Suction resistance detection method and device based on mass flow method

A mass flow, detection device technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of cost consumption of tobacco companies, CFO can not use the life cycle, affecting the measurement results of suction resistance value, etc., to avoid the cost burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

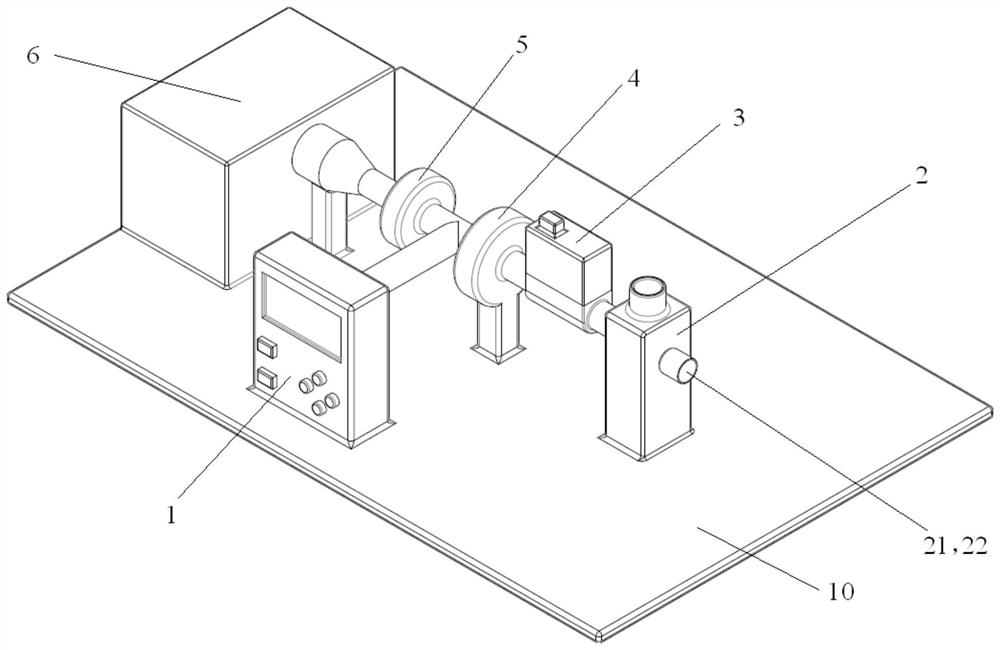

[0038] An example of an embodiment of the present invention will be described in detail below, and an example of an embodiment is shown in the drawings, in which the same or similar reference numerals are indicated by the same or similar elements or elements having the same or similar functions. The following is exemplary by way of reference to the accompanying drawings, and is intended to be construed as limiting the invention.

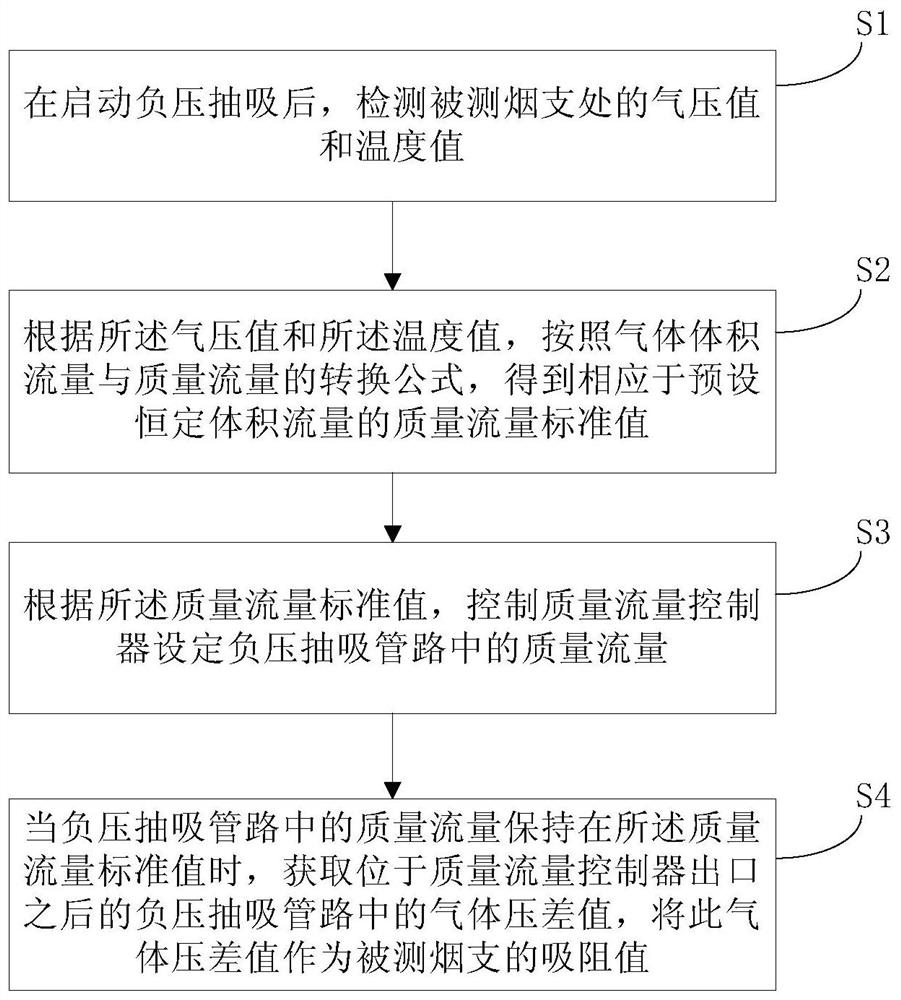

[0039] The present invention proposes an embodiment of a resistance detection method based on mass flow method, such as figure 1 As shown, including:

[0040] Step S1, after starting the negative pressure suction, detect the air pressure value and temperature value of the smoke;

[0041] Step S2, according to the air pressure value and the temperature value, a mass flow standard value corresponding to the preset constant volume flow is obtained according to the conversion formula of the gas volume flow and the mass flow;

[0042] Step S3, according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com