Weighing air flotation device for simulating weightlessness

An air flotation and weighing technology, which is applied to the simulation device of space navigation conditions, measurement device, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of impact and weightlessness that are difficult to simulate, and improve the carrying capacity and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

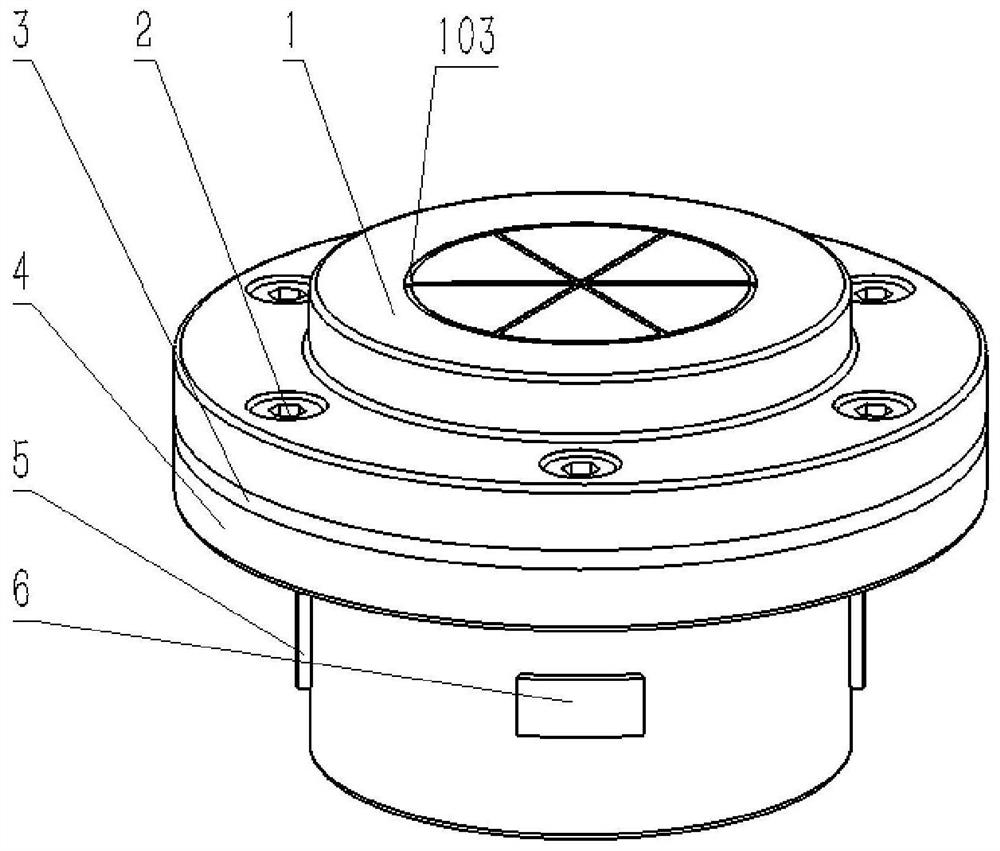

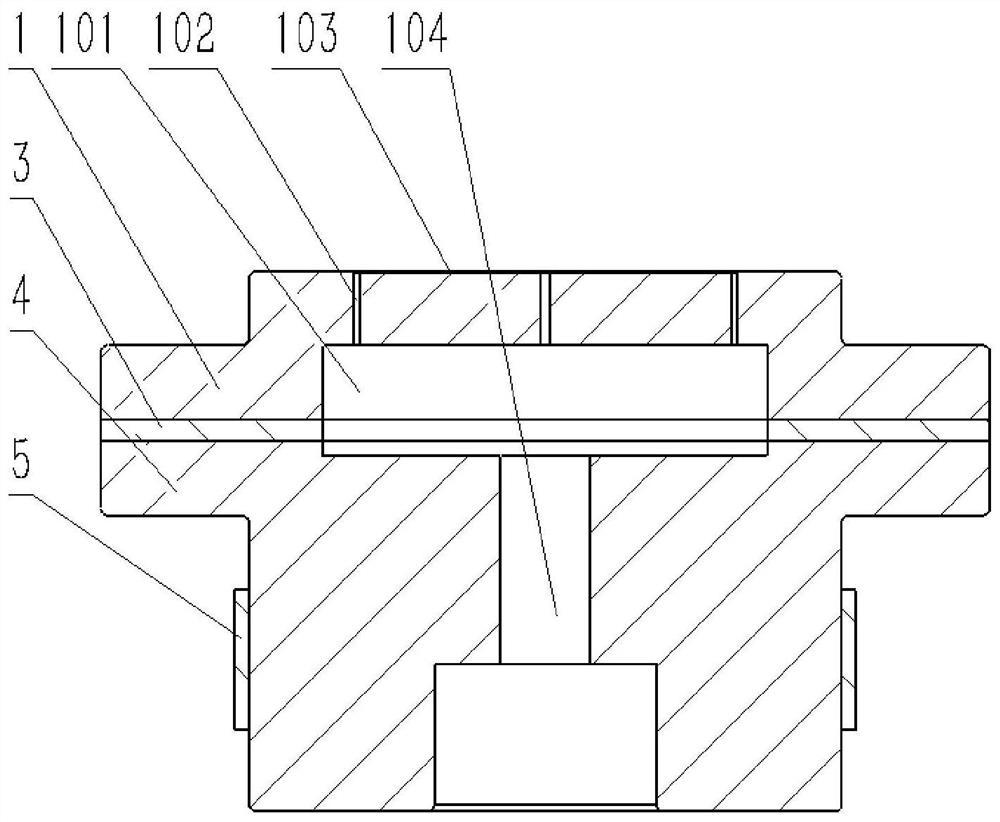

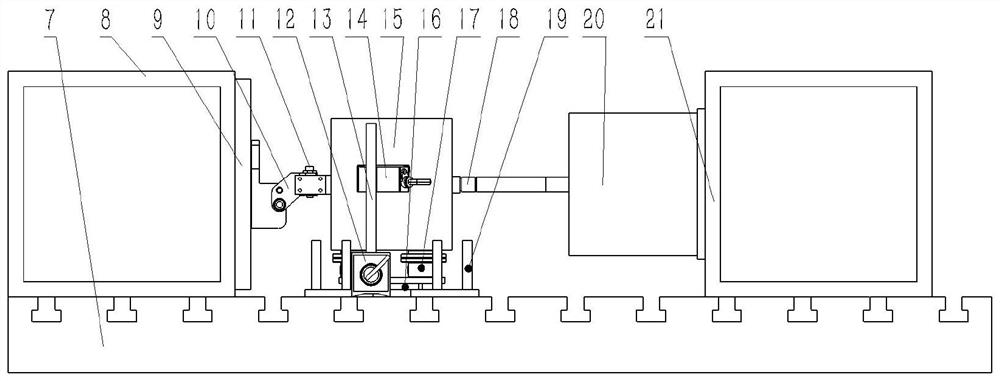

[0021] like Figure 1~3 As shown, a weighing air flotation device for simulating weightlessness, a weighing air flotation device for simulating weight loss, includes an upper air flotation pad 1, a sealing ring 3, a lower air intake block 4 and three strain gauges . An orifice 102 is opened on the upper side of the upper air-floating cushion 1, and an air supply hole is opened on the lower side. The upper part of the lower air intake block 4 is provided with the same air supply hole as the upper air bearing pad, and the lower part is provided with an air inlet 104 connected with the air supply hole. The upper air bearing pad 1 is connected with the lower air intake block 4 by screws 2, and the connecting part is equipped with a sealing ring 3 for preventing the air supply hole 101 from leaking. The three strain gauges are all installed on the lower air intake block 4 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com