Storage battery acid adding and vacuum formation system and method capable of automatically discharging acid

A storage battery and vacuum technology, applied in the direction of lead-acid battery, lead-acid battery construction, battery pack components, etc., can solve the problems such as the inability to add acid to the consistency of formation, and the inability to use vacuum formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

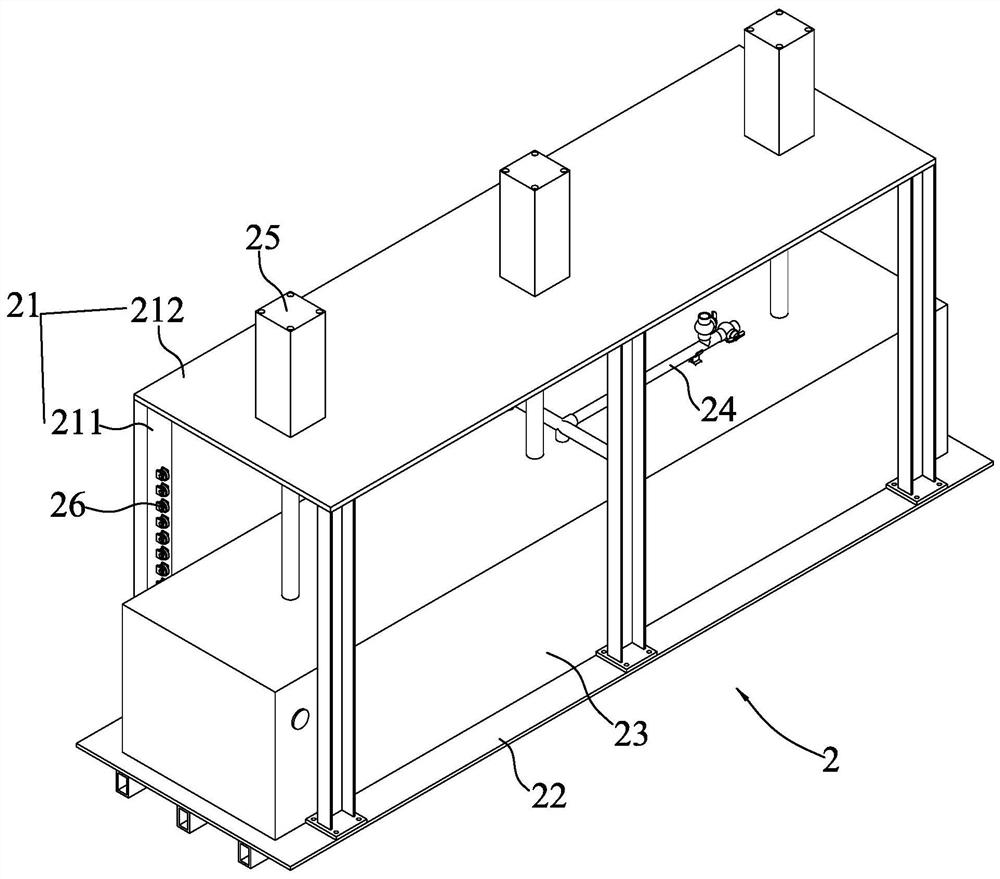

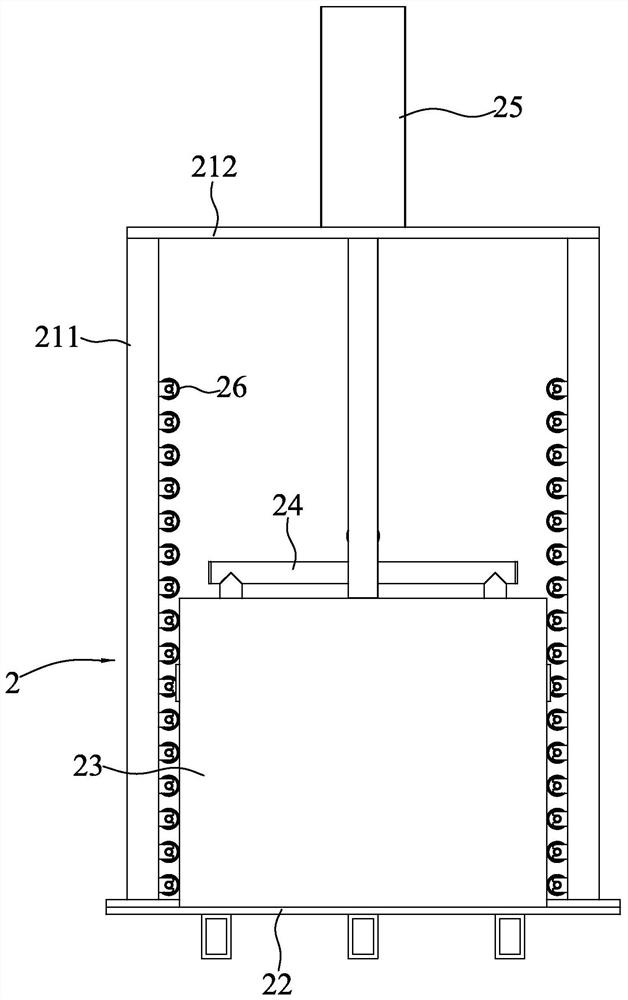

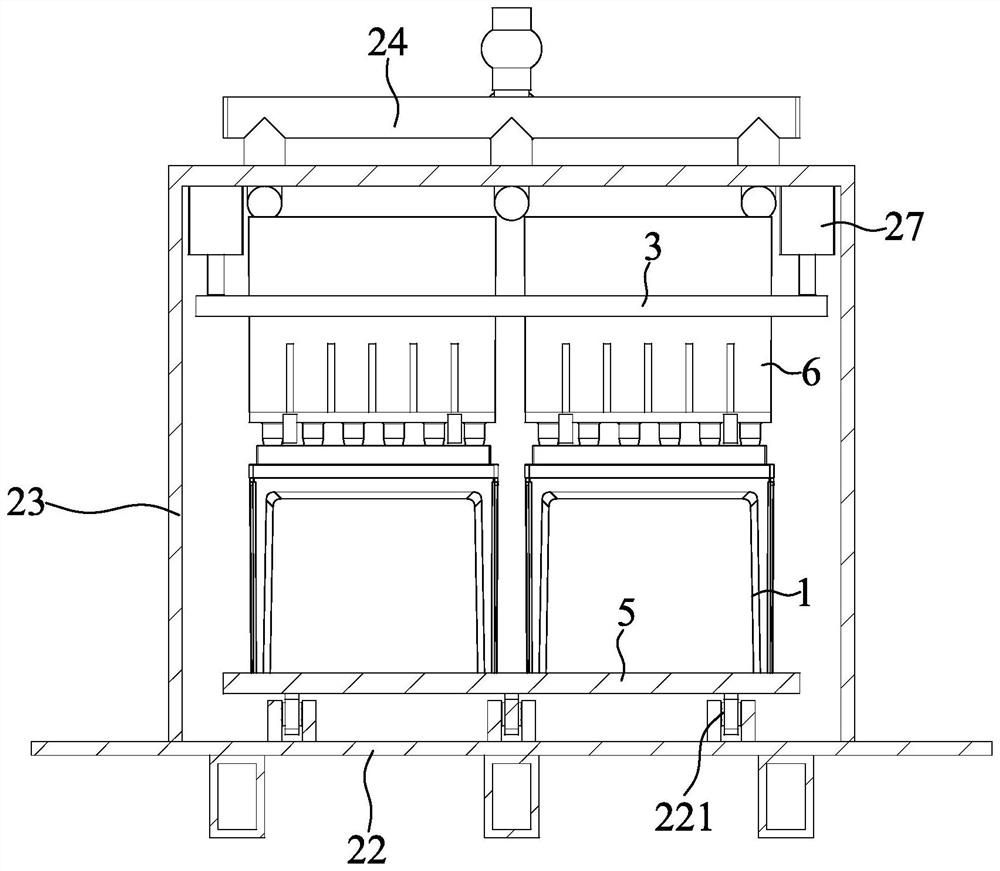

[0065] Such as Figure 1~3 As shown, an automatic battery acid addition and vacuum formation system is used for simultaneous quantitative addition of acid to a batch of batteries 1 at the same time, and vacuum formation after acid addition. The accumulator acid adding and vacuum forming system for automatic acidification of the present invention includes a vacuum forming box 2, the vacuum forming box 2 includes a support 21, a bottom plate 22 and a sealing cover 23, and the bottom plate 22 is used to place the accumulator 1 to be added and formed, the support 21 is disposed on the bottom plate 22 , the bracket 21 includes a plurality of columns 211 surrounding the outer periphery of the sealing cover 23 , and a top plate 212 supported by each column 211 . The sealing cover 23 is arranged on the bracket 21 in a liftable manner, and when the sealing cover 23 is closed with the bottom plate 22, the inner cavity of the vacuum formation box 2 is formed. For the convenience of obse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com