Organic-inorganic nano composite particle as well as preparation method and application thereof

A technology of inorganic nano and composite particles, applied in the field of polymer materials, can solve the problems of complicated operation procedures and difficult separation of organic-inorganic composite nanoparticles, and achieve the effect of high solid content, strong versatility and clean system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

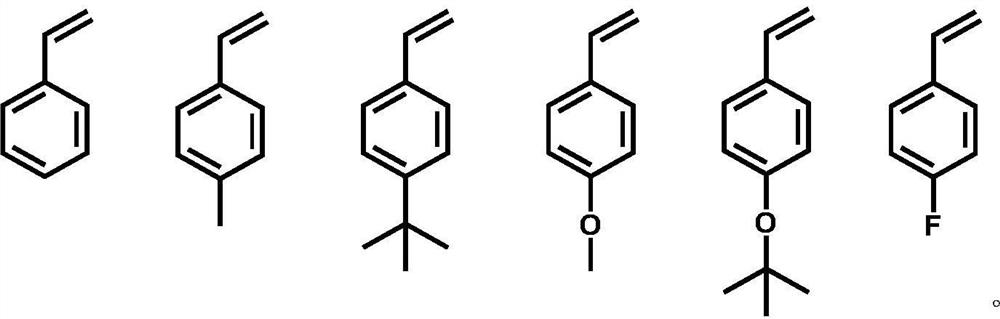

Method used

Image

Examples

Embodiment 1

[0046] Fe 3 O 4 Preparation of @polyisoprene-b-poly(4-vinylpyridine) nanocomposite particles

[0047] Preparation of S1 polyisoprene macroinitiator

[0048] First, 62.5mL of toluene (54.35g), 7.3mL of tetrahydrofuran (6.52g), and 9.4mL of isoprene (6.40g) were poured into a dry and clean 250mL ampoule bottle in turn, placed in an ice-water bath to start stirring, and filled with Then, 1.0 mL of n-butyllithium (1.60 mmol / mL) was quickly poured into the ampoule, and the reaction was carried out for 30 min to obtain the macromolecular initiator PI. M n,SEC =5,500g / mol,M w / M n =1.11.

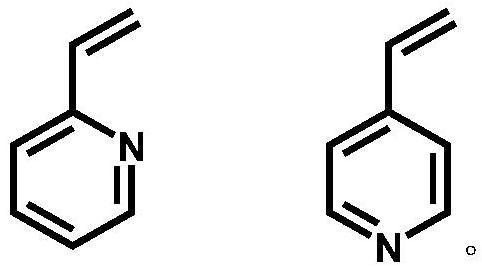

[0049] Preparation of S2 polyisoprene-b-poly(4-vinylpyridine) block polymer nanoparticle self-assembled

[0050] First, a mixture of 5.0 mL of toluene (4.40 g) and 0.9 mL of diphenylethylene (1.15 g) was added to the above-mentioned ampoule bottle containing the polyisoprene macroinitiator, the reaction system immediately turned red, and the reaction continued to be stirred. 20min. Then, 5...

Embodiment 2

[0056] Preparation of NiO@polybutadiene-b-poly(2-vinylpyridine) nanocomposite particles

[0057] The isoprene monomer in Example 1S1 was replaced with butadiene, the 4-vinylpyridine monomer in Example 1S2 was replaced with 2-vinylpyridine, the FeCl in Example 1S4 was replaced with 2 , FeCl 3 The NiO@polybutadiene-b-poly(2-vinylpyridine) nanocomposite particles can be prepared by replacing with 0.6217g nickel nitrate hexahydrate, passing hydrogen into it and reducing at 200°C for 5h, and other steps are the same as those in Example 1.

Embodiment 3

[0059] TiO 2 Preparation of @polymyrcene-b-poly(4-vinylpyridine) nanocomposite particles

[0060] The isoprene monomer in Example 1S1 was replaced with myrcene, and the FeCl in Example 1S4 was replaced by 2 , FeCl 3 Replace with 0.3163g of titanium tetraisopropoxide (TTIP), replace the ammonia water with 1ml of ethylene glycol, heat at 180°C for reduction for 2h, and the other steps are the same as in Example 1, to prepare TiO 2 @Polymyrcene-b-poly(4-vinylpyridine) nanocomposite particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com