Method and device for manufacturing multi-core optical fiber connector

A multi-core optical fiber and connector technology, applied in the field of multi-core optical fiber connector production, can solve the problems of low efficiency, dislocation of assembly and matching, and achieve the effect of firm fixation, reduction of matching dislocation, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

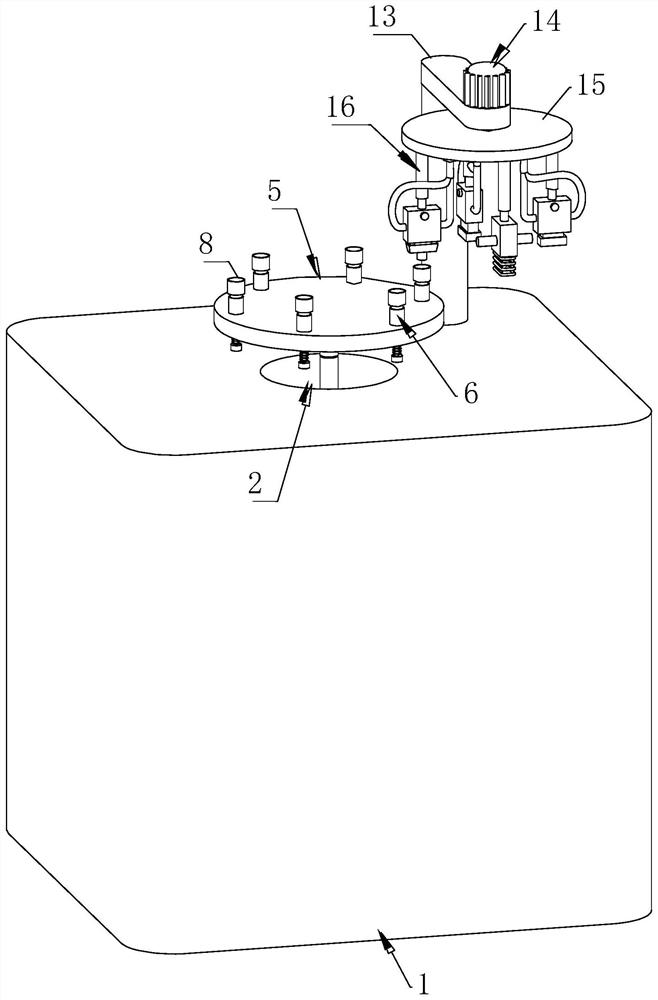

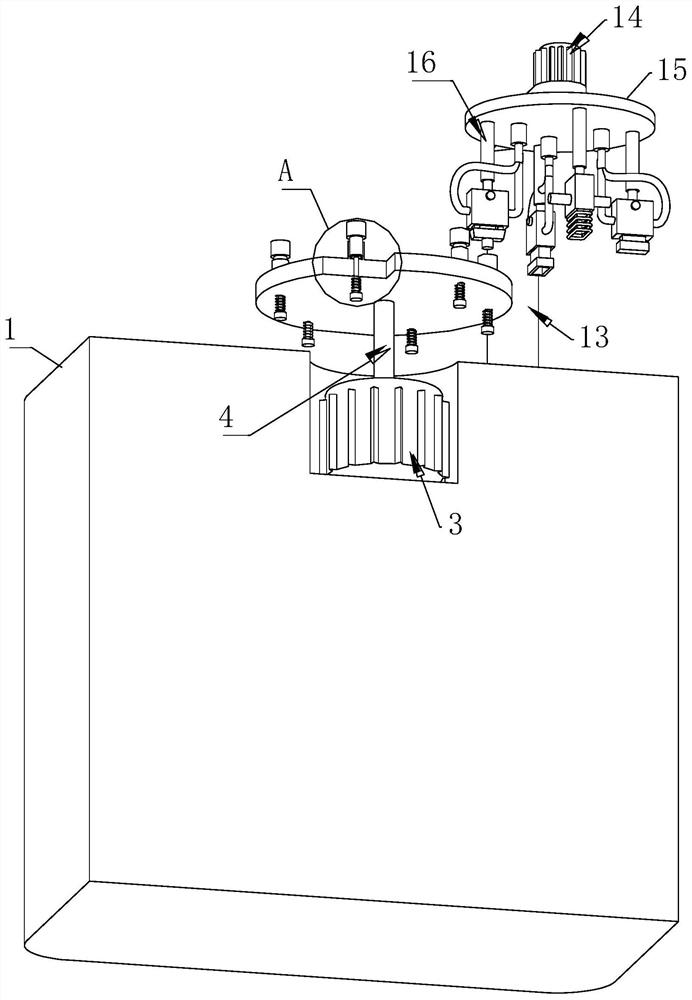

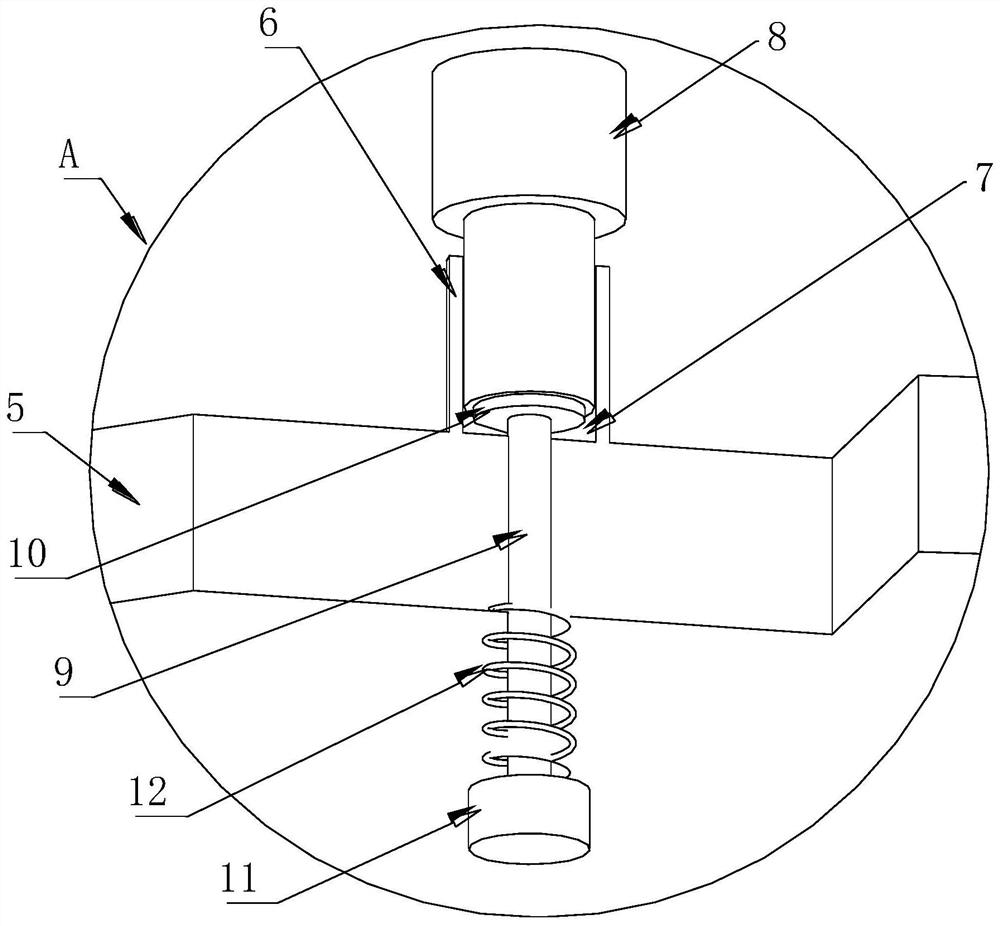

[0038] see Figure 1-6, a multi-core optical fiber connector manufacturing equipment, used to manufacture connectors including a beam ring 8, a spring seat 19, a spring 31, an optical fiber sleeve 32, and a housing 33, the equipment includes a host 1, a beam ring 8, The spring seat 19, the spring 31, the optical fiber sleeve 32, and the housing 33 are assembled into a connector in sequence. A control module is arranged inside the host 1, which can control the operation of the entire device. A first stepping motor 3 is fixedly connected, the output end of the first stepping motor 3 is fixedly connected with a rotating shaft 4, and the top of the rotating shaft 4 extends to the outside of the drive slot 2 and is fixedly connected with a first turntable 5, on which a first turntable 5 is arranged. A positioning mechanism, the top of the host 1 is fixedly connected to the L-shaped support arm 13, and one end of the top of the L-shaped support arm 13 is fixedly connected to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com