Outer rotor type permanent magnet motor with rotor position sensor, method for detecting rotor position and servo motor system

A permanent magnet motor, rotor position technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of increased wiring, difficult to reduce the thickness of the motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0034] The outer rotor permanent magnet motor provided by the present invention, that is, the permanent magnet motor in which the rotor is outside the stator, mainly includes a rotor and a stator.

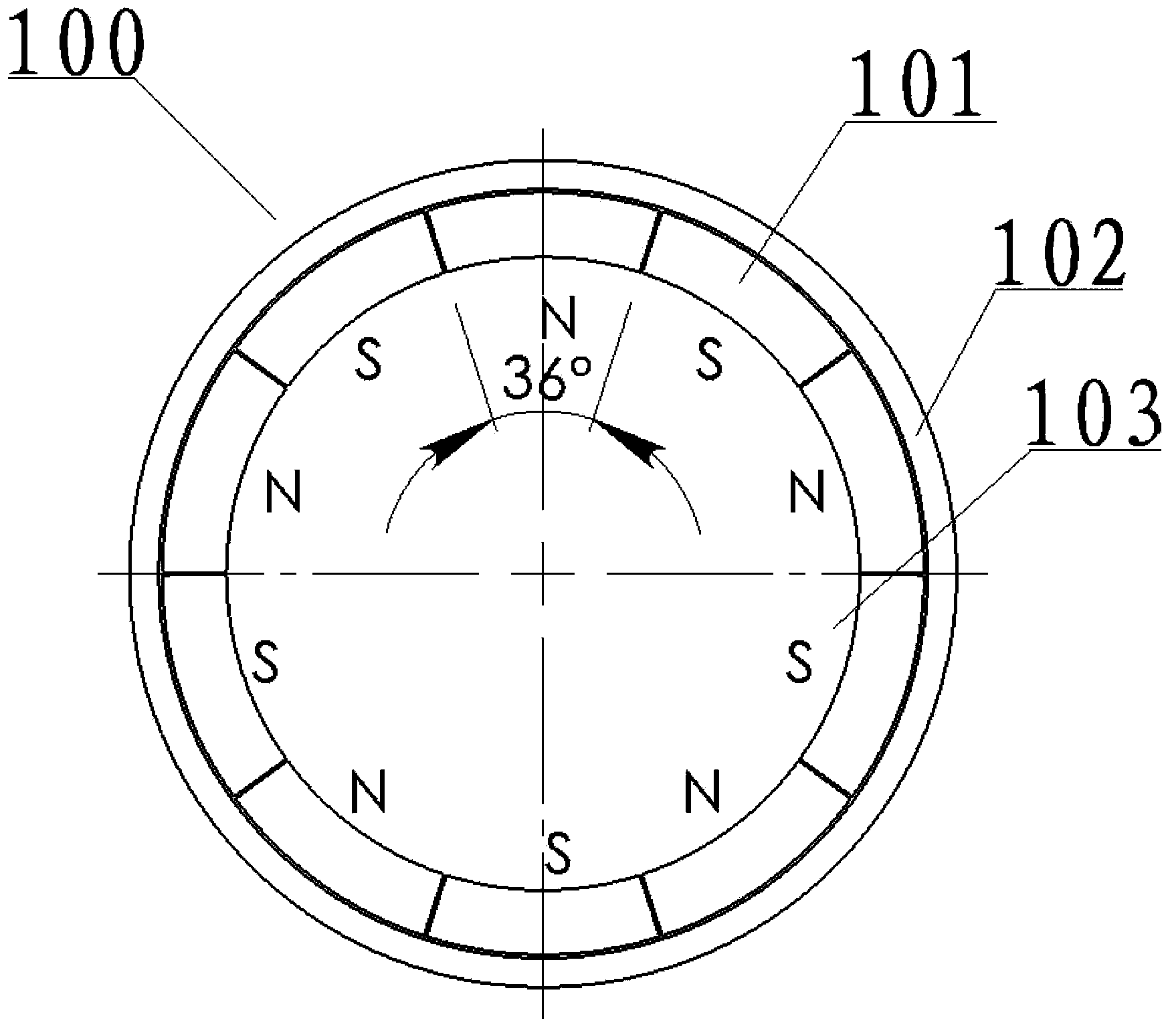

[0035] see figure 2 , The rotor 100 is composed of a permanent magnetic steel 101 , a soft magnetic material yoke 102 and a rotating shaft 103 . The magnetic poles of the rotor are evenly distributed along the outer surface of the rotor (or embedded in the rotor), and the polarities are arranged alternately. The magnetic steel is tile-shaped or ring-shaped, and the number of permanent magnetic pole pairs is an integer of P≥2.

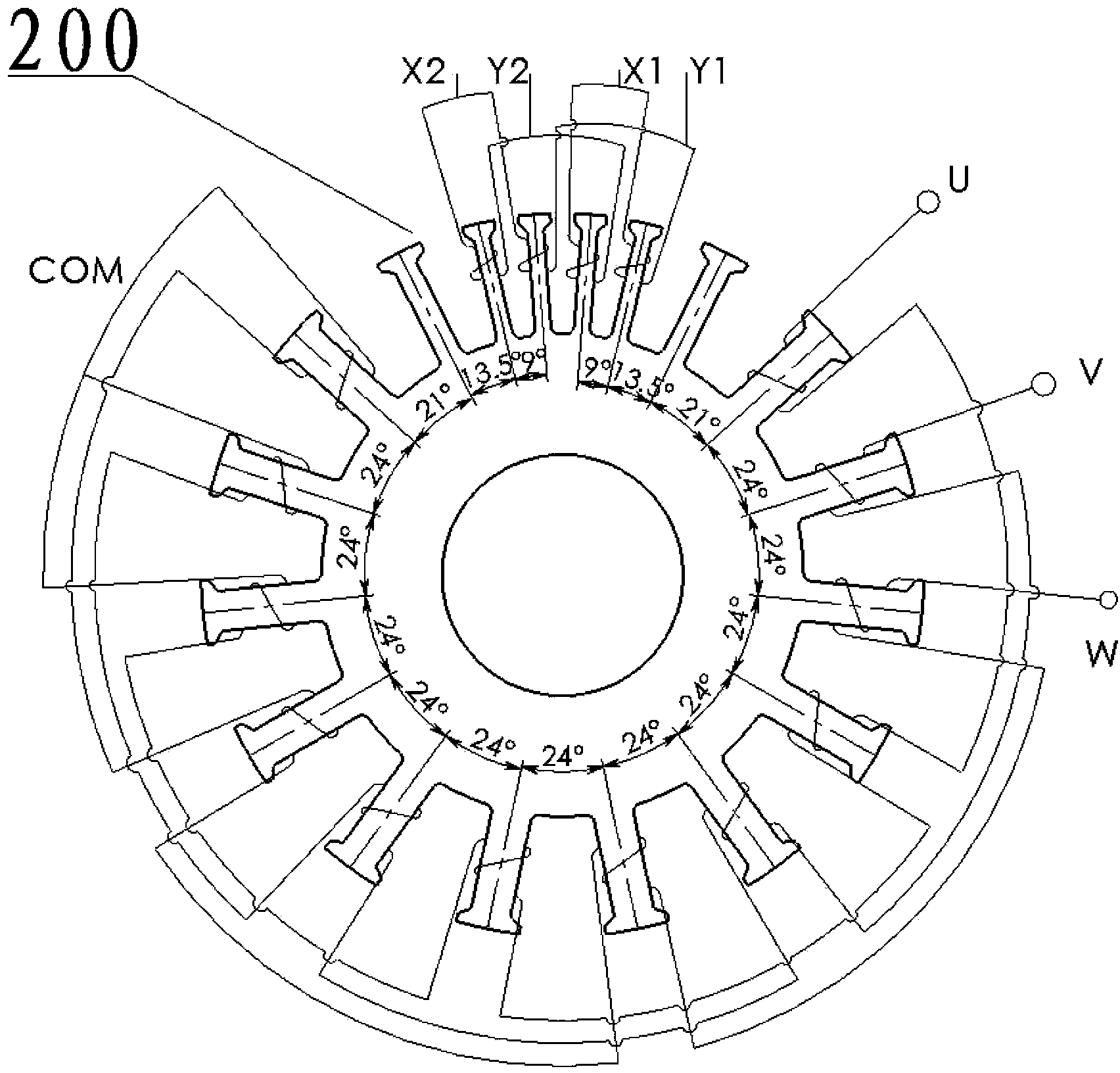

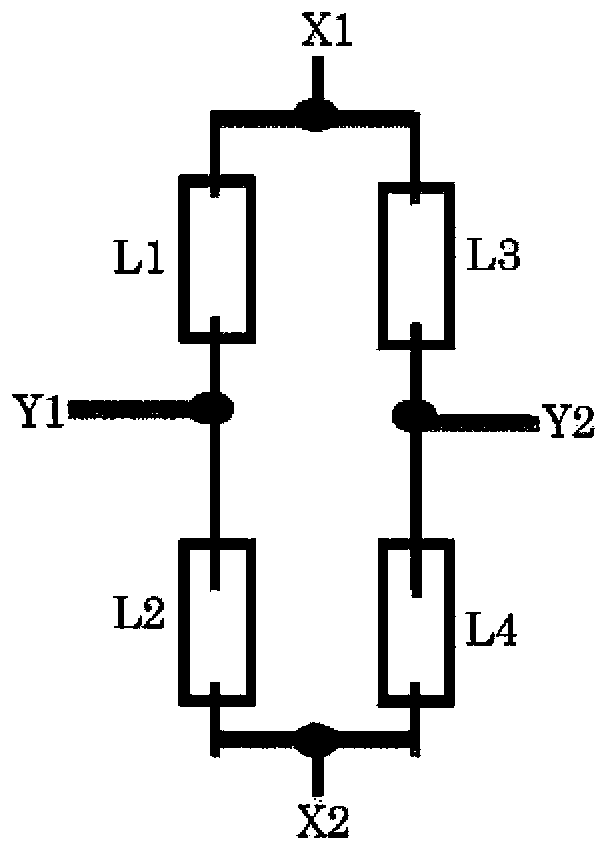

[0036] see figure 1 , The stator 200 is made of soft magnetic materials such as silicon steel sheets and coils, the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com