Construction method for test pile with ultra-buried depth in rock stratum

A construction method and technology of test piles, which can be applied in foundation structure tests, sheet pile walls, earthwork drilling and mining, etc., can solve the problem of limited static load detection operating conditions at the bottom of ultra-deep foundation pits and inaccurate elevation of underwater concrete overfilling Controlling, difficulty in forming holes in complex rock strata, etc., to achieve the effect of solving large-tonnage static load tests, improving the quality of test piles, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

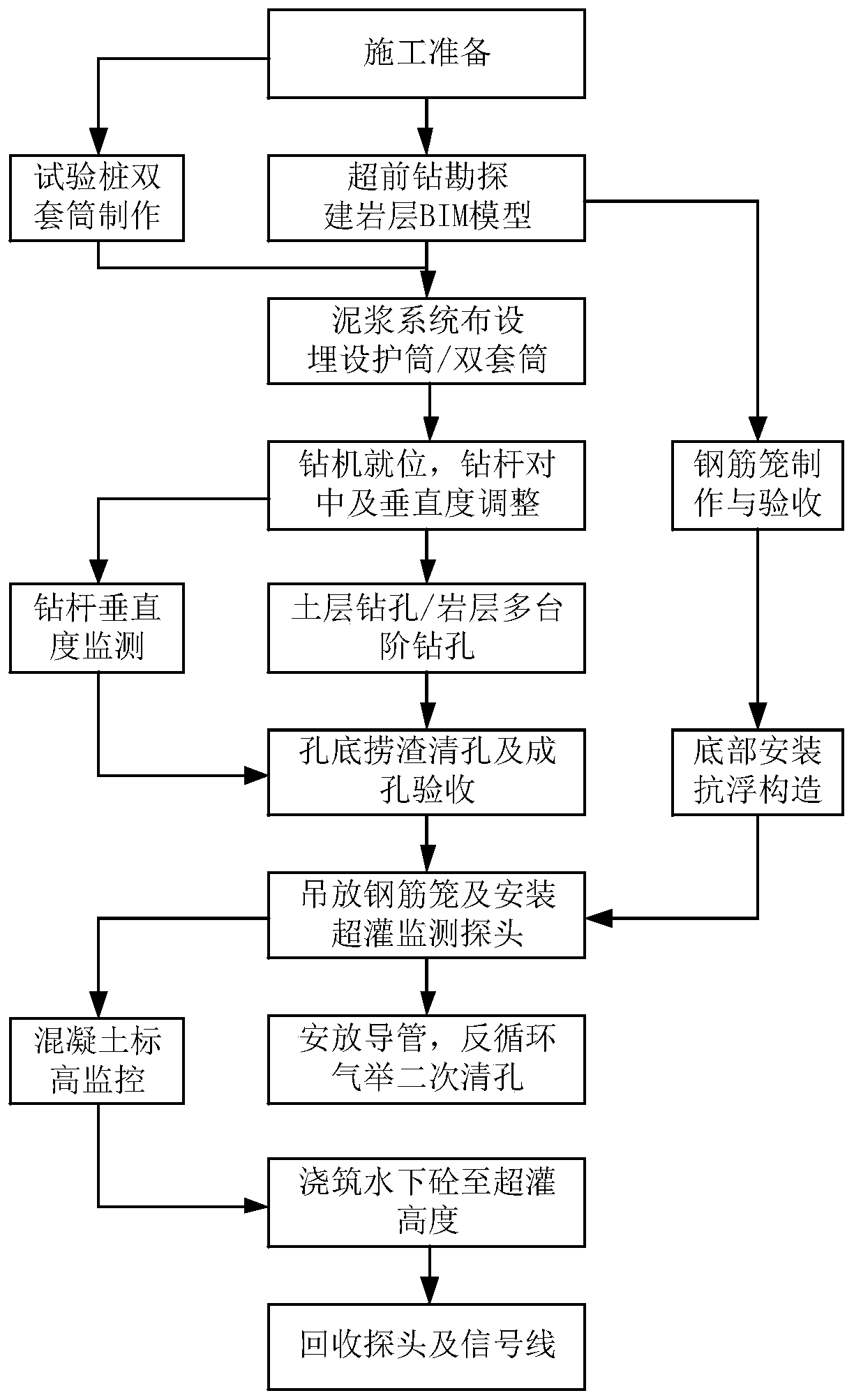

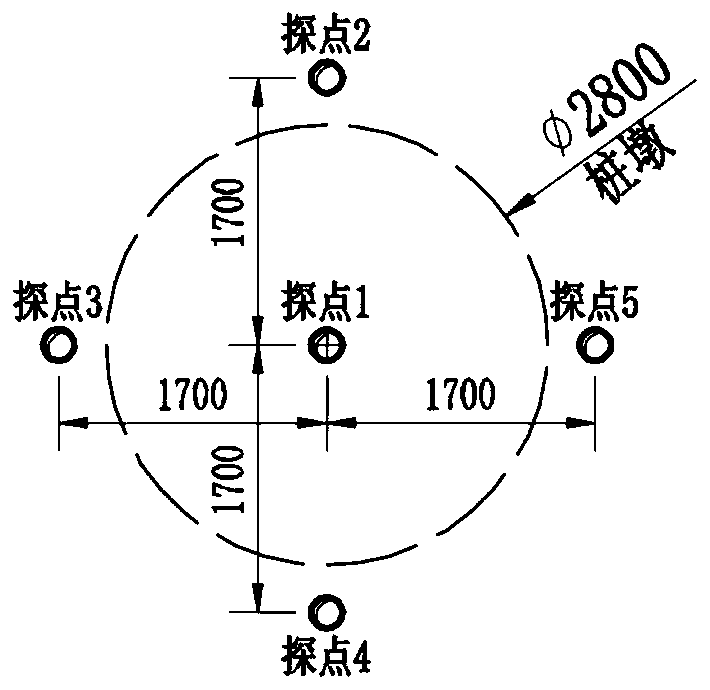

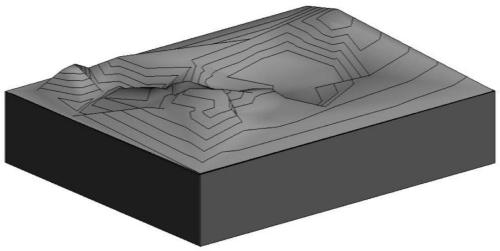

[0097] attached figure 1 As shown, the super-buried depth test pile construction method in the rock stratum of the present invention is a super-buried depth test pile construction method in the rock stratum. The method adopts a double sleeve structure, utilizes the outer sleeve to resist the soil pressure, and the inner sleeve as Concrete external formwork isolates the frictional resistance of the pile body of the empty pile, and realizes the accurate detection of the bearing capacity of the effective pile body before the excavation of the deep foundation pit; and then uses BIM technology to form a rock layer information model with the soil layer parameters obtained by multiple advanced drilling, and pre- Determine the length of the pile; then use the monitoring probe to automatically collect technical parameters in the process of underwater concrete pouring and perform data processing to dynamically monitor the height of the poured concrete, and use the preset limit value to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com