Method and device for measuring and calculating heat leakage of intermediate joint of superconducting cable

A technology for intermediate joints and superconducting cables, applied in measuring devices, usage of superconducting elements, calculations, etc., can solve problems affecting the electrical characteristics of superconducting cables, blank stages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

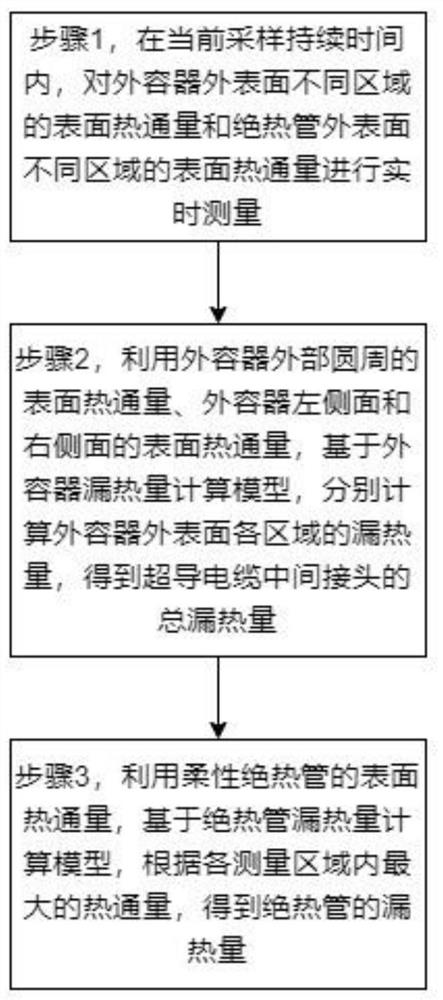

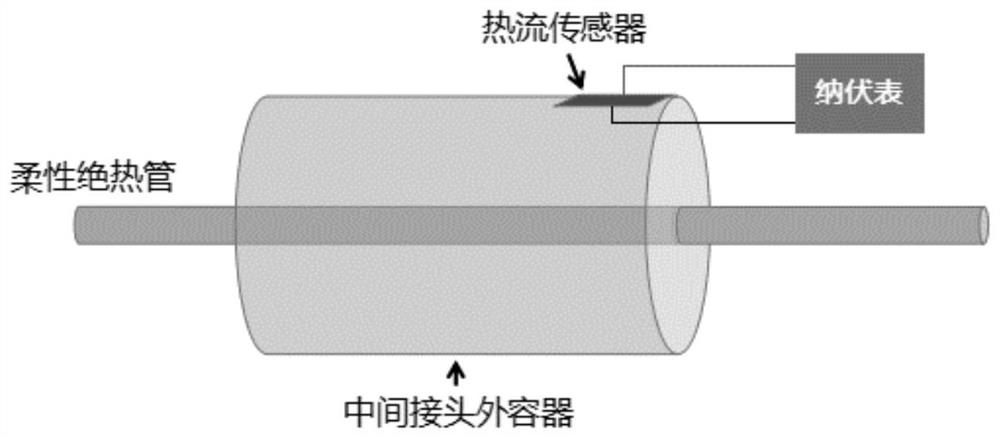

[0089] The intermediate joint of the superconducting cable runs through the flexible heat-insulated pipe and is located in a double-layer low-temperature constant temperature container, such as figure 1 , the heat leakage measurement and calculation method of the intermediate joint of the superconducting cable are as follows:

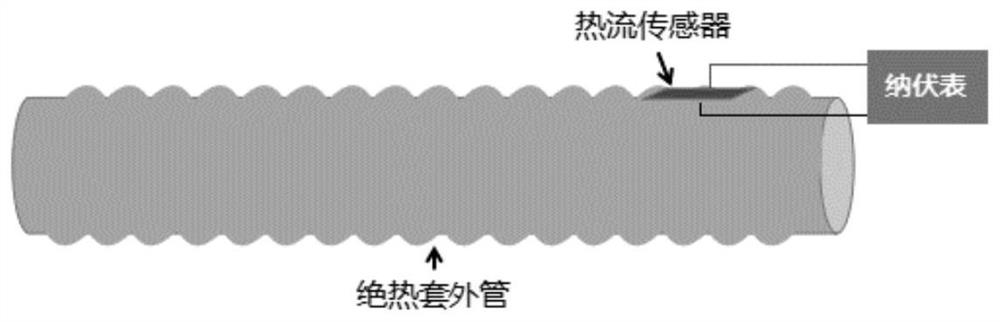

[0090] Step 1. During the current sampling duration, the surface heat flux of different areas on the outer surface of the outer container and the surface heat flux of different areas on the outer surface of the adiabatic tube are measured in real time: from the left side of the inner and outer container of the cryogenic constant temperature container to the right side surface, in the direction of the axis of the outer container, at intervals of a certain horizontal distance, collect the surface heat flux of the outer container along the outer circumference of the outer container, and collect the surface heat flux of the left and right sides of the outer ...

Embodiment 2

[0157] The present invention takes the type sample superconducting cable system as an example, and explains in detail the measurement and calculation method of the leakage heat of the middle joint of the superconducting cable when the system connected to the sample cable is in normal operation.

[0158] The measured heat flux of each detection point on the surface of the outer container is shown in Table 1 and Figure 4 , see Table 2 and Figure 5 .

[0159] Table 1 The heat flux of each detection point on the surface of the outer container of the superconducting cable intermediate joint

[0160] Figure 4 Middle detection point position heat flux symbol Measured value of heat flux (W / m 2 )

Right q c11

13 upper right q c7

8.8 middle right q c8

8.8 bottom right q c9

9.8 upper middle q c4

7.6 middle side q c5

7.6 middle and lower q c6

8.2 upper left q c1

10.4 middle left q c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com