Formwork positioning assembly and formwork combination

A technology for positioning components and templates, which is applied in the direction of formwork/formwork components, connectors of formwork/formwork/work frames, and on-site preparation of building components, which can solve the problems of low efficiency, difficulty in control by construction personnel, and accurate positioning Highly dependent on the welding accuracy of positioning steel bars and other issues, to achieve the effect of improving positioning accuracy and simplifying steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present application will be clearly and completely described below in conjunction with the accompanying drawings of specific embodiments. Apparently, the described implementations are only some of the implementations of this application, not all of them.

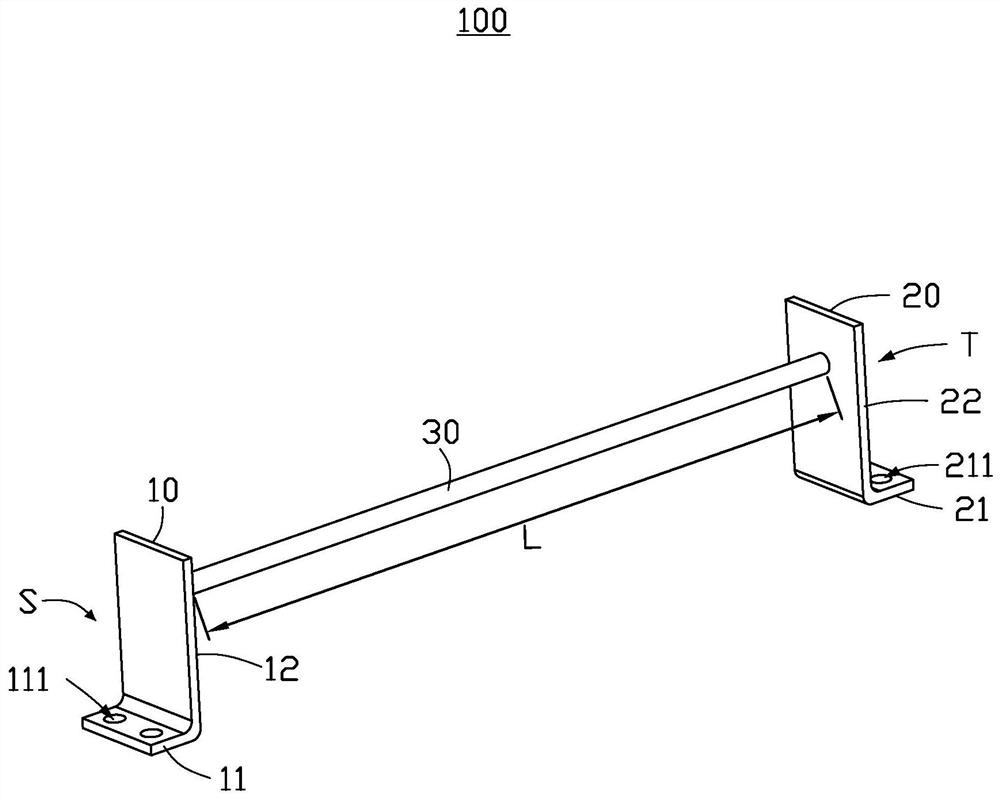

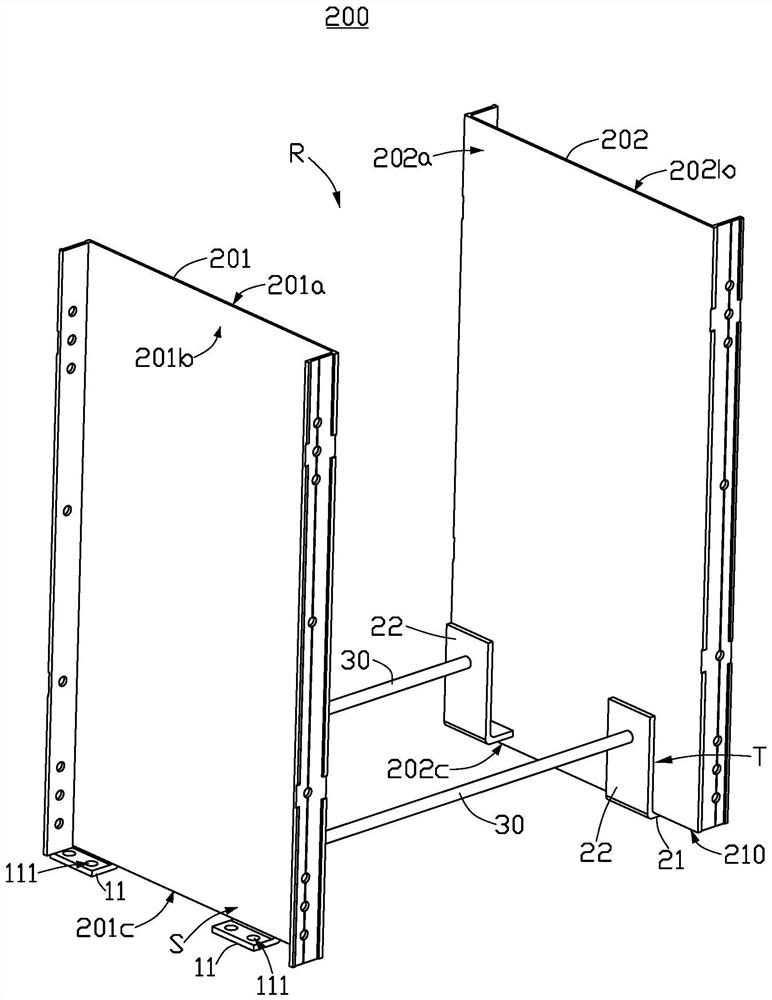

[0043] See figure 1 and figure 2 , the embodiment of the present application provides a template positioning assembly 100, the template positioning assembly 100 is used to position the first template part 201 and the second template part 202, so that the first template part 201 and the second template part 202 The size of the concrete pouring space R formed by the enclosure conforms to the construction blueprint.

[0044] The template positioning assembly 100 includes a first limiting plate 10, a second limiting plate 20 and a connecting rod 30, the first limiting plate 10 is spaced apart from the second limiting plate 20, and the connecting rod 30 It is arranged between the first lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com