Organic sludge dehydration method

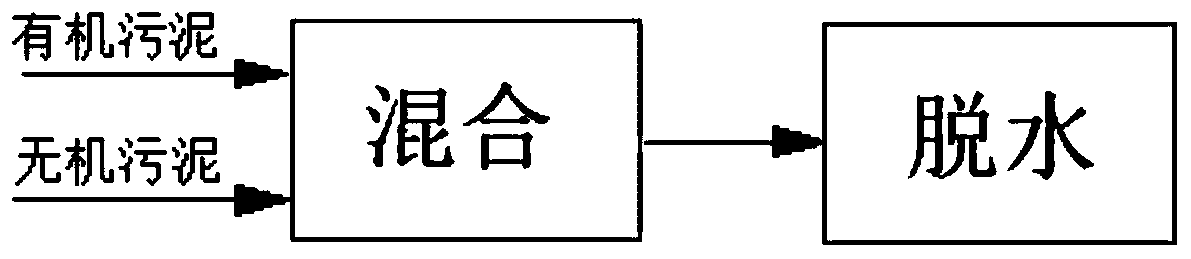

A technology of organic sludge and inorganic sludge, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. It can improve the efficiency of solid-liquid separation, improve the dehydration effect, and save the transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] Example 1. The following is a sewage treatment station in Suzhou that adopts the above-mentioned organic sludge dehydration method for treatment. At present, the sewage treatment station is limited by the small area and the investment cost. The sludge concentration technology is not designed, so it only uses The plate and frame filter press directly dehydrates organic sludge mechanically, but the dehydration effect is very poor. After dehydration, the sludge does not form and has a high water content.

[0035] The inorganic sludge and organic sludge at a certain time point are treated by the above method, and the moisture content of the organic sludge is about 98% and the moisture content of the inorganic sludge is about 97.5% after testing;

[0036] Mix and stir the above-mentioned organic sludge and inorganic sludge containing inorganic particles for 25 minutes, during which the method of aeration and stirring is adopted, and the mass ratio of the two materials is 6:1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com