Patents

Literature

41results about How to "Facilitate subsequent processing operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-steel meridian tire sidewall rubber composition and preparation method thereof

InactiveCN106432830AHigh modulusIncrease stickinessSpecial tyresPolymer scienceManufacturing technology

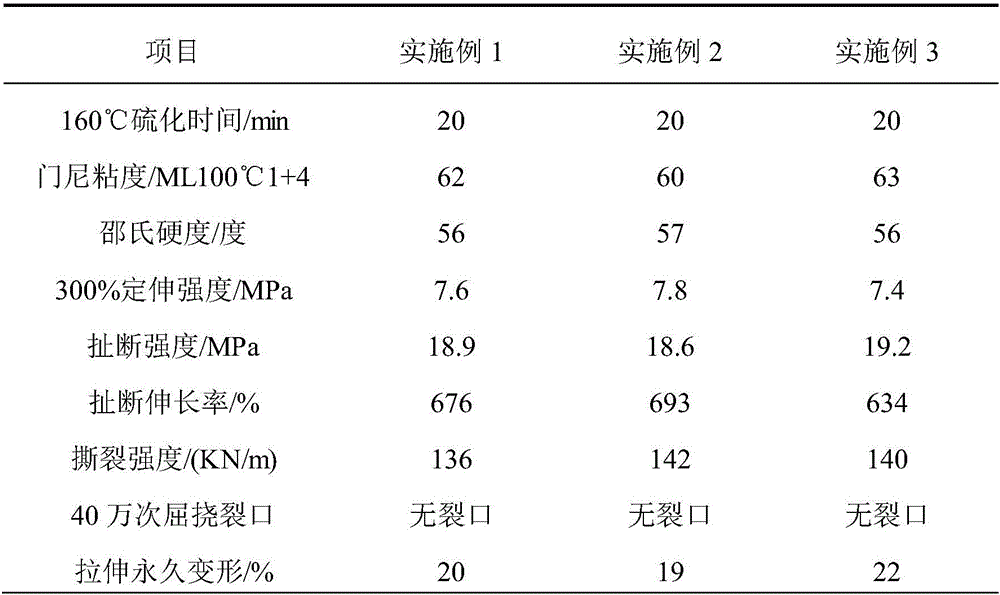

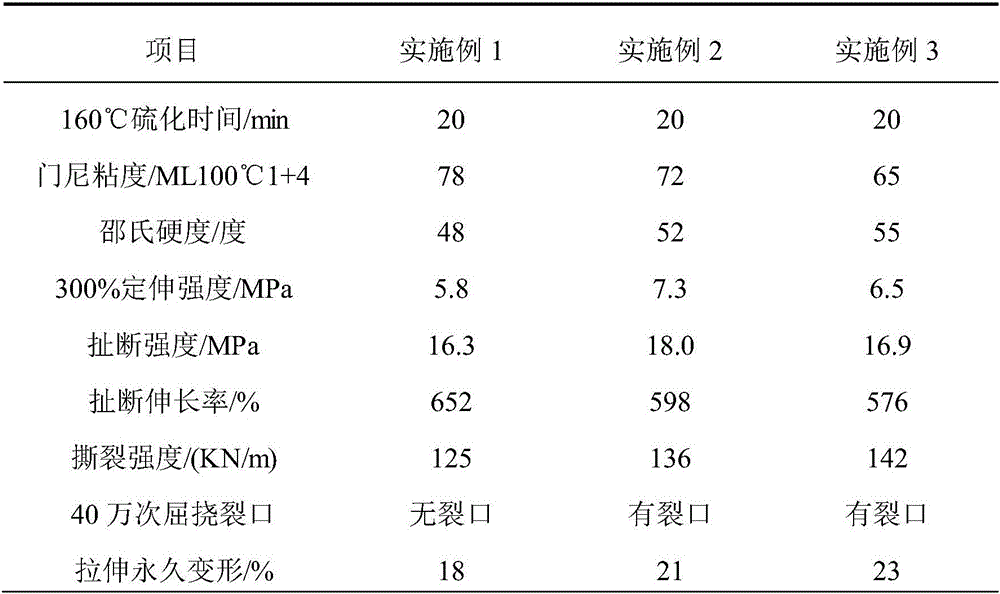

The invention belongs to the technical field of rubber tires and chemical engineering manufacturing, and concretely relates to a liquid isoprene rubber-containing semi-steel meridian tire sidewall rubber composition and a preparation method thereof. The tire sidewall rubber composition comprises, by weight, 30-50 parts of natural rubber, 40-60 parts of butadiene rubber, 10-20 parts of liquid isoprene rubber, 52-56 parts of carbon black, 4.6-5.7 parts of an activator, 3.7-4.2 parts of an antioxidant, 1.8-2.5 parts of protection wax, 2-4 parts of a homogenizing agent, 0.7-1.0 part of a promoter and 1.76-1.8 parts of sulfur. The liquid isoprene rubber is used in semi-steel tire sidewalls, and rubber processing oil in traditional formulas is eliminated, so the problems of visual pollution and color change of tires, caused by migration and precipitation of the rubber processing oil from the surfaces of the tires in the late stage are solved, thereby the visual brightness of the tires is improved; and the use of the liquid isoprene rubber makes produced tires be better than tires produced by using the rubber processing oil in tire sidewall deflection heating reduction, tear resistance, cold resistance and ageing resistance.

