Multi-station automatic feeding device for flange silencer welding

An automatic feeding device and muffler technology, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low docking efficiency, incompatible with intelligent manufacturing, and affecting welding work of flange mufflers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

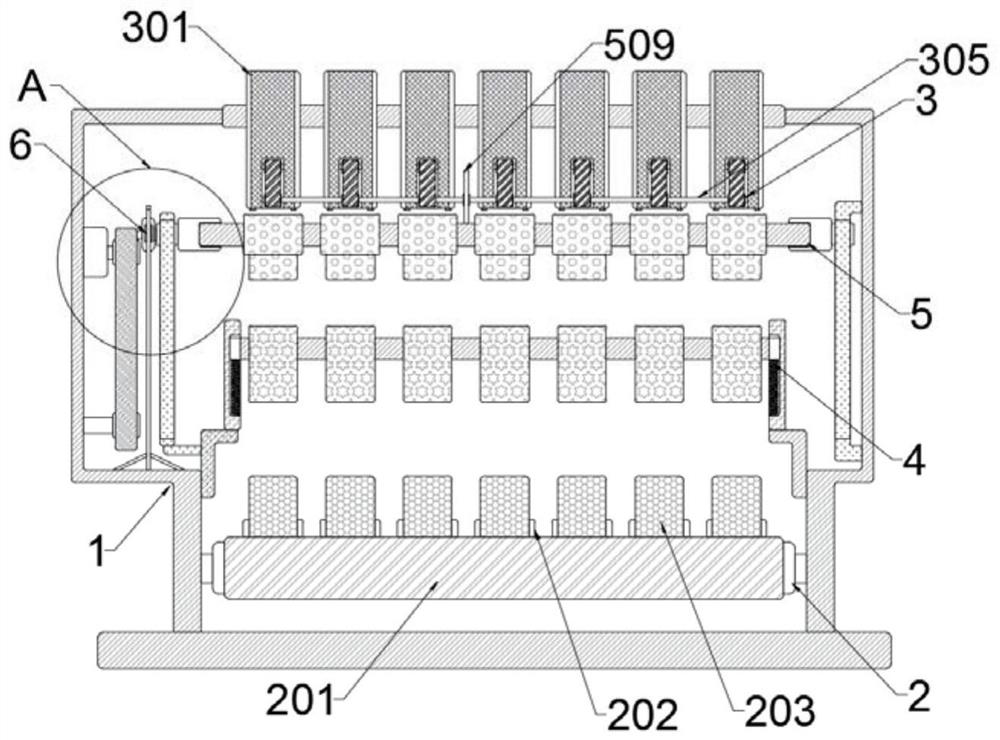

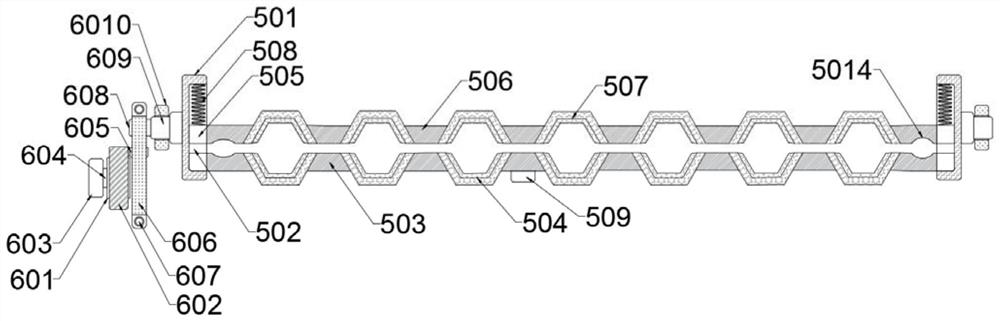

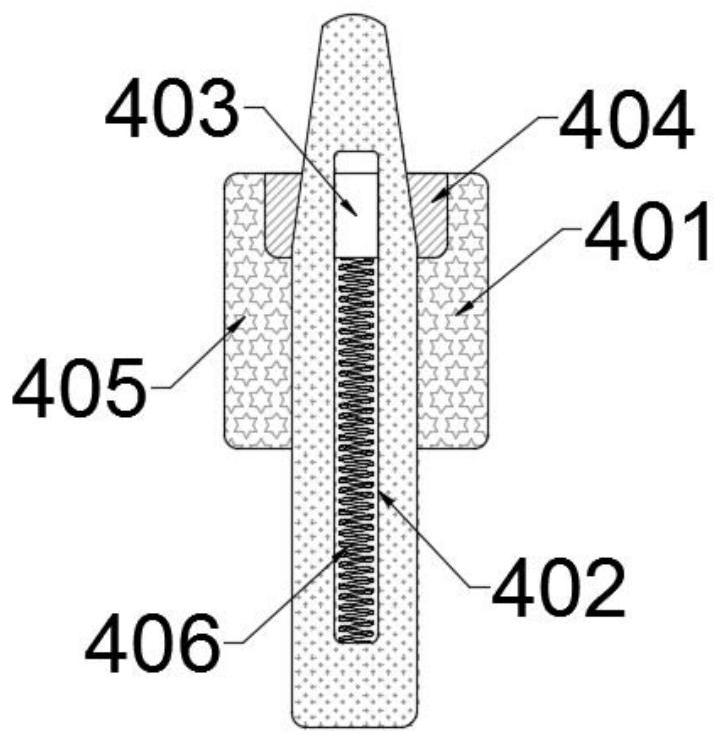

[0023] Example 1: Please refer to figure 1 , 2 and 3, a multi-station automatic feeding device for flange muffler welding, including a mounting frame 1, a transmission mechanism 2 is fixedly installed at the bottom of the mounting frame 1, and a butt joint is fixedly installed on the mounting frame 1 above the transmission mechanism 2 Mechanism 4, a transfer mechanism 5 is installed on the mounting frame 1 above the docking mechanism 4, a drive mechanism 6 is connected to one side of the transfer mechanism 5, and a blanking mechanism 3 is fixedly installed on the mounting frame 1 above the transfer mechanism 5, and the blanking mechanism 3 Including the discharge pipe 301 evenly distributed on the installation frame 1, the bottom end of the discharge pipe 301 is symmetrically provided with the installation groove 302, the upper and lower ends of the installation groove 302 are symmetrically installed with the first rotating roller 303, and the first rotating roller 303 is slee...

Embodiment 2

[0027] Example 2: Please refer to Figure 1-6 , a multi-station automatic feeding device for flange muffler welding, including a mounting frame 1, a transmission mechanism 2 is fixedly installed at the bottom of the mounting frame 1, and a docking mechanism 4 is fixedly installed on the mounting frame 1 above the transmission mechanism 2 , a transfer mechanism 5 is installed on the mounting frame 1 above the docking mechanism 4, a drive mechanism 6 is connected to one side of the transfer mechanism 5, a blanking mechanism 3 is fixedly installed on the mounting frame 1 above the transfer mechanism 5, and the blanking mechanism 3 includes a uniform The discharge pipe 301 distributed on the installation frame 1, the bottom end of the discharge pipe 301 is symmetrically provided with the installation groove 302, and the upper and lower ends of the installation groove 302 are symmetrically installed with the first rotating roller 303, and the first rotating roller 303 is covered wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com