Felt cloth sound insulation board

A felt cloth and sound insulation board technology, applied in the field of sound insulation boards, can solve problems such as single performance, felt cloth sound insulation board can only be silenced, and felt cloth is not easy to replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

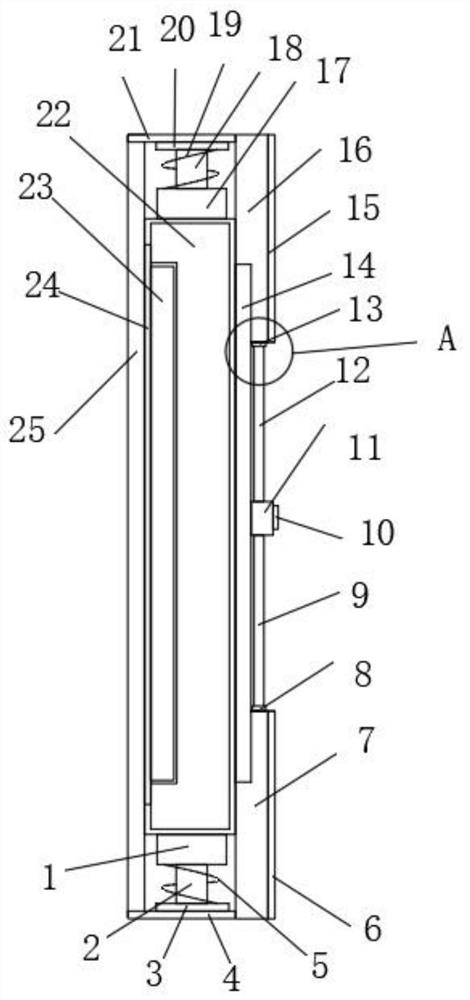

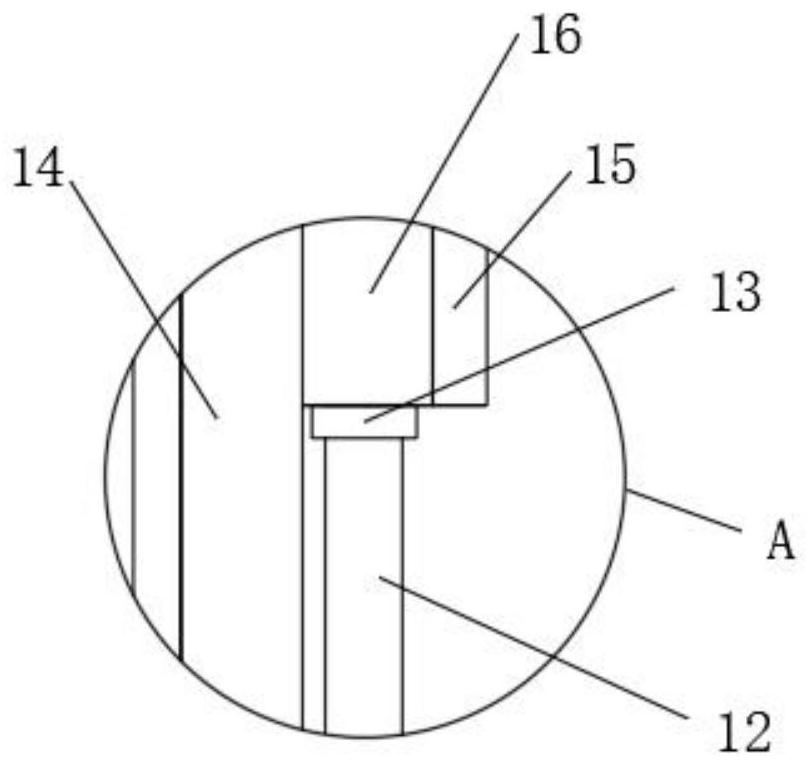

[0026] like Figure 1-4 As shown, the embodiment of the present invention provides a felt cloth, including a support plate 22, and a support plate 22 side fixing a sliding groove 14 and the inner upper and lower ends of the inner side of the slide groove 14 are slidably connected to the adhesive plate 16 and the adhesive plate 7. The other side of the upper adhesive plate 16 is provided with the upper side of the glass glue 15 and the lower side of the upper adhesive plate 16 is rotated by the second rotary shaft 13, and the second threaded rod 12 bottom thread is connected to the inside of the fixed slot 11. Further, the fixed slot 11 is fixed to the inside of the slide groove 14, and the other side of the lower adhesive plate 7 is provided with a glass glue 6 and the upper side of the lower adhesive plate 7 is rotated through the first spindle 8, and the first threaded rod 9 is connected. A threaded rod 9 is threaded on the inside of the fixed slot 11, and the outer tube 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com