Owner:山东新大陆橡胶科技有限公司

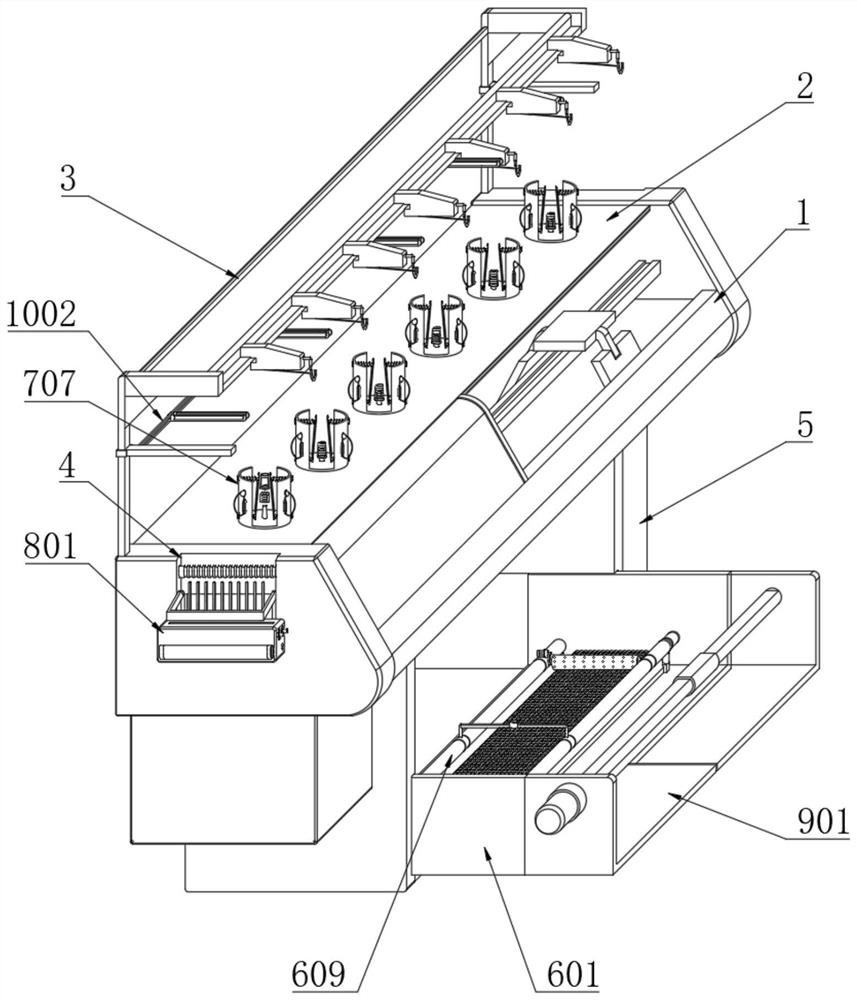

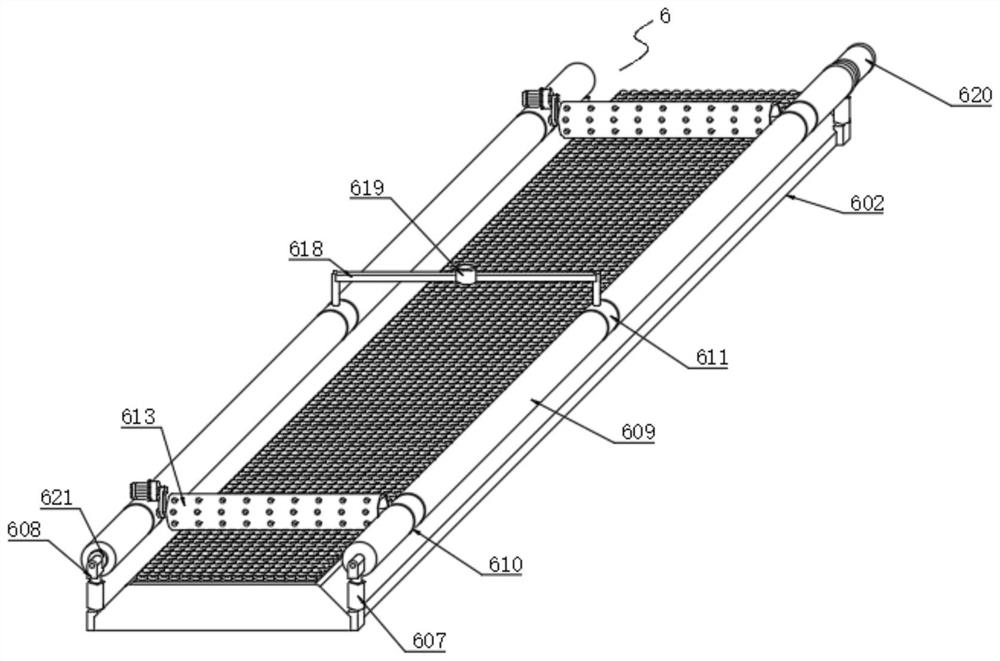

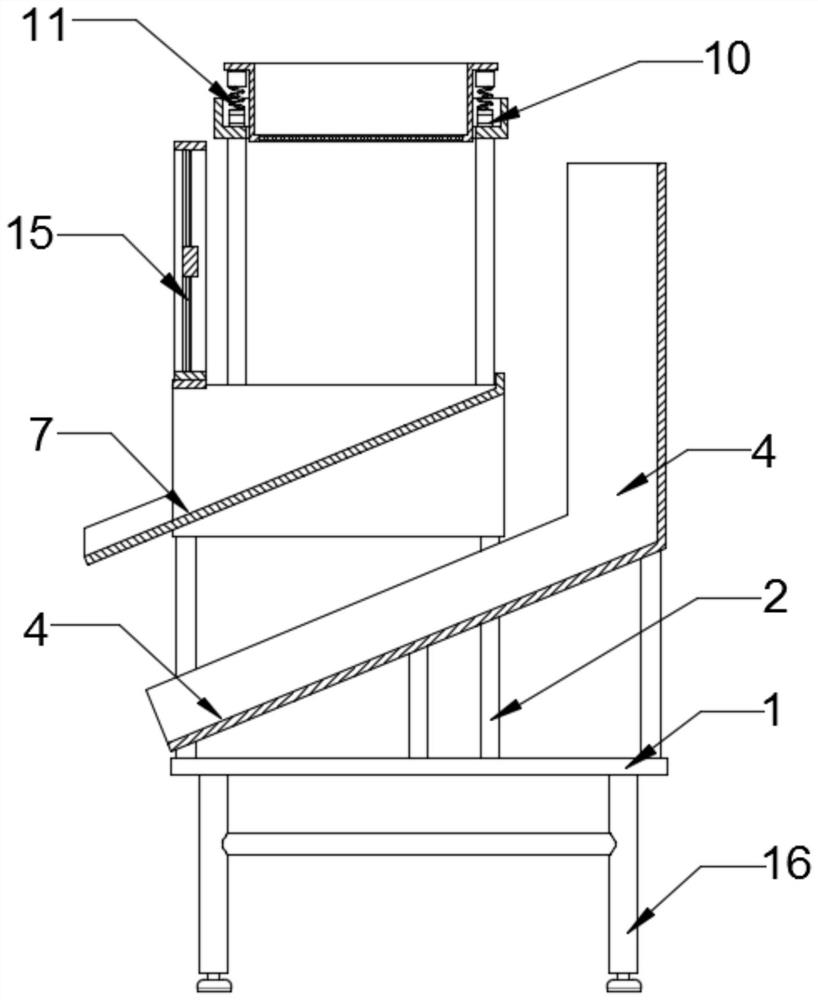

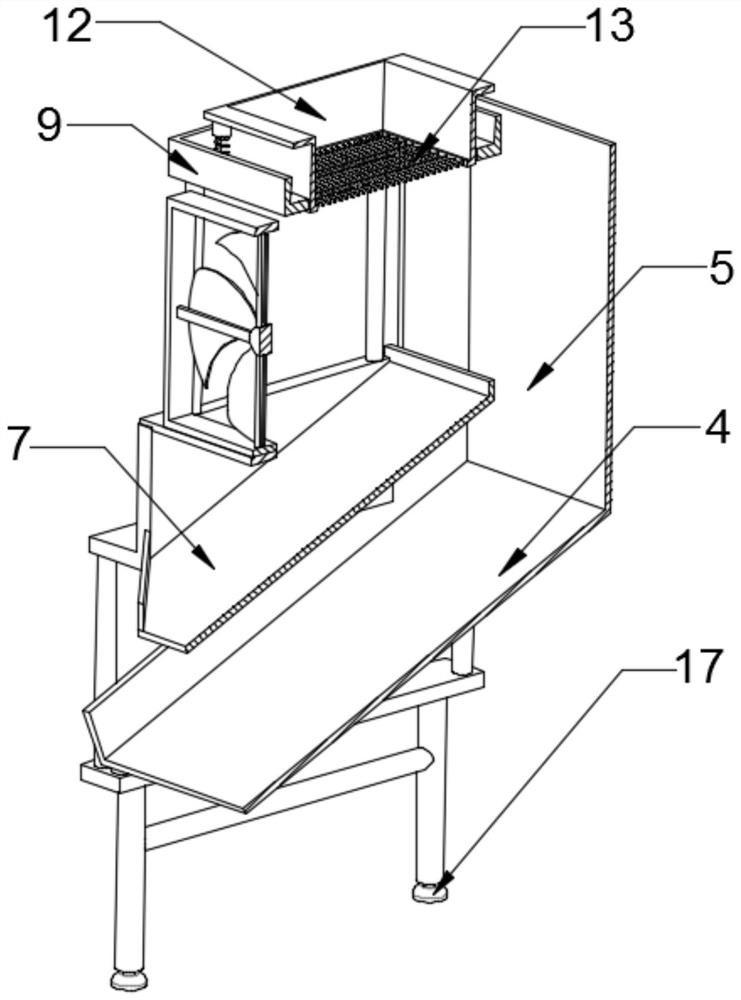

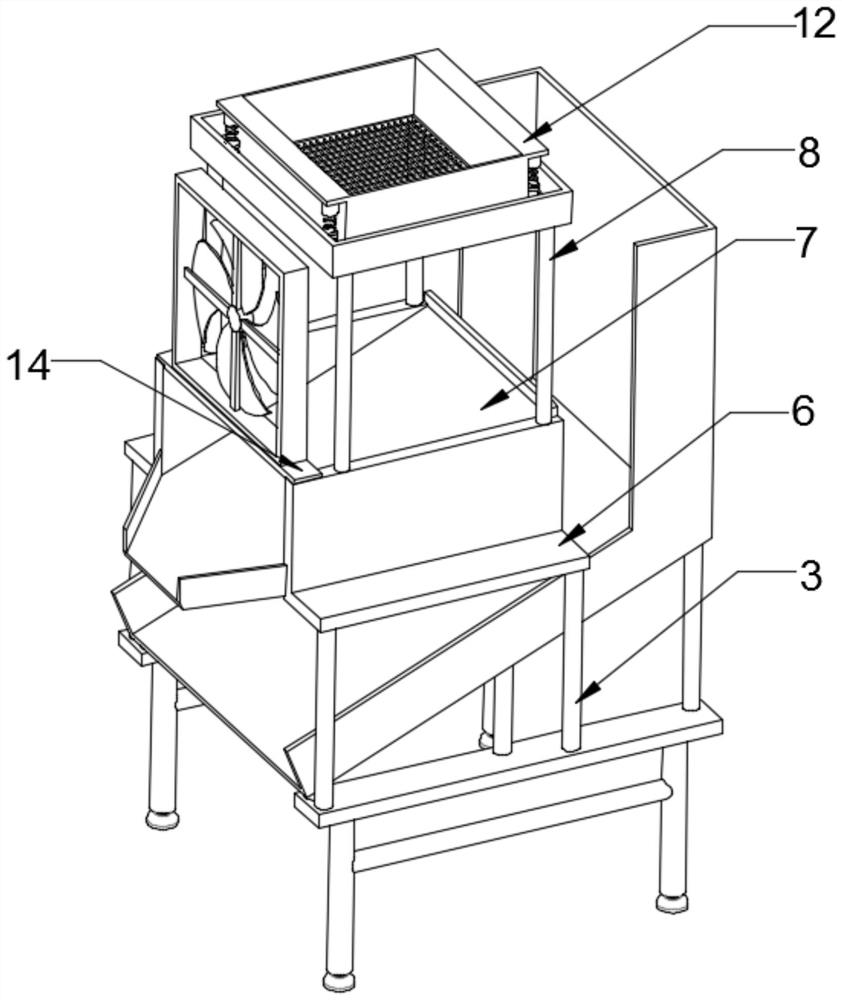

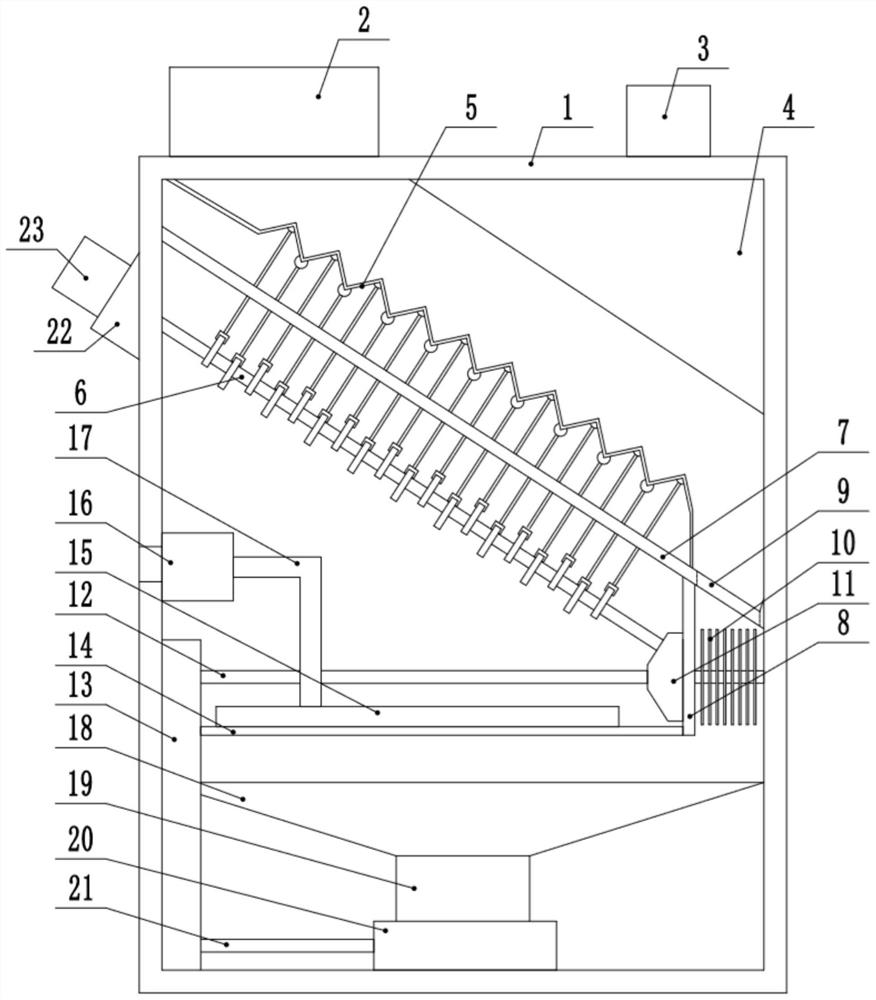

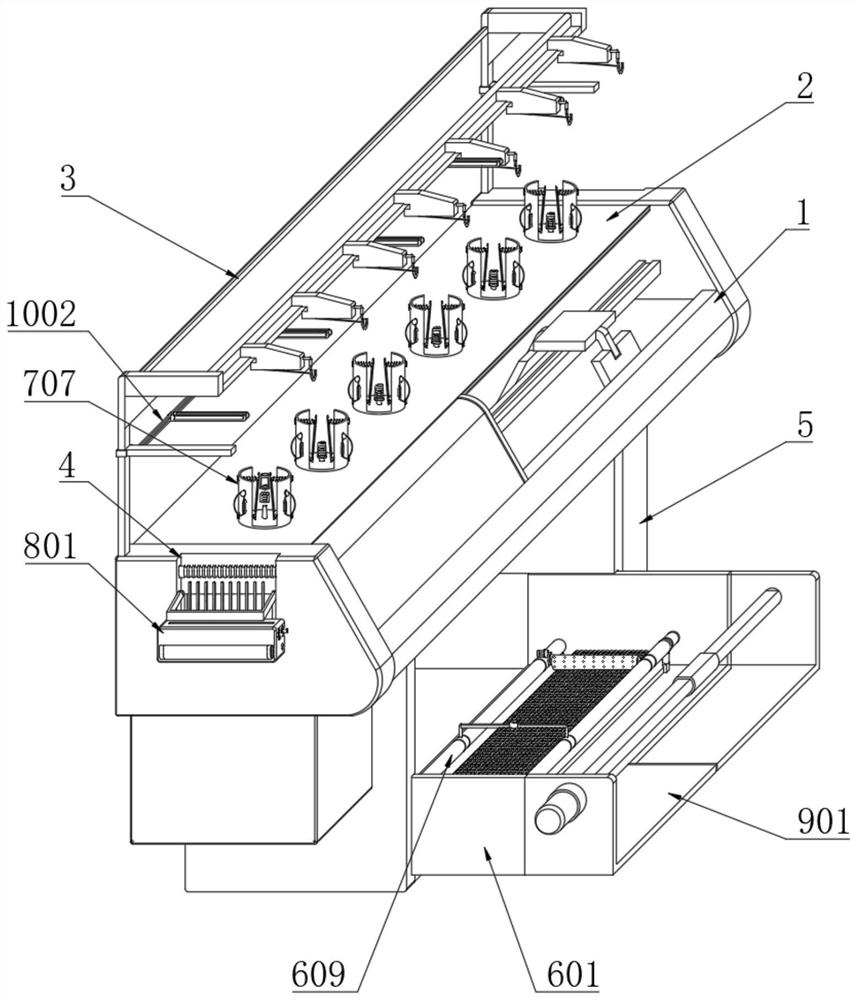

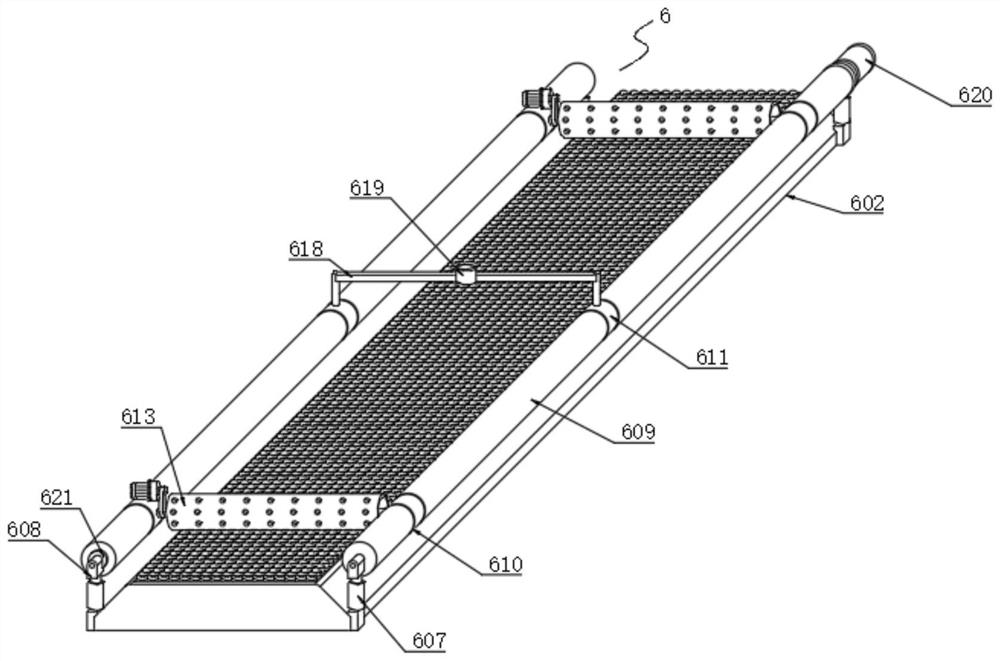

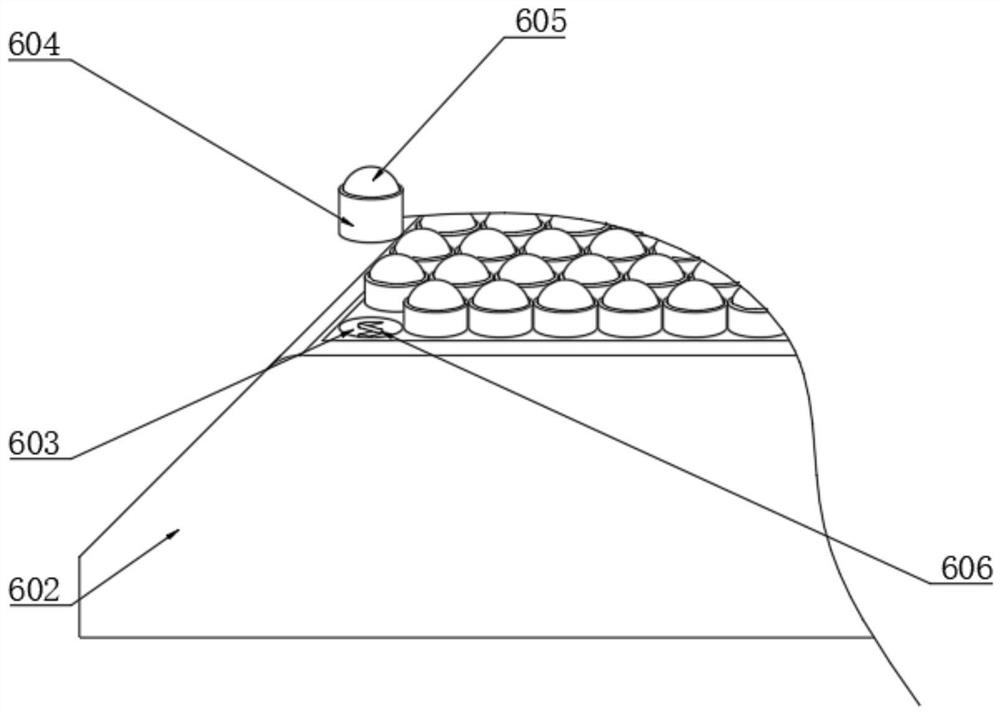

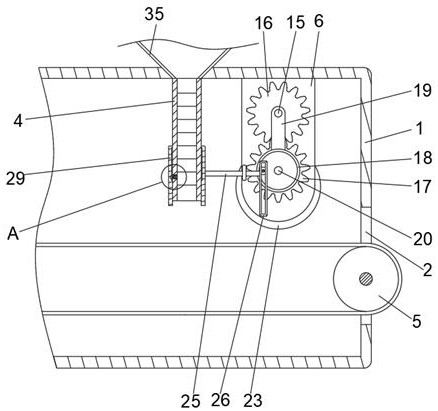

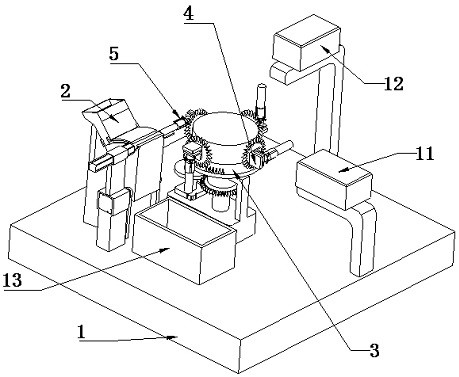

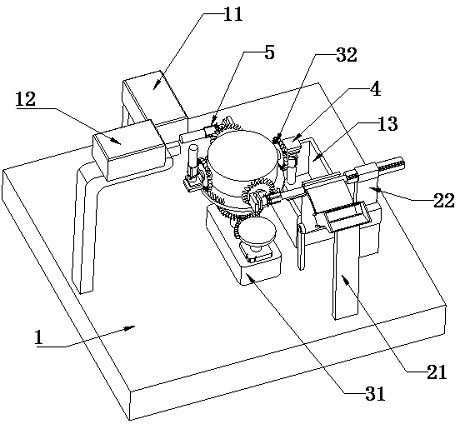

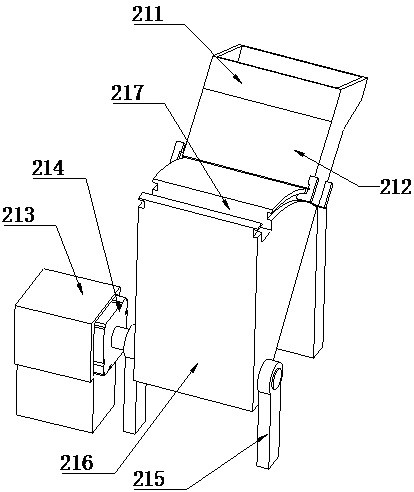

Full-automatic traditional Chinese medicinal material preliminary processing production line and use method thereof

InactiveCN111774303AAvoid accumulationAvoid blockingSievingGas current separationProcess engineeringManufacturing line

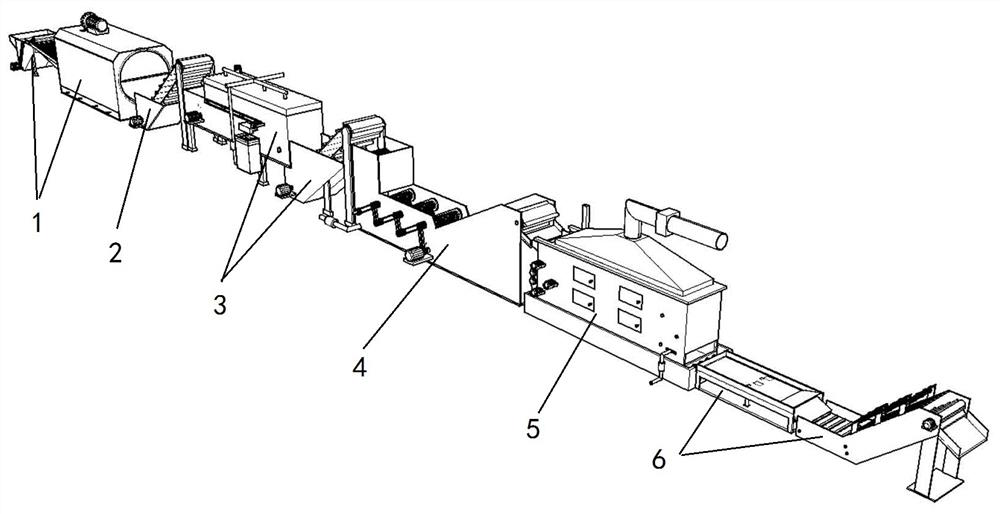

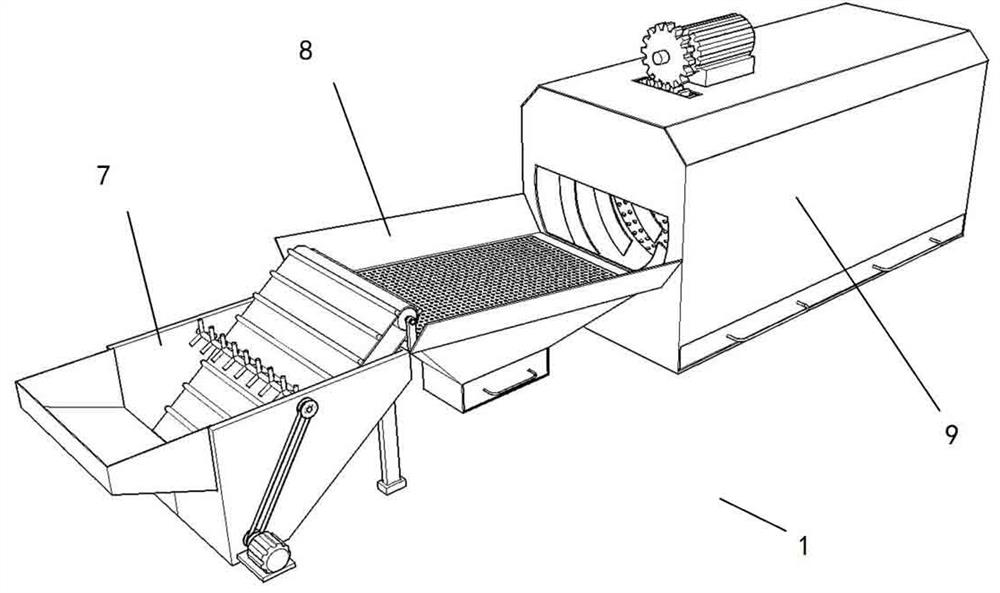

Provided are a full-automatic traditional Chinese medicinal material preliminary processing production line and a use method thereof. The full-automatic traditional Chinese medicinal material preliminary processing production line comprises a screening device, a washing device and a soaking device. The discharging end of the screening device is matched with the feeding end of a first conveying device, and the discharging end of the first conveying device is matched with the feeding end of the washing device. The discharging end of the washing device is matched with the feeding end of a secondconveying device, and the discharging end of the second conveying device is matched with the feeding end of the soaking device. The discharging end of the soaking device is matched with the feeding end of a third conveying device. By means of the structure, the whole production line is high in automation degree, device arrangement is reasonable and compact, and processing and operating are stable;and the full-automatic traditional Chinese medicinal material preliminary processing production line is suitable for processing mass traditional Chinese medicinal materials, and the economic benefitsof enterprises are improved.

Owner:五峰知杏堂药业有限公司

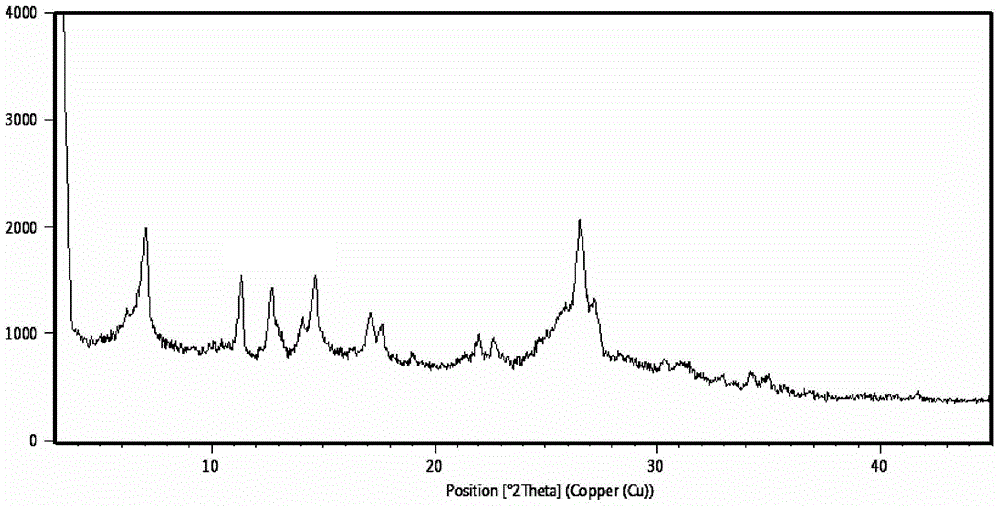

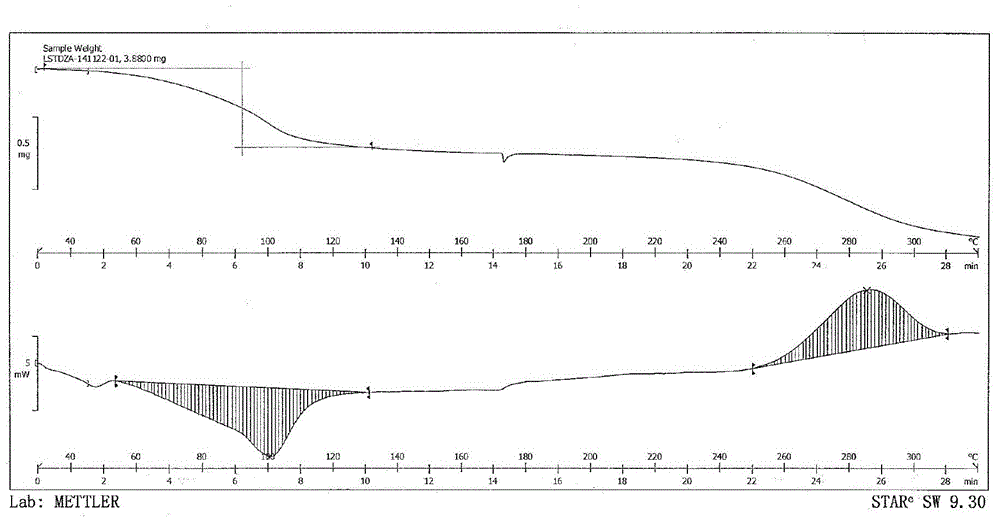

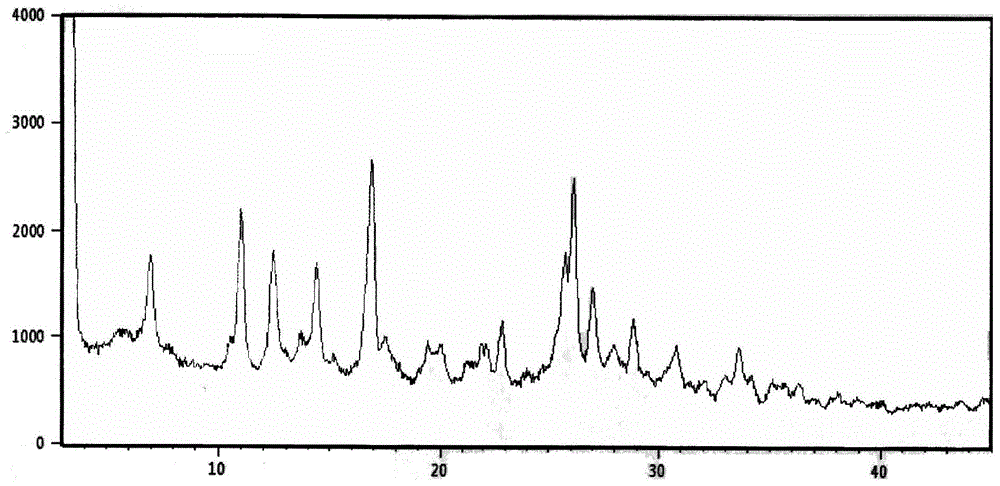

Novel crystal form of tedizolid phosphate disodium salt and preparation method of novel crystal form

InactiveCN104558034AImprove stabilityGood reproducibilityGroup 5/15 element organic compoundsState of artPhosphate

The invention belongs to the field of medical chemistry and particularly relates to a novel crystal form of tedizolid phosphate disodium salt with efficient antibacterial activity and a preparation method of the novel crystal form. The novel crystal form has good fluidity and repeatability and is convenient to separate and store; the defects that tedizolid phosphate disodium salt is poor in degree of crystallinity and is inconvenient to separate and store in the prior are overcome.

Owner:QILU PHARMA

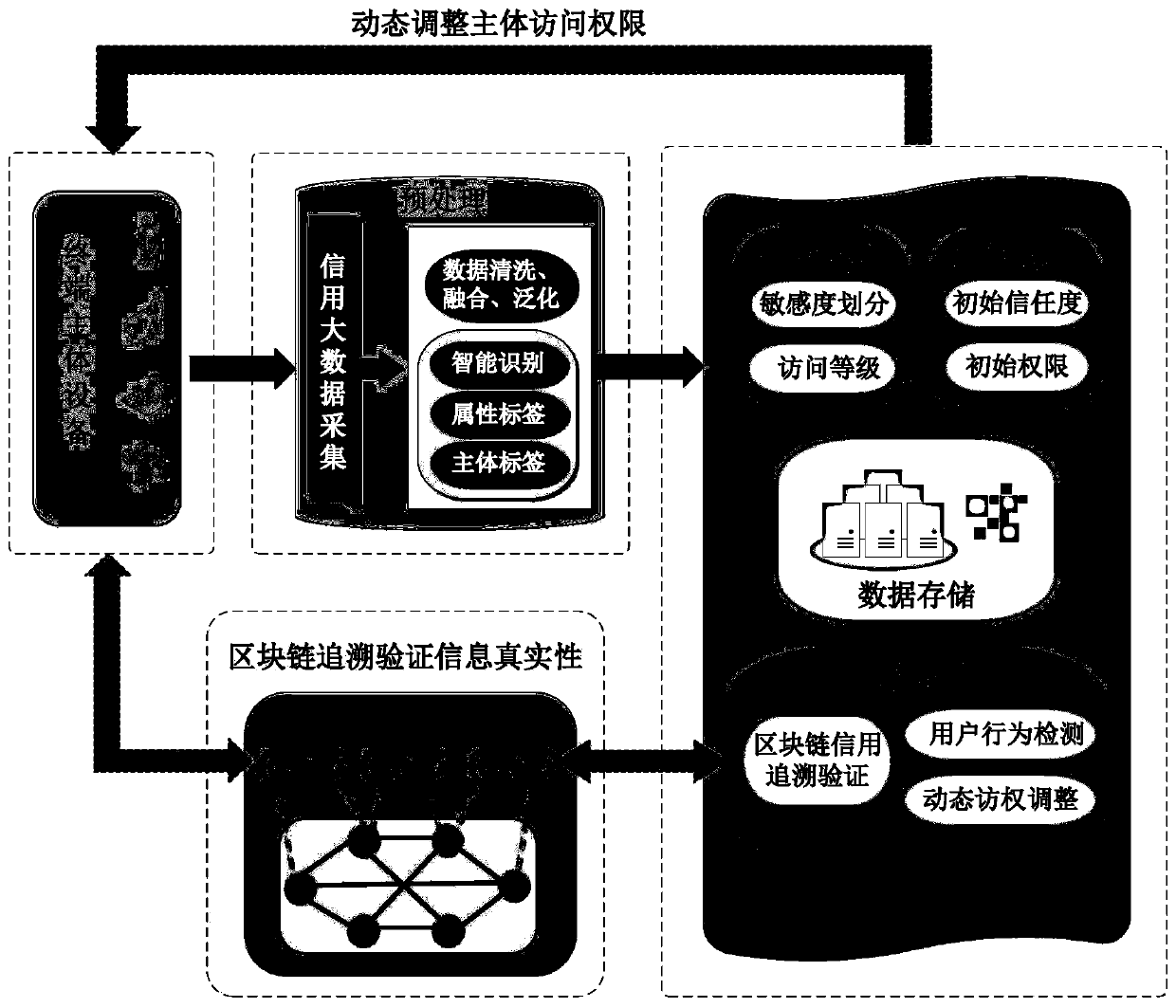

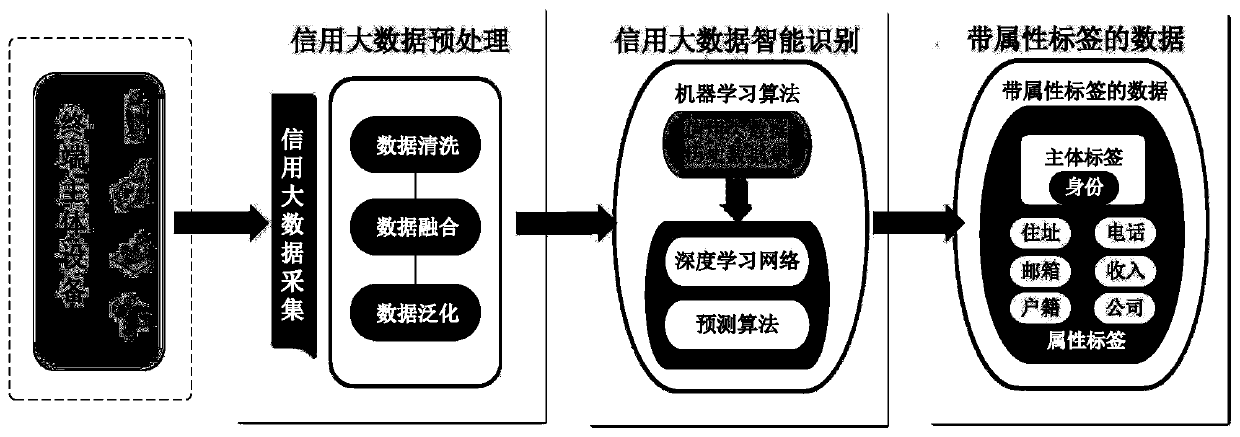

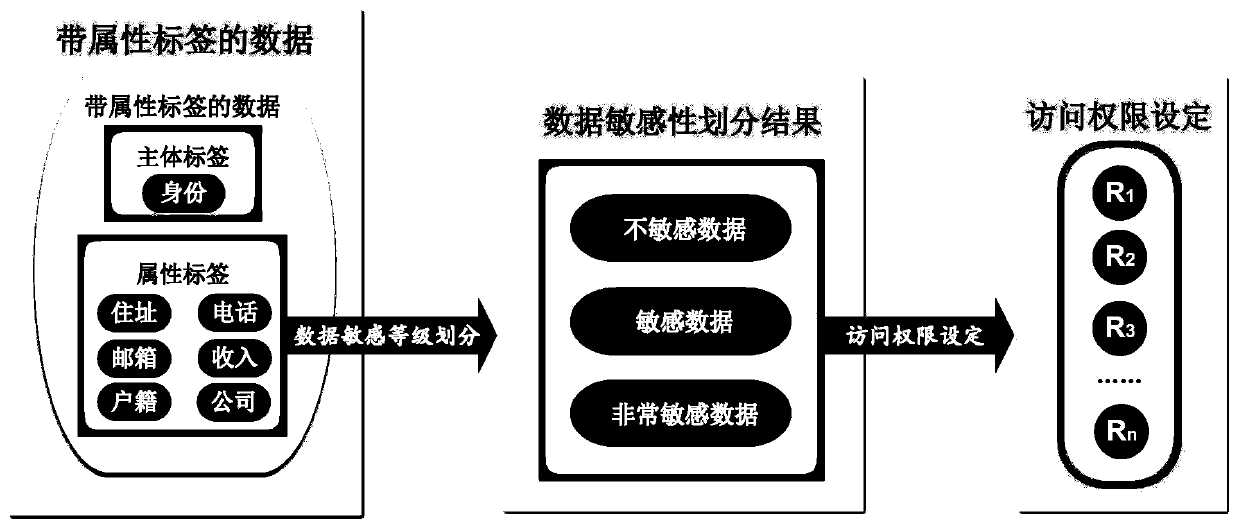

Credit big data-oriented risk control method and credit big data-oriented risk control system

ActiveCN111177743AImprove accuracyImprove reliabilityDigital data protectionRisk ControlTerminal equipment

The invention discloses a credit big data-oriented risk control method and a credit big data-oriented risk control system. The credit big data-oriented risk control method comprises the following steps of: finishing data acquisition by terminal equipment, finishing data fusion and cleaning by a server, labeling an attribute label and a main body label and the like to realize data preprocessing; designing a risk control module for native data acquired by the trusted terminal, and dividing the data into different sensitivity levels by performing tagging processing and sensitivity division on thedata to realize first-level risk control; for the initial credit problem of a user of the data storage platform, evaluating the initial credibility and authority of a data visitor by analyzing a mainbody label in the native data, so as to achieve the purpose of secondary risk control; and finally, for the problem that the system and the storage platform need to monitor data visitor behaviors inreal time, dynamically defining the trust degree of the subject according to the visitor behaviors so as to complete three-level risk control for credit big data.

