Water-based paint filtering machine

A water-based paint and filter technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of long time consumption, affecting the time and quality of paint filtration, poor filtration effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

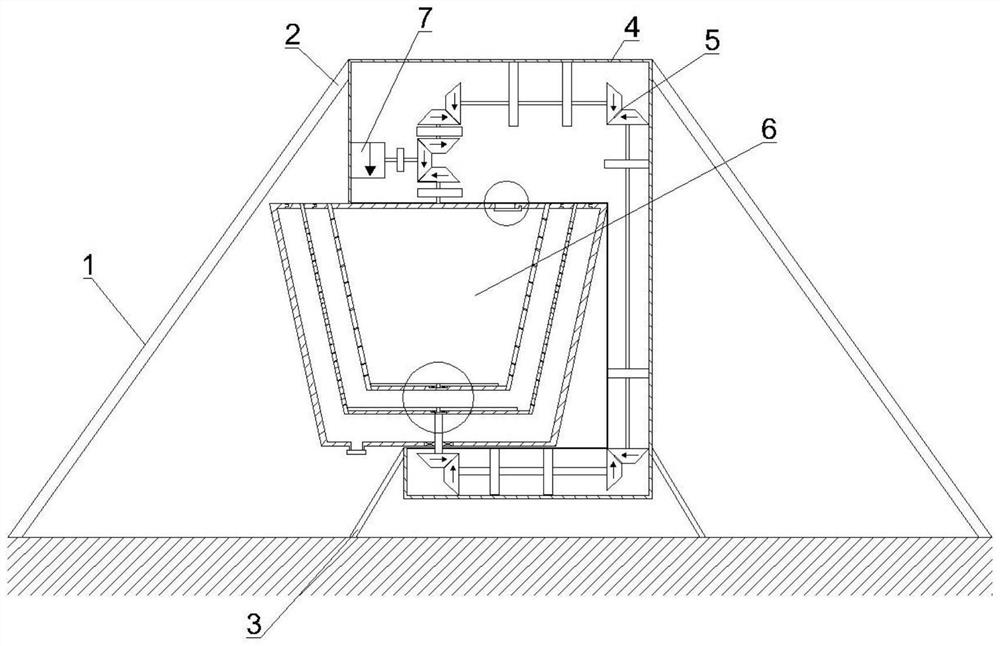

[0028] Embodiment 1: a kind of water-based paint filter, see Figure 1 to Figure 7 .

[0029] Such as figure 1As shown, a frame 1 is included, and the frame 1 includes two first legs 2 and two second legs 3, and the two first legs 2 are symmetrically and obliquely installed on both sides of the upper end of the hood 4 respectively. , the two second outriggers 3 are installed symmetrically and obliquely on both sides of the lower end of the machine cover 4, and the two first outriggers 2 and the two second outriggers 3 are fixedly installed on the working surface, A differential reversing gear structure 5 is fixedly installed inside the hood 4, and the differential reversing gear structure 5 is connected to a two-stage filter structure 6, and a motor 7 drives the differential reversing gear structure 5 to move and then drives the The two-stage filter structure 6 rotates coaxially with different directions and with differential speed.

