Basin-type insulator surface charge prevention and control method based on flexible coating

A pot-type insulator and surface charge technology, which is applied in the direction of insulators, circuits, electrical components, etc., can solve the problems of UHV DC gas-insulated equipment research and lack of engineering examples, and achieve low price, improved surface insulation performance, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

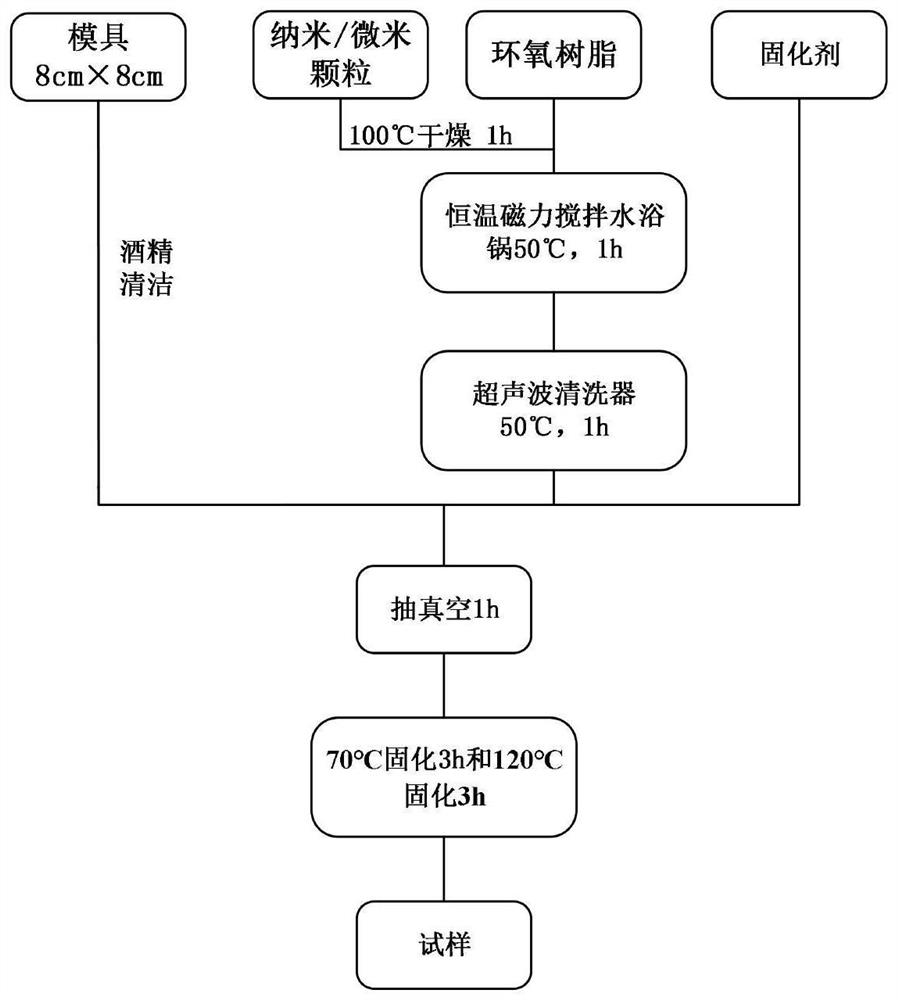

[0033] A method for preventing and controlling the surface charge of basin-type insulators based on flexible coating, the innovative feature of which is that the steps of the method are:

