Mounting structure of fabricated ceiling

An installation structure and assembly technology, applied in the direction of ceilings, building components, building structures, etc., can solve problems such as drumming and surface shedding, and achieve the effect of enhancing friction and avoiding vertical light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

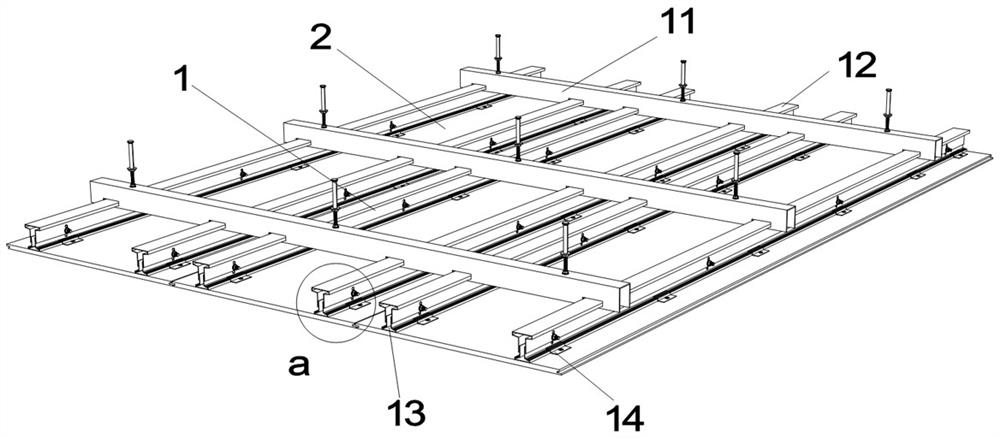

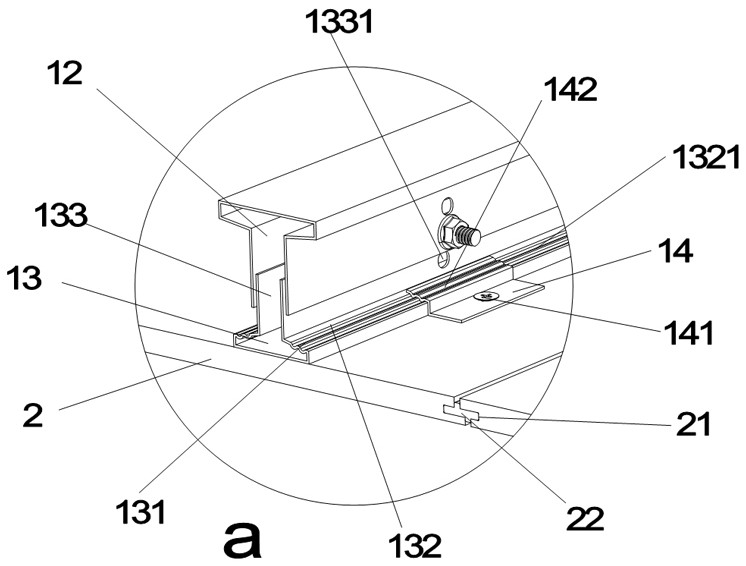

[0029] An installation structure for a prefabricated suspended ceiling, comprising a keel assembly 1 and a ceiling panel 2 fixed on the keel assembly 1, the keel assembly 1 includes a main keel 11 for fixing to the ceiling, and the main keel 11 is clamped The clamping sub-keel 12 connected together and the hoisting sub-keel 13 cooperating with the snap-fitting sub-keel 12, the ceiling panel 2 is fixedly connected with the hoisting sub-keel 13 through several fixing pieces 14, so The two sides of the hoisting auxiliary keel 13 are respectively provided with limiting parts 131, and the said limiting part 131 is an inclined surface 132 with an inclination angle of 5-30°, and said inclined surface 132 is horizontally provided with strip-shaped convex surfaces and strips. Reinforcing areas 1321 composed of alternating concave surfaces; the fixing member 14 has a fixing portion 141 for fixing to the ceiling panel 2 and an abutting portion 142 that fits with the limiting portion 131 ....

Embodiment 2

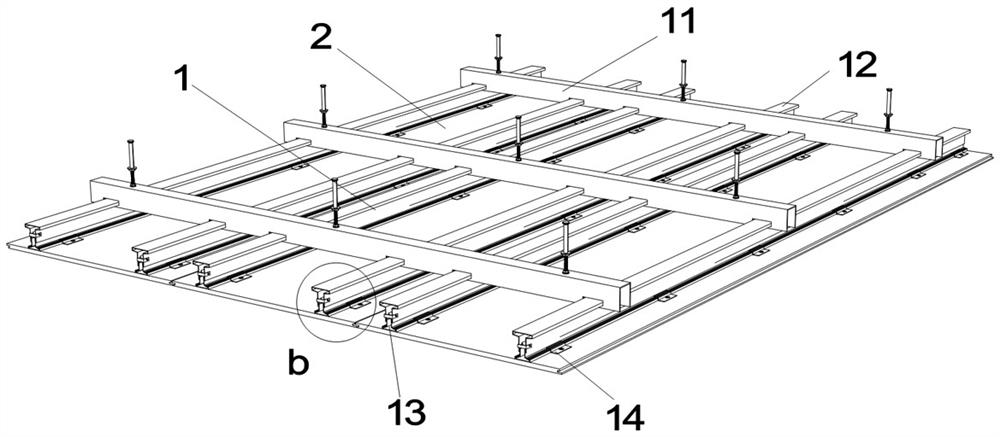

[0039] An installation structure for a prefabricated suspended ceiling, comprising a keel assembly 1 and a ceiling panel 2 fixed on the keel assembly 1, the keel assembly 1 includes a main keel 11 for fixing to the ceiling, and the main keel 11 is clamped The clamping sub-keel 12 connected together and the hoisting sub-keel 13 cooperating with the snap-fitting sub-keel 12, the suspended ceiling panel 2 is fixedly connected with the hoisting sub-keel 13 through several fixing pieces 14, which The feature is that the two sides of the hoisting auxiliary keel 13 are respectively provided with limiting portions 131, the limiting portion 131 is an inclined surface 132 with an inclination angle of 5-30°, and the inclined surface 132 is horizontally provided with strips Reinforcing area 1321 composed of alternating convex surfaces and concave strips; the fixing member 14 has a fixing part 141 for fixing to the ceiling panel 2 and an abutting part 142 that fits with the limiting part 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com