Method for matching corresponding drying shrinkage under internal humidity gradient of cement-based material

A technology for cement-based materials and humidity gradients, which is used in analytical materials, material inspection products, special data processing applications, etc. Time and resource consumption, the effect of avoiding the interference of time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0030] The method for matching the drying shrinkage corresponding to the humidity gradient in the cement-based material of the present invention specifically includes the following steps:

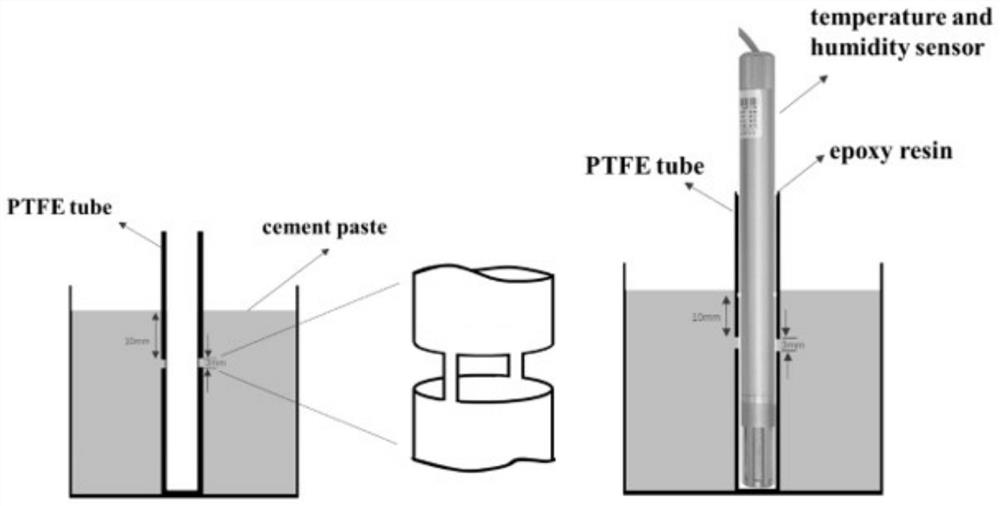

[0031] Step 1, mix cement powder and water to form cement slurry, the cement powder is Jiangnan Onoda P·II 52.5 grade, the water-cement ratio is 0.5, make a mark at 40mm above the bottom of the two PTFE hoses (denoted as P 1 , P 2 ), respectively at P 1 , P 2 Make a 2mm cut at 5mm and 10mm below the mark and insert a steel rod to prevent the cement from seeping out, then insert a 25mm diameter mold and touch the bottom ( figure 1 ); Another parallel sample is used to obtain a three-dimensional image;

[0032] Step 2. After the final setting, place the cement-based sample and parallel samples in saturated calcium hydroxide solution for 28 days, then remove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com