combined and separated, the inner side of the cast-in-place concrete step is completely solved. There is a problem with stencil imprints on the surface. The overall structure of the steps casted by the present invention is complete, without cold joints, and the internal quality meets the design standards; the surface has no template marks, no cracks, no bubbles or spots, pockmarks, etc., and the appearance quality meets the requirements of the specifications, and can be applied to various The cast-in-place stepped concrete project has significant practical significance and good social benefits.

Owner:卜群惠

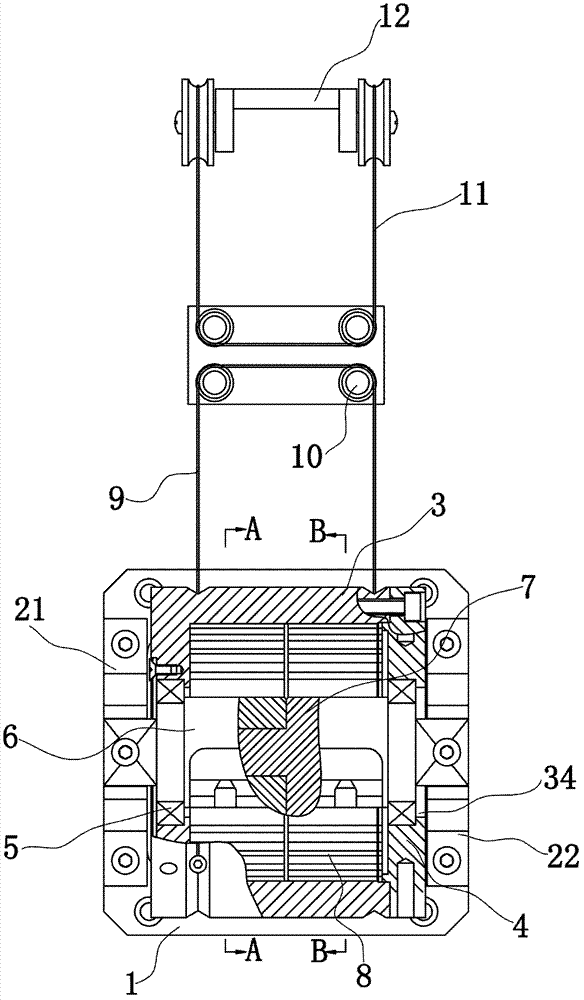

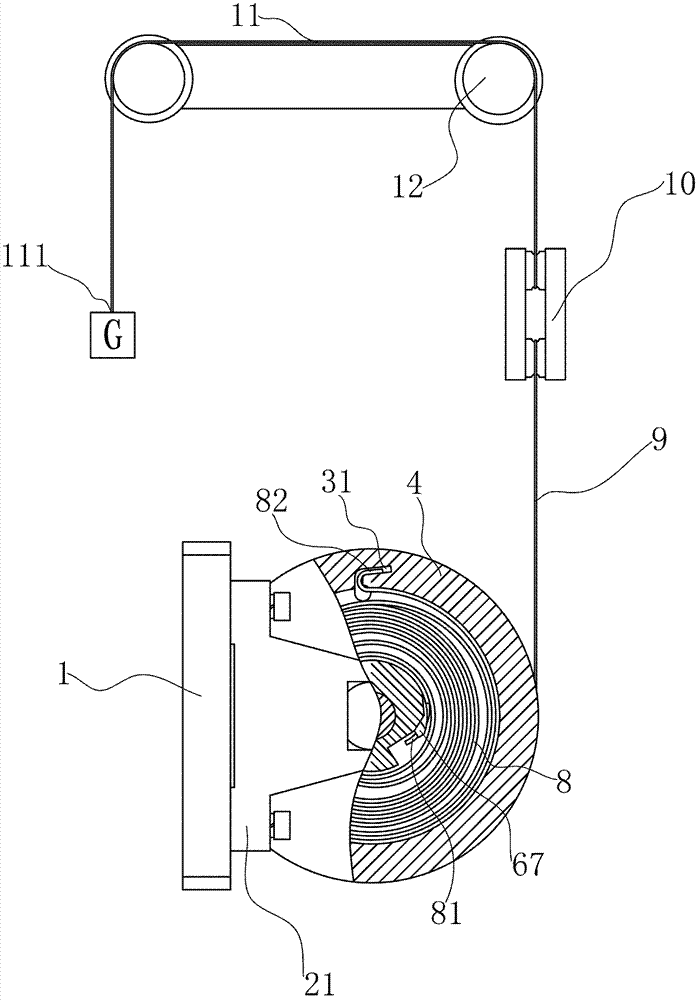

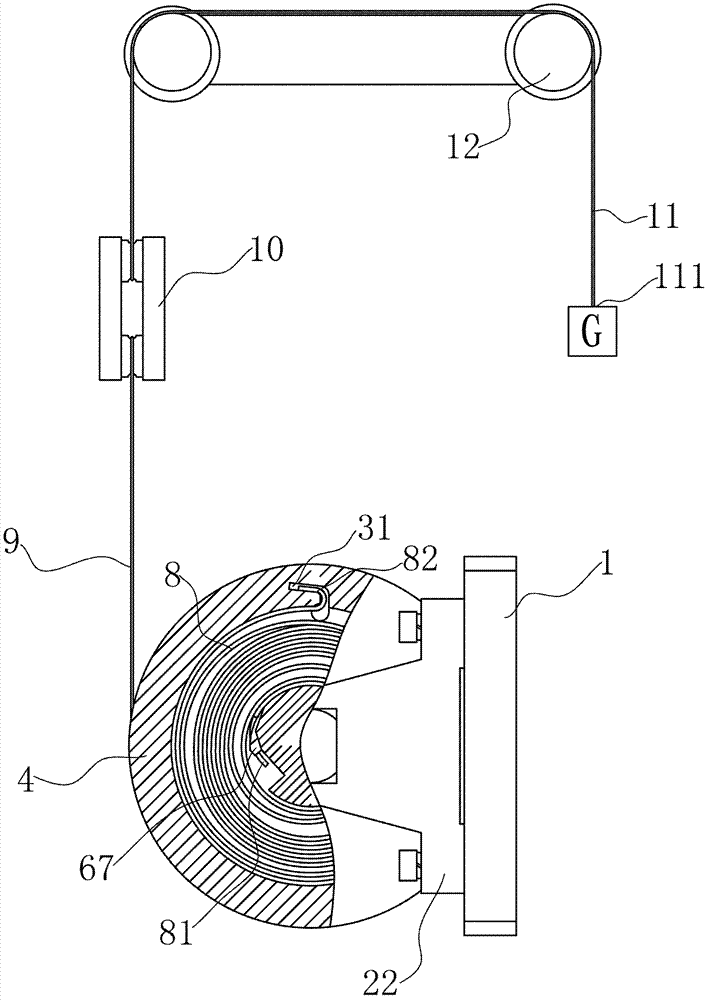

Double-spring anti-balance device

ActiveCN102411199BImprove connection stabilityElevation is accurateMicroscopesMicroscopeComputer engineering

The invention discloses a double-spring anti-balance device, which comprises a bottom plate, a left bracket, a right bracket, a spring box and a spring box cover, wherein the left bracket and the right bracket are fixed on the left side and the right side of the bottom plate; the spring box and the spring box cover have hollow structures, the spring box and the spring box cover are arranged between the left bracket and the right bracket, and the spring box cover is fixed on the spring box; after the spring box cover and the spring box are matched, the left and right sides of the spring box cover and the spring box are provided with a bearing mounting hole respectively, and a bearing is nested into the bearing mounting hole; a concave spring shaft is sleeved in the bearing close to a left supporting plate, and the part of the concave spring shaft outside the spring box is fixed with the left supporting plate; and a convex spring shaft is sleeved in the bearing close to a right supporting plate, and the part of the convex spring shaft outside the spring box is fixed with the right supporting plate. The double-spring anti-balance device is connected with the lifting part of a microscope, so that the lifting part of the microscope overcomes self weight in an effective space range, the accurate lifting of the lifting part is ensured and the connection stability is also improved.

Owner:NINGBO TEACHING INSTR

A construction method of ultra-deep buried test piles in rock formations

ActiveCN111519613BGuaranteed accuracyImprove the quality of test pilesGeometric CADEarth drilling toolsRebarDeep excavation

The invention discloses a construction method for super-buried test piles in rock strata, which belongs to the field of test pile construction. The technical problems to be solved by the invention are that it is difficult to form holes in complex rock strata often encountered by cast-in-situ piles, and the super-filling elevation of underwater concrete cannot be accurate. Controlling, operating conditions of ultra-deep foundation pit bottom static load detection are limited, and controlling frictional resistance affects load-bearing detection. The technical solution is as follows: S1, construction preparation; S2, advance drilling exploration, and establish a BIM model of the rock surface; S3, positioning And bury the casing, and make and place the double sleeve of the test pile; S4, the drilling rig is in place, the drill pipe is centered and the verticality is adjusted; S5, the soil layer drilling, the retaining wall and the multi-level stepped drilling of the rock layer; S6 1. Use the internal and external double control method to monitor the verticality of the drill pipe; S7. According to step 2, carry out the production of the steel cage and the installation of the anti-floating structure, and hang the steel cage and install the superfill monitoring probe; S8. Secondary hole cleaning by circulation method; S9, monitoring of underwater concrete pouring and overfilling height.

Owner:CHINA CONSTR EIGHTH ENG DIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com