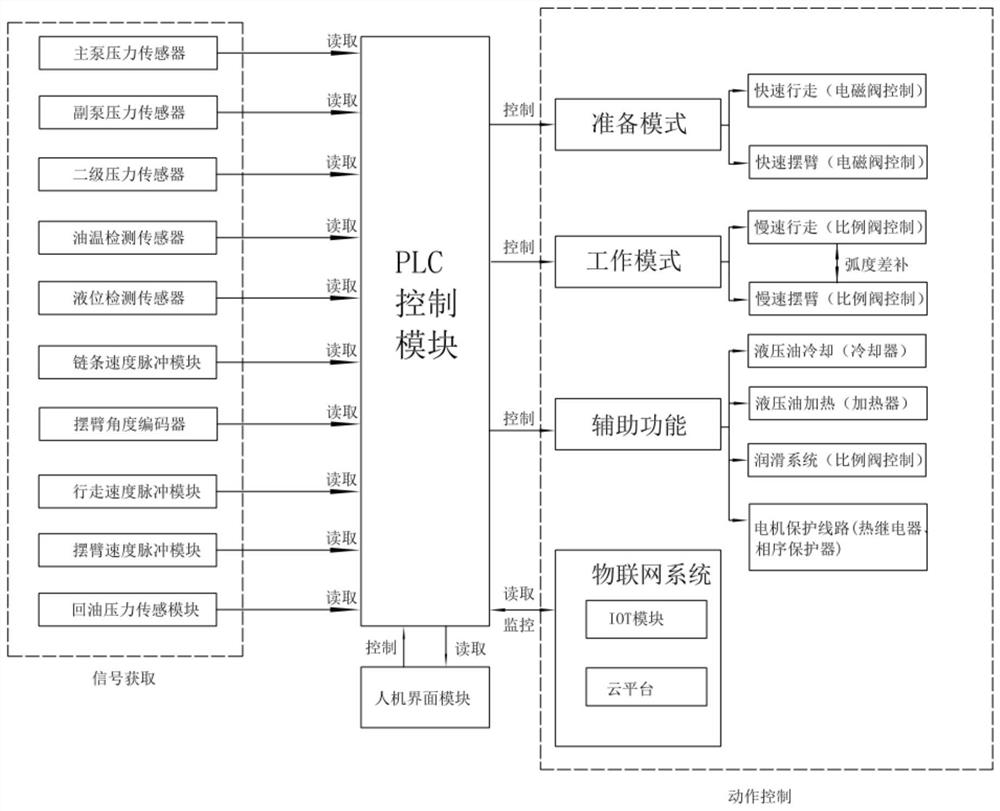

A chain arm saw electrical control system

An electrical control system and chain saw technology, applied in the direction of electrical program control, general control system, control/adjustment system, etc., can solve problems affecting equipment production efficiency, rich functions, poor upgradeability, waste of resources, etc., to achieve The effect of shortening the time for troubleshooting, improving work productivity, and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

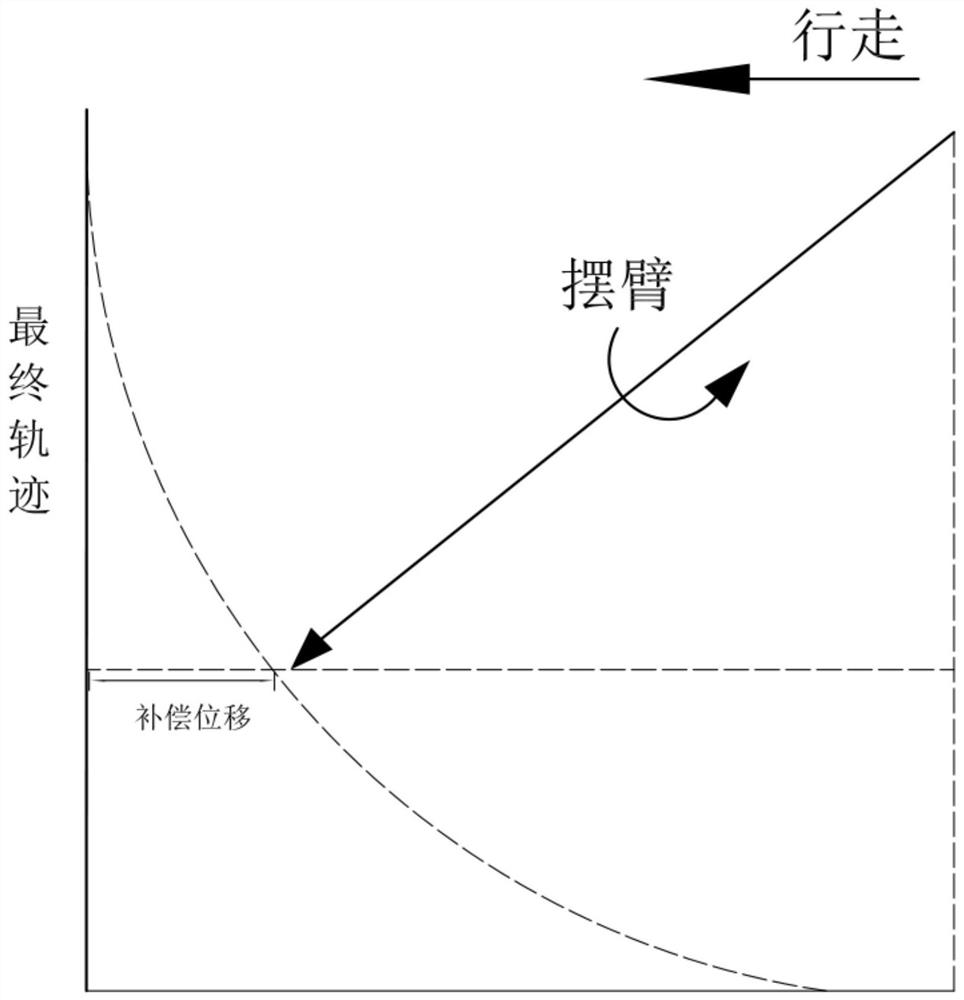

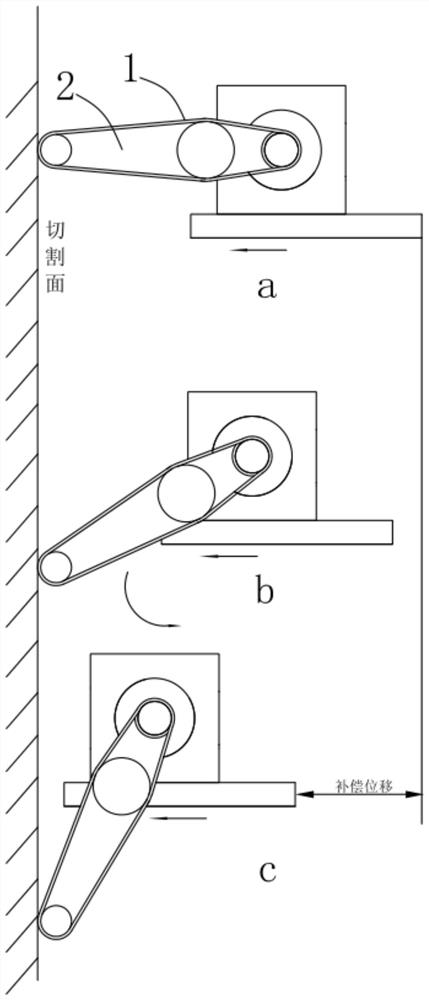

Method used

Image

Examples

Embodiment Construction

[0033] The following will be combined with the accompanying drawings and embodiments to elaborate on the embodiments of the present invention, whereby the present invention how to apply technical means to solve technical problems, and to achieve a technical effect of the realization process can be fully understood and implemented. It should be noted that, as long as it does not constitute a conflict, the various embodiments of the present invention and the various features in each embodiment may be combined with each other, and the resulting technical solutions are within the scope of the present invention.

[0034] At the same time, in the following description, for the purpose of interpretation and elaboration of many specific details, to provide a thorough understanding of the embodiments of the present invention. However, to those skilled in the art will appreciate, the present invention may be implemented without the specific details herein or in a particular manner described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com