Hand-held reinforcing steel bar hoop bending and straightening machine for building and use method thereof

A technology for steel bar bending hoops and construction. It is applied in the field of hand-held steel bar bending hoop straightening machines for construction. It can solve the problems of labor and efficiency, lack of straightness, and affecting work efficiency, so as to increase stability and prevent overturning. The effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

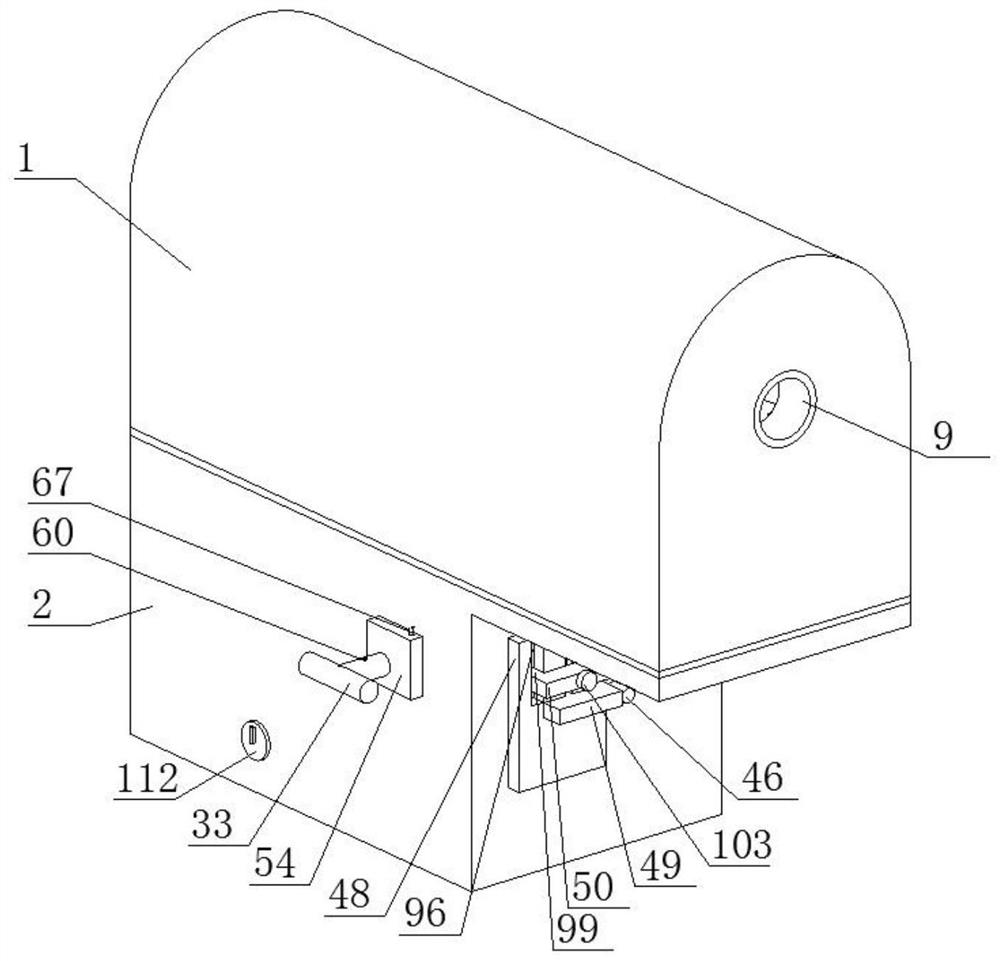

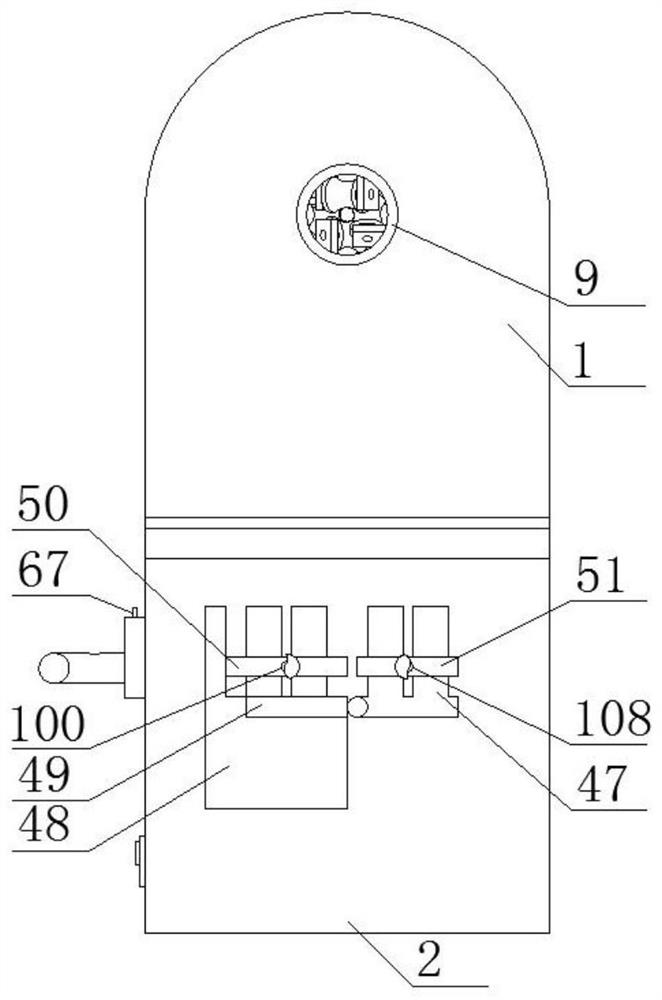

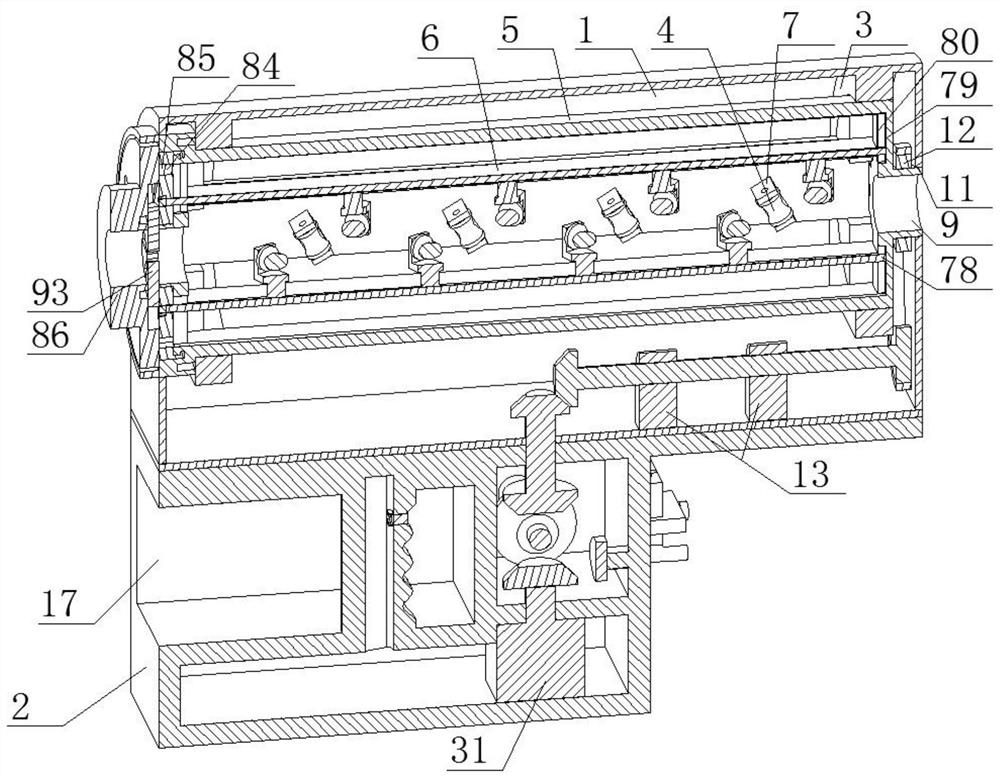

[0031] Refer to attached Figure 1-7 Shown: a hand-held steel bar hoop straightening machine for construction, including an upper casing 1 and a lower casing 2, the lower casing 2 is fixedly installed on the left side of the lower end of the upper casing 1, and the upper casing 1 The left and right sides are all provided with a limit fixed plate 3, and the inside of the limit fixed plate 3 is connected with a straightening device. The straightening device includes a runner 4, a straightening frame 5, and a runner plate 6. The straightening The frame 5 is rotatably connected in the limit fixing plate 3, and the upper side, the lower side, the front side and the rear side of the straightening frame 5 are equipped with a runner plate 6, and the runner plate 6 is fixed on one end towards the center. Several first runner fixing blocks 7 are connected, and the first runner fixin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap