Stirring bar for artificial stone raw materials

A technology of stirring stick and artificial stone, which is applied in the field of artificial stone processing, can solve the problem that the separation of raw materials, the uniform stirring, the easy agglomeration of raw material particles in the stirring rod and the surrounding of the stirring rod, the incomplete stirring of artificial stone raw materials, etc. can be solved. problem, to achieve the effect of simple structure, low cost and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

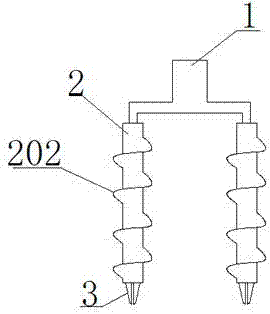

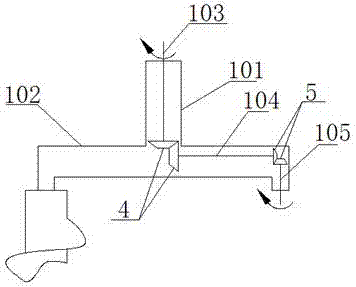

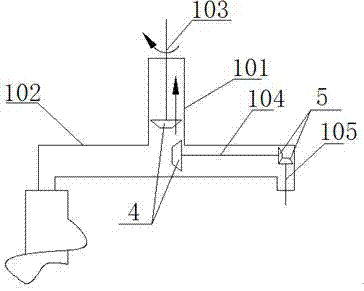

[0023] Embodiment 1: as Figures 1 to 4 Shown:

[0024] A stirring rod for artificial stone raw materials, comprising a rotating part 1, a stirring part 2 and a paddle 3, the rotating part 1 is connected to the motor shaft, the stirring part 2 is connected to the rotating part 1 and can rotate around the rotating part 1, the The paddle 3 is arranged at the bottom of the stirring part 2;

[0025] The stirring part 2 includes a hollow pipe body 201, and the inner wall of the pipe body 201 is provided with internal threads;

[0026] The paddle 3 includes a paddle bar 301, the outer wall of the paddle bar 301 is provided with an external thread and matches with the internal thread of the pipe body 201;

[0027] The lower end of the paddle bar 301 is connected with two symmetrically arranged blades 302, and the blades 302 and the paddle bar 301 are hinged through a gear plate 303, and the gear plate 303 can drive the blade 302 to rotate an angle;

[0028] A preferred solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com