Wet joint post-cast strip multifunctional four-wheel trolley working platform

A technology of working platform and post-casting belt, which is applied in the direction of injection device and liquid injection device, can solve the problems of general ease of use, unfavorable control, and general convenience, and achieve good overall functionality, good ease of use, and convenience sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

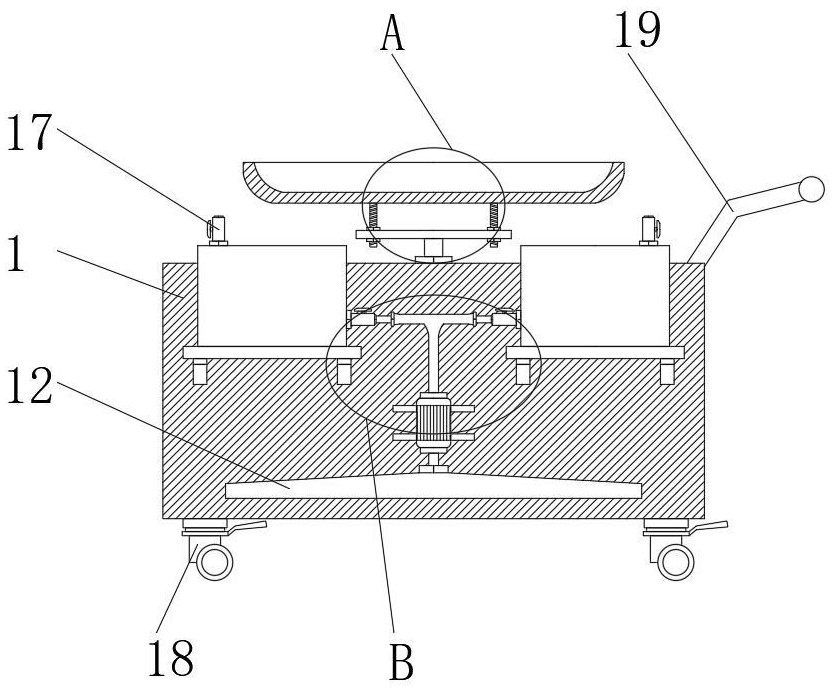

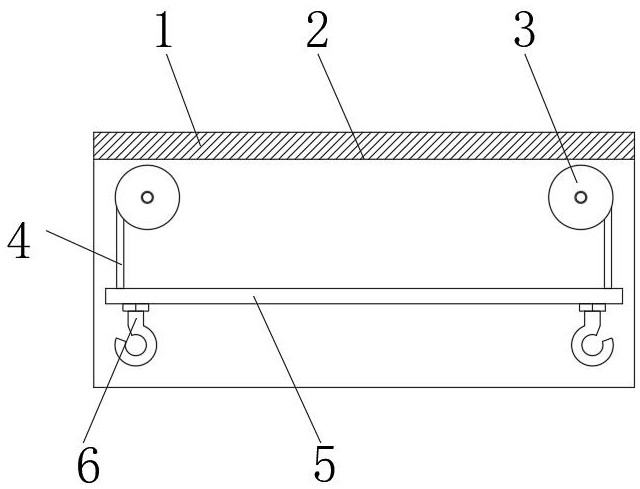

[0026] Multifunctional four-wheel trolley operating platform with wet joint post-pouring, such as figure 1 - Image 6 As shown, it includes a box body 1, which is characterized in that: the middle part of the bottom of the box body is provided with a lifting and arranging platform mechanism, the top of the box body is provided with a workbench lifting mechanism, and the top sides of the box body are respectively provided with Material storage box 8, adjacent material storage box 8 is directly provided with tee joint 10, and the bottom of described tee joint is provided with pump body 11, and the discharge end of described pump body 11 is provided with nozzle 12; The mechanism includes a groove 2, an electric winch 3, an arrangement table 5, and a hook 6. The middle part of the bottom of the box is provided with a through groove 2, and the two ends of the groove are respectively provided with an electric winch 3, and the electric winch 3 is provided with a steel cable 4, and t...

Embodiment 2

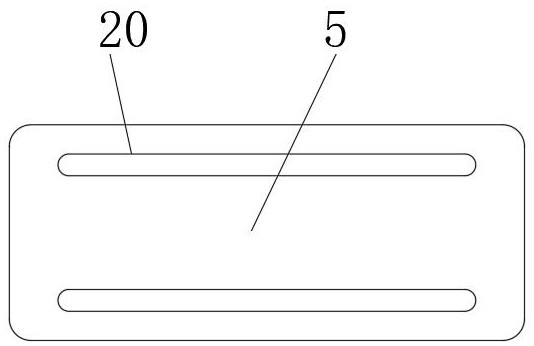

[0029] This embodiment is optimized on the basis of embodiment 1, such as figure 2 and image 3 As shown, two strip-shaped installation holes 20 are arranged in parallel on the arrangement table 5 along the length direction, and the hook 6 is slidably connected to the strip-shaped installation holes 20 . The strip-shaped installation holes 20 provided on the arrangement table are conducive to the installation of the instruments to be arranged in cooperation with the fixed installation components.

[0030] Further, a discharge valve 9 is provided at the connection between the storage tank 8 and the three-way joint. Setting the discharge valve 9 can accurately control the use of pouring material, which has better practicability.

[0031] Further, a feed valve 17 is provided on the top of the storage tank 8 . Setting the feeding valve 17 is beneficial to the feeding control work and has better practicability.

[0032] Other parts of this embodiment are the same as those of E...

Embodiment 3

[0034] This embodiment is optimized on the basis of embodiment 1 or 2, as figure 1 As shown, the workbench lifting mechanism includes a shaft seat 13, a mounting plate 14, and a workbench 16. The top of the box is connected with the mounting plate 14 through the shaft seat 13, and the two ends of the top of the mounting plate 14 are respectively connected by bolts. Connect with the two ends of workbench 16. The height of the workbench 16 can be adjusted by adjusting the bolts, and the workbench 16 can be rotated and adjusted; the workbench 16 is adjusted by setting a lifting mechanism. When actually working, the convenience is good and the overall functionality is good.

[0035] Other parts of this embodiment are the same as those of Embodiment 1 or 2, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com