Ultrahigh-damping rubber support base and manufacturing method thereof

A technology of damping rubber and high-elastic rubber, which is applied in flat products, other household appliances, building components, etc., can solve the problems of restricted support areas, hidden dangers of environmental pollution, poor energy consumption, etc., and achieve a wide range of adjustments , Wide range of applications, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

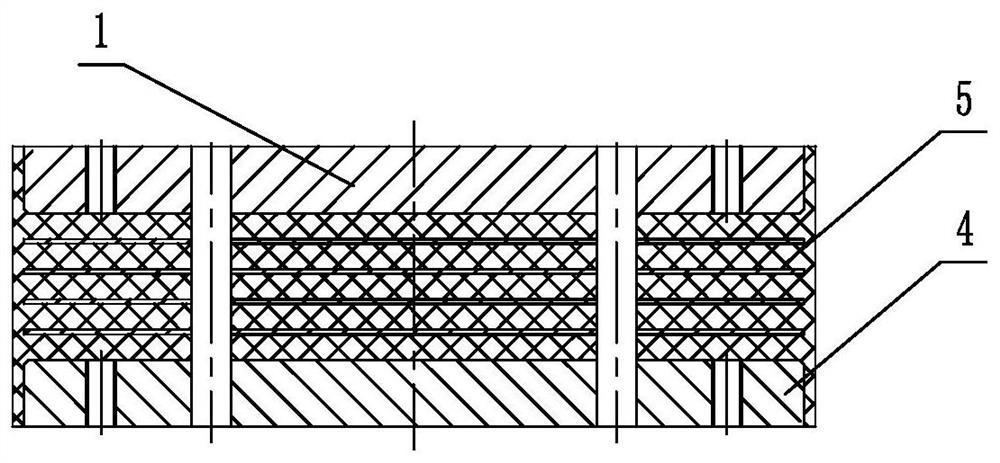

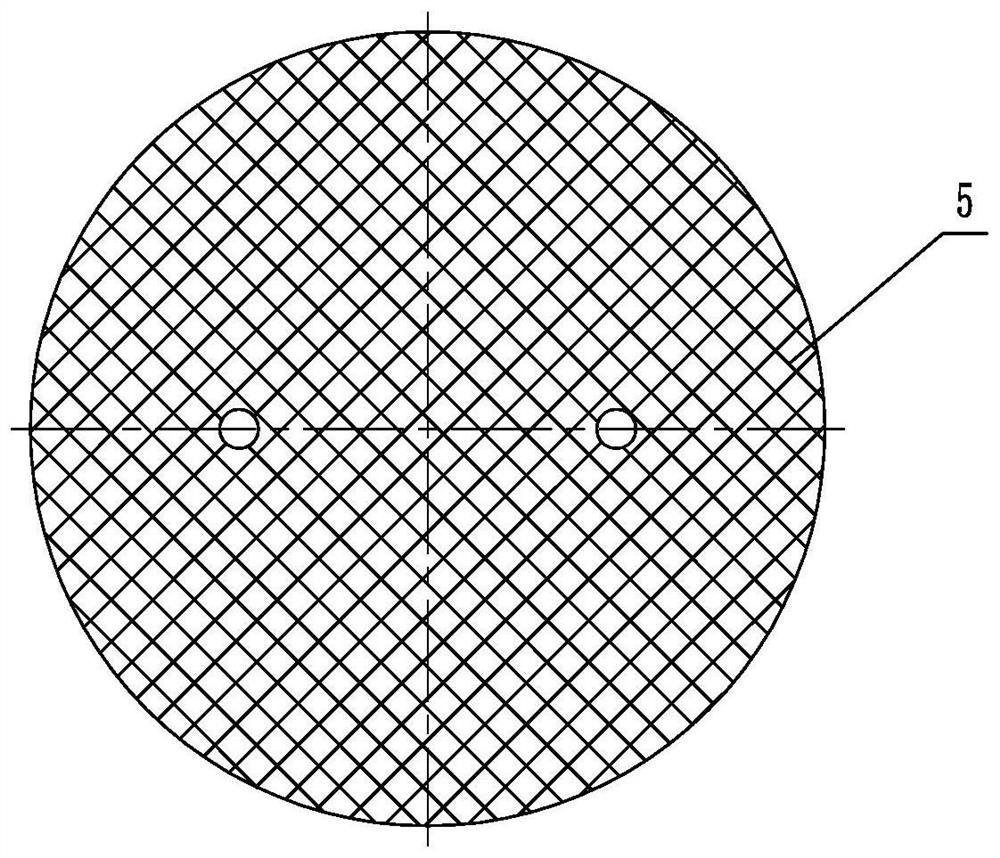

[0084] An ultra-high damping rubber bearing, including a rubber bearing body formed by alternate lamination and vulcanization of inner connecting steel plates (including upper inner connecting steel plates 1 and lower upper inner connecting steel plates 4), rubber sheets and stiffening steel plates. The sheet is a composite rubber sheet composed of an intermediate rubber layer and a cover layer covering the outer periphery of the intermediate rubber layer; the composite rubber sheet is a composite rubber sheet I, and the intermediate rubber layer is rubber A—high energy-dissipating damping rubber. The covering layer is rubber B—high elastic rubber (see attached Figure 5 ); the composite rubber sheet I has only one cover layer, and the volume of the high-elastic rubber accounts for 5% to 90% of the total volume of the rubber sheet;

[0085] Described rubber A—high energy consumption damping rubber, its composition is by weight:

[0086] 30~60 parts of natural rubber, 20~40 pa...

Embodiment 2

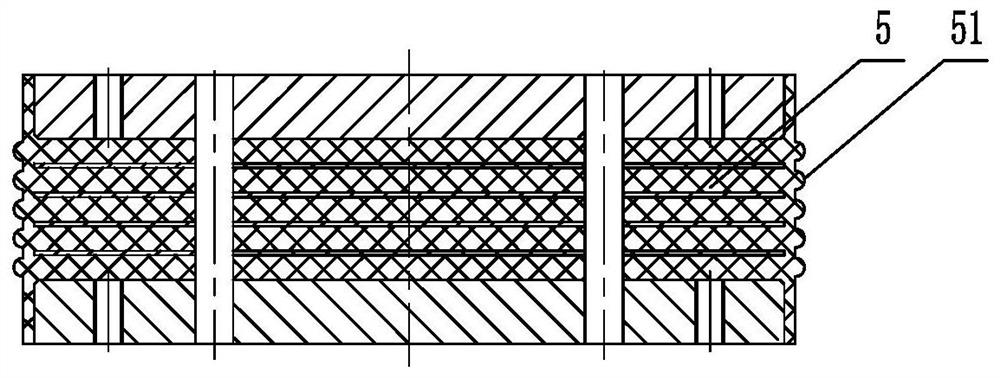

[0096] An ultra-high damping rubber bearing, the composition of the rubber A—high energy-dissipating damping rubber and the rubber B—high elastic rubber is the same as that of Embodiment 1, and its structure is basically the same as that of Embodiment 1, including internally connected steel plates, The rubber bearing body is formed by alternate lamination and vulcanization of rubber sheets and stiffened steel plates. The rubber sheet is a composite rubber sheet composed of an intermediate rubber layer and a rubber covering layer covering the outer periphery of the intermediate rubber layer. The composite rubber sheet is Composite rubber sheet I, the difference is: the middle rubber layer is rubber A, and the covering layer is 3 layers (that is, M=3). Rubber B and rubber A are staggered from the inside to the outside, in order: the first layer The covering layer is rubber B, the second covering layer is rubber A, and the third covering layer is rubber B (see attached Image 6 )...

Embodiment 3

[0111] A preparation method of an ultra-high damping rubber bearing, comprising the steps of:

[0112] S1 Preparation of high energy consumption damping rubber blank film

[0113] S11 preparation of masterbatch:

[0114] S111 is prepared according to the following parts by weight:

[0115] 30~60 parts of natural rubber, 20~40 parts of neoprene rubber, 10~30 parts of nitrile rubber, 15~40 parts of chlorinated butyl rubber, 2~40 parts of damping reinforcement material, 10~100 parts of filler, anti-aging agent 4 ~12 servings;

[0116] S112 Put the above materials into the internal mixer for mastication, slowly increase the pressure of the top bolt on the internal mixer, stir for 1 to 20 minutes to remove the glue, cool and place for more than 1 hour for use;

[0117] S12 Preparation of rubber compound:

[0118] S121 Put 120-220 parts of the above-mentioned cooled and ready-to-use masterbatch into the internal mixer, slowly increase the top bolt pressure on the internal mixer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com