Quantitative sampling filling device and method for quantitative sampling filling using the same

A filling device and liquid mixing technology, which is used in laboratory containers, chemical instruments and methods, measuring tubes/pipettes, etc., can solve the problems of inconvenience of carrying, easy pollution, and high requirements for environmental cleanliness, and reduce detection and detection. Failure and misoperation, easy to carry and store, improve the effect of using experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

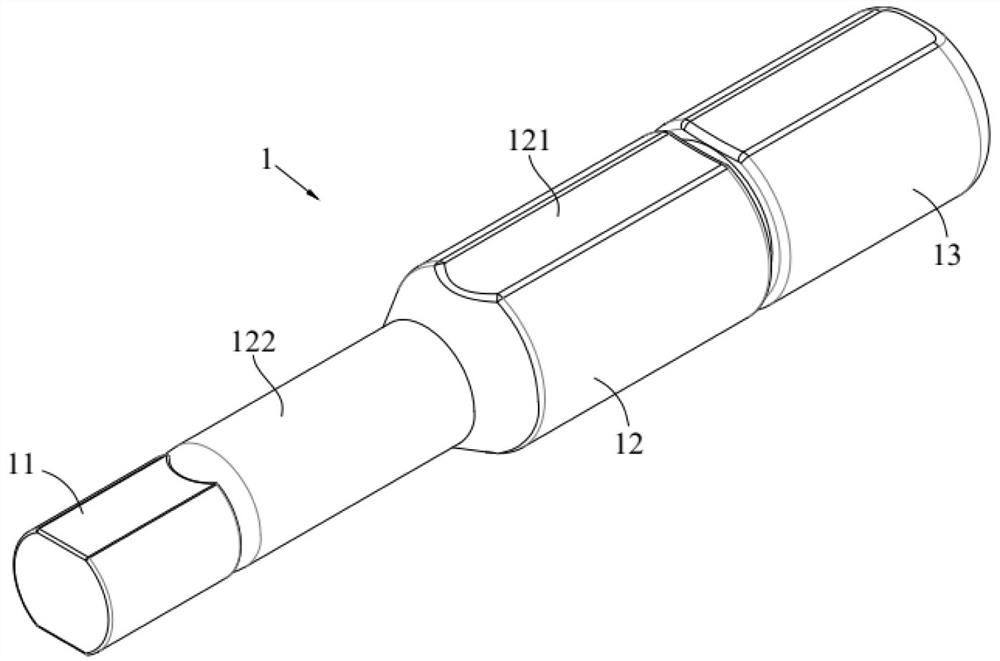

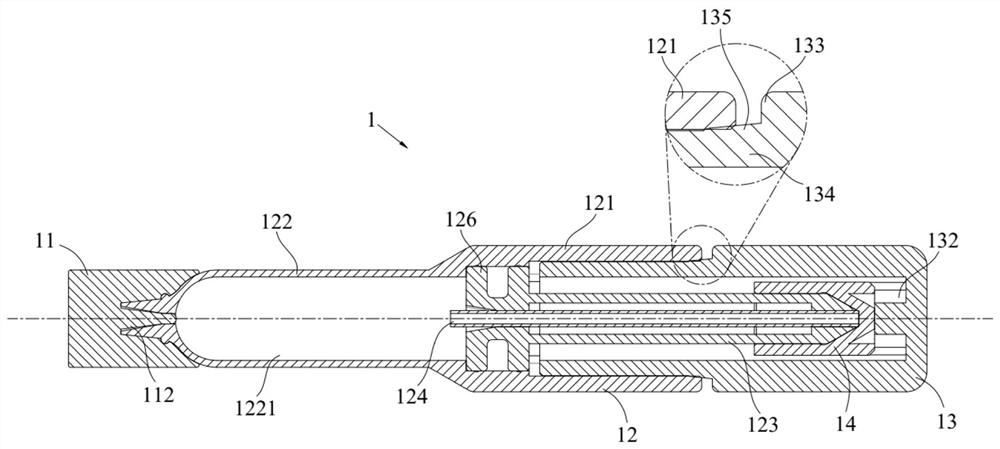

[0078] Figure 1~Figure 3 Embodiment 1 of the present invention is shown, and it can be seen that the quantitative sampling filling device 1 includes:

[0079] The outer tube 12, which includes a guiding tube 121 defining a guiding cavity 1211 and a mixing tube 122 defining a mixing cavity 1221, the guiding cavity 1211 communicating with the mixing cavity 1221;

[0080] Inner tube 123, which has a proximal end 126 and a distal end 1231, at least part of the inner tube 123 is installed in the guide cavity 1211, the proximal end 126 of the inner tube 123 is opposite to the end of the guide cavity 1211 Blocking to isolate the guiding cavity 1211 from the mixing cavity 1221; and

[0081] A capillary tube 124, which extends axially from the distal end 1231 to the proximal end 126 inside the inner tube 123, and the liquid mixing chamber 1221 communicates with the outside through the capillary tube 124;

[0082] Wherein, the liquid mixing tube 122 is provided with a liquid outlet 1...