Owner:XI AN JIAOTONG UNIV

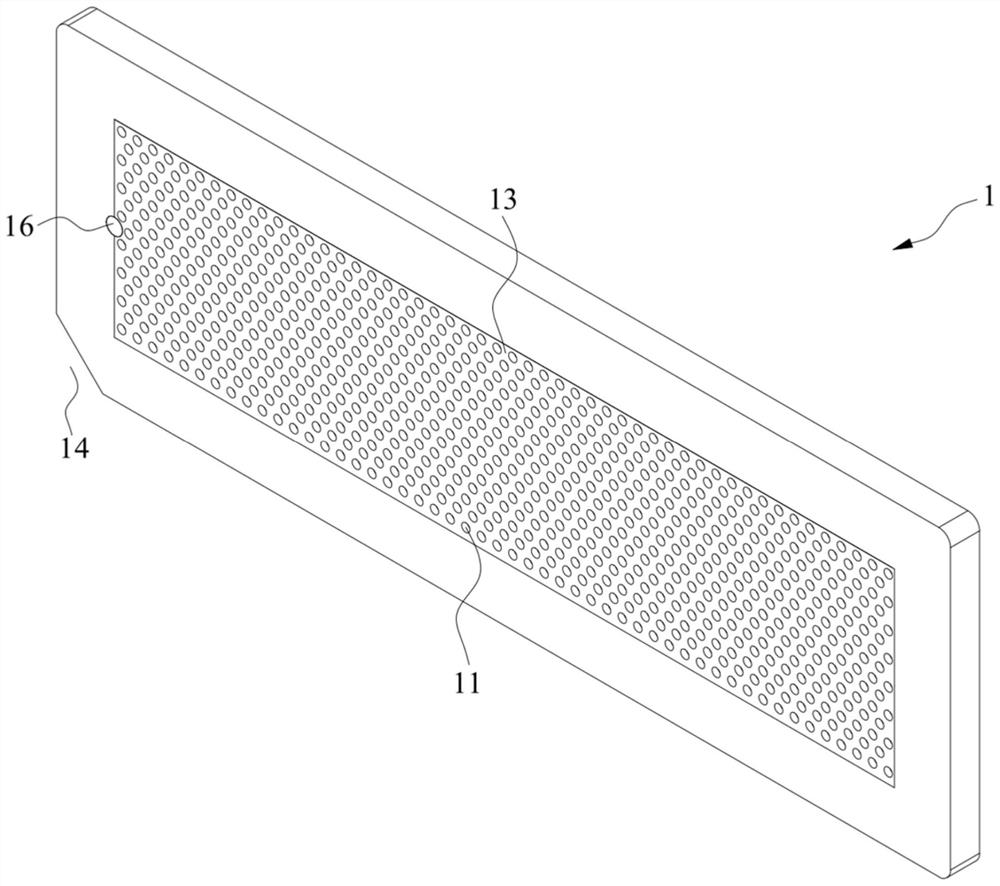

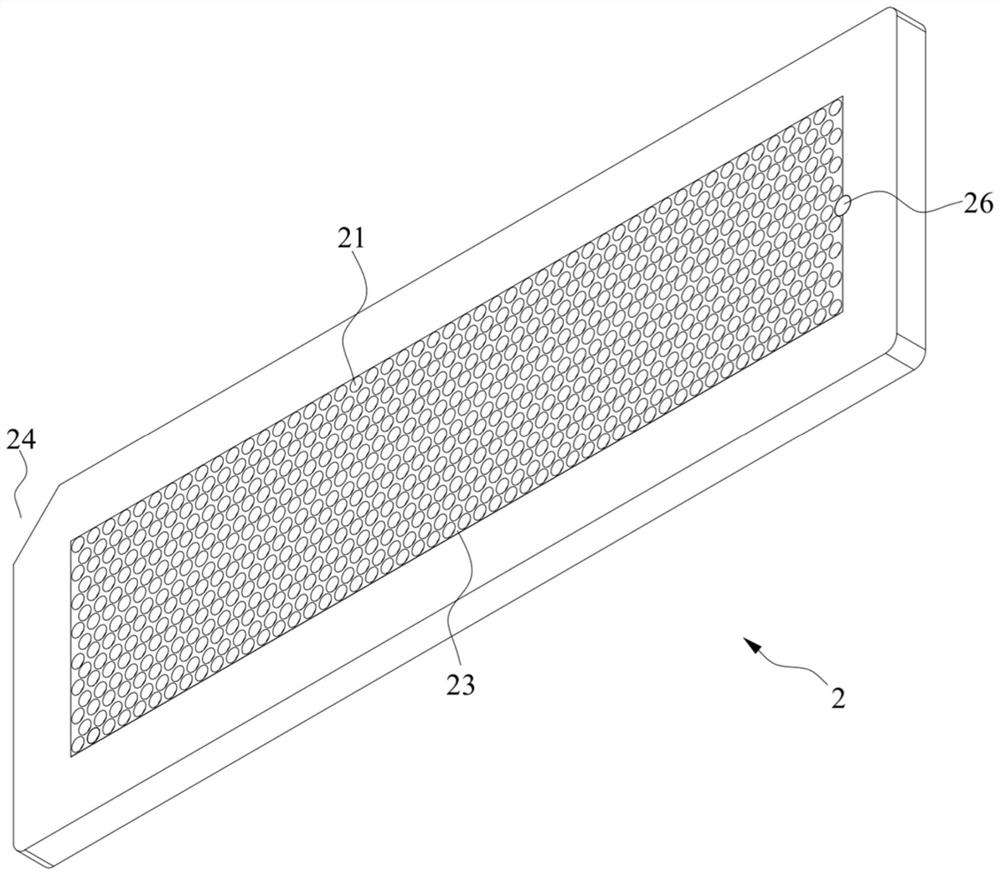

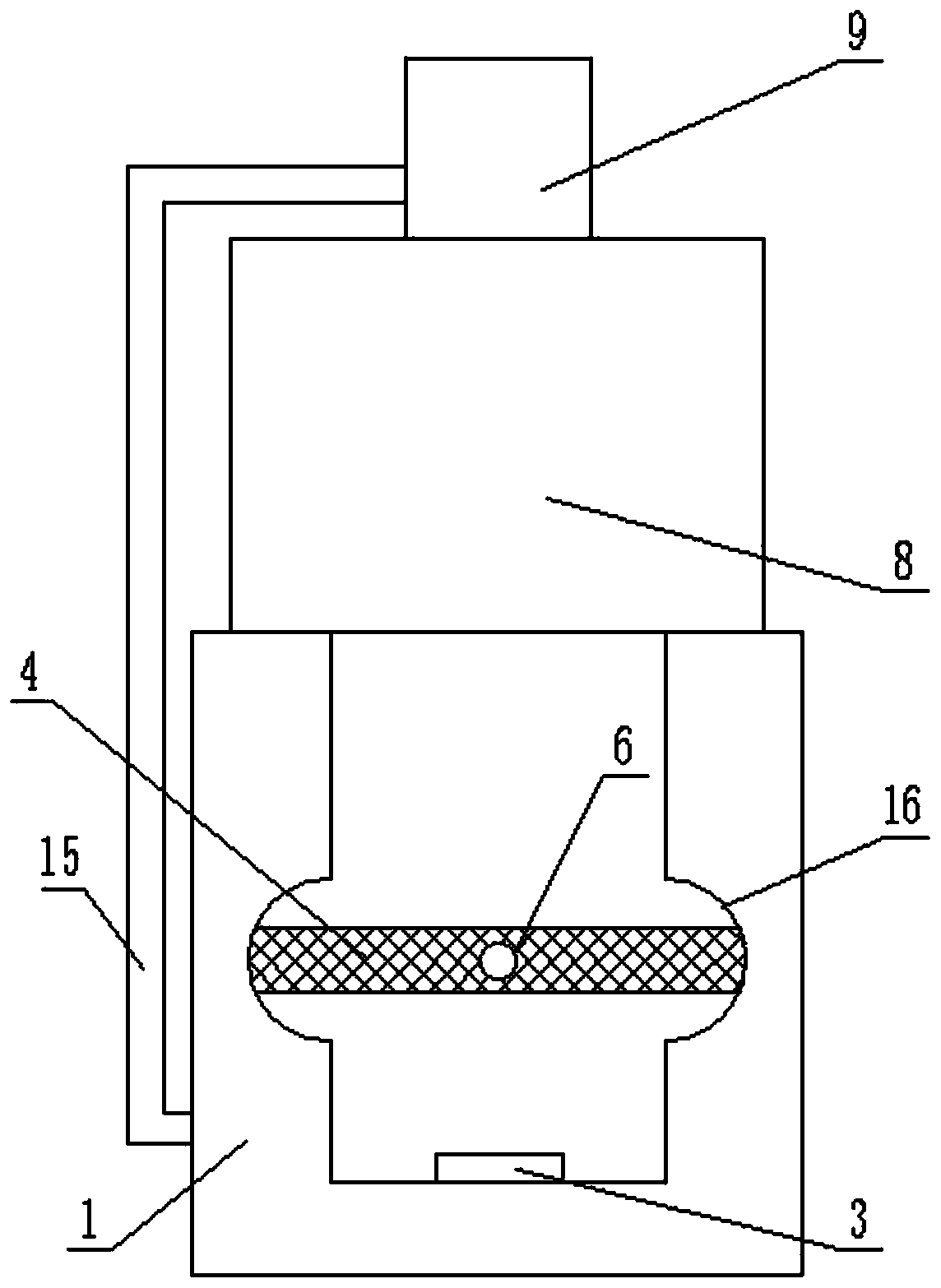

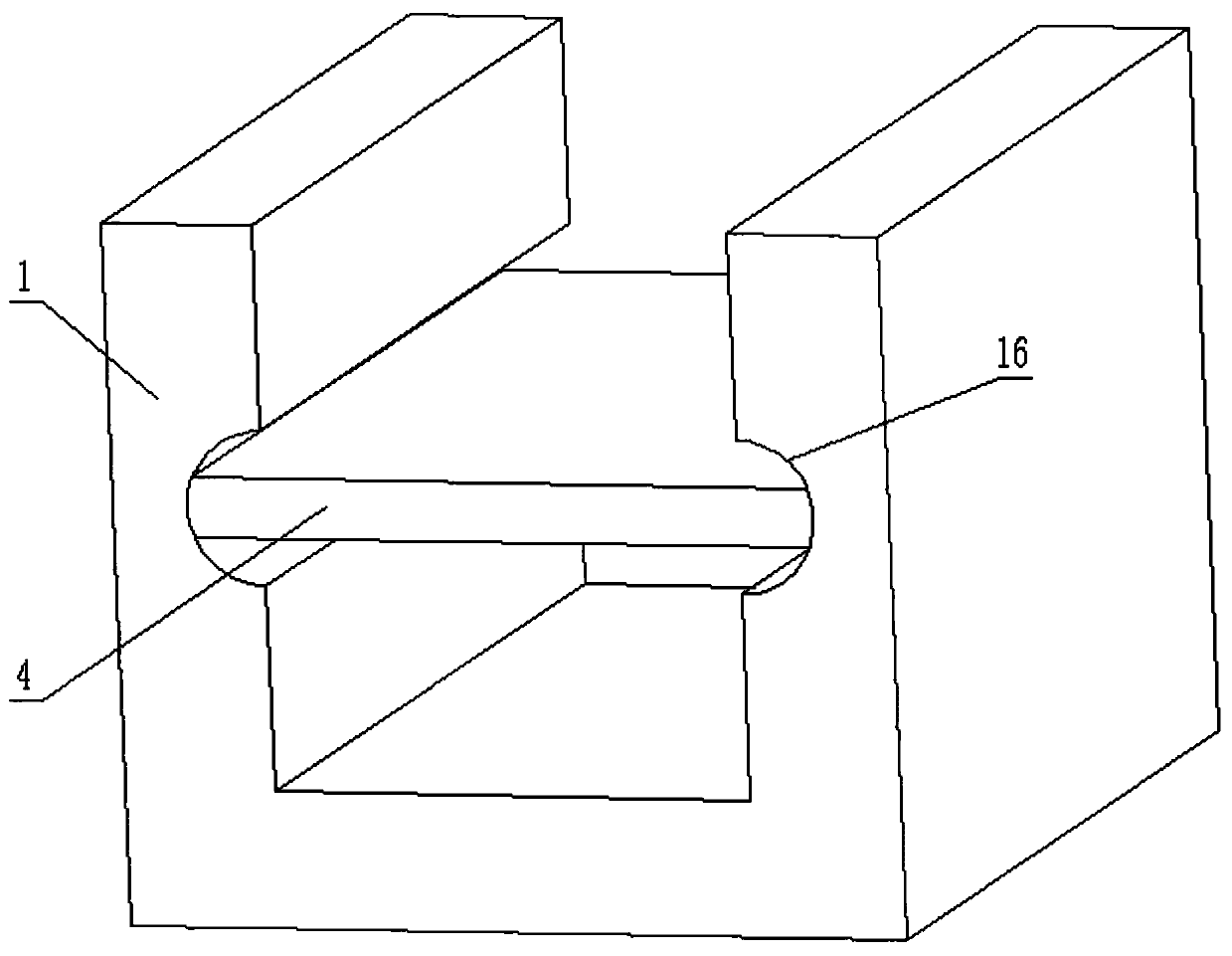

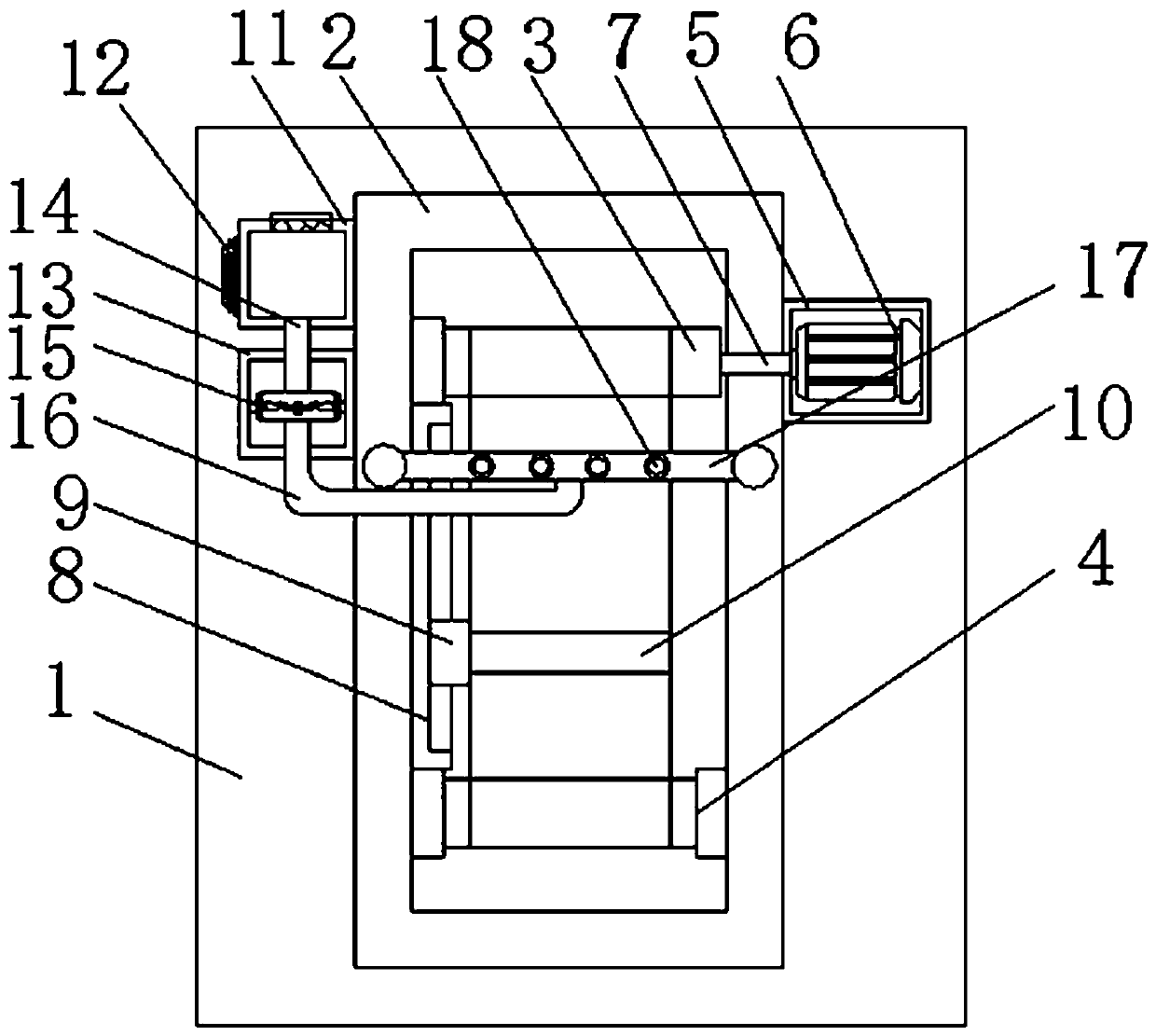

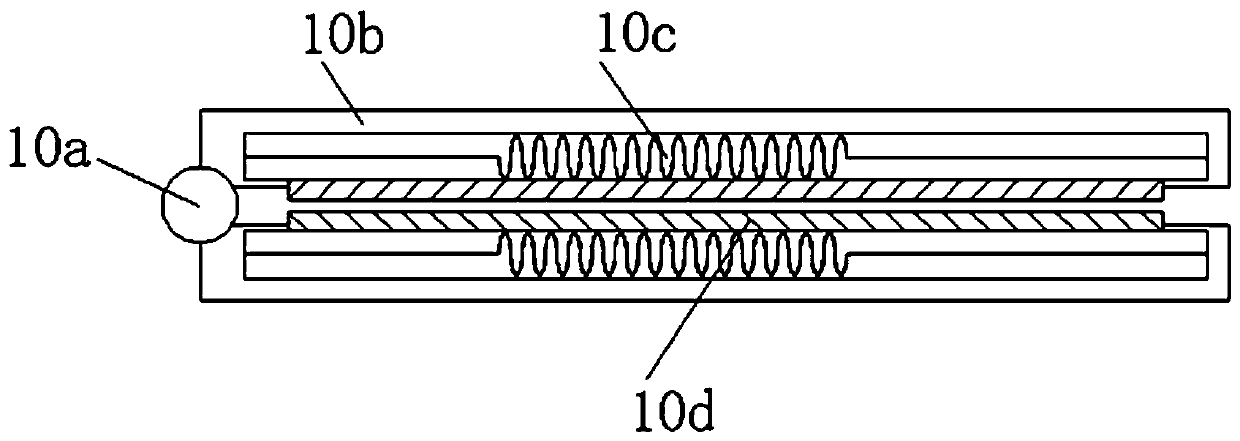

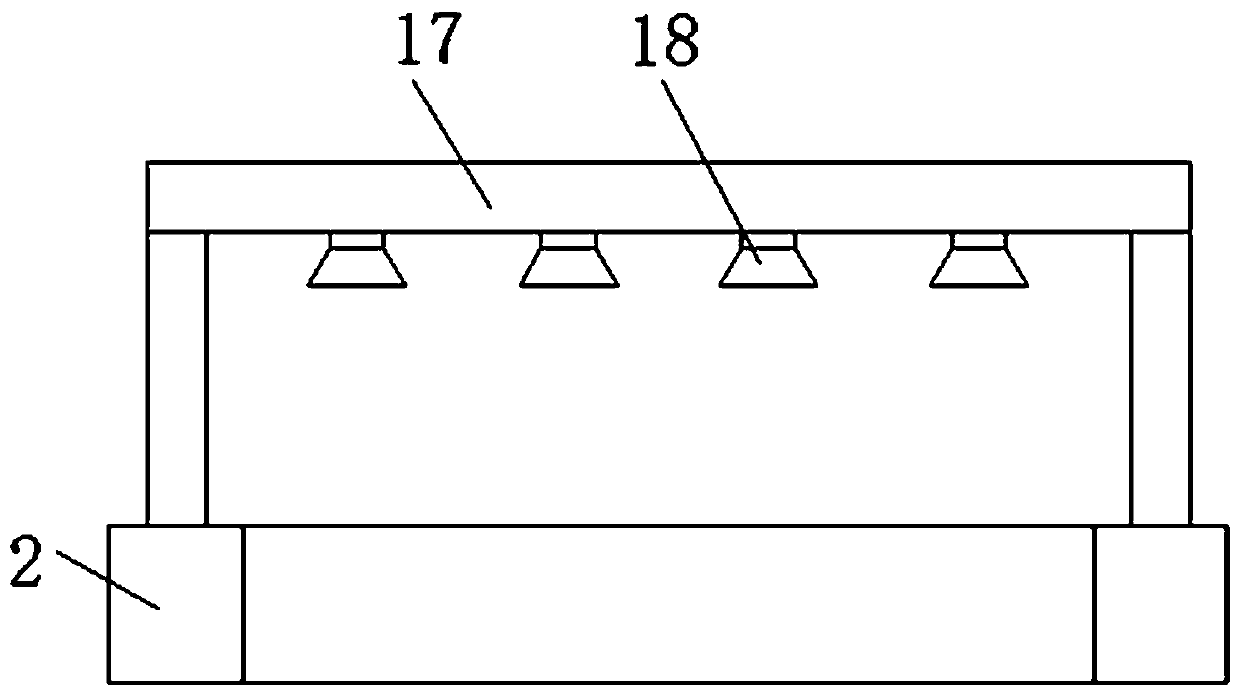

Cell screening device and cell screening method

PendingCN112300897AFacilitate subsequent processing operationsImprove filtering effectBioreactor/fermenter combinationsBiological substance pretreatmentsMedicineEngineering

The invention relates to the technical field of cell screening, and particularly discloses a cell screening device and a cell screening method. The cell screening device comprises a first chip and a second chip, wherein a plurality of first blind holes are formed in one side of the first chip, and each first blind hole is used for collecting a microbead or a cell; and one side of the second chip is provided with a plurality of second blind holes, when the second chip and the first chip are overlapped, the second blind holes and the first blind holes are formed in a one-to-one correspondence mode, and the diameter of each second blind hole is larger than that of each first blind hole. According to the device, while the cell screening effect is improved, the range of the cell screening sizeis expanded, so that the effective number of screening results is increased, and the integrity and applicability are guaranteed.

