Four-connecting-rod two-oil-cylinder single-side movable arm structure of skid steer loader and lifting method

A skid steer loader and four-bar linkage technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problem of low work efficiency and failure to fully utilize the vertical lifting working device function, the long stroke of the boom, etc., to achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

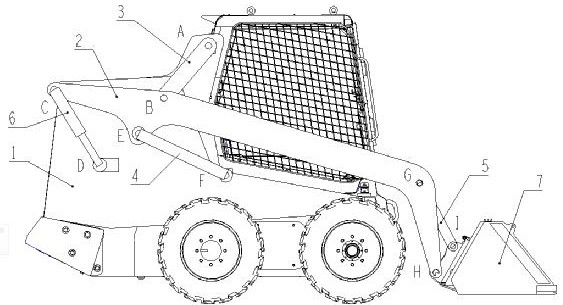

[0025] combine figure 1 As shown, a four-link two-cylinder skid steer loader unilateral boom structure includes a frame 1, a boom 2, a connecting rod 3, a boom cylinder 4, a dump cylinder 5, a conversion cylinder 6, and a bucket 7 . The boom 2 is hinged to the conversion cylinder 6 at point C, the boom 2 and the boom cylinder 4 are hinged at point E, the boom 2 and the connecting rod 3 are hinged at point B, the boom 2 and the bucket cylinder 5 are hinged at point G, and Arm 2 and bucket 7 are hinged at point H. Transformation cylinder 6 and frame 1 are hinged at point D; boom cylinder 4 and frame 1 are hinged at point F; connecting rod 3 and frame 1 are hinged at point A; dump cylinder 5 and bucket 7 are hinged at point I. The boom 2, the connecting rod 3, the conversion cylinder 6 and the dump cylinder 5 are located on the same side of the vehicle frame 1, so that the number of the boom lifting cylinders is still two, which avoids increasing the cost.

[0026] In this emb...

Embodiment 2

[0029] A lifting method, the skid steer loader uses a four-link two-cylinder skid steer loader unilateral boom structure in the embodiment;

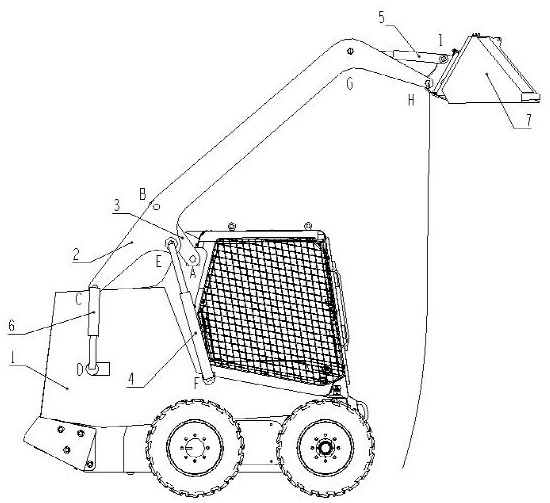

[0030] like figure 2 As shown, when vertical lifting is required: the conversion cylinder 6 is kept in a high-pressure tension state, and the conversion cylinder 6 is at the maximum stroke position, so that the skid steer loader can complete the vertical lifting work;

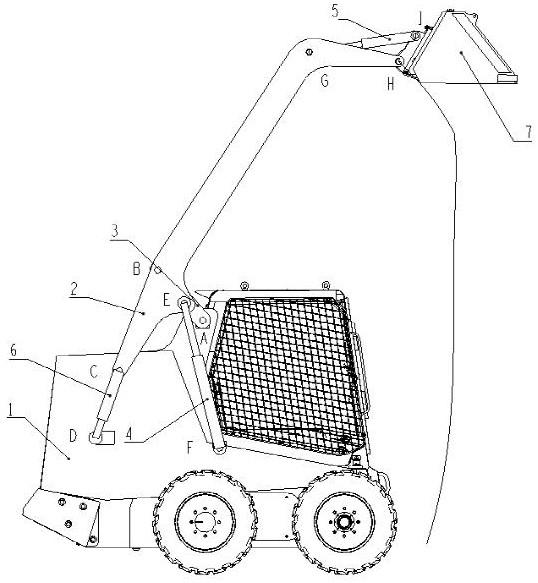

[0031] like image 3 As shown, when a larger unloading height is required: after the boom 2 is lifted to the highest position, the control conversion cylinder 6 shrinks, so that the boom 2 continues to lift to achieve a higher unloading height;

[0032] like Figure 4 As shown, when there is no need for vertical lifting: control the conversion cylinder 6 and the boom cylinder 4 to contract simultaneously, which can make the lifting speed faster and complete the lifting operation more efficiently; the operating speed ratio of the conversion cylinder 6 and the boom cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com