A leather notcher

A leather and shaft technology, applied in the field of leather goods manufacturing, can solve the problems of time-consuming and laborious operation, difficulty in controlling the movement of the gear lever, etc., and achieve the effect of convenient distance adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

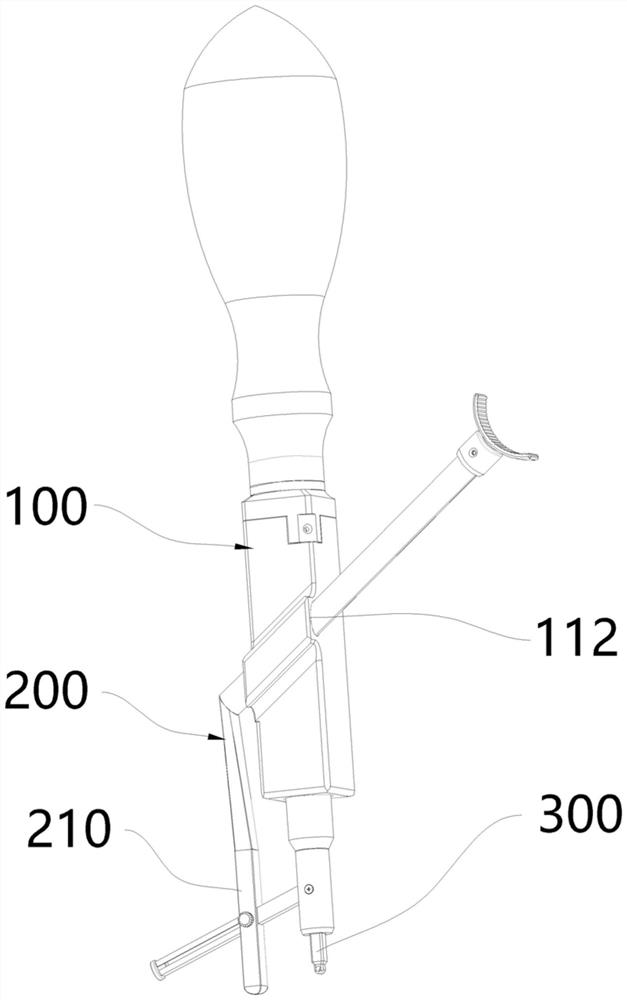

[0031] Such as figure 1 As shown, the present invention provides a leather groover, including a cutter bar 100, an adjusting member 200 and a cutter head 300 installed on the cutter bar 100, the adjusting member 200 is movably installed on the cutter bar 100, and the adjusting member 200 The gear bar 210 is included, and the distance between the gear bar 210 and the cutter head 300 is adjusted through the adjustment member 200 according to the actual needs during use.

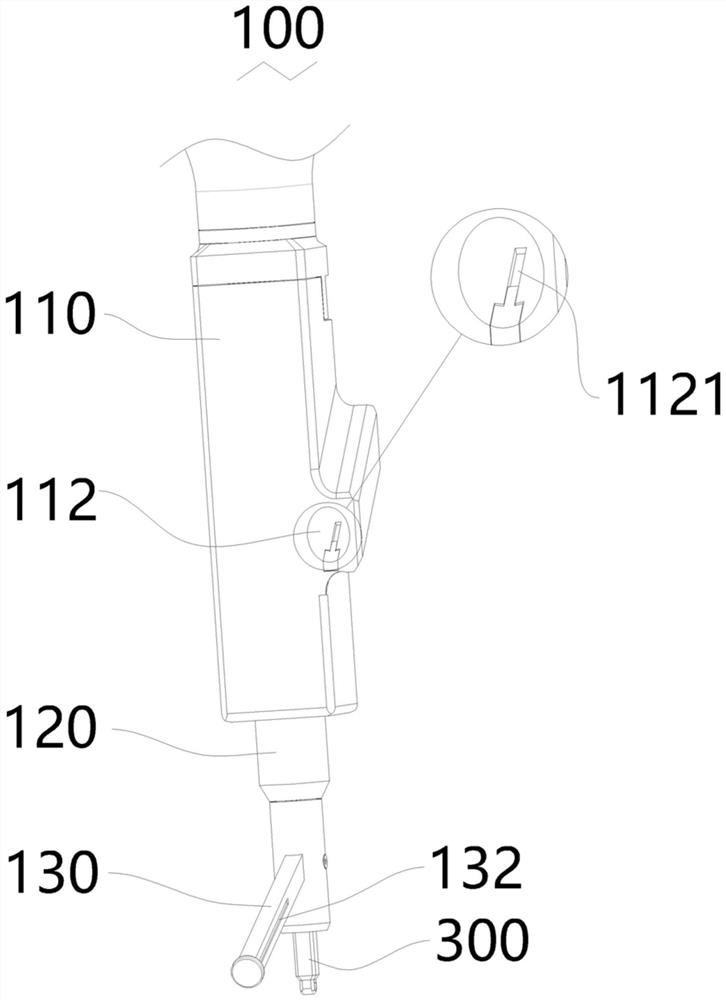

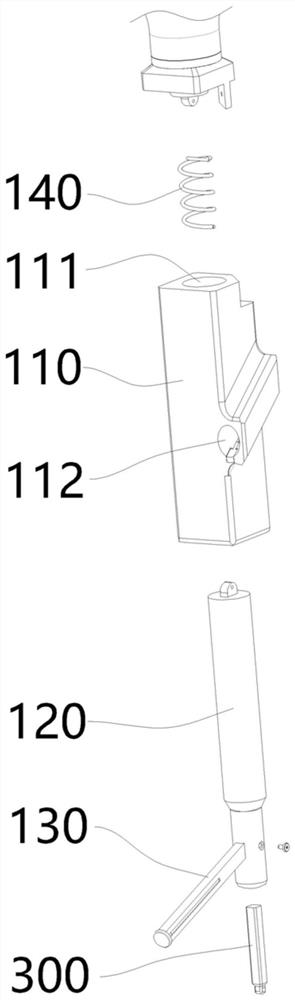

[0032] refer to figure 2 As shown, in a specific embodiment, the tool holder 100 includes a shaft 110 , a mounting rod 120 and a linkage rod 130 .

[0033] The installation rod 120 is slidably disposed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com