Owner:SUZHOU SINGLERON BIOTECHNOLOGIES LTD

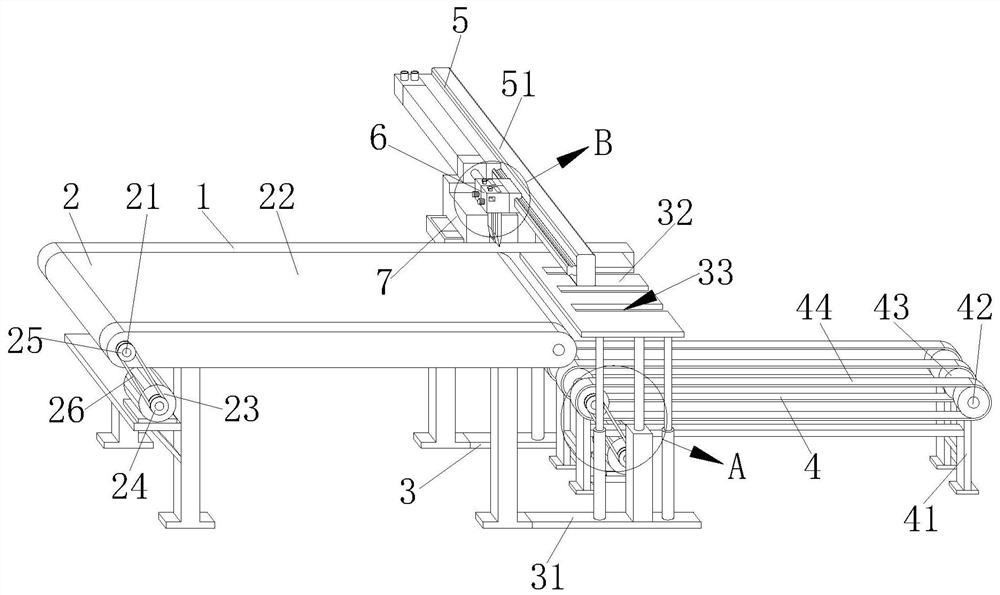

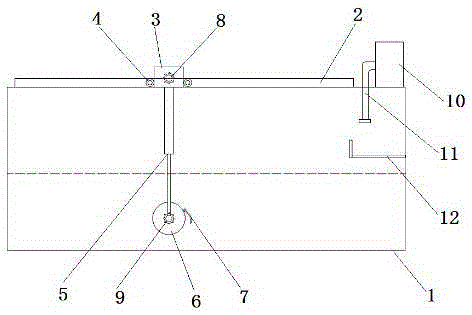

Efficient intelligent production equipment for knitted garments

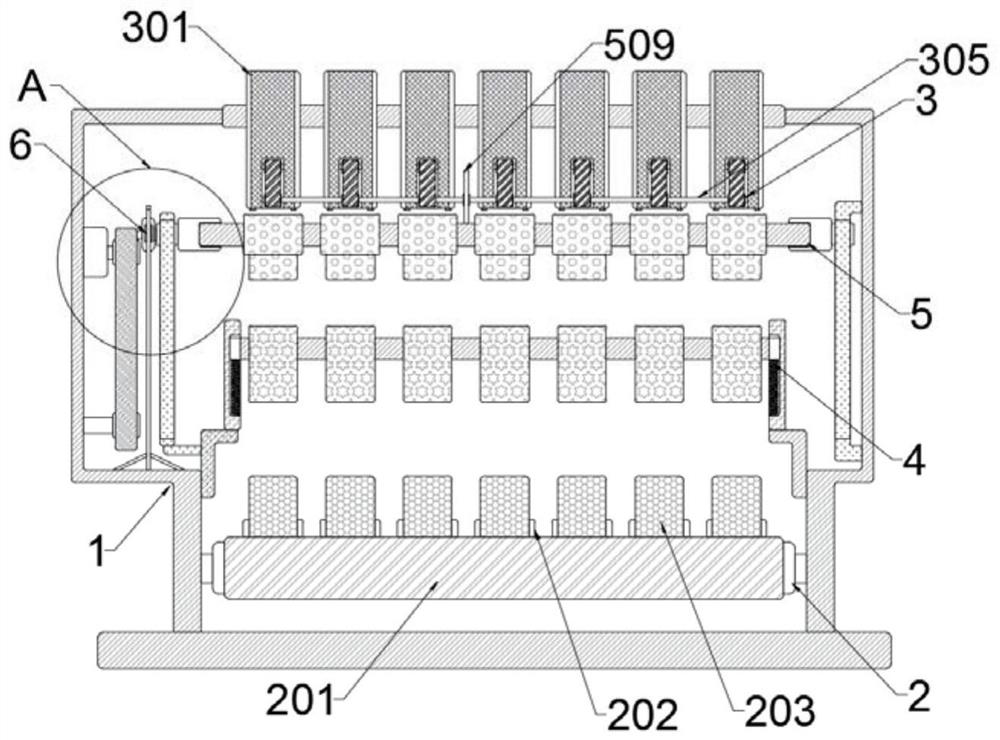

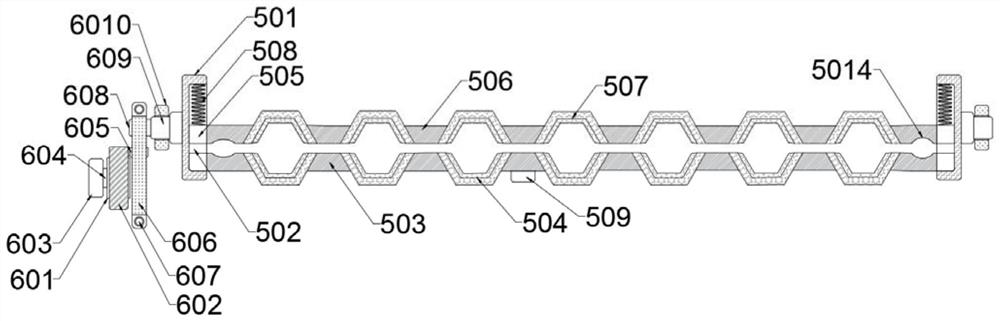

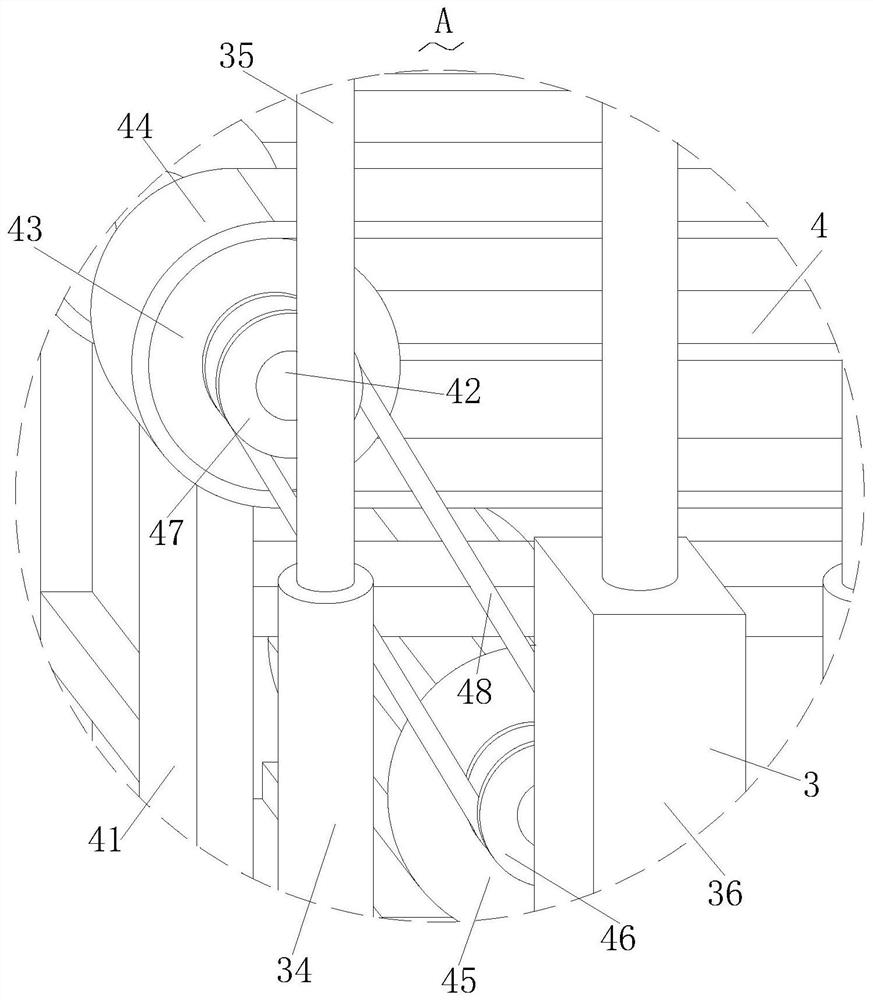

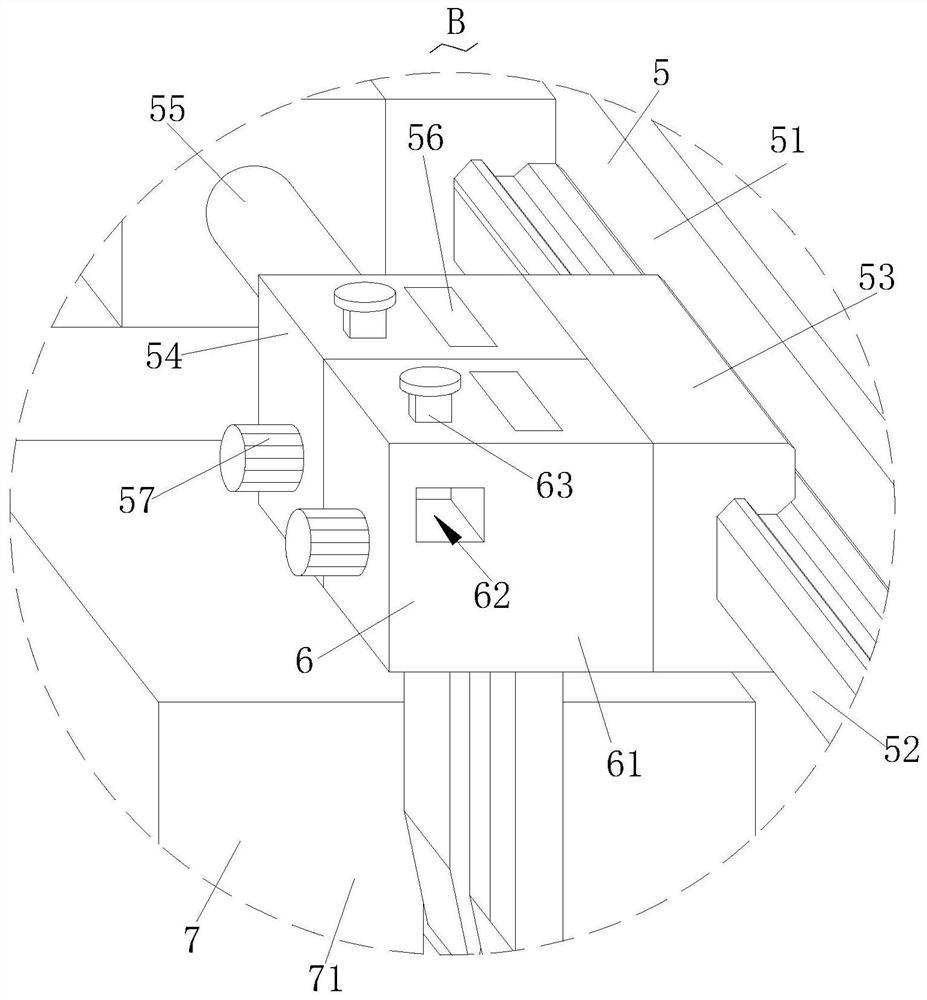

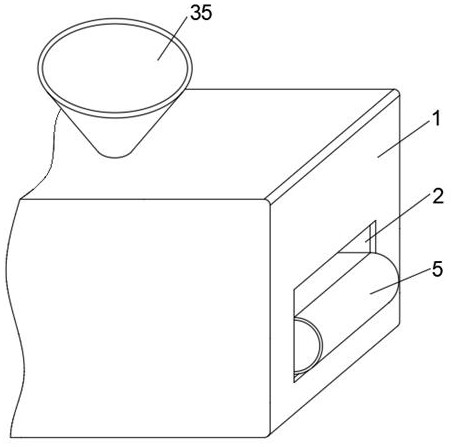

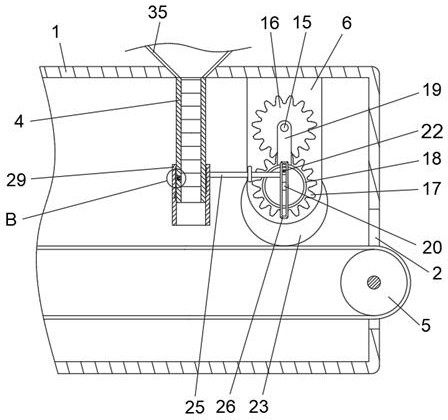

ActiveCN112481800AScientific and reasonable structureEasy to useWeft knittingStretchingYarnIndustrial engineering

The invention discloses efficient intelligent production equipment for knitted garments. A knitting inspection assembly is mounted at the bottom end of a bottom frame; a top column is slidably mountedin a sliding groove; a bobbin positioning detection assembly is mounted at the top end of a yarn placing table; a yarn feeding and arrangement assembly is mounted at the bottom end of a yarn feedinghole; a traction and collection assembly is mounted on one side of a sliding frame; and a twisting-proof assembly is mounted in the middle of a machine frame. According to the invention, the tractionand collection assembly is used in cooperation with the knitting inspection assembly and used for inspecting cloth after knitting is completed; whether the problems occur in a knitting process or notis known by judging whether the flatness of the surface of the cloth is uniform or not; leveling and inspection are conducted at the same time, so that inspection is fast and efficient, collection iseasy and fast, and the subsequent processing operation is facilitated; and yarns sequentially penetrate through the bobbin positioning detection assembly, the twisting-proof assembly and the yarn feeding and arrangement assembly and then enter a flat knitting machine to be knitted, so that the yarns are treated in the aspects of yarn discharging, guiding and waxing, knitting operation of the yarnsis better facilitated, and the quality of the finished product obtained after cloth knitting is better.

Owner:上海优利优针织服饰有限公司

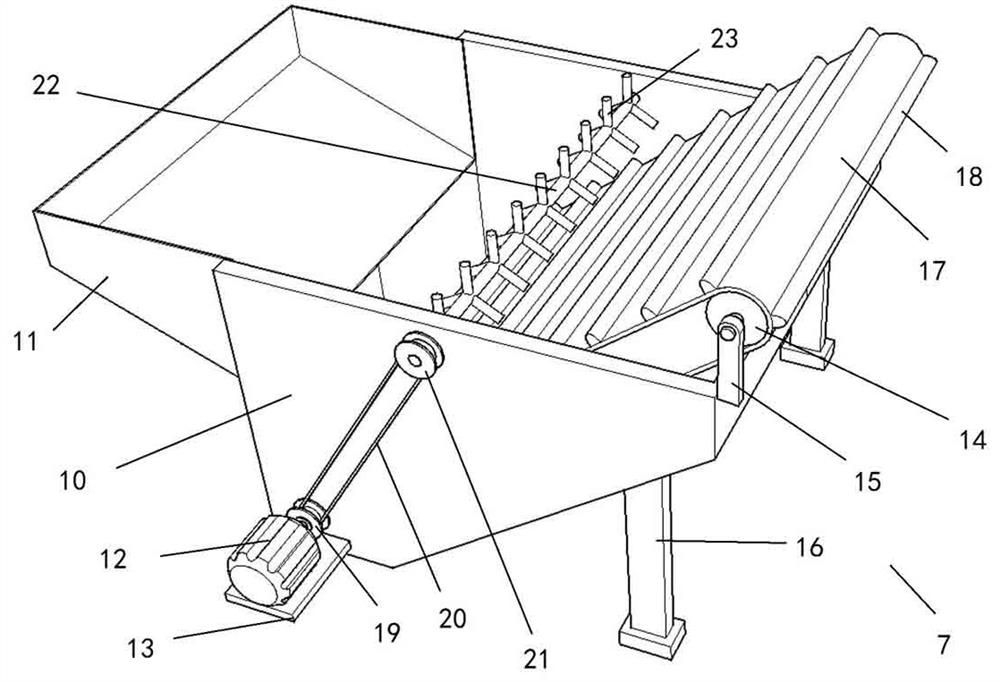

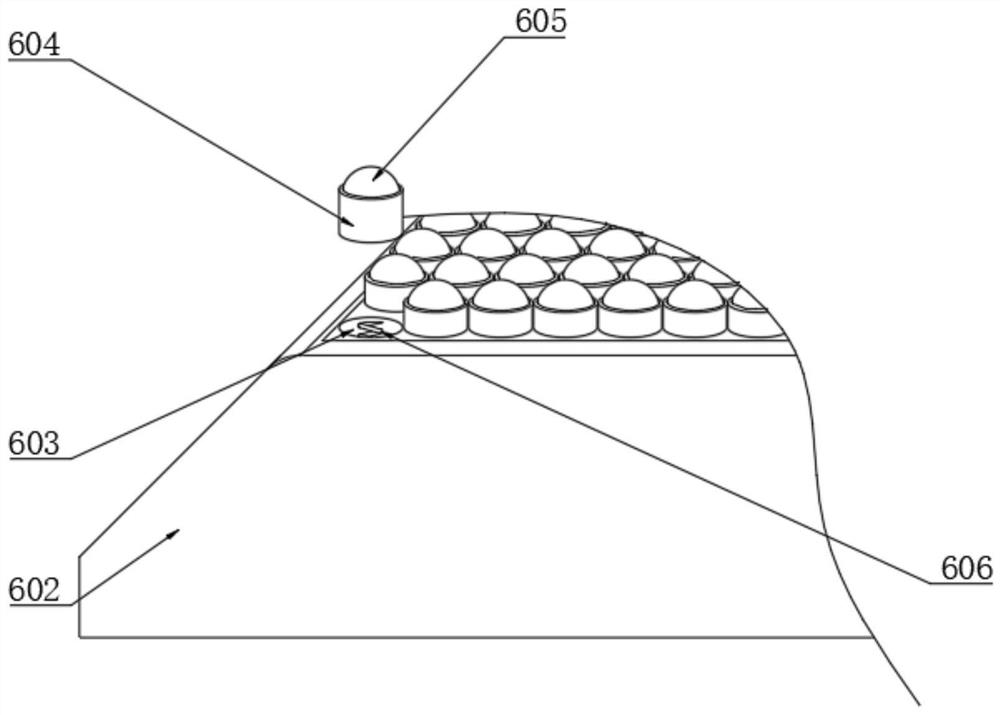

Impurity removing device for nut machining

PendingCN112742709AFacilitate subsequent processing operationsPracticalGas current separationEngineeringWaste material

The invention relates to the technical field of nut machining auxiliary equipment, in particular to an impurity removing device for nut machining. The impurity removing device comprises supporting transverse plates in front-back symmetry, first supporting rods and second supporting rods in front-back symmetry are fixed on the top end surfaces of the supporting transverse plates correspondingly, and the first supporting rods are located on the inner sides of the second supporting rods, the top ends of the first supporting rods are connected with a waste material inclined plate, and the right end of the waste material inclined plate is connected with a baffle with the same front-back width as the waste material inclined plate, the top ends of the second supporting rods are connected with front-back symmetrical L-shaped connecting plates in a supported mode, a material guiding inclined plate is connected between the connecting plates, and front-back symmetrical third supporting rods are fixed to the top end faces of the connecting plates. The impurity removing device for the nut machining is reasonable in structural design, can collect nuts subjected to impurity removal and can also collect impurities subjected to impurity removal, so that subsequent machining operations are facilitated, the practicability is high, and the impurity removing device has extremely good market popularization value.

Owner:安徽凯瑞汽配制造有限公司

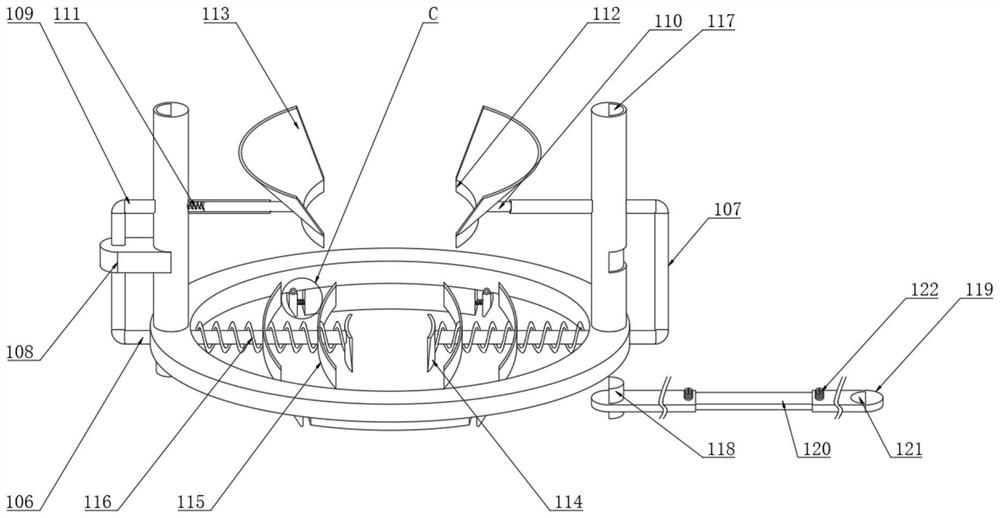

Knitted garment manufacturing system

ActiveCN112251899AScientific and reasonable structureSafe and convenientWeft knittingInspecting textilesEngineeringStructural engineering

The invention discloses a knitted garment manufacturing system. A feeding device comprises a bottom ring; rubber clamping blocks are hinged to the positions, close to the two ends of a clamping plate,of the bottom ring; supporting columns are welded to the two ends of the top face of the bottom ring; vertical rods are welded to the top ends of the bottom rods; guide pipes movably penetrate through the middles of the supporting columns; the ends, away from the vertical rods, of the guide pipes are connected to one ends of drawing rods in a sleeving mode; one ends, located in the guide pipes, of the drawing rods are spot-welded to one end of a retaining spring; an arc-shaped rubber plate is bonded to the ends, away from the retaining spring, of the drawing rods; a guide plate is bonded to the top end of the arc-shaped rubber plate; shifting pieces are bonded to the ends, located in the bottom ring, of bottom rods; the outer sides of the bottom rods are sleeved with rubber supporting strips; the shifting pieces, the rubber supporting strips and the adjacent rubber supporting strips are connected through sleeving springs; connecting positioning blocks are welded to the positions, corresponding to the connecting positioning holes, of the bottom end of the bottom ring; the opposite ends of two extension pipes are sleeved with the two ends of extension rods respectively; and butt joint holes are formed in the positions, corresponding to the connecting positioning blocks, of the extension pipes.

Owner:浙江晞尔波针织有限公司

Cosmetic powder scattered drying device

InactiveCN111692871AGood conditionFully contactedDrying gas arrangementsDrying solid materialsMechanical engineeringIndustrial engineering

The invention discloses a cosmetic powder scattered drying device, and relates to the technical field of cosmetic production. The cosmetic powder scattered drying device comprises a drying box; a first fixing plate is provided with a pushing guiding device; one side of the bottom of a second fixing plate is fixedly connected with a third fixing plate; the upper portion of the third fixing plate isprovided with a hot air device, and the lower portion of the third fixing plate is provided with a receiving housing; the bottom end of a discharging pipe is connected with a conveying device; and the top of a drying box is provided with an air exhausting device. According to the cosmetic powder scattered drying device, by arranging the hot air device and the air exhausting device, it can be achieved that hot air flows from top to bottom, and cosmetic powder is dried; by arranging the pushing guiding device, on the premise that guiding of cosmetic powder is achieved, the cosmetic powder is pushed to be bounced and then fall, the cosmetic powder can make sufficient contact with the hot air conveniently, and accordingly, the drying speed is increased effectively; and by arranging scatteringrods, caked cosmetic raw materials can be scattered and conveniently dried, meanwhile, the cosmetic powder can have a better state, and follow-up machining operation is facilitated.

Owner:李凯

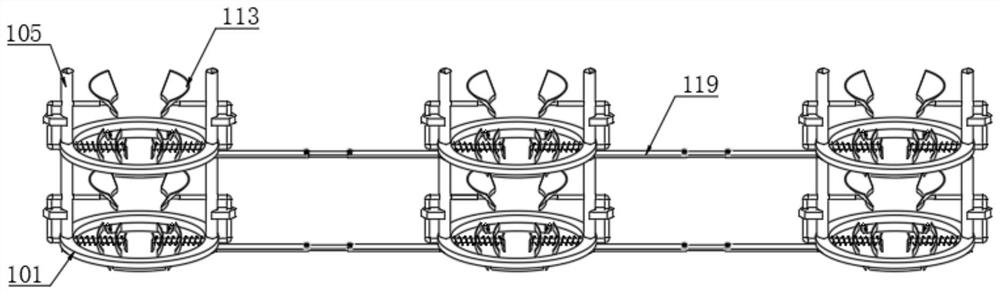

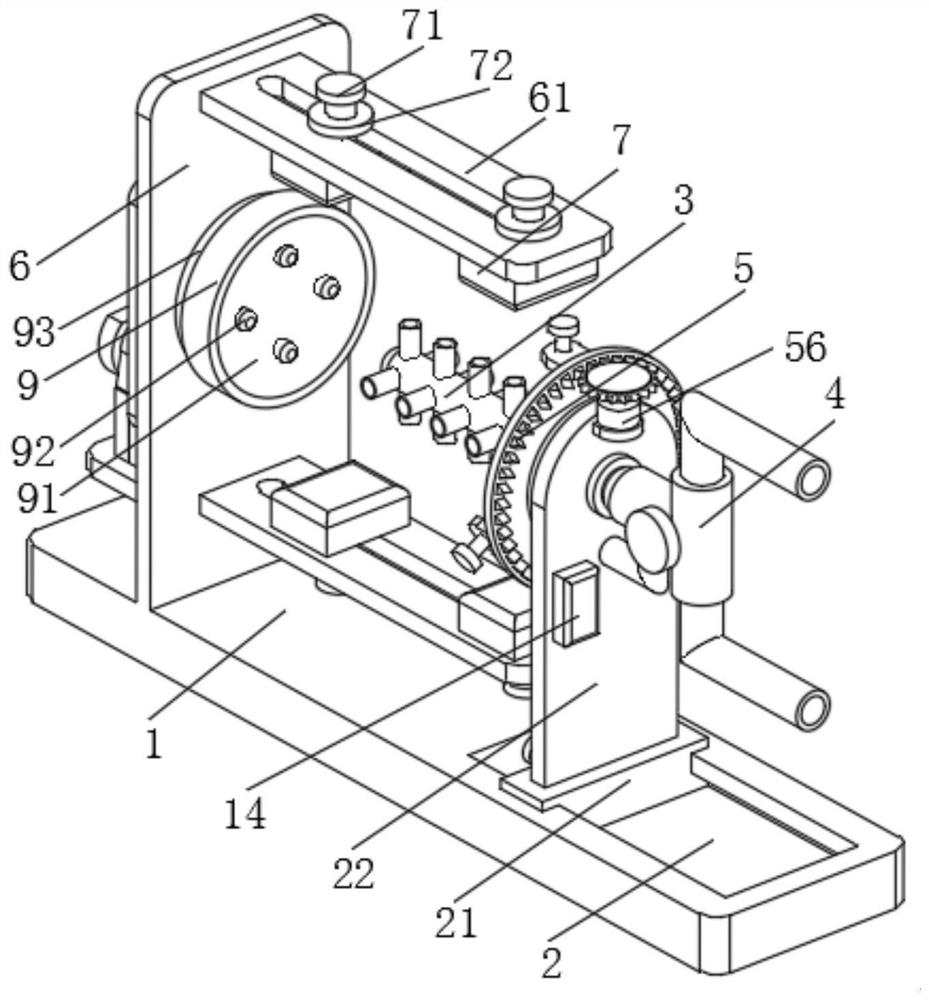

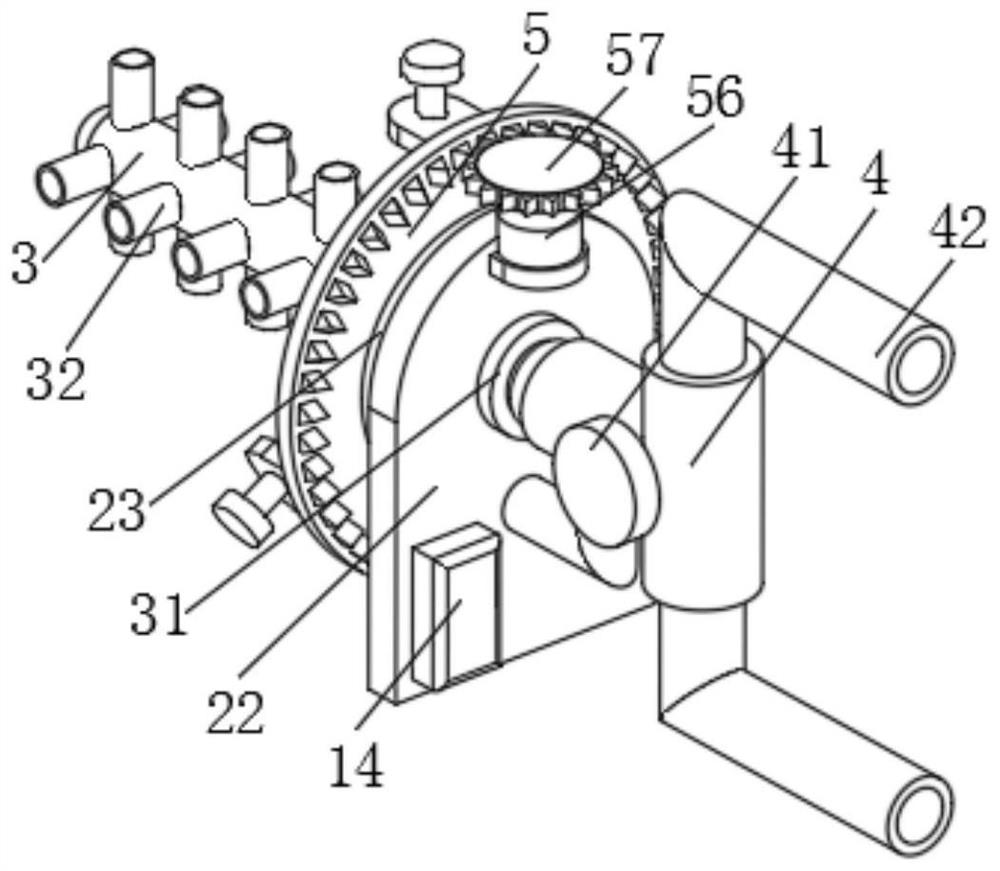

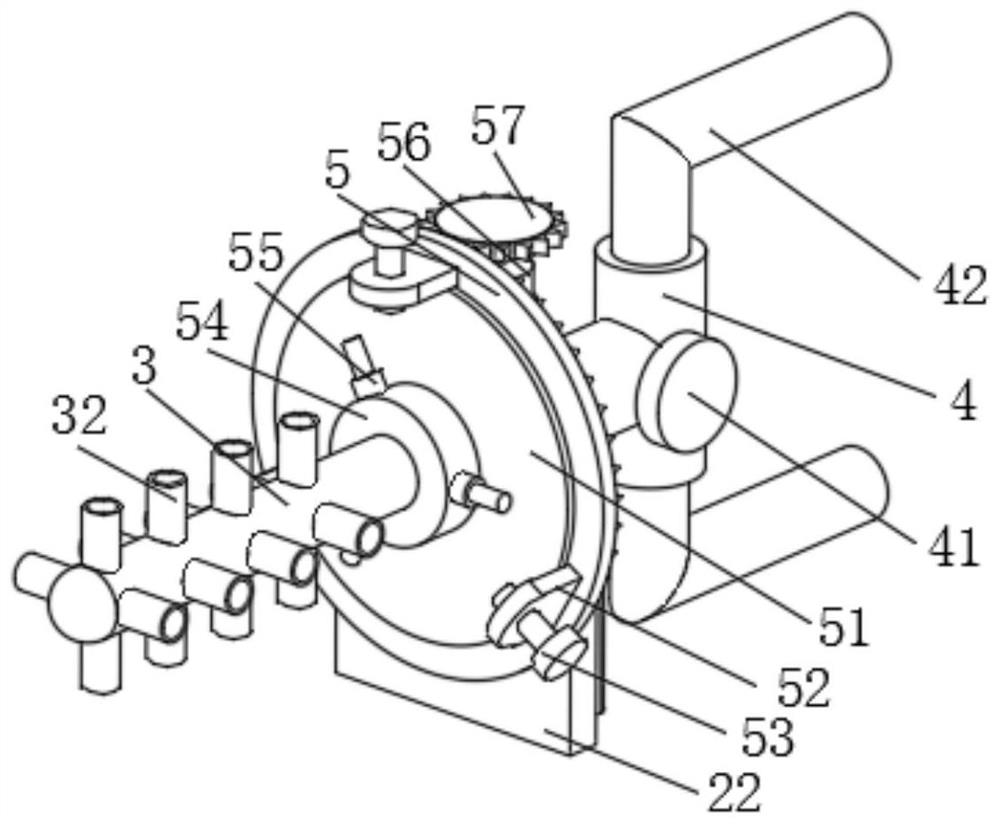

Multi-station automatic feeding device for flange silencer welding

InactiveCN113352042ARealize precise docking operationFacilitate subsequent processing operationsWelding/cutting auxillary devicesAuxillary welding devicesButt jointTransfer mechanism

The invention relates to the technical field of flange silencer machining, and discloses a multi-station automatic feeding device for flange silencer welding. The multi-station automatic feeding device comprises a mounting frame, a conveying mechanism is fixedly mounted at the bottom end of the mounting frame, and a butt joint mechanism is fixedly mounted on the mounting frame above the conveying mechanism; a transfer mechanism is installed on the mounting frame above the butt joint mechanism, one side of the transfer mechanism is connected with a driving mechanism, and a discharging mechanism is fixedly installed on the mounting frame above the transfer mechanism, flanges in a discharging pipe can be automatically discharged into the transfer mechanism through the discharging mechanism, and the transfer mechanism can transfer the flanges into the butt joint mechanism; and then the butt joint mechanism is pressed to make the butt joint mechanism make contact with the silencer so that the flange can accurately fall into a flange mounting groove in the silencer, subsequent welding machining operation of the flange and the silencer is facilitated, the process that the flange and the silencer are in butt joint by workers can be omitted through the mechanisms, and the machining efficiency is improved.

Owner:郝营春

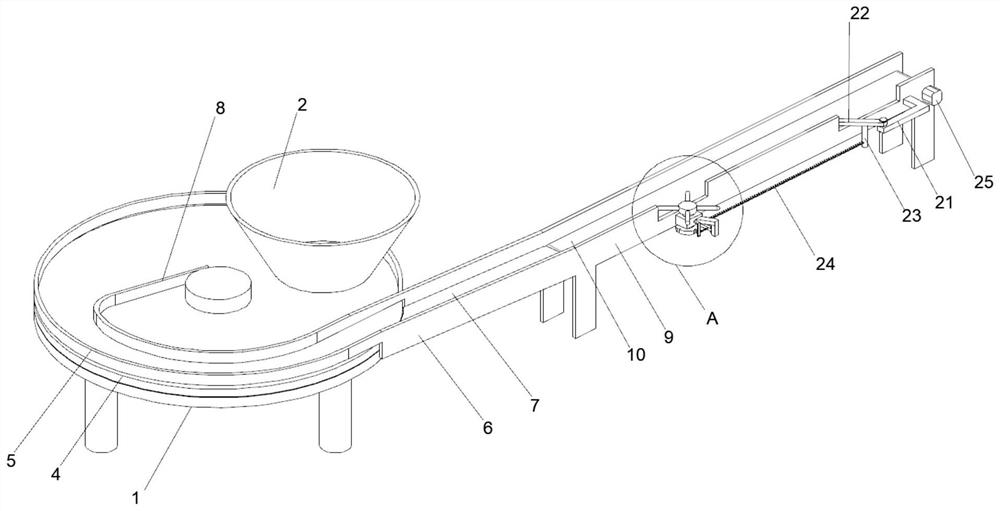

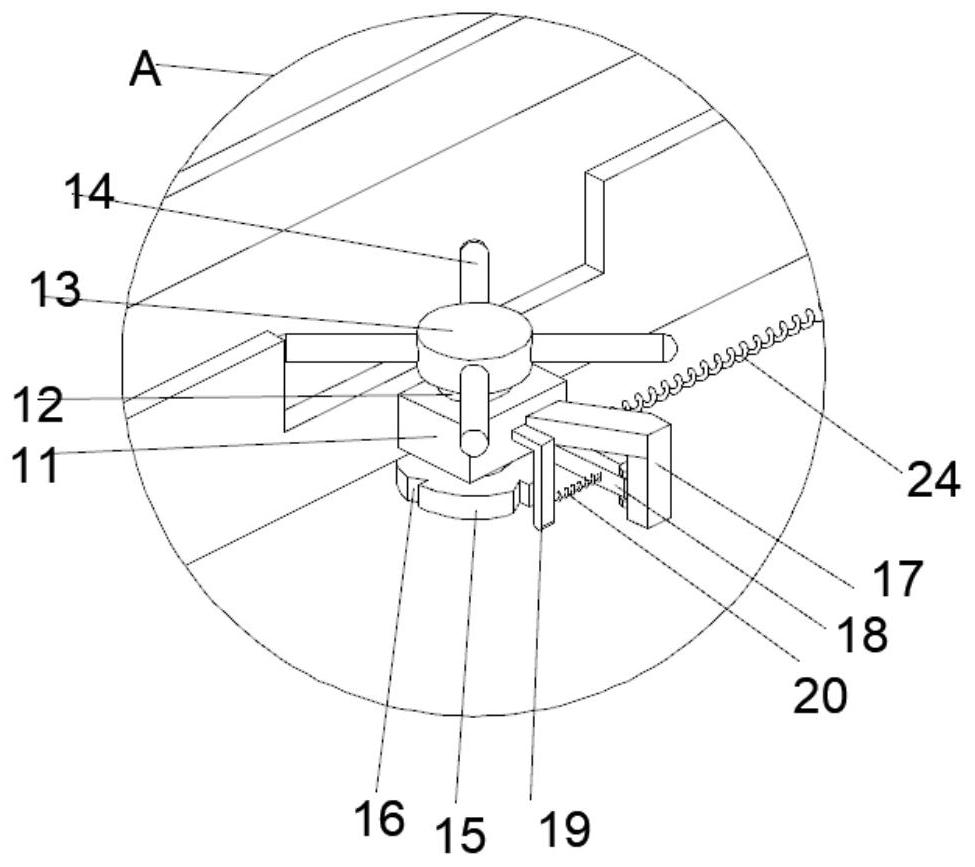

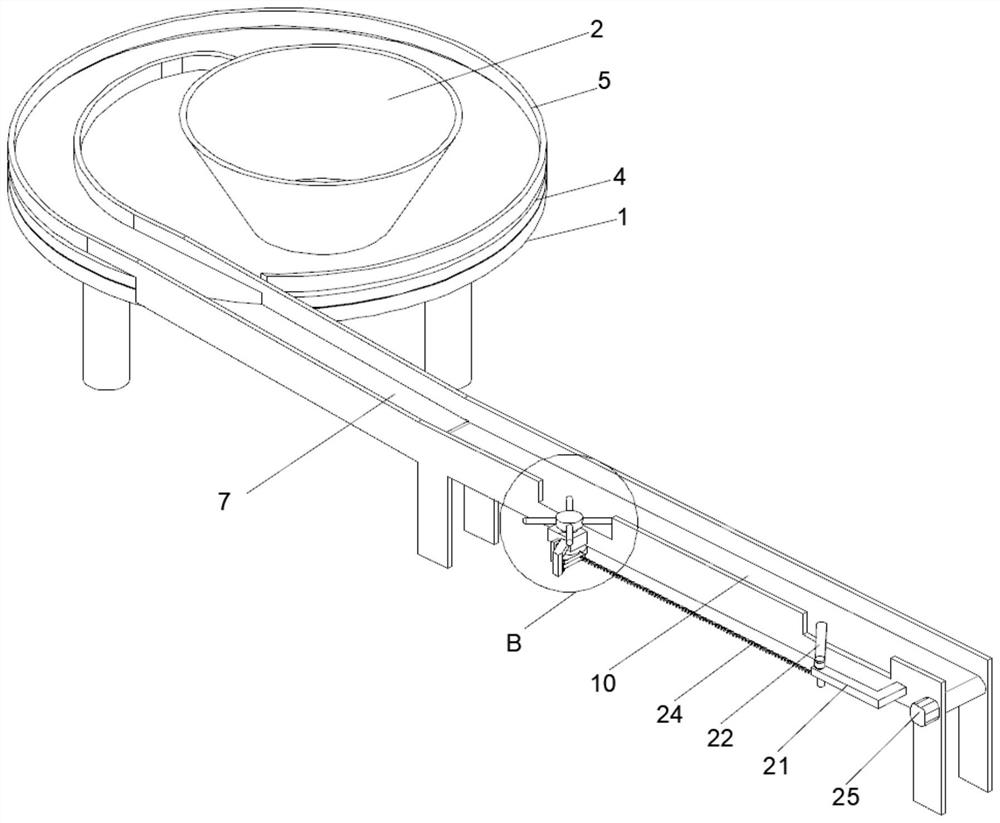

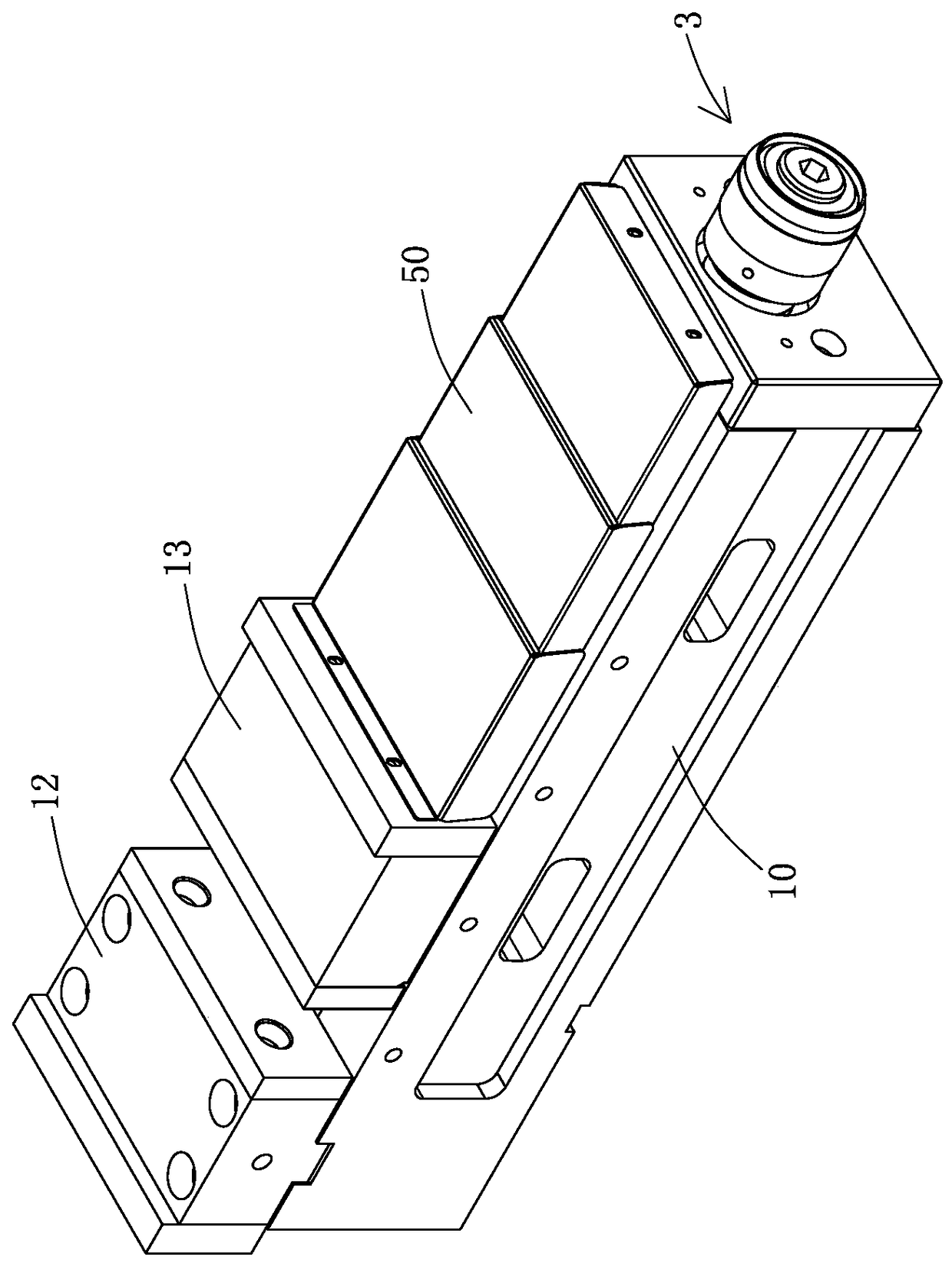

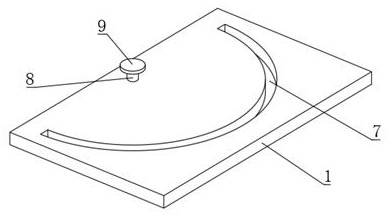

Feeding device for bearing outer ring machining

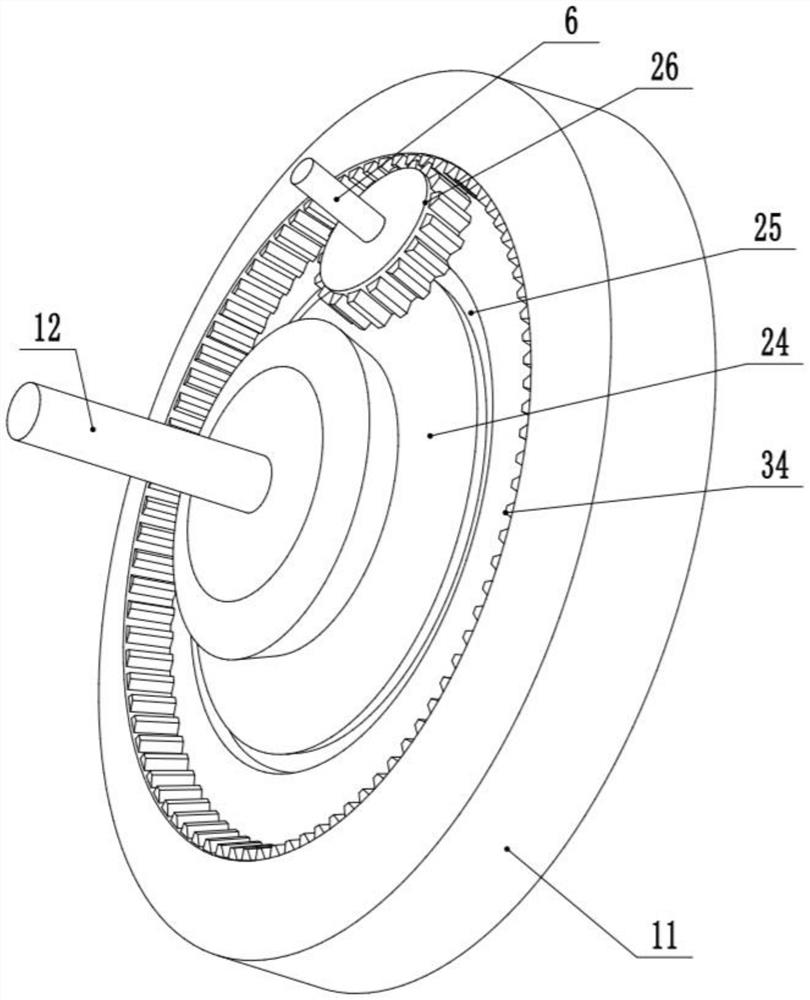

PendingCN113697399AArrangement rulesEasy to transportGrinding feedersConveyor partsElectric machineryEngineering

The invention discloses a feeding device for bearing outer ring machining. The feeding device for bearing outer ring machining comprises a base, a discharging barrel and a first support, a first motor is fixedly installed at the lower side of the base, a rotating disc is fixedly installed at the output end of the first motor and rotationally connected with the base, and an arc-shaped ring and a flow guide ring are fixedly connected to one end of the first support. A guide plate is fixedly mounted at the bottom of the first support. The first motor drives the rotating disc to rotate anticlockwise, bearing outer rings fall on the surface of the rotating disc through the discharging barrel, and when the bearing outer rings at the inner side of the rotating disc move to make contact with the flow guide ring, the bearing outer rings will slide relative to the rotating disc along with continuous rotation of the rotating disc and gradually move towards the outer ring of the rotating disc; and when the bearing outer rings move to a channel between the flow guide ring and the arc-shaped ring, the bearing outer rings will move to the guide plate along with the rotating disc all the time, the bearing outer rings slide down from the material guide plate and move to a conveying belt, the bearing outer rings can be regularly arranged through the arrangement, and follow-up feeding is facilitated.

Owner:赵亚东

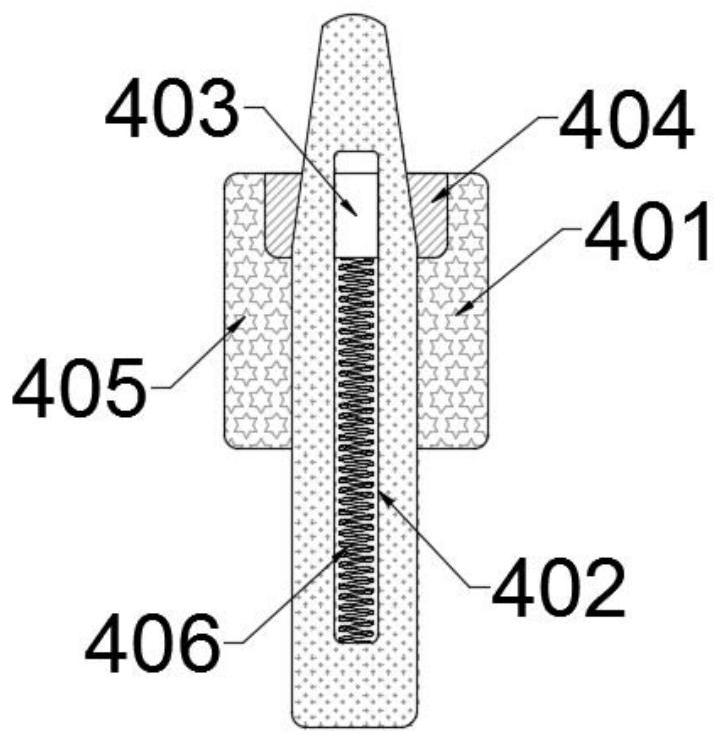

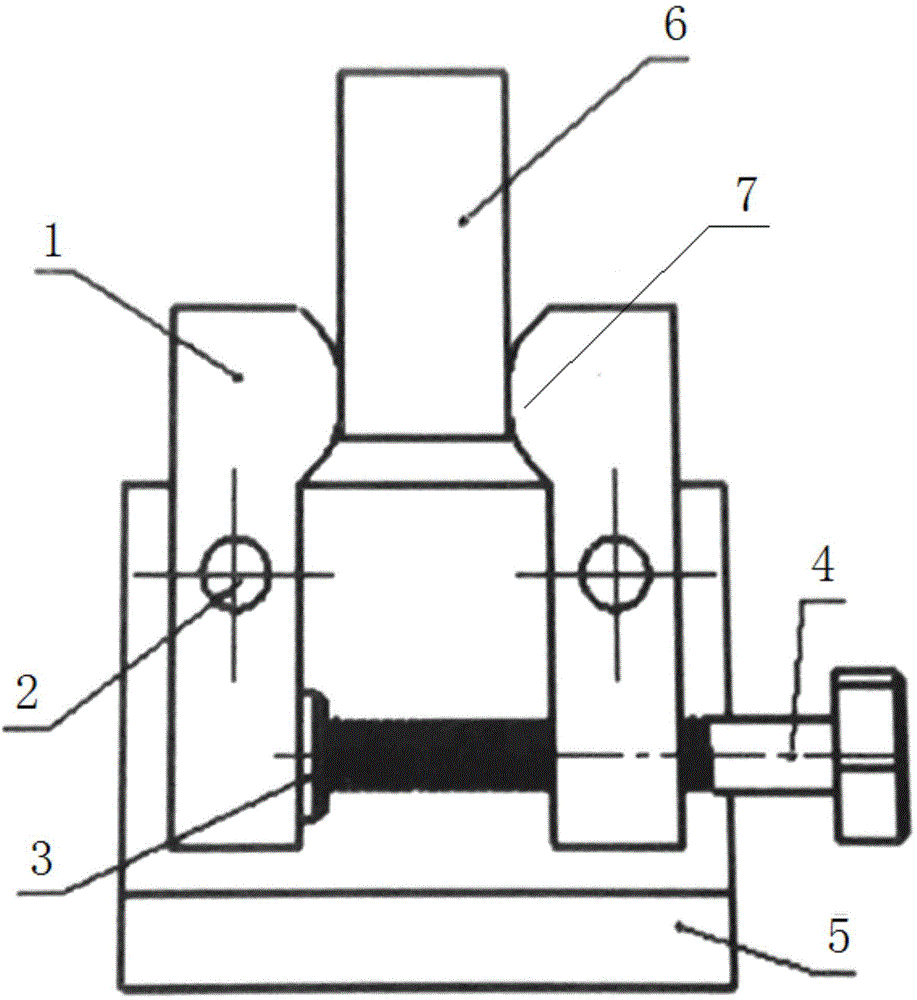

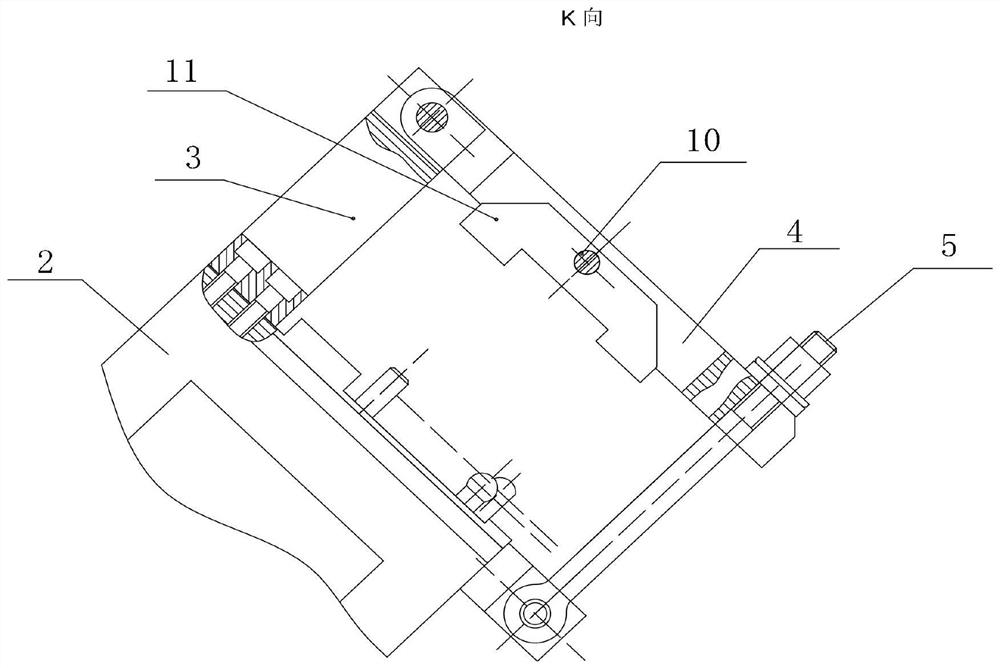

Non-self-locking floating clamping mechanism

InactiveCN104440187AAvoid damagePlay a buffer roleWork holdersPositioning apparatusSelf lockingUltimate tensile strength

The invention provides a non-self-locking floating clamping mechanism. The non-self-locking floating clamping mechanism comprises a rear supporting plate and is characterized by further comprising a screw, two floating pressing plates and two cylindrical pins; the two floating pressing plates are movably installed on the front surface of the rear supporting plate through the cylindrical pins, floating pressing plate pins are symmetrically arranged, a space for clamping a part is reserved between the two floating pressing plates, a threaded through hole is formed in one floating pressing plate, the screw penetrates through the threaded through hole of the floating pressing plate, and the end, penetrating through the threaded through hole, of the screw jacks the side face of the other floating pressing plate. The non-self-locking floating clamping mechanism solves the problems that the part can move, but a clamping arm is fixed, clamping work cannot be well finished, machining accuracy is affected, due to too large clamping strength, the part is easily damaged, and large loss is caused, and the non-self-locking floating clamping mechanism is simple in structure and continues conducting effective clamping along with the change of the position of the part.

Owner:倪传华

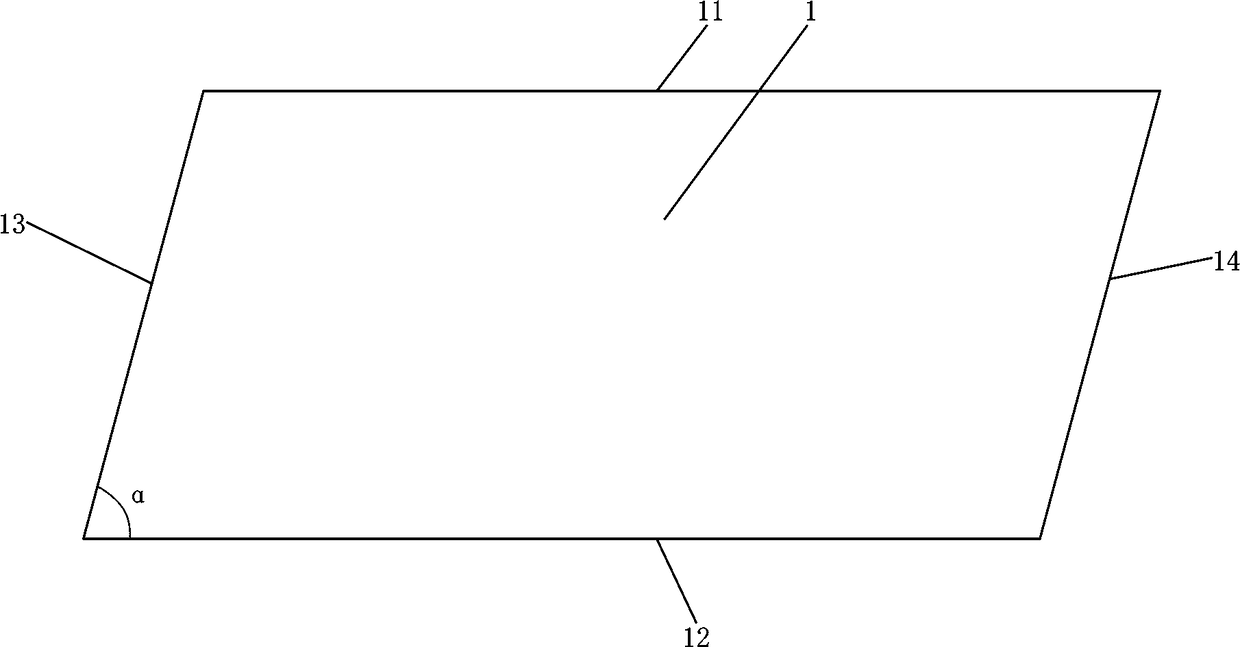

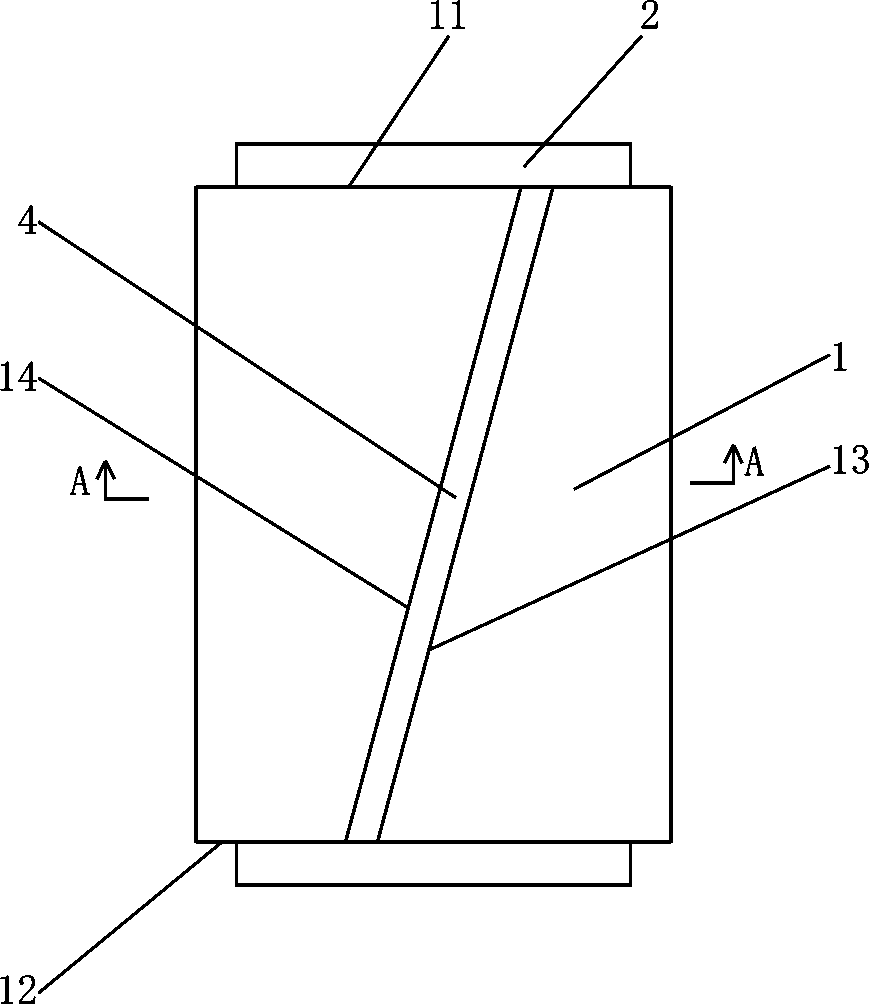

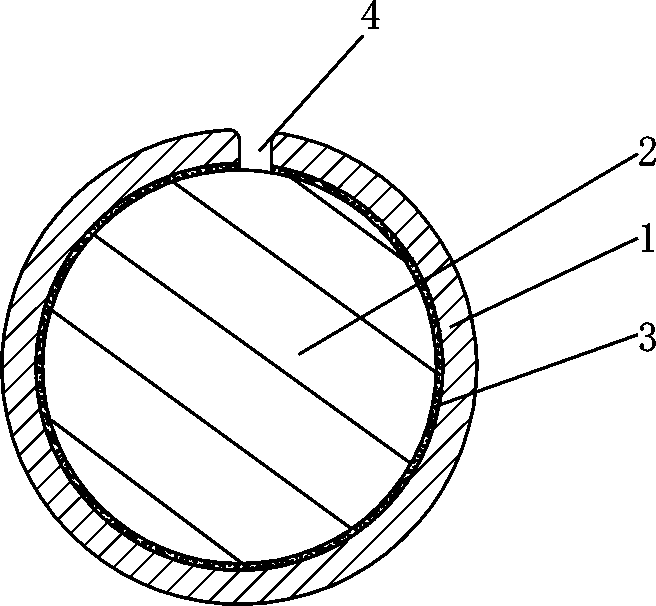

Production method of plate-seam-free molding plate roller

The invention relates to a production method of a plate-seam-free molding plate roller. The method comprises the following steps of (1) making a parallelogram molding work plate; (2) cleanly cleaningthe surface of the plate roller body; pasting the molding work plate onto the outer surface of the plate roller body; after the pasting of the molding work plate, the first pairs of opposite edges arepositioned in the peripheral direction of the plate roller body; in addition, a connecting seam is formed between the second pair of opposite edges; (3) the inside of the connecting seam is cleanly cleaned; the edge parts of the second pair of opposite edges of the molding work plate are downwards pressed to reach the downwards recessed state; (4) the connecting seam is filled with UV curing filling materials; a mother film is used, is pasted onto the UV curing filling material and is pressed; (5) the UV curing filling material is cured; after the curing is completed, the mother film is peeled away to obtain the plate-seam-free molding plate roller. The plate-seam-free molding product can be obtained by using the manufactured plate-seam-free molding plate roller through once molding; in addition, the plate roller can be integrally heated; the plate roller surface temperature difference is small; after the molding material is heated, the deformation is small; the product surface is smooth; the color difference is small; the brightness is stable.

Owner:SHANTOU JIAXIN PACKING MATERIAL CO LTD

A high-efficiency intelligent manufacturing equipment for knitted garments

ActiveCN112481800BScientific and reasonable structureEasy to useWeft knittingStretchingYarnSmart manufacturing

Owner:上海优利优针织服饰有限公司

Glass tape production device

InactiveCN112723730AImprove feeding efficiency and safetyImprove unloading efficiencyGlass severing apparatusFixed frameTool bit

The invention relates to the field of glass tape production devices, and particularly discloses a glass tape production device. The device comprises a fixing frame, a first conveying structure, a material receiving structure, a second conveying structure, a cutting structure, a slitting structure and a cleaning structure. The arrangement of the first conveying structure can automatically and continuously convey the glass tape, manual feeding is not needed, the feeding efficiency and safety can be greatly improved, the arrangement of the material receiving structure is matched, automatic discharging is conducted after the glass tape is cut into small pieces of glass, manual discharging is not needed, the discharging efficiency can be improved, and the discharging safety is improved. The second conveying structure is arranged, so that the glass on the material receiving structure can be automatically conveyed after the material receiving structure automatically descends, the automatic conveying efficiency can be improved, the distances between the pieces of placed glass can be equal, subsequent processing of the blocky glass is facilitated, and the production efficiency is improved. And through the cutting structure, the glass cutting tool bit can be quickly mounted and replaced.

Owner:秦志千

Intelligent capacitor bending and cutting device for producing and manufacturing electronic components

InactiveCN114210877AImprove processing efficiencyFacilitate subsequent processing operationsCapacitanceSlide plate

The invention discloses an intelligent capacitor bending and cutting device for electronic component production and manufacturing, and relates to the technical field of electronic component production devices.The intelligent capacitor bending and cutting device comprises a box body, a discharging opening is formed in the surface of the box body, a conveying pipe is fixedly connected to the upper end of the box body, and a conveying belt is fixedly installed in the box body; a first mounting plate and a second mounting plate are fixedly connected to the top of the inner wall of the box body, a sliding groove is formed in the surface of the second mounting plate, a sliding plate is slidably connected to the inner wall of the sliding groove, a first spring is fixedly connected to the upper surface of the sliding plate, and the top end of the first spring is fixedly connected with the inner wall of the sliding groove; the two ends of the bottom face of the sliding plate are fixedly connected with a telescopic bending plate and a cutting plate correspondingly, and the telescopic bending plate and the cutting plate are driven to move up and down intermittently. Through mutual cooperation of the structures, the capacitor bending and cutting device has the effects that equidistant conveying is conducted on capacitors in batches, pin bending and cutting operation is conducted at the same time, the production efficiency is improved, the automation degree is high, and auxiliary operation of workers is not needed.

Owner:南通诺澳电子有限公司

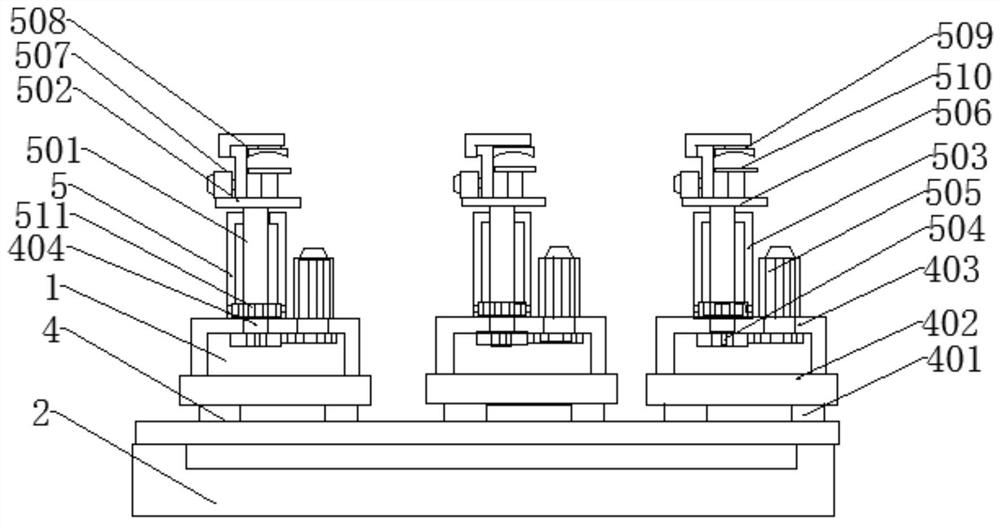

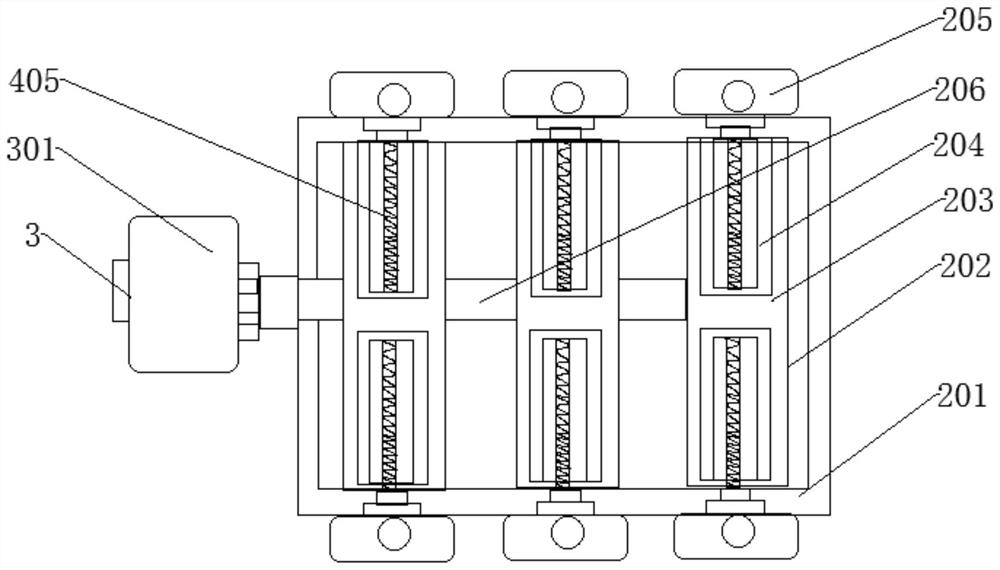

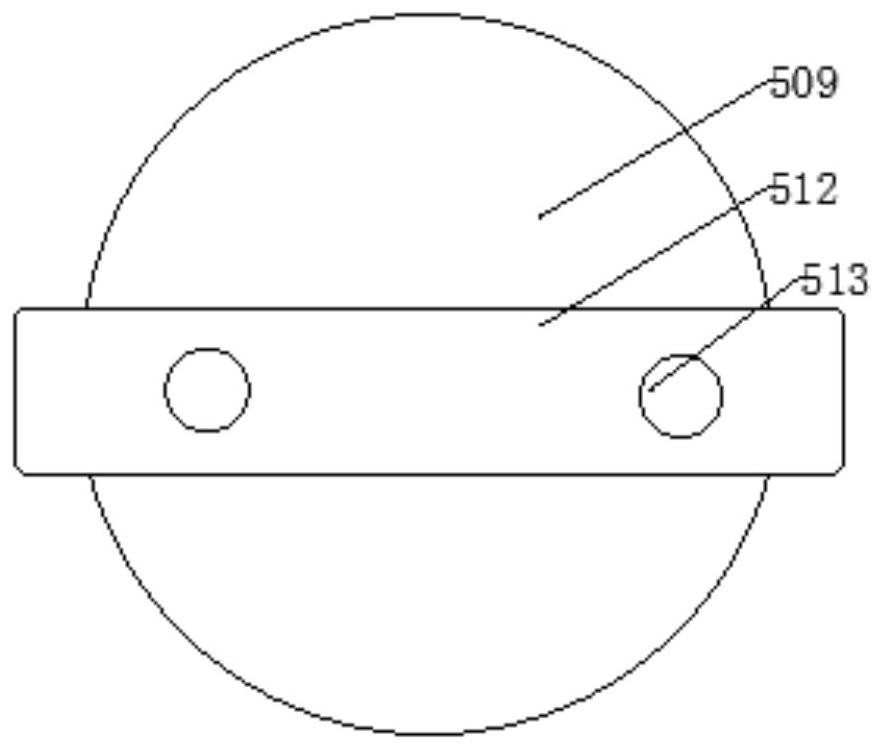

Positioning device for sensor machining

InactiveCN114104671AConvenient welding workFacilitate subsequent processing operationsWelding/cutting auxillary devicesAuxillary welding devicesPositioning equipmentEngineering

The invention discloses a positioning device for sensor machining, and belongs to the technical field of positioning equipment.The positioning device comprises a workbench, marking equipment, welding equipment, a feeding device, a clamping positioning device, a rotating positioning device, a four-direction positioning device and a discharging storage box, and the marking equipment and the welding equipment are arranged on the workbench; the discharging storage box is arranged at the side end of the marking equipment, the feeding device is arranged on one side of the discharging storage box, the four-direction positioning device is arranged at the center of the workbench, the rotating positioning device is arranged on the four-direction positioning device, the clamping positioning device is arranged on the rotating positioning device, and the four-direction positioning device comprises a driving assembly and a rotating assembly. According to the device, the sensor can be accurately positioned and fed, the sensor to be machined is driven to accurately move to the position of needed machining equipment, the sensor is accurately positioned, the machining equipment accurately conducts machining operation on the sensor, and therefore product deviation cannot be caused.

Owner:湖南麦旭科技有限责任公司

Internal cleaning equipment for special-shaped parts

ActiveCN112917249AFacilitate subsequent processing operationsImprove stabilityEdge grinding machinesPolishing machinesPolishingPipe

The invention discloses internal cleaning equipment for special-shaped parts. The internal cleaning equipment comprises a bottom plate, wherein a vertical plate capable of moving in the length direction of the bottom plate is arranged on one side of the upper surface of the bottom plate; a conveying pipe is rotationally arranged at the upper end of the side face of the vertical plate, and evenly-distributed discharging pipes are arranged on the side, close to the middle portion of the bottom plate, of the conveying pipe; and a feeding and discharging assembly is rotationally arranged at a feeding port of the conveying pipe, a driving sealing piece is arranged on the side face of the conveying pipe, and a switch set is arranged on the side face of the vertical plate. The internal cleaning equipment for the special-shaped parts can be adjusted, the special-shaped parts can be clamped and positioned, polishing, and polishing rust removal and impurity removal operation can be carried out on special-shaped inner cavities of the special-shaped parts by controlling magnetic fluid and polishing sand to continuously move inside the special-shaped parts, so that the impurity removal effect is good, and the strength of the parts can be indirectly improved; and after impurity removal is completed, impurities, the magnetic fluid and the polishing sand can be extracted together, so that the situation that the impurities drift into air and hurt the environment and operators is avoided, and use is convenient.

Owner:烟台晟嘉机械有限公司

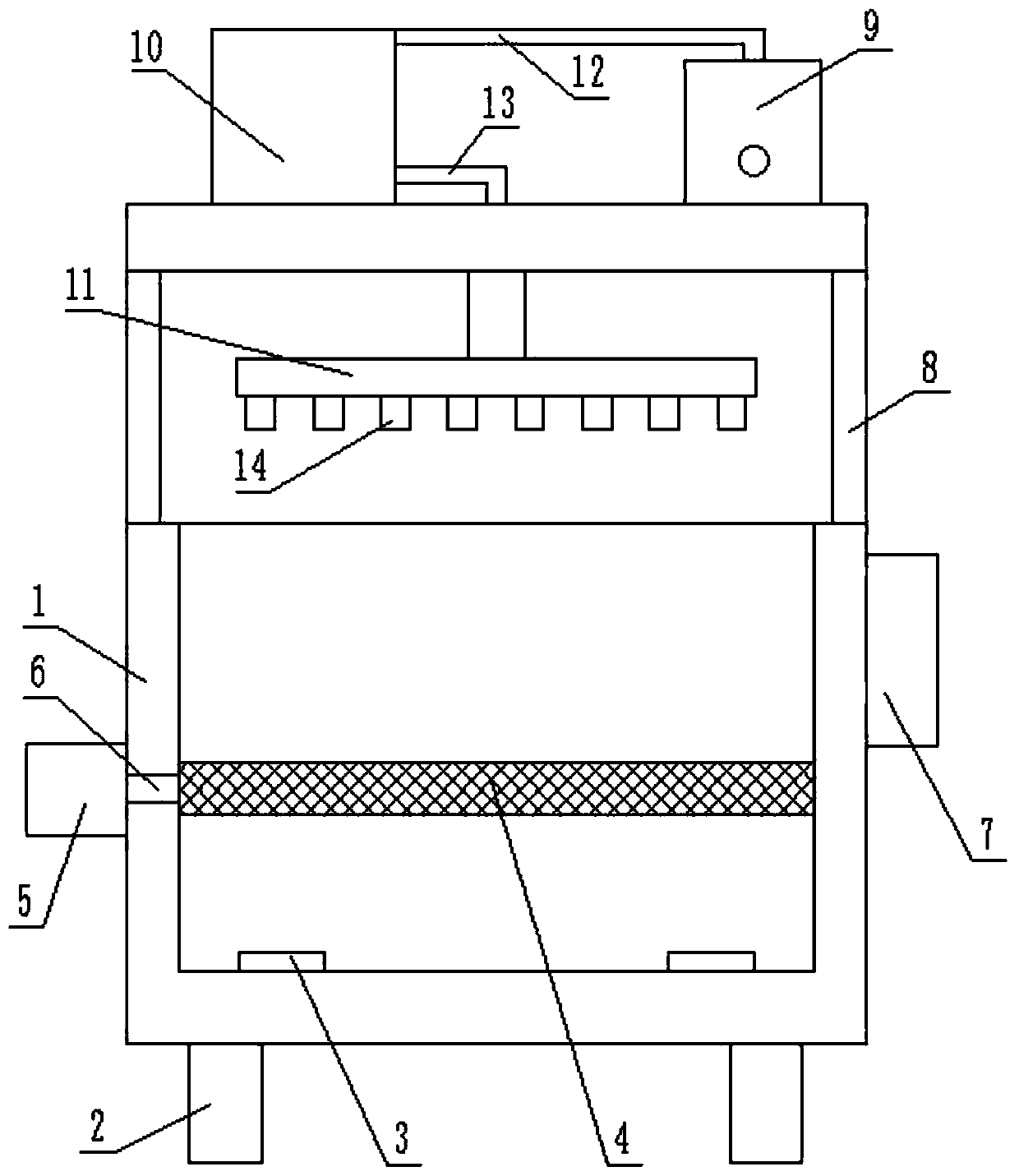

Residue-free cleaning device for electronic components

InactiveCN110976417APrevent fallingAvoid the work of manual cleanupCleaning using liquidsMegasonic cleaningElectric machinery

The invention discloses a residue-free cleaning device for electronic components. The residue-free cleaning device comprises a box body; supporting legs are arranged at the bottom of the box body; anopening is formed in the top surface of the box body; an ultrasonic generator is arranged at the bottom of the interior of the box body; a supporting net is arranged in the box body; the supporting net is a stainless steel net; a driving motor is arranged on the side face of the box body; and a connecting shaft penetrating into the box body and rotationally connected with the side wall of the boxbody is arranged at the output end of the driving motor. In the cleaning process of the device, the driving motor operates to drive the supporting net to slide back and forth along the inner wall surface of a cylindrical groove, and therefore, an electronic component placed on the supporting net is driven to shake; the electronic component is completely separated from stripped dirt after ultrasonic cleaning is conducted, so that manual cleaning work in a later period is avoided, and therefore, cleaning efficiency is improved; and the cylindrical groove is adopted, the electronic component canbe prevented from falling downwards when the supporting net rotates, and therefore, a cleaning effect is guaranteed, and meanwhile, subsequent processing operation in a later period is facilitated.

Owner:江西诺驰科技咨询有限公司

Roller-type rubber tube cooling system

The invention discloses a roller-type rubber tube cooling system. The roller-type rubber tube cooling system comprises a cooling pool, sliding rails, sliding blocks, driving systems, connecting rods, rollers, opening-and-closing doors, first rotary systems, second first rotary systems, a drying system and a hot air tube; the sliding rails are installed on the two sides of the upper end of the cooling pool, the sliding blocks are installed in the sliding rails, and the driving systems are installed at the two ends of each sliding block; the first rotary systems are installed on the inner sides of the sliding blocks, the connecting rods are installed on the first rotary systems, and the second first rotary systems are installed at the lower ends of the connecting rods; the rollers are installed between the second rotary systems installed on the two sides of the roller-type rubber tube cooling system, and the rollers are each of a tube-shaped structure enclosed by a metal net; and the opening-and-closing doors are installed on the side walls of the rollers, the drying system is installed on the upper portion of one end of the cooling pool, and the hot air tube is installed on the drying system. According to the roller-type rubber tube cooling system, the structure is simple, using is convenient, the cooling effect is good, the surface of a rubber tube is clean, and machining efficiency is improved.

Owner:TIANJIN BINHAI ZHONGGUAN RUBBER HOSE

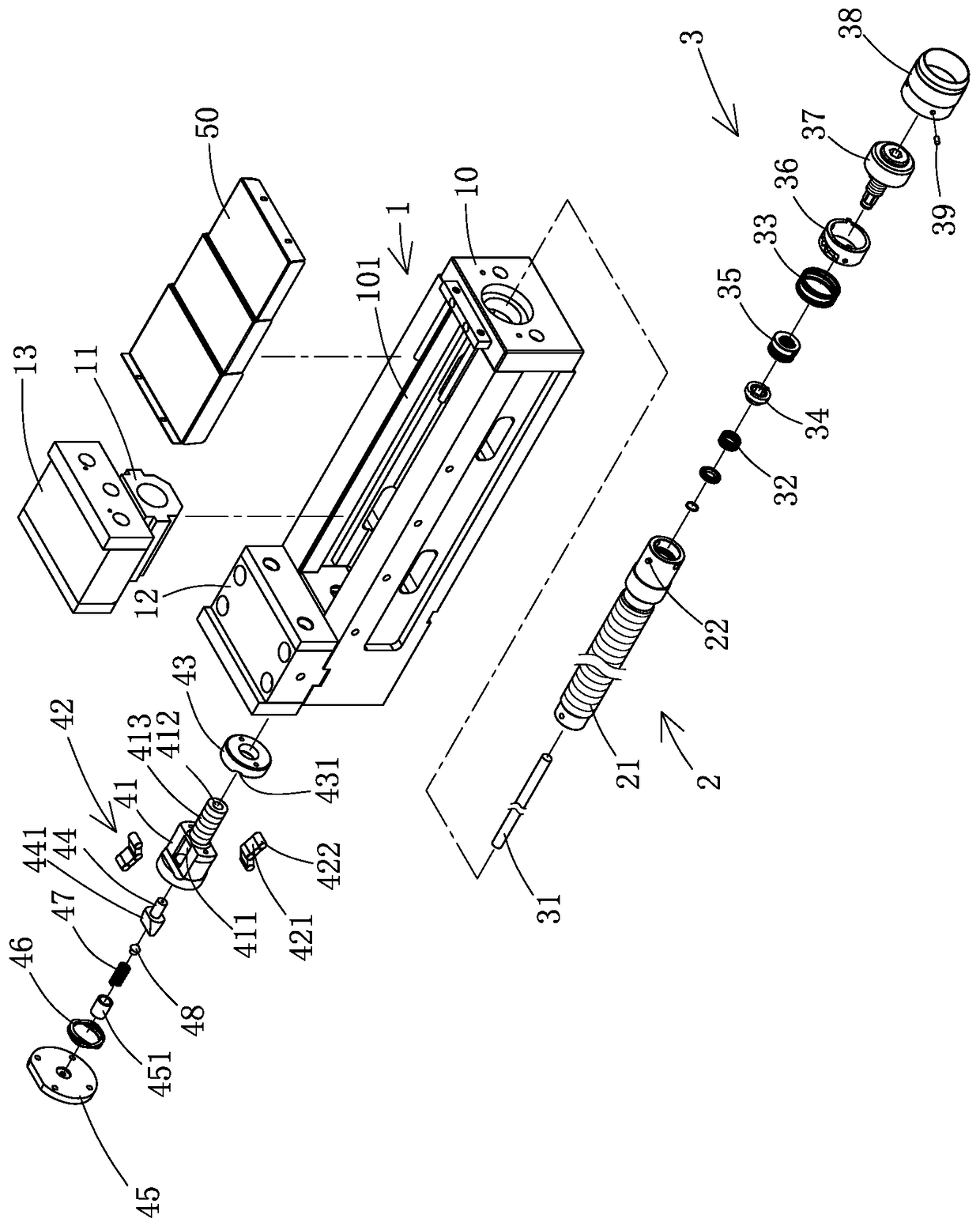

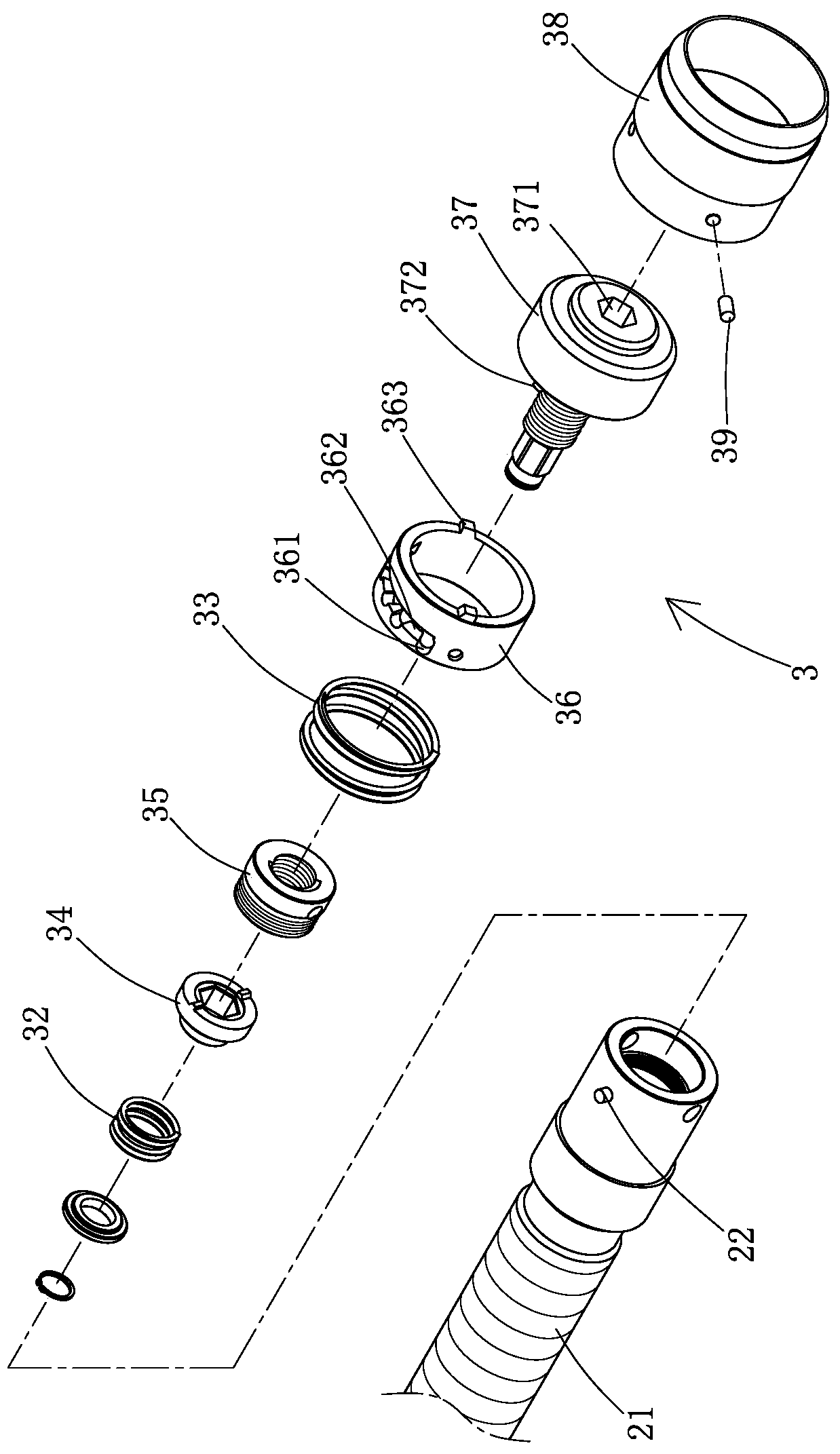

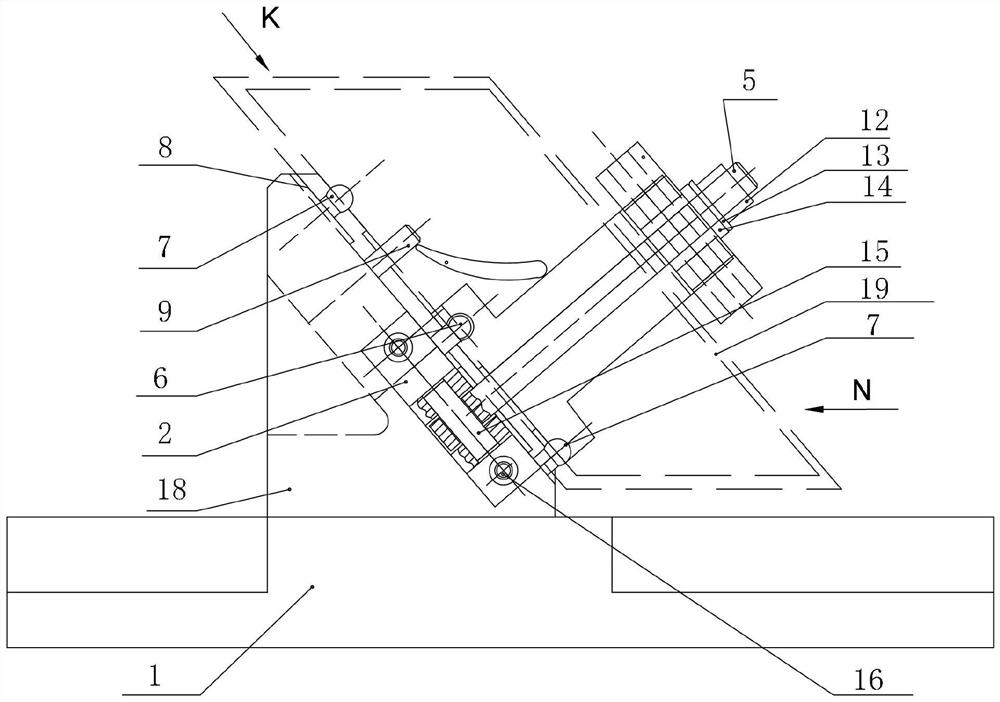

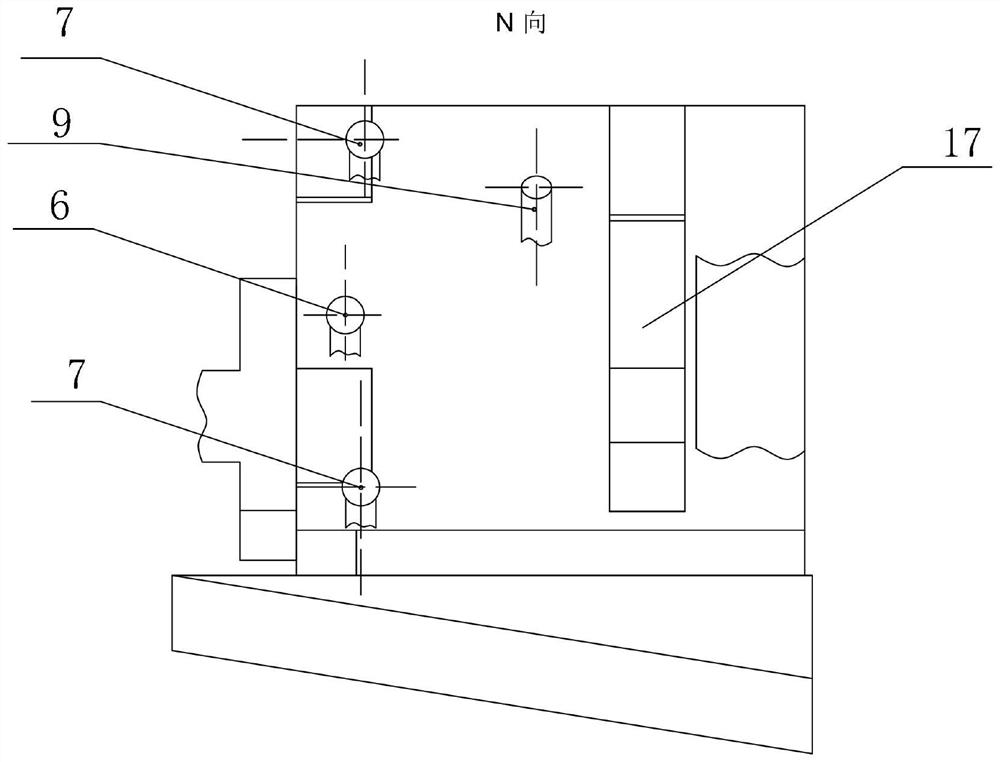

Pressure-adjusting structure for double-force-type vice

The invention discloses a pressure-adjusting structure for a double-force-type vice. The pressure-adjusting structure is composed of a vice unit, a transmission unit, an adjusting unit and a double-force unit. A push rod of the adjusting unit is arranged in a guide screw in a penetrating mode, a thread sleeve is arranged at the end of the guide screw in a threaded mode, and thus a second elastic element pushes against a pressing block; a clutch ring is arranged on the periphery of the guide screw in a sleeving mode, and provided with a plurality of axial adjusting grooves with different lengths, and a radial sliding oblique groove is arranged among the axial adjusting grooves in a connected mode. The axial adjusting grooves allow an embossment of the guide screw to move relatively, a driving tube is arranged in the thread sleeve in a threaded mode, and the end of the driving tube pushes against the push rod. An adjusting ring is fixedly connected with the clutch ring through a bolt soas to be integrally linked with the clutch ring, and thus the pressure-adjusting structure can adjust of the pressure increasing amount in a multi-stage mode and easily slides into the axial adjustinggrooves, and operation is simple, easy and effortless.

Owner:HOMGE MACHINERY IND

Turbine blade dihedral angle chord width machining device and machining method

PendingCN114227462AFacilitate subsequent processing operationsEasy to operateGrinding machinesGrinding work supportsTurbine bladeStructural engineering

Owner:GUIYANG AVIC POWER PRECISION CASTING

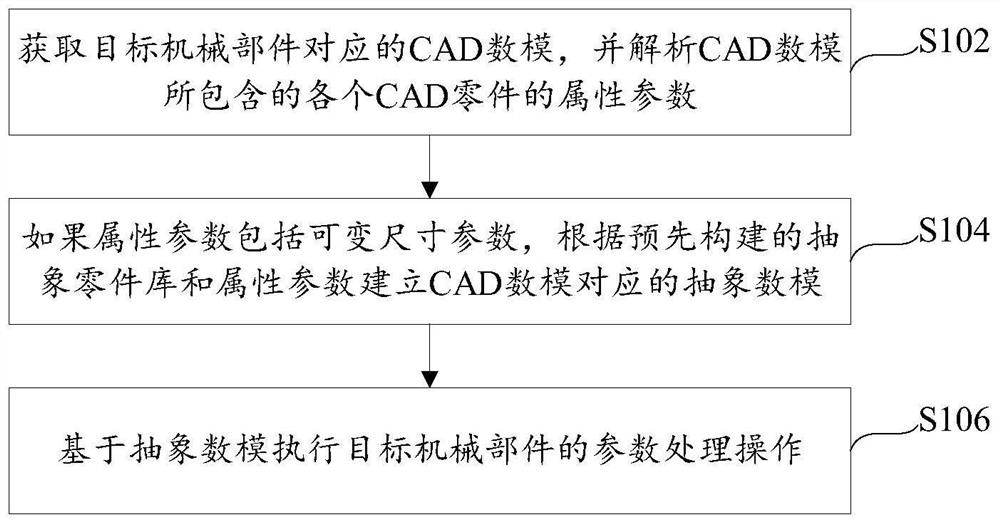

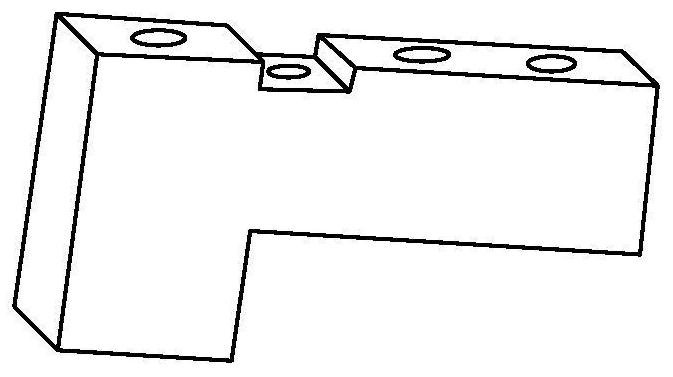

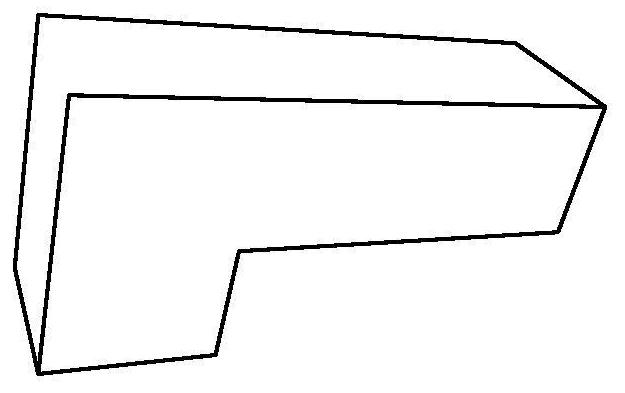

Parameter processing method and device for mechanical part and server

PendingCN112560203AFacilitate subsequent processing operationsGeometric CADDesign optimisation/simulationSimulationSoftware engineering

The invention provides a parameter processing method and device for a mechanical part and a server, and relates to the technical field of intelligent mechanical design, and the method comprises the steps: obtaining a CAD digital model corresponding to a target mechanical part, and analyzing the attribute parameters, contained in the CAD digital model, of all CAD parts; if the attribute parameterscomprise variable size parameters, establishing an abstract digital model corresponding to the CAD digital model according to a pre-constructed abstract part library and the attribute parameters, theabstract digital model being used for simulating a CAD digital model; and executing parameter processing operation of the target mechanical part based on the abstract digital model. The method supports modification of variable-size parameters of the abstract digital model, so that subsequent processing of mechanical part parameters is facilitated.

Owner:上海设序科技有限公司

Walking board printing machine for spinning pillow patterns

InactiveCN111591013AEasy to dryFacilitate subsequent processing operationsRotary pressesPrinting press partsTextile printerRotational axis

The invention discloses a walking board printing machine for spinning pillow patterns. The walking board printing machine comprises a base, a frame is fixed to the upper portion of the base, a first winding drum and a second winding drum are sequentially mounted on the inner side of the frame from back to front, a mounting box is arranged on one side of the frame, and a motor is mounted in the mounting box; and a rotating shaft penetrating through one side of the frame and extending into the first winding drum is arranged at the output end of the motor, a sliding groove is formed in one side of the interior of the frame, a sliding block matched with the sliding groove is arranged in the sliding groove, and a preheating assembly is arranged on the side, close to the first winding drum, of the sliding block. According to the walking board printing machine, through the arrangement of the first winding drum and the second winding drum, a fabric can be straightened, so that the situation that wrinkles are generated during fabric printing, the attractiveness of the pillow fabric is affected, and the printing effect is poor is avoided; and the sliding block moves inside the sliding groove, so that a preheating assembly preheats the pillow fabric, and the temperature of the fabric meets the temperature requirement suitable for printing.

Owner:嘉兴市五只蚂蚁电子商务有限公司

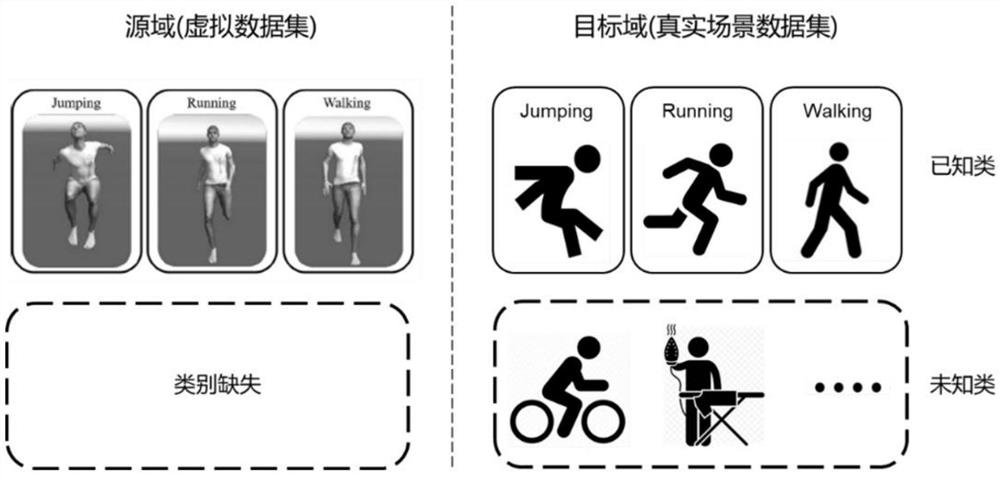

Mixed reality open set human body posture recognition method based on deep learning

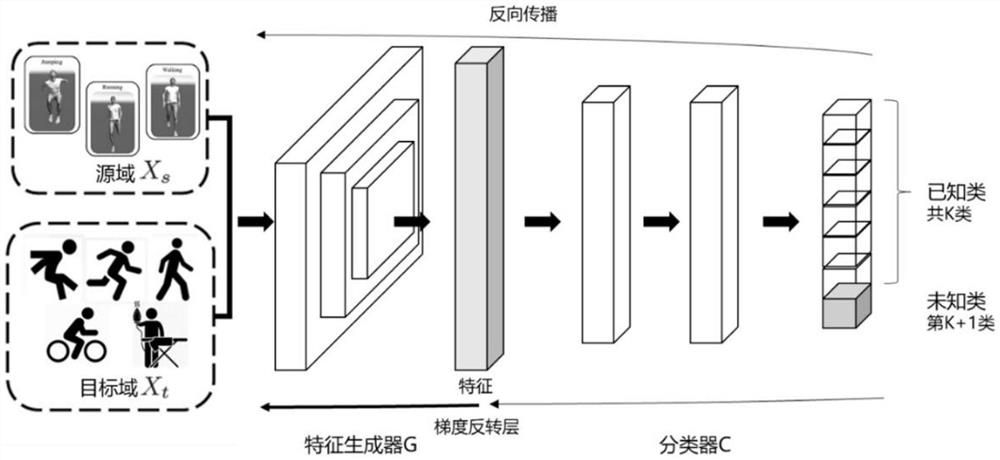

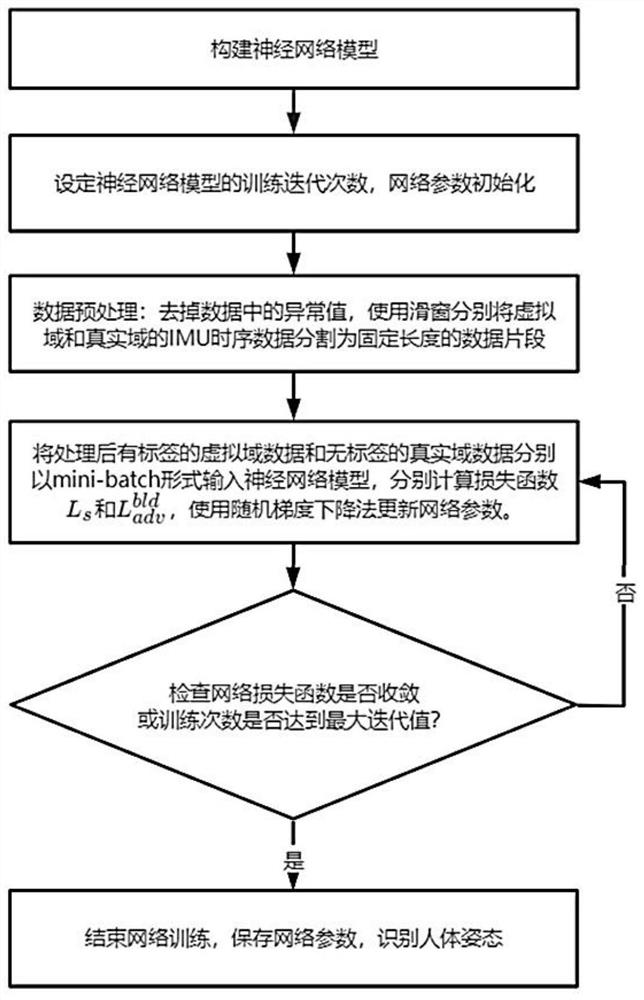

ActiveCN113705507AAddressing Quantitative ImbalancesSolve the problem of sample imbalanceCharacter and pattern recognitionNeural architecturesHuman bodyMixed reality

The invention discloses a mixed reality open-set human body posture recognition method based on deep learning. The method includes using a neural network of an open-set human body posture recognition algorithm based on mixed reality, and setting a training loss function through a decision boundary based on a sample number imbalance problem to obtain a trained neural network; and migrating the domain invariant features learned from the virtual domain to the real domain to guide the real domain to carry out feature extraction, thereby realizing mixed reality human body posture recognition. According to the invention, unknown activities which do not appear in the training set can be detected while known human activities are accurately identified.

Owner:SHANGHAI JIAO TONG UNIV

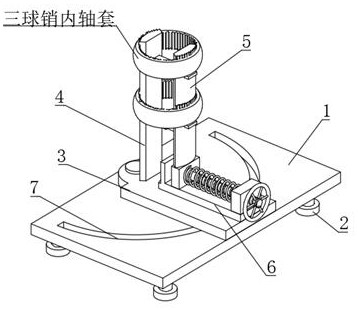

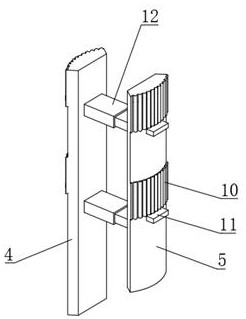

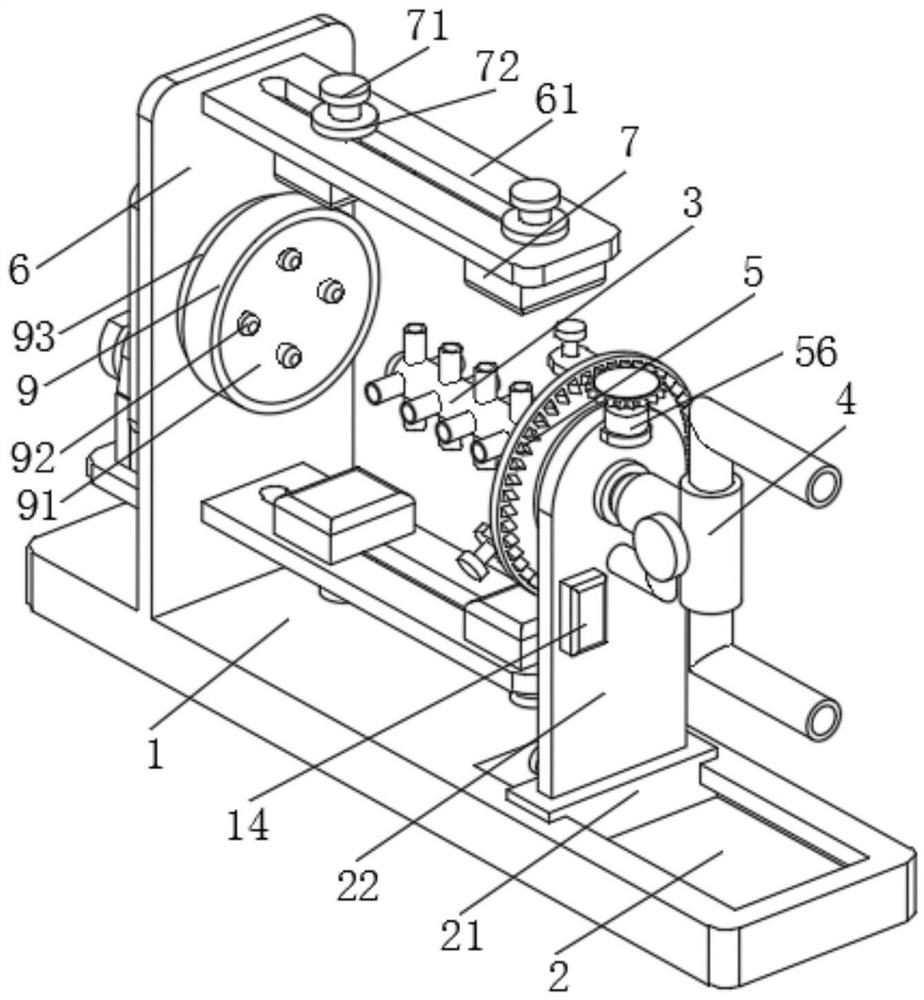

