Circuit breaker assembly

A technology for circuit breaker components and copper parts, applied in the field of circuit breaker components, can solve the problems of insufficient heat dissipation, permanent damage to external insulation, and heat dissipation effects, and achieve the effects of simple and convenient assembly, increased creepage distance, and improved electric field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

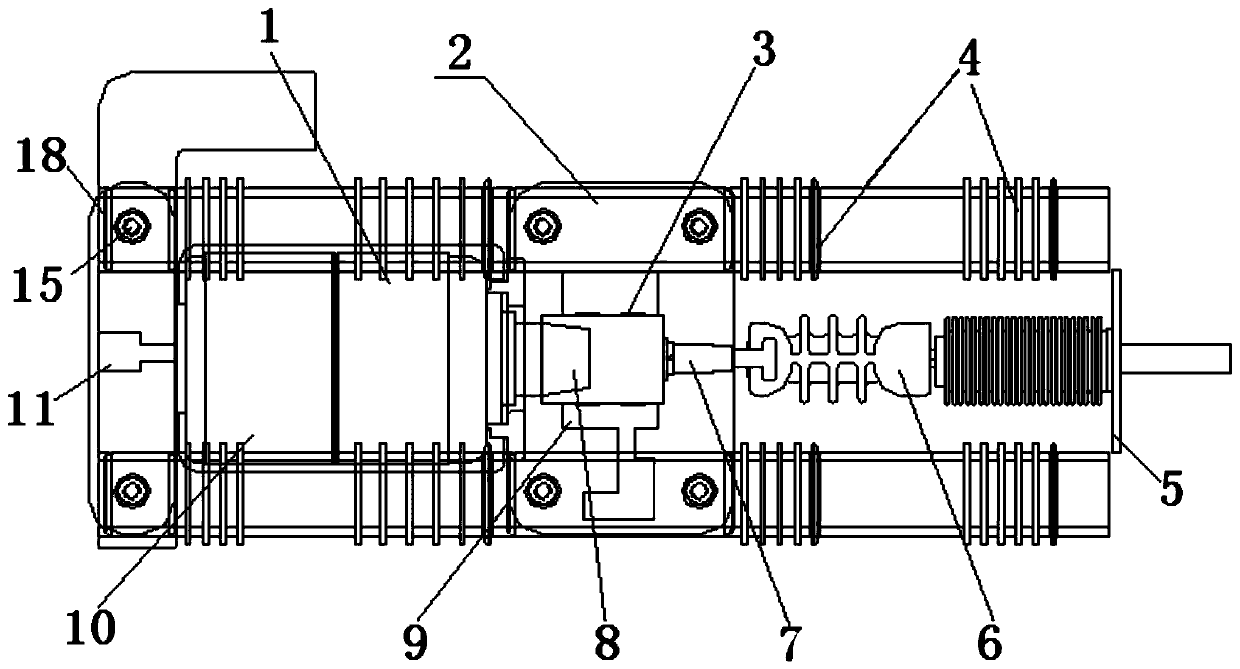

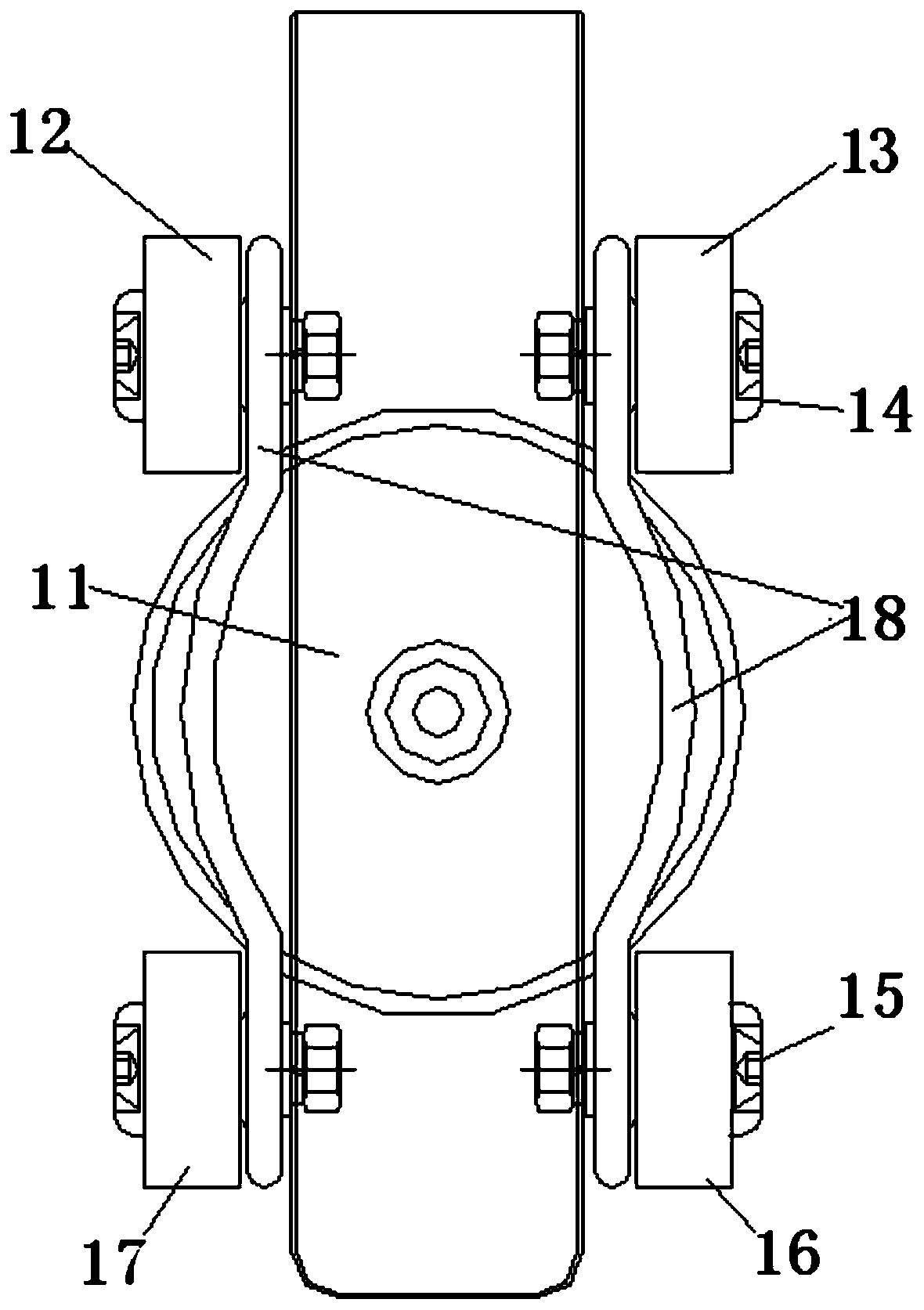

[0039] Such as figure 1 , figure 2 , image 3 As shown, a circuit breaker assembly 1 includes a vacuum bubble 10, a vacuum bubble static end copper piece 11, a vacuum bubble dynamic end copper piece 9, a double-ended screw 7, an insulating pull rod 6, a bellows 5, an aluminum clamping piece, insulating rod;