Embodiment 2

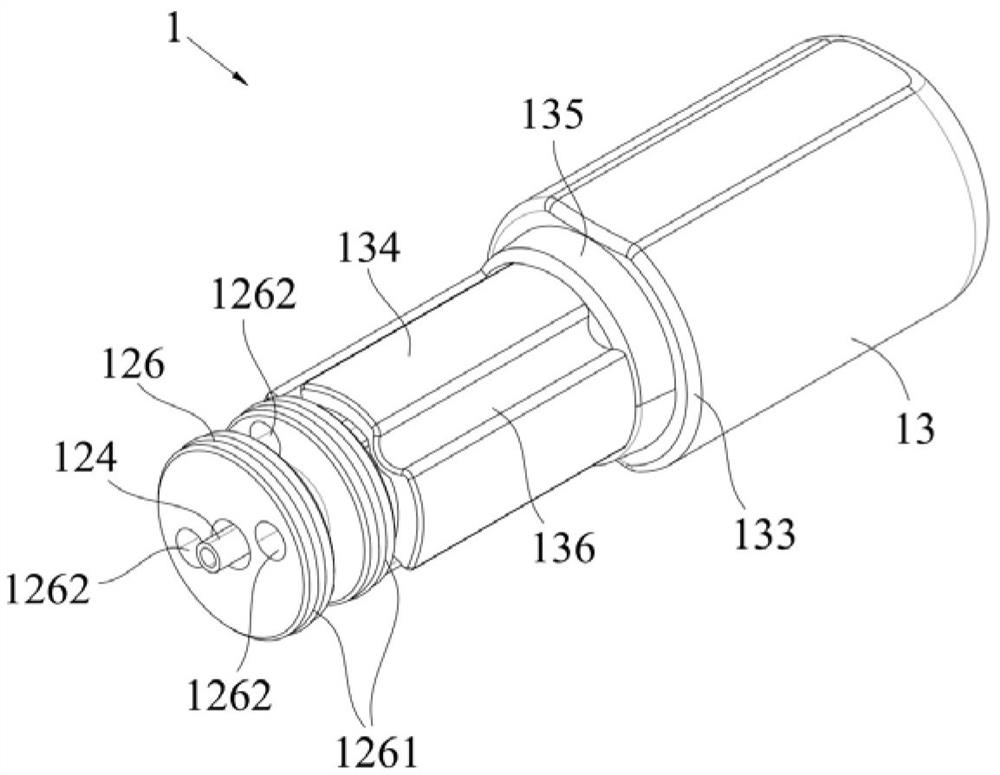

[0108] Figure 4 Embodiment 2 of the present invention is shown. The difference between embodiment 2 and embodiment 1 is that: the outer surface of the side wall 134 of the docking pipe 13 is provided with at least one ventilation groove 136, and the ventilation groove 136 is connected from the docking port. 132 extends along the outer surface of the butt joint 13 toward the other end of the butt joint 13 . exist Figure 4 In the illustrated embodiment, the ventilation groove 136 extends linearly along the axis of the butt joint 13 . In another embodiment, the ventilation groove 136 extends in a spiral shape around the axis of the butt joint 13 . In yet another embodiment, the ventilation groove 136 extends in a wave shape around the axis of the butt joint 13 .

[0109] As a further improvement, the gap passage is at least one ventilation groove opened on the side wall of the guide cavity 1211, and the ventilation groove starts from the partition assembly along the side wal...

Embodiment 3

[0115] Embodiment 3 discloses a method for quantitative sampling and filling using a quantitative sampling and filling device, comprising the following steps:

[0116] Step S1, refer to Figure 1~Figure 3 , provide a certain amount of sampling and filling device, said quantitative sampling and filling device includes: outer tube 12, which includes a guide tube 121 that defines a guide cavity 1211 and a mixed liquid tube 122 that defines a mixed liquid cavity 1221, said guide The chamber 1211 communicates with the liquid mixing chamber 1221, and the liquid mixing pipe 122 is provided with a liquid outlet 1222 communicating with the liquid mixing chamber 1221;

[0117] Inner tube 123, which has a proximal end 126 and a distal end 1231, at least part of the inner tube 123 is installed in the guide cavity 1211, the proximal end 126 of the inner tube 123 is opposite to the end of the guide cavity 1211 Blocking to isolate the guiding cavity 1211 from the mixing cavity 1221; and

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com