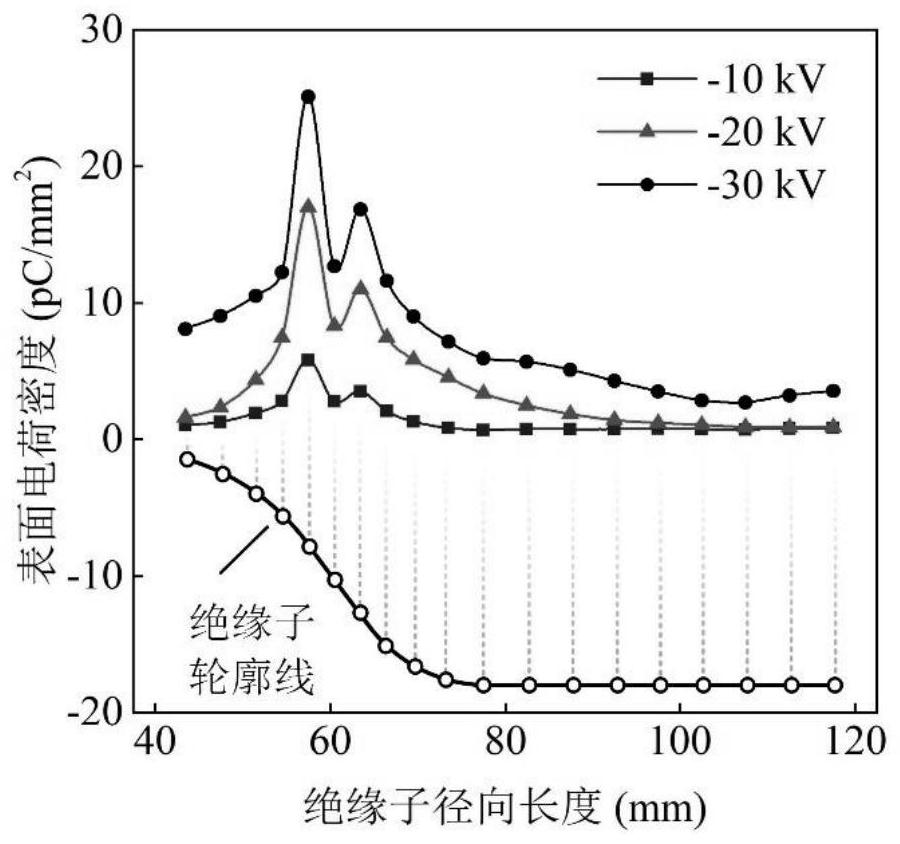

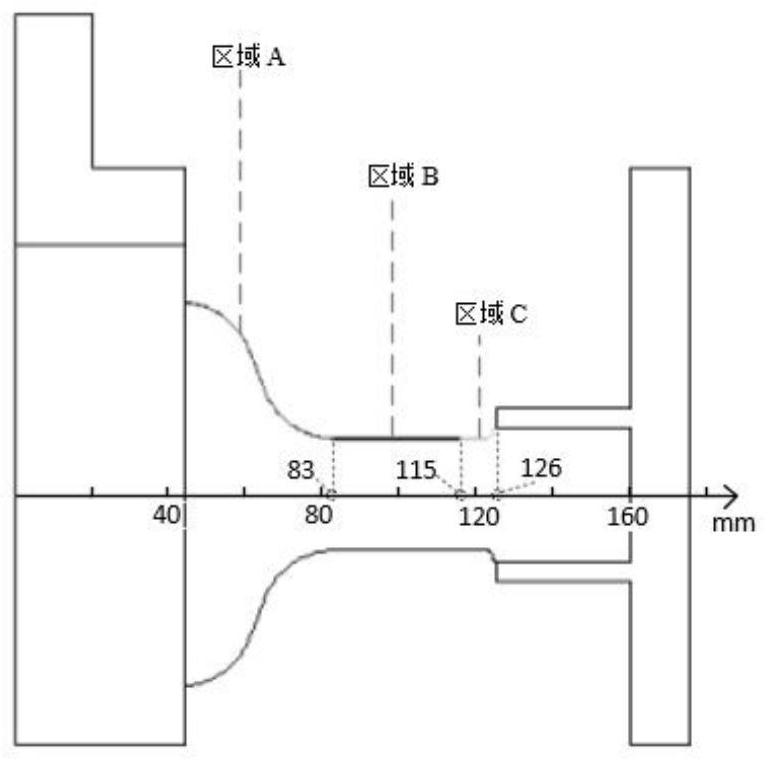

[0034] S1. Determination of the coating area: For the real-sized pot-type epoxy insulator with complex surface morphology, the surface charge accumulation test under DC voltage is carried out. The average density diameter of the surface charge of the insulator is To the distribution such as figure 1 As shown in the figure, it can be seen that the peak value of the radial distribution of the average charge density increases with the increase of the voltage, and the maximum peak values at -10kV, -20kV, and -30kV are 5.8pC / mm2, 16.9pC / mm2, and 25.1 pC / mm2 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap