Adhesive cement stirrer

A mixer and mortar technology, applied in mixer accessories, mixers, shaking/oscillating/vibrating mixers, etc., can solve problems such as poor mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

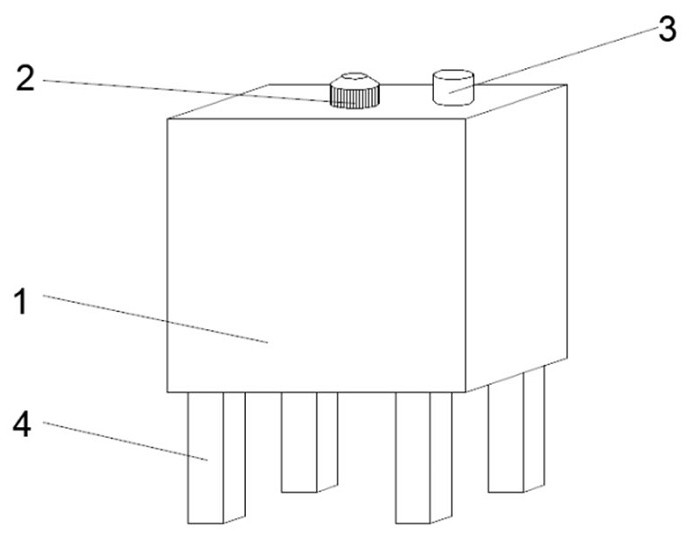

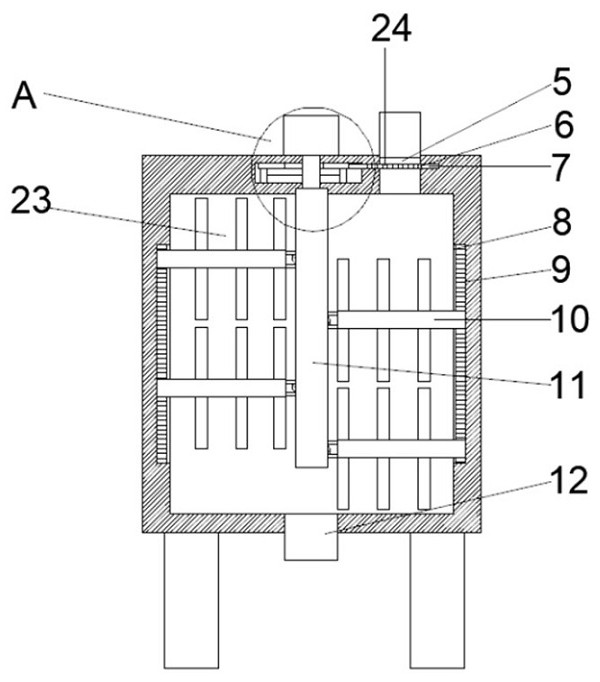

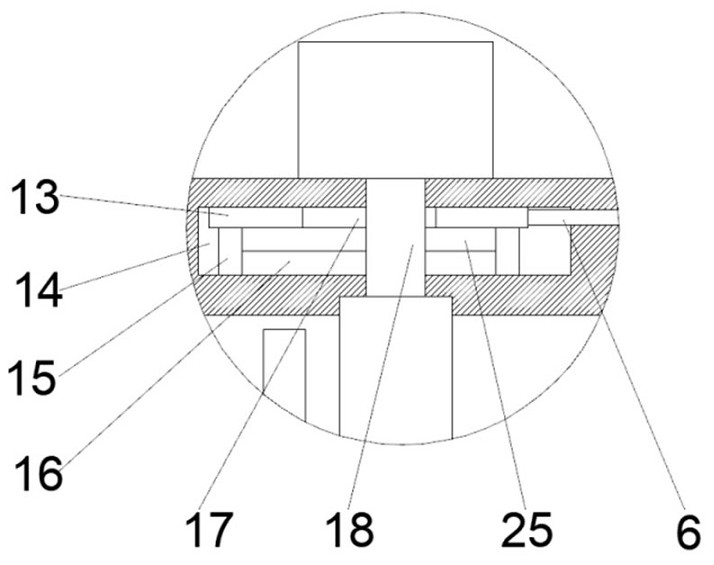

[0025] see Figure 1-5 , in an embodiment of the present invention, a mortar mixer includes a box body 1, a mixing chamber 23 is provided inside the box body 1, a servo motor 2 is connected to the upper end of the box body 1 by riveting, and the servo motor 2 contacts the end surface of the box body 1 Rotationally connected with a rotating shaft 18, the rotating shaft 18 is located in the box body 1, the other end of the rotating shaft 18 is welded to a stirring shaft 11, the stirring shaft 11 is located in the stirring chamber 23, and the outer surface of the stirring shaft 11 is provided with several bumps 22, the Both ends of the box body 1 are provided with card slots 8, one end of the card slot 8 is connected to the stirring chamber 23, and the vertical end surface of the side of the box body 1 in contact with the card slot 8 is provided with engaging teeth 9, and the two sides of the box body 1 are A plurality of rotating rods 10 are provided, one end of the rotating rod...

Embodiment 2

[0027] see Figure 1-5 , on the basis of Embodiment 1, the bump 22 is an oval ring, the bump 22 is obliquely sleeved on the outer surface of the stirring shaft 11, the bump 22 is welded to the stirring shaft 11, and the two ends of the bump 22 are respectively located at Between the limit rods 20, the projection 22 is in sliding contact with the limit rod 20. Since the two ends of the projection 22 are respectively located between the limit rods 20, the projection 22 is obliquely fixedly connected with the stirring shaft 11, that is, when the stirring shaft 11 When turning, one end of the projection 22 moves up and down gradually and the other end moves down.

[0028] One side of the upper end of the box body 1 is provided with a feed port 3, one end of the feed port 3 is connected to the stirring chamber 23, a nylon mesh 5 is arranged inside the feed port 3, and the end surface of the nylon mesh 5 is welded to the box body 1.

[0029] The inside of the box body 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com