Automatic adhesive tape pasting equipment for grinding disc

An automatic, glue-stripe technology, applied in the direction of coating, devices for coating liquid on the surface, etc., can solve the problems of labor-intensive, grinding and polishing effects, and high production costs, reducing production costs, improving the quality of finished products, and the depth of pressing consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

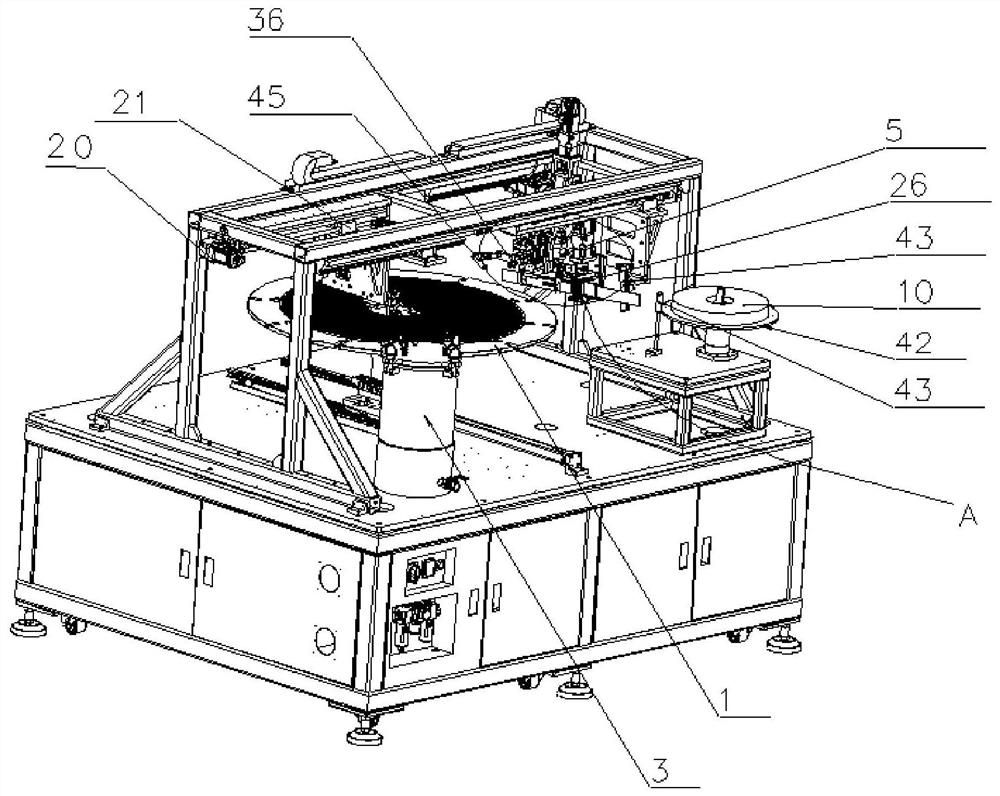

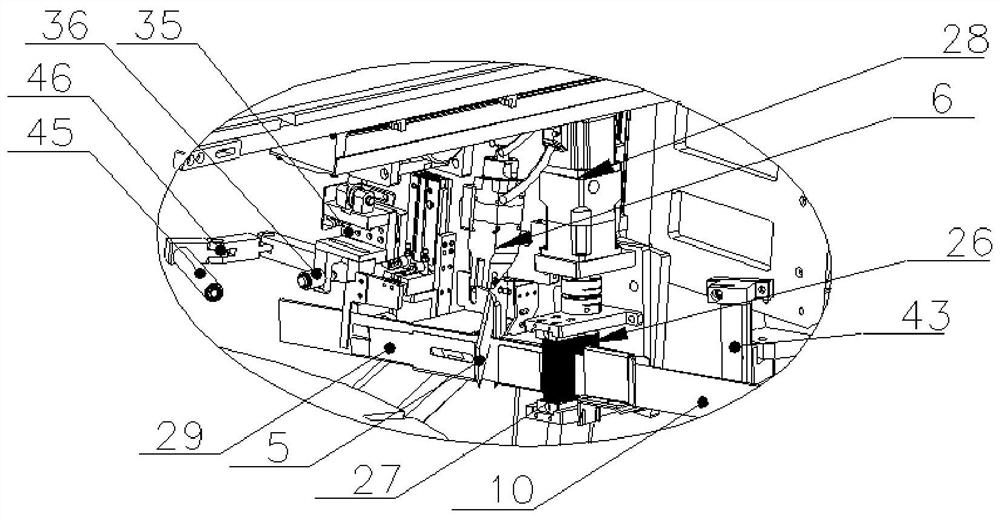

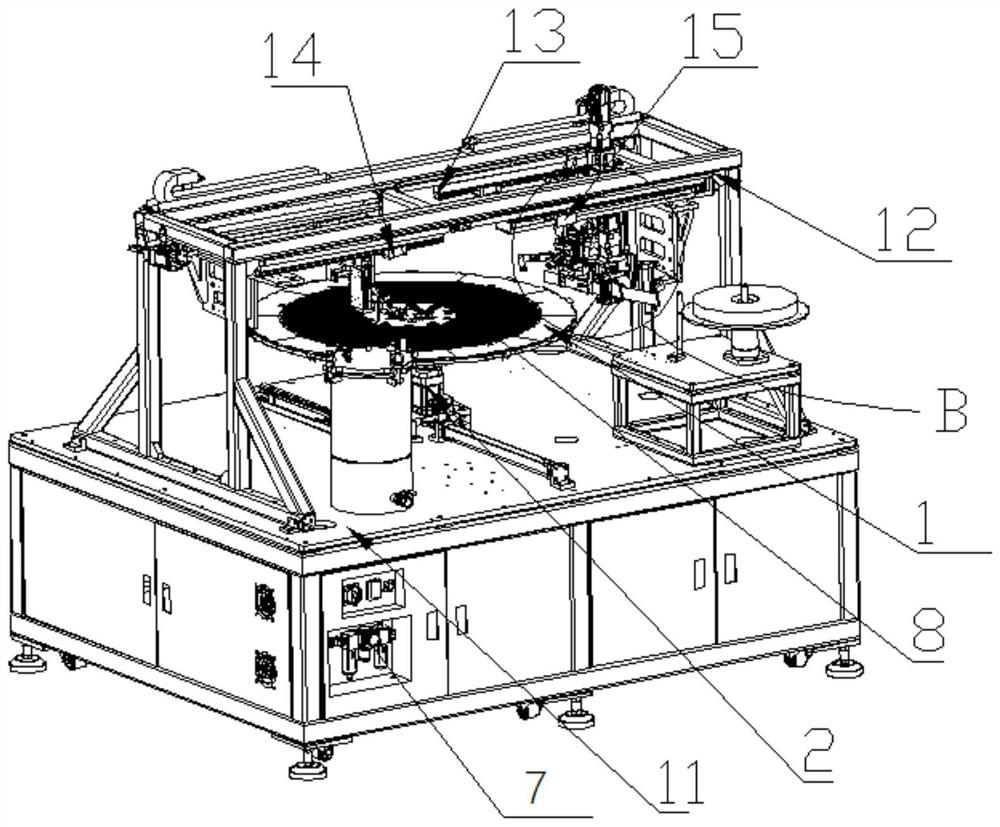

[0031]Embodiment: A grinding disc automatic glue sticking equipment, including a frame, a turntable 1, a turntable drive device 2, a glue bucket 3, a glue dispensing head 4, a glue dispensing drive device, a flocking strip material tray positioning device, and a flocking strip feeding device, flocking strip feeding driving device, flocking strip pressing device, flocking strip pressing driving device, flocking strip scissors 5, flocking strip scissors driving device 6 and control system 7, the turntable 1 can rotate around the vertical The rotating shaft is installed on the frame. The splicing tray positioning device is provided on the turntable 1. The splicing tray positioning device can fix the splicing tray 8 on the turntable 1. The turntable driving device 2 drives the turntable 1 to rotate. The barrel 3 is fixedly installed on the frame, the glue barrel 3 and the dispensing head 4 are connected by pipes, the glue barrel 3 supplies glue to the dispensing head 4, and the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com