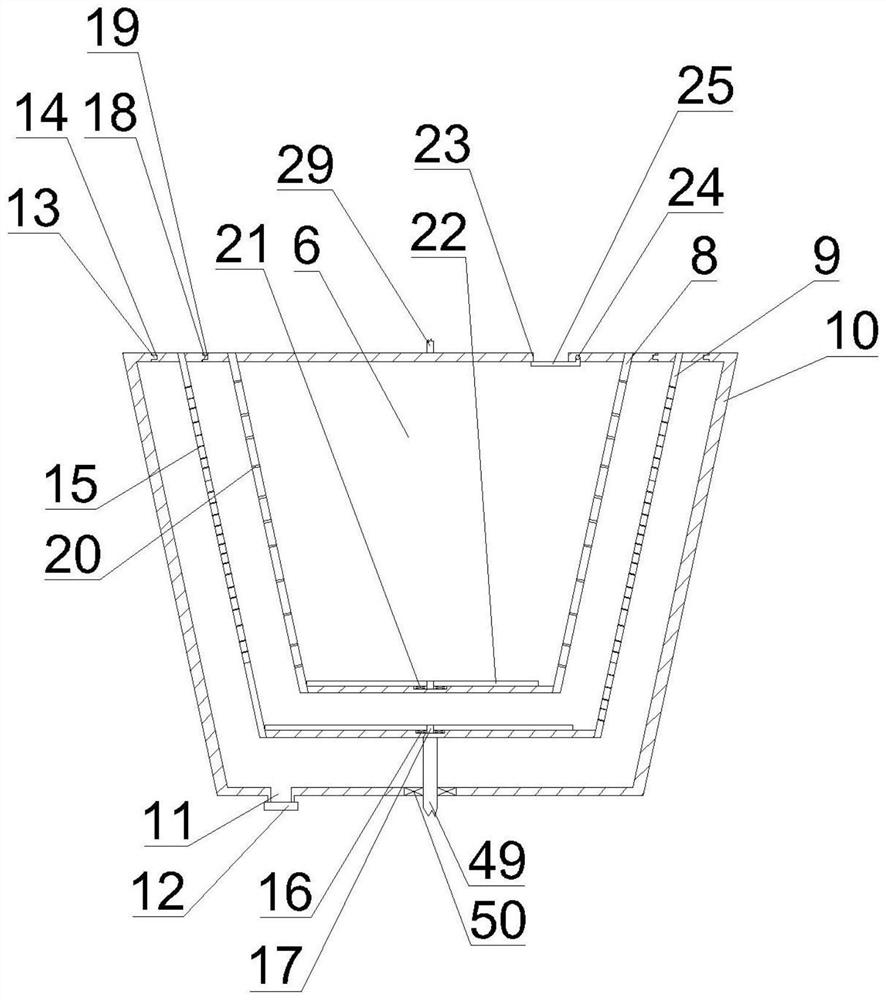

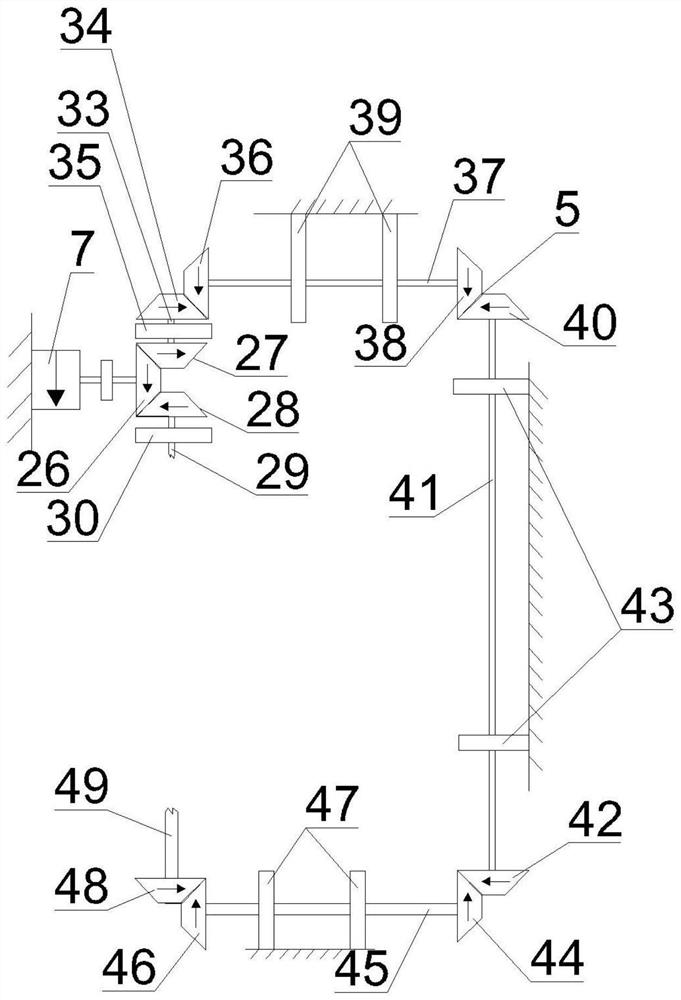

[0030] Specifically, as figure 2 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com