Multifunctional electrostatic powder spraying device

A technology of electrostatic powder and spraying device, which is applied in the direction of electrostatic spraying device, spraying device, spraying electric energy device, etc., can solve problems such as uneven thickness, achieve uniform charge adhesion, ensure durability and environmental adaptability, and spray coating with uniform thickness consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

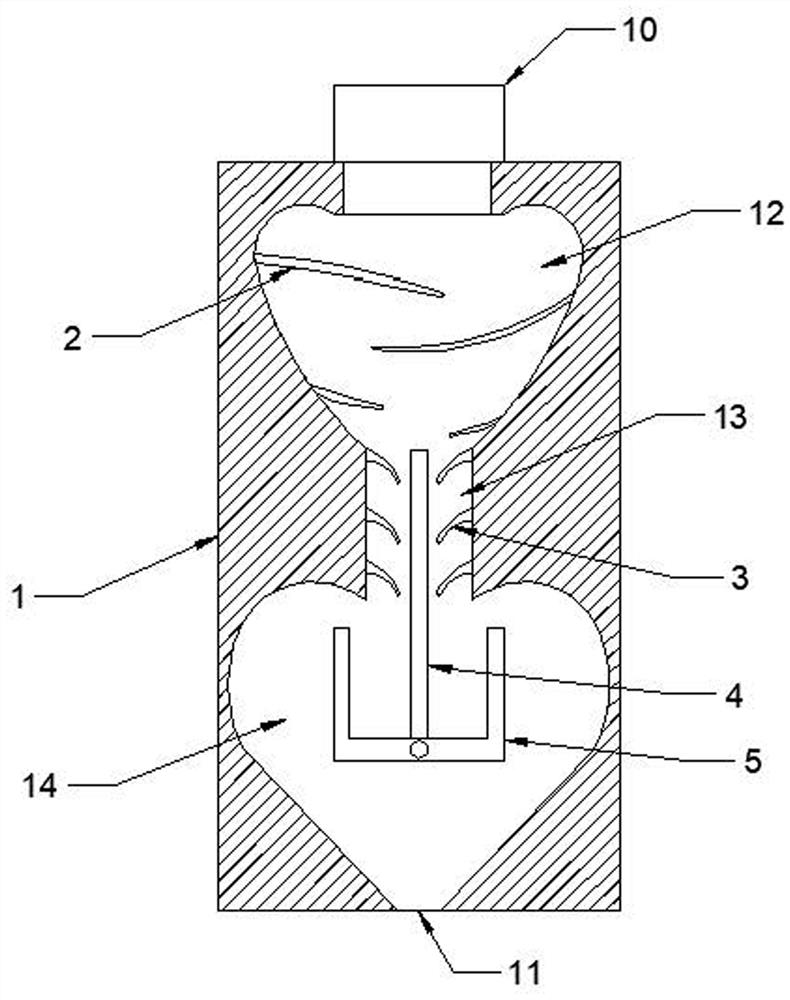

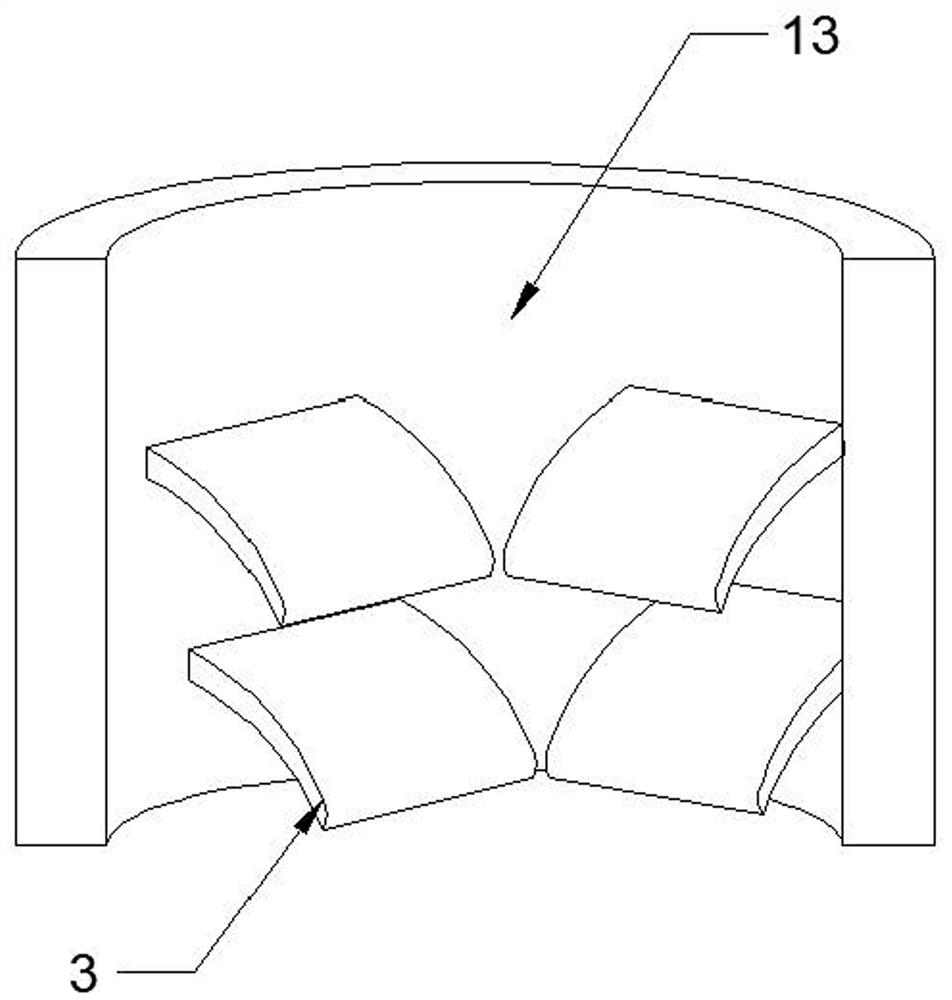

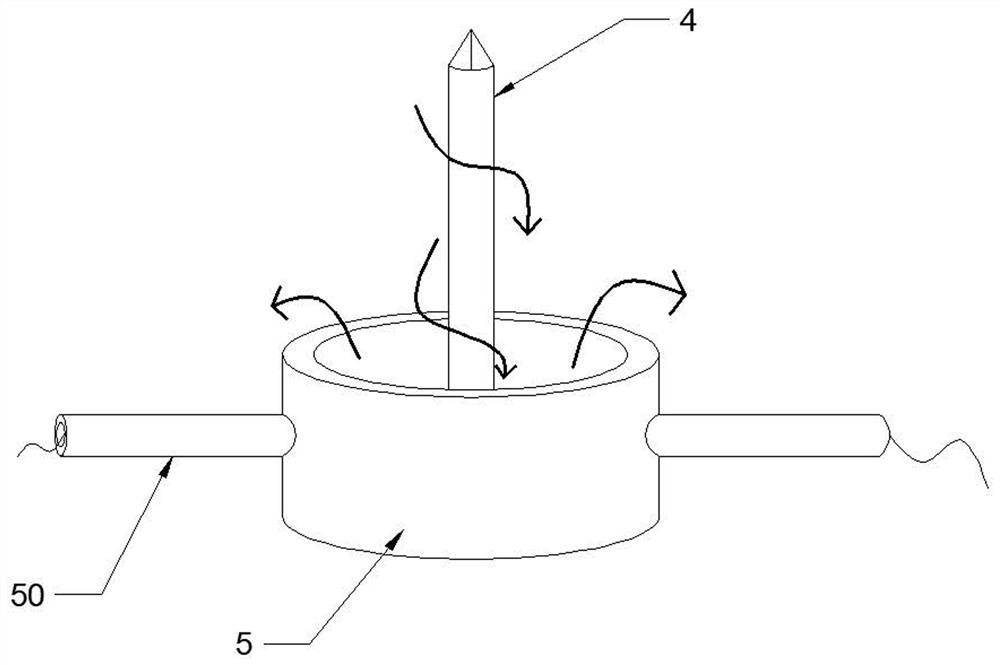

[0023] see Figure 1~3 , in an embodiment of the present invention, an electrostatic powder multifunctional spraying device includes a nozzle cavity 1, and the first and last ends of the nozzle cavity 1 are respectively provided with powder injection ports 11 for externally spraying electrostatic powder and for communicating with the outside. The powder supply port 10 is sealed and connected to the powder supply end. The nozzle cavity 1 is equipped with a discharge needle 4 for discharging and attaching negative charges to the powder. The nozzle cavity 1 is equipped with a pressurized swirl cavity 12 and electrostatic spraying Cavity 14, the tail end of the pressurized swirl chamber 12 is connected to the powder interface 10, the front end of the pressurized swirl chamber 12 is connected to the tail end of the electrostatic ejection chamber 14 through the diversion channel 13, and the powder injection port 11 is set in the electrostatic ejection chamber 14 The front end of the...

Embodiment 2

[0031] see Figure 4 and Figure 5 , the difference between this embodiment and embodiment 1 is:

[0032] The outer opening of the powder injection port 11 is provided with an air guide head 6 for guiding the powder outlet angle to be perpendicular to the front end of the nozzle cavity 1. The air guide head 6 is provided mainly because when the powder is ejected from the electrostatic ejection chamber 14, the actual The above is confluence from the inner walls of the left and right sides of the electrostatic spraying chamber 14, which causes the powder sprayed from the powder spraying port 11 to bifurcate, or disturb the flow at the powder spraying port 11, so the air guide head 6 is installed. Targeted adjustments are made to the powder spraying angle at the air outlet of the powder spraying port 11.

[0033]The interior of the air guide head 6 is provided with a penetrating air guide channel 60 along the head and tail direction of the nozzle cavity 1, and the left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com