Drill rod straightness detection device and method

A detection device and straightness technology, applied in measurement devices, instruments, etc., can solve the problems of inaccurate data, difficult establishment of detection benchmarks, and lack of effective detection methods and devices, so as to ensure detection accuracy and strong engineering achievability. , The effect of efficient straightness detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

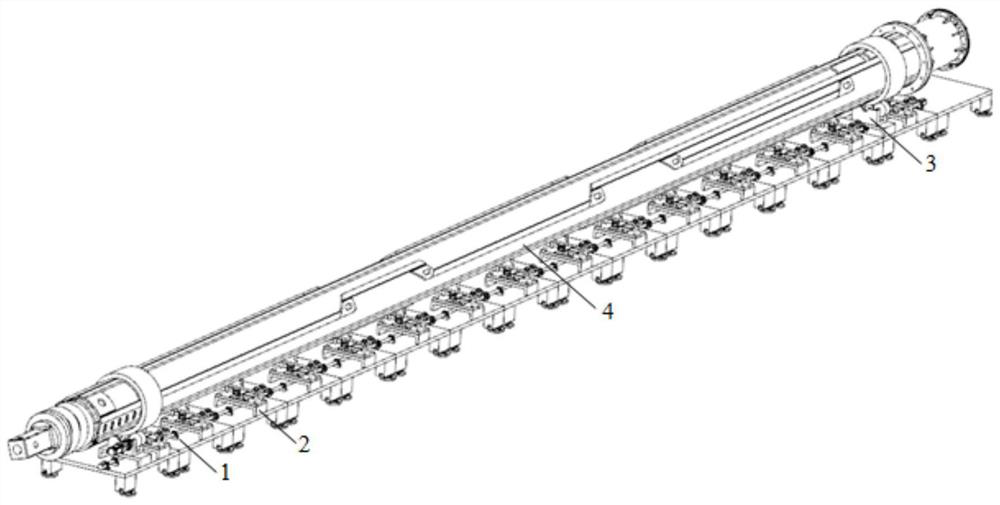

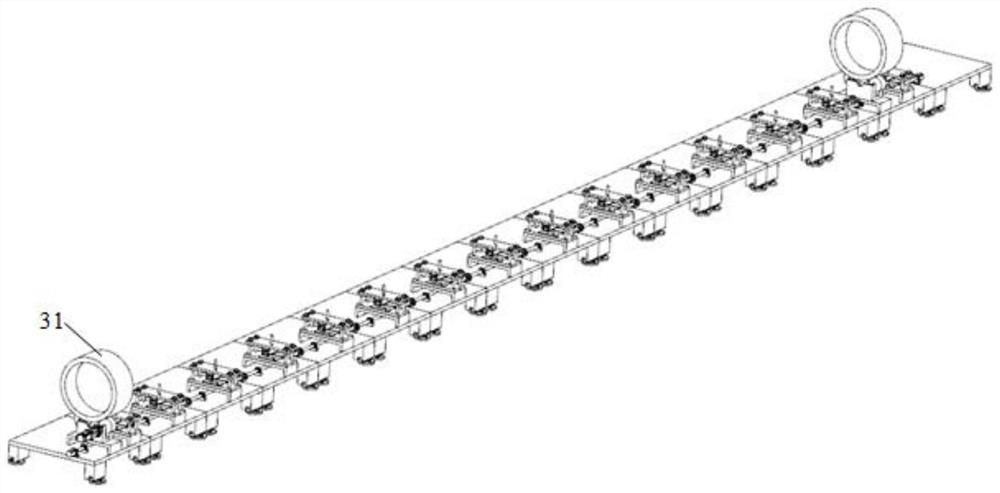

[0048] An embodiment of the present invention provides a drill pipe straightness detection device, such as Figure 1-7 As shown, it includes a first support mechanism 1, a second support mechanism 3 and a detection mechanism 2;

[0049] The second support mechanism 3 is connected to the first support mechanism 1, supported by the first support mechanism 1, and used to support the drill pipe 4 to be tested;

[0050] The detection mechanism 2 includes a drive unit and a spatial position information acquisition unit; the drive unit drives the spatial position information acquisition unit to rotate; the spatial position information acquisition unit is used to contact the drill pipe 4 to be measured, and collect the measured position in real time. Spatial position information of the drill pipe 4.

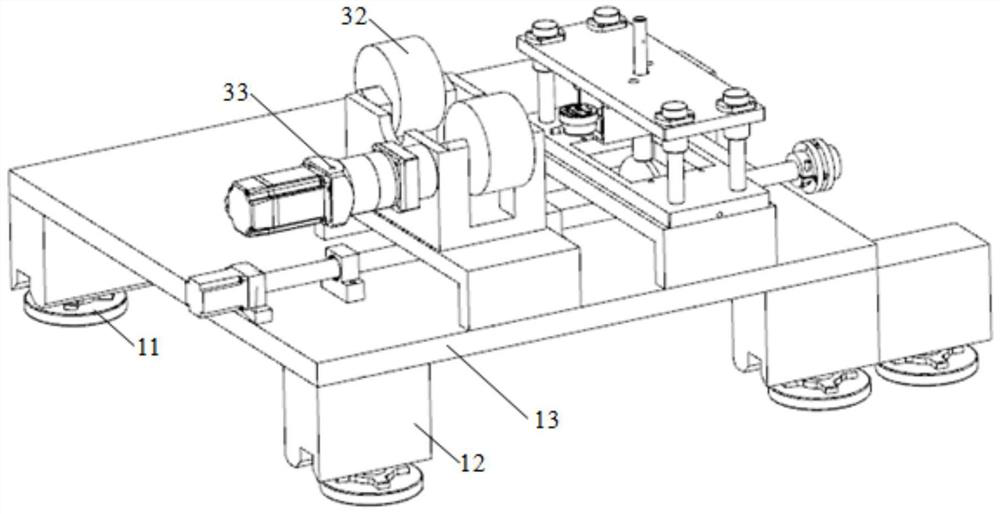

[0051] In a specific implementation manner of the embodiment of the present invention, such as Figure 4-5 As shown, the drive unit includes a drive motor 21, a connecting rod 22, a su...

Embodiment 2

[0080] A method for detecting the straightness of a drill pipe is provided in an embodiment of the present invention, comprising the following steps:

[0081] Utilizing the first supporting mechanism to support the second supporting mechanism, while using the second supporting mechanism to support the drill pipe to be tested;

[0082] Utilize the drive unit to drive the rotation of the spatial position information collection unit, and when the spatial position information collection unit turns to correspond to the non-line position of the drill pipe to be measured, control the spatial position information collection unit and the outer wall of the drill pipe to be measured Contact to collect the spatial position information of the drill pipe to be tested. .

[0083] The method in the embodiment of the present invention can be realized based on the straightness detection device of the drill pipe 4 in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com