Round cloth telescopic pipe for ventilation and dust removal and manufacturing method of round cloth telescopic pipe

A production method and technology of telescopic pipes, which are applied in the directions of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as adverse effects on the health of construction workers, threats to people's lives and health, and large pipe diameters, and achieve flexible layout. , The effect of reducing the probability of causing disease and low cost of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

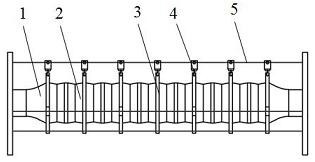

[0025] The invention provides a method for making a circular fabric telescopic tube for ventilation and dust removal, comprising the following steps:

[0026] (1) Prepare a rectangular main fabric 1 first, and then prepare several rectangular cloth strips 2. The materials of the main fabric 1 and the cloth strips 2 are all made of polyester, and the length of the cloth strips 2 is the same as that of the main fabric. The length of 1 is consistent; the length of described main cloth 1 is 160cm, and width is 150cm, and the length of described cloth strip 2 is 160cm, and width is 5cm;

[0027] (2) Sew one side of the long side of the cloth strip 2 to the long side of the main fabric, and not sew the long side of the other side of the cloth strip 2 temporarily;

[0028] (3) Repeat the operation in step (2) at intervals of 20 cm until the main fabric 1 is laid out with strips 2 along the longitudinal interval;

[0029] (4) Sew the short sides of both sides of the main fabric 1 cov...

Embodiment 2

[0032] The invention provides a method for making a circular fabric telescopic tube for ventilation and dust removal, comprising the following steps:

[0033] (1) Prepare a rectangular main fabric 1 first, and then prepare several rectangular cloth strips 2. The materials of the main fabric 1 and the cloth strips 2 are all made of nylon, and the length of the cloth strip 2 is the same as that of the main fabric. The length of 1 is consistent; the length of described main cloth 1 is 200cm, and width is 150cm, and the length of described cloth strip 2 is 200cm, and width is 6 cm;

[0034] (2) Sew one side of the long side of the cloth strip 2 to one side of the long side of the main fabric 1, and not sew the long side of the other side of the cloth strip 2 temporarily;

[0035] (3) Repeat the operation in step (2) at intervals of 15 cm until the main fabric 1 is laid out with strips 2 along the longitudinal interval;

[0036] (4) Sew the short sides of both sides of the main fa...

Embodiment 3

[0039] The invention provides a method for making a circular fabric telescopic tube for ventilation and dust removal, comprising the following steps:

[0040] (1) Prepare a rectangular main cloth 1 first, and then prepare several rectangular cloth strips 2, the materials of the main cloth 1 and the cloth strip 2 are all made of acrylic fiber, and the length of the cloth strip 2 is the same as that of the main cloth The length of 1 is consistent; the length of described main cloth 1 is 230cm, and width is 150cm, and the length of described cloth strip 2 is 230cm, and width is 7cm;

[0041] (2) Sew one side of the long side of the cloth strip 2 to one side of the long side of the main fabric 1, and not sew the long side of the other side of the cloth strip 2 temporarily;

[0042] (3) Repeat the operation in step (2) at intervals of 25 cm until the main fabric 1 is covered with strips 2 along the longitudinal interval;

[0043] (4) Sew the short sides of both sides of the main f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com