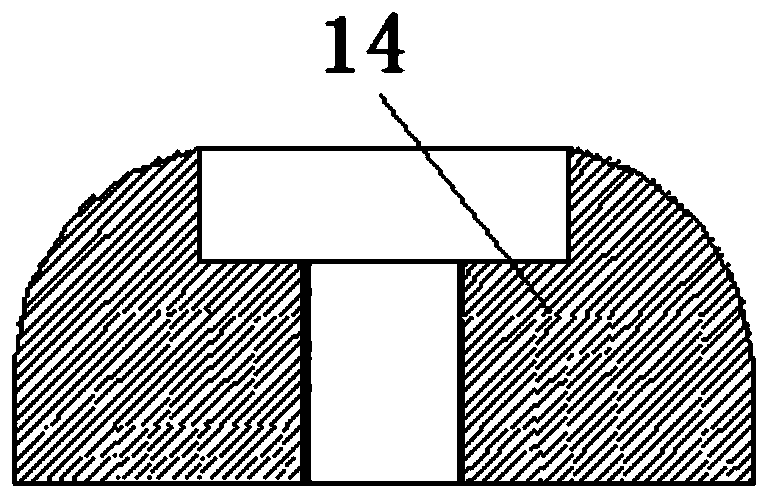

[0040] In this example, if figure 2 As shown, the aluminum clamping member is a left-right symmetrical hoop structure. The aluminum clamping parts include a rear aluminum part 18 and a front aluminum part 2;

[0041] The outer end of the static conductive rod of the vacuum bubble is fixedly connected to the copper piece 11 at the static end of the vacuum bubble;

[0042] The outer end 8 of the vacuum bubble moving conductive rod is slidingly connected with the copper part 9 at the vacuum bubble moving end;

[0043] The outer end 8 of the vacuum bubbling conductive rod is connected to one end of the insulating pull rod 6 through the double-ended screw 7, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com