Device and method for detecting residual stress on inner wall of turning pipeline based on magnetoelastic effect

A residual stress and detection device technology, which is applied in the direction of measuring device, measurement of the change force of material magnetic properties caused by applied stress, force/torque/power measuring instrument, etc., can solve the problem of complex structure, large module or volume, Limit small-diameter pipeline detection and other problems, achieve the effect of low working environment requirements, accurate detection results, and broaden the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides an inner wall residual stress detecting device based on a magnetic bulge effect.

[0038] In the first aspect, the present invention provides an inner wall residual stress detecting apparatus based on a magnetic bulge effect.

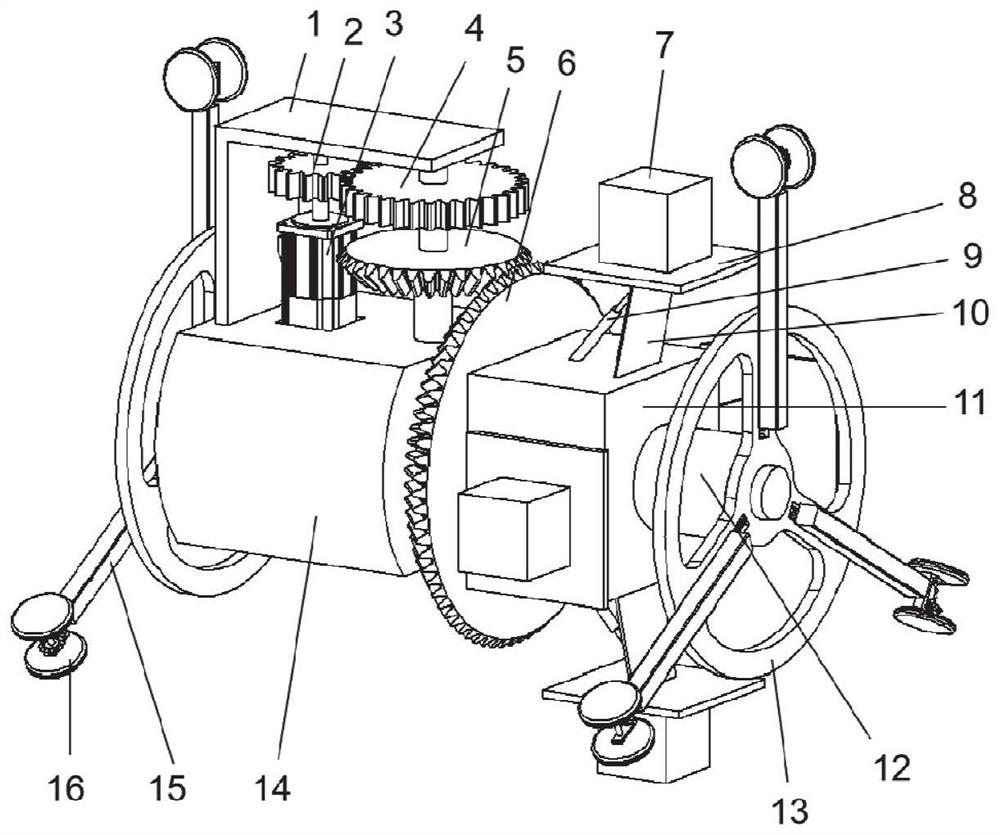

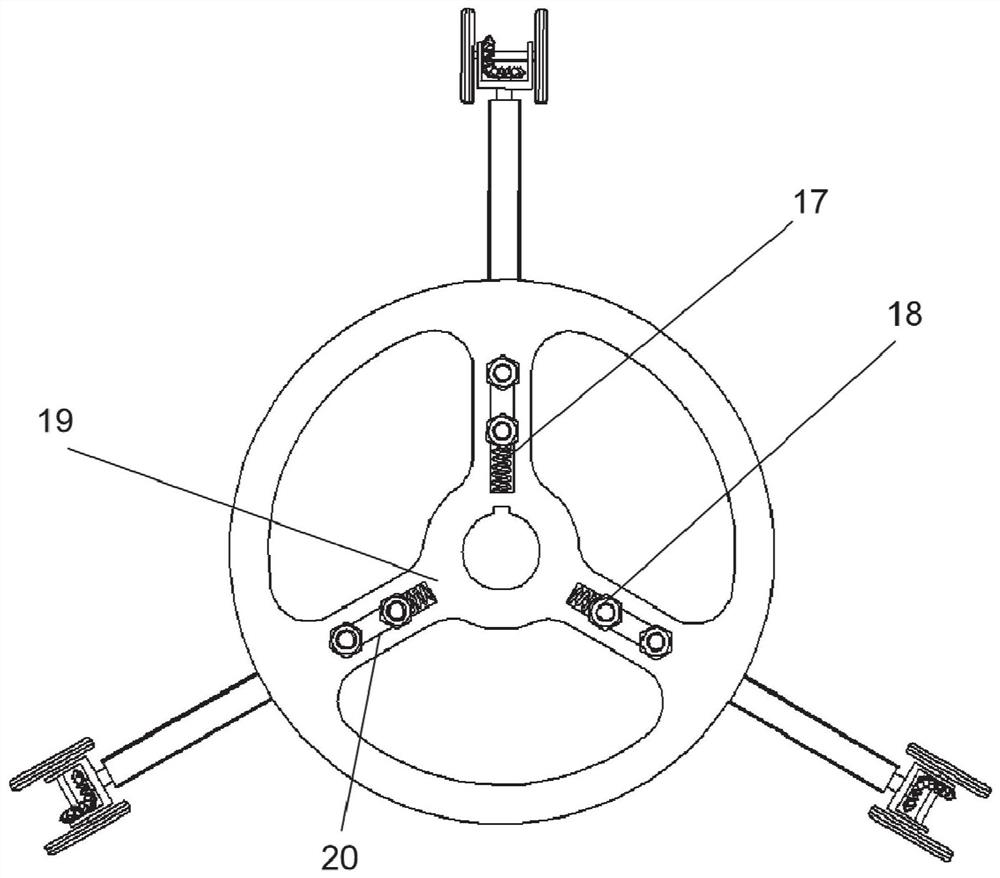

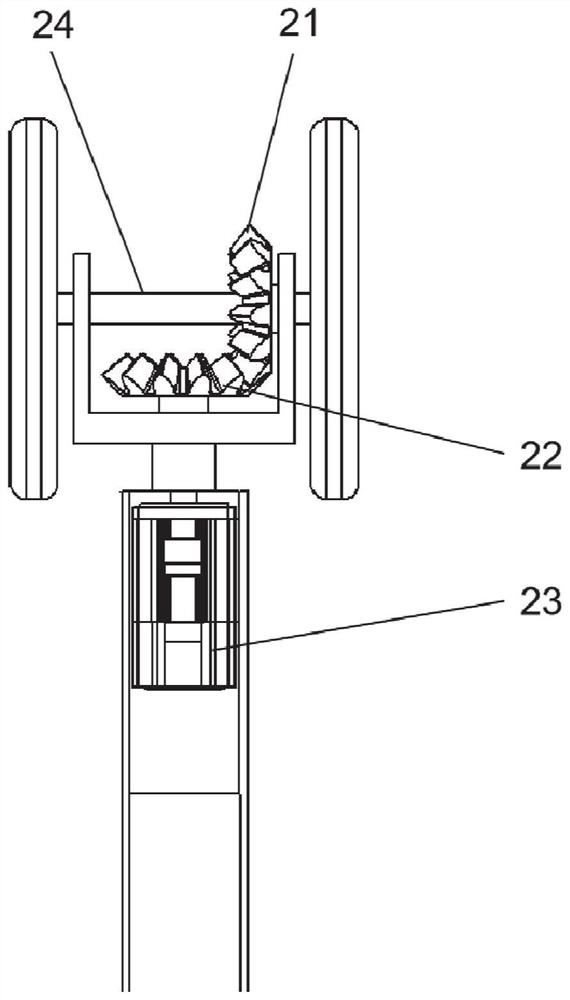

[0039] The internal wall residual stress detecting device based on the magnetic bullet effect, including: fixedly disposed on the support sleeve and support table on the spindle, the support station is fixedly fixed, and the drive motor is provided with an active cylindrical gear, active cylindrical gear meshing. The driven cylindrical gear is rotated, and the coated gear is engaged with a small cone gear rotation. The small cone gear is engaged with a large cone gear rotation, and the large tapered gear rotation is rotated to fix the support sleeve on the large cone gear, and the support sleeve rotation is fixed. The detection probe of the support sleeve is rotated.

[0040] Specific: figure 1 As shown, the support sleeve 11...

Embodiment 2

[0053] This embodiment provides a method of residual stress detecting based on the inclined pipeline based on the magnetic bulge effect.

[0054] The internal wall residual stress detection method based on the magnetic bullet effect, the internal wall residual stress detecting apparatus of the fiber-based direction of the above-described embodiment, including: drive motor drive active cylindrical gear rotation, active cylinder The gear mesh is rotated from the cylindrical gear, and the coated gear is engaged with a small cone gear rotation. The small cone gear is engaged with the large cone gear rotation. The large cone gear rotates the support sleeve to rotate, the support sleeve rotates to detect the probe, to achieve the pipe Full angle detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com