Mounting method of modularized steel structure

An installation method and steel structure technology, applied to the preparation of building components on site, the connectors of formwork/formwork/work frame, building components, etc., can solve the difficulty of construction, uncontrollable risks, and the difficulty of protecting the finished products of the underlying equipment Major problems, to achieve the effect of reducing installation safety risks, reducing installation safety risks, and reducing on-site installation and calibration risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

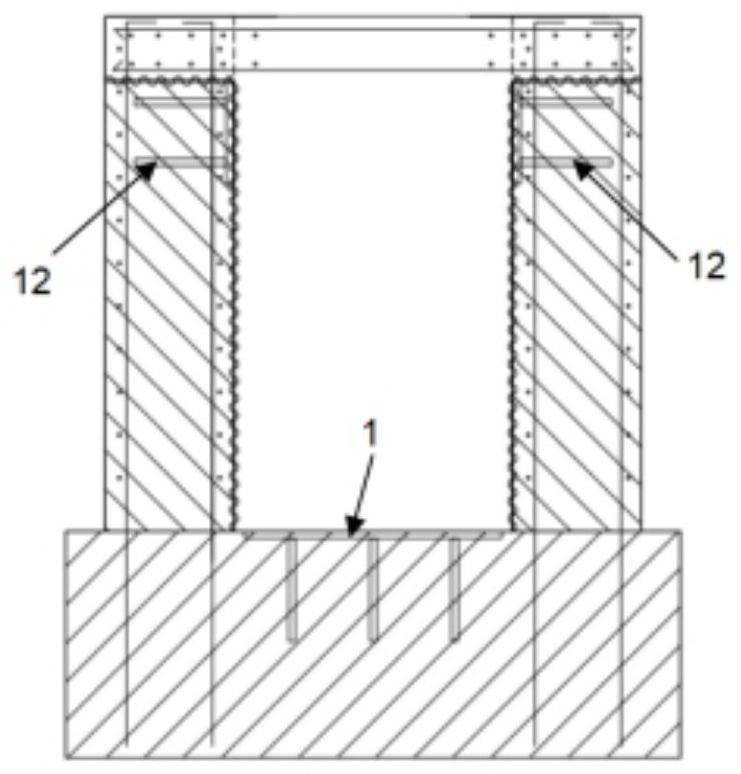

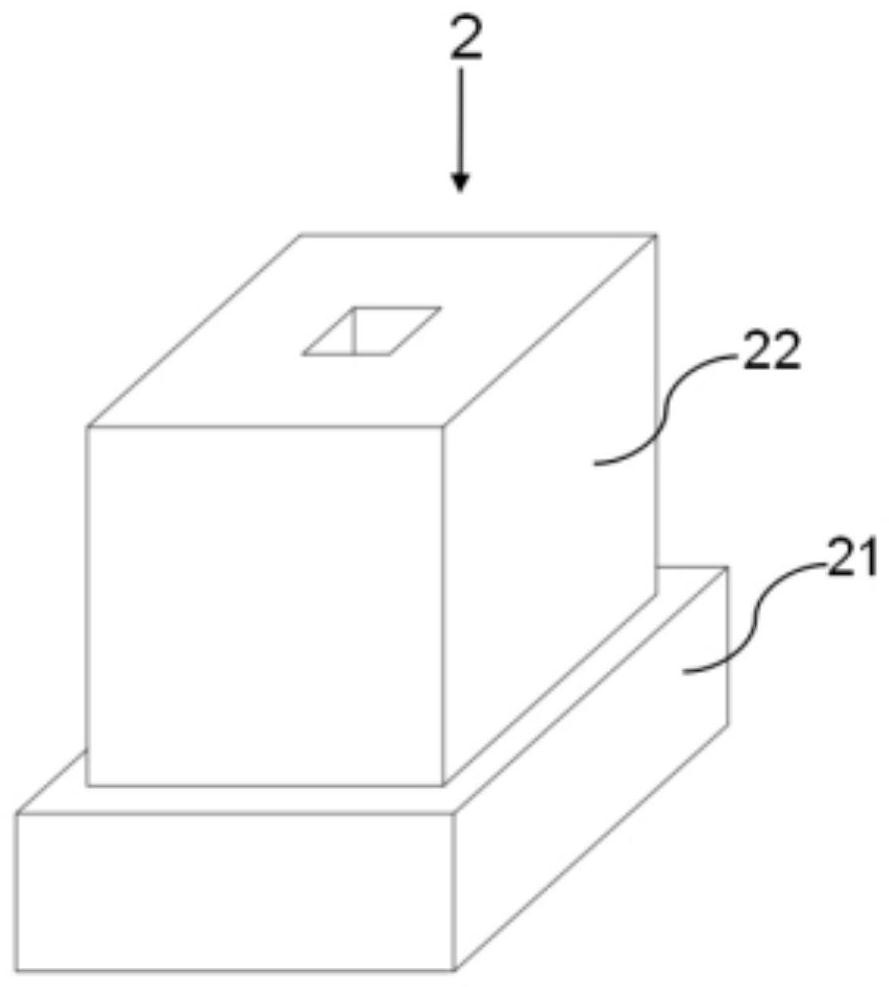

[0038] A method for installing a modular steel structure specifically includes the following steps:

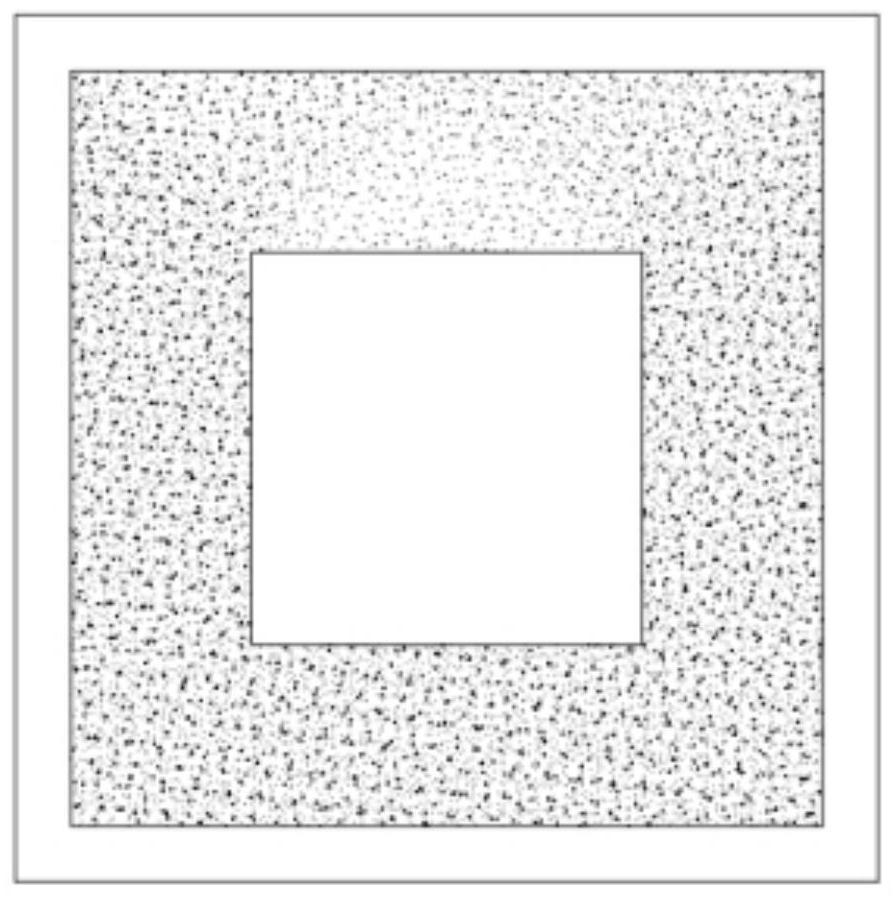

[0039] Step 1: Bind ground beam reinforcement and formwork on the foundation to obtain a plurality of foundation units.

[0040] Among them, the ground beam reinforcement includes multiple vertically interlaced steel bars. After being bundled, multiple horizontal steel cages parallel to each other and multiple vertical steel cages parallel to each other are obtained. .

[0041] Step 2. At the intersection of the foundation cells, bind the cup-mouth steel bars upward along the foundation and set up the formwork to obtain the cup-mouth reinforcement cage base and cup-mouth reinforcement cage connected together. The upper end of the cup-mouth reinforcement base and the ground beam reinforcement The upper surface of the ground beam is flush with the upper surface of the column foot and the cup mouth reinforcement cage extends upwards along the upper surface of the ground beam rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com