Plastering slide track device for surface finishing when pouring concrete bottom plate in hole

A technology of concrete floor and slide rail, which is used in construction, earthwork drilling, water conservancy projects, etc., can solve the problems of lack of accurate quantitative control methods, uneven flatness control, and many human uncertain factors, and achieves simple installation. , precise control, precise elevation and flatness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

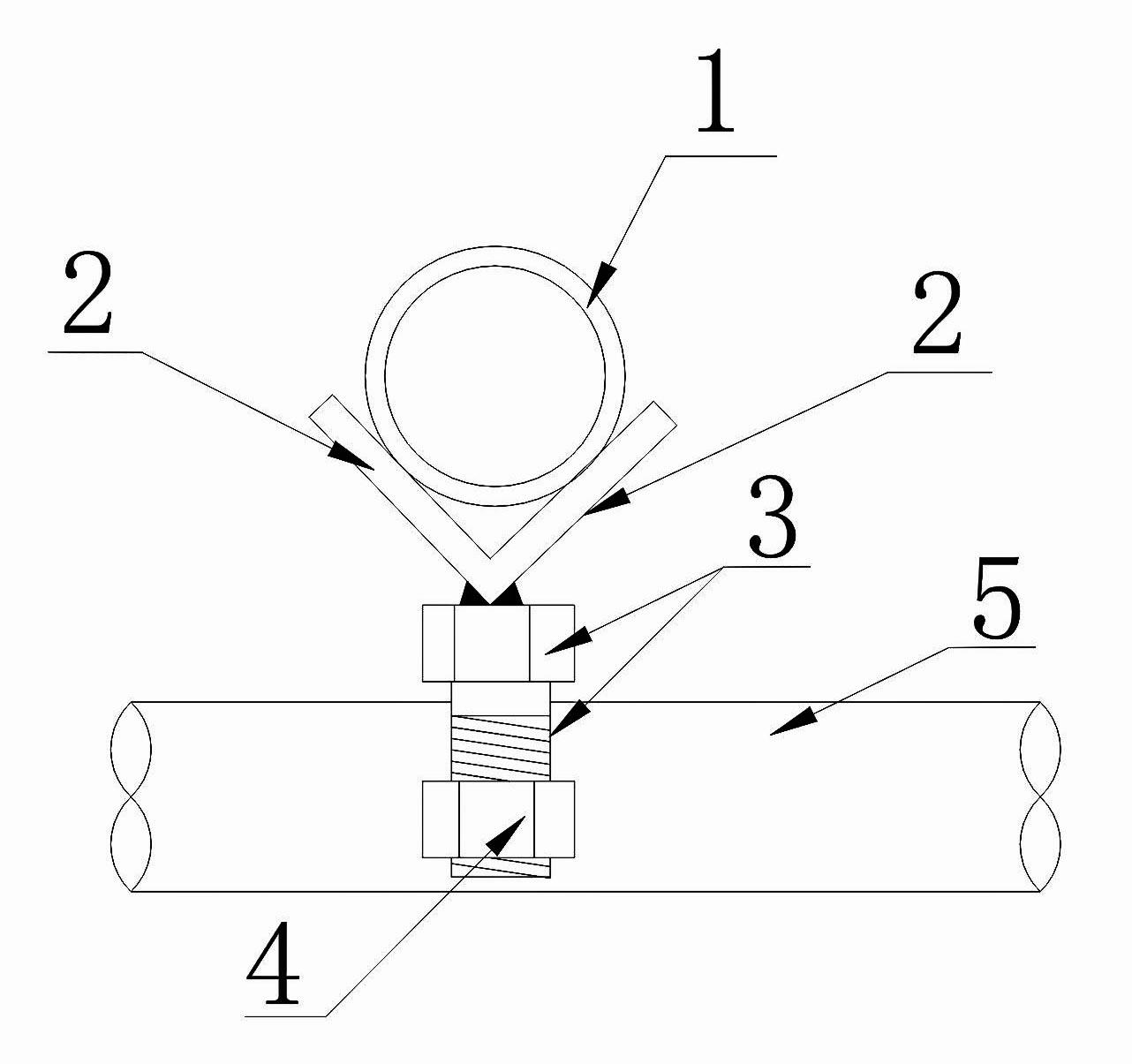

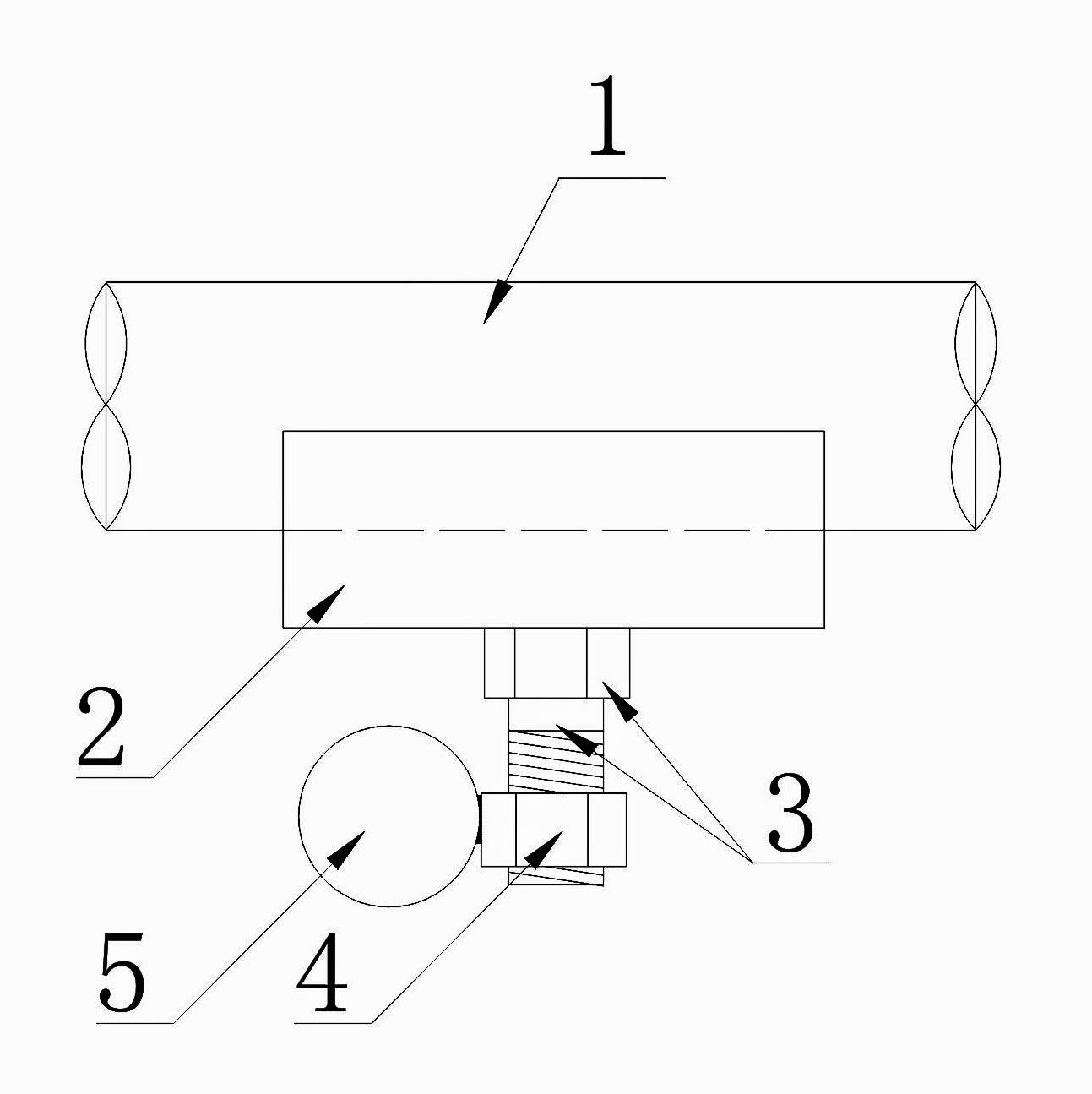

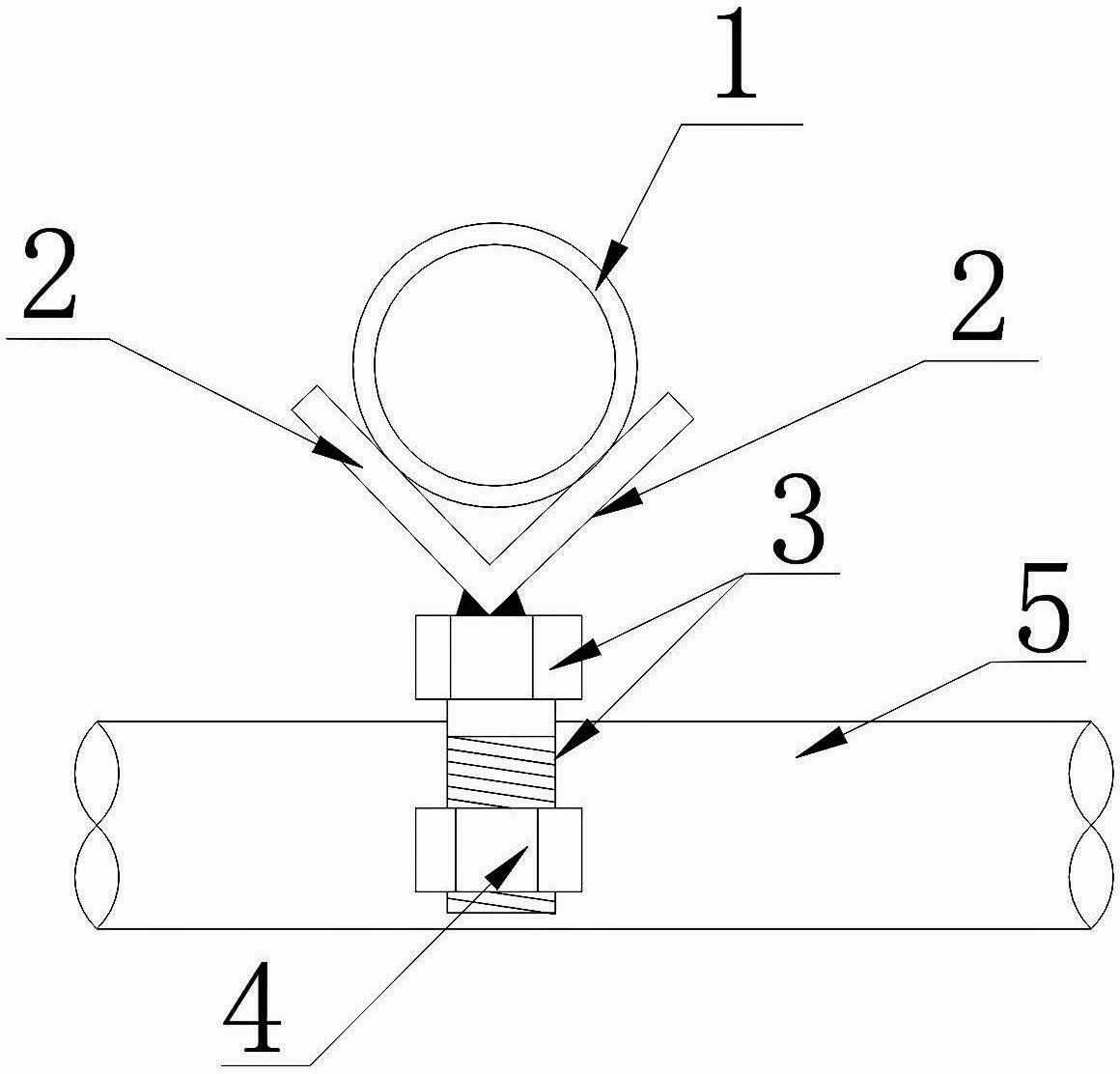

[0009] A plastering slide rail device for closing the surface when pouring the concrete bottom plate in the cave, such as figure 1 and figure 2 As shown, it is composed of steel pipe slide rail 1, angle steel support 2, screw rod 3, nut 4 and upper steel bar 5 on the bottom plate, wherein: steel pipe slide rail 1 is placed on the angle steel support 2, and the lower end of angle steel support 2 is welded with screw rod 3 Together, they constitute the main body of the plastering slide rail device. The nut 4 is welded on the upper steel bar 5 on the bottom plate, and the screw rod 3 is screwed into the nut 4 to fix the device. Among them: steel pipe slide rail 1 is welded by 1.5-inch steel pipe, angle steel support 2 is made of L50×5 equilateral angle steel, screw 3 and nut 4 are made of M18-22 standard screw and nut. When the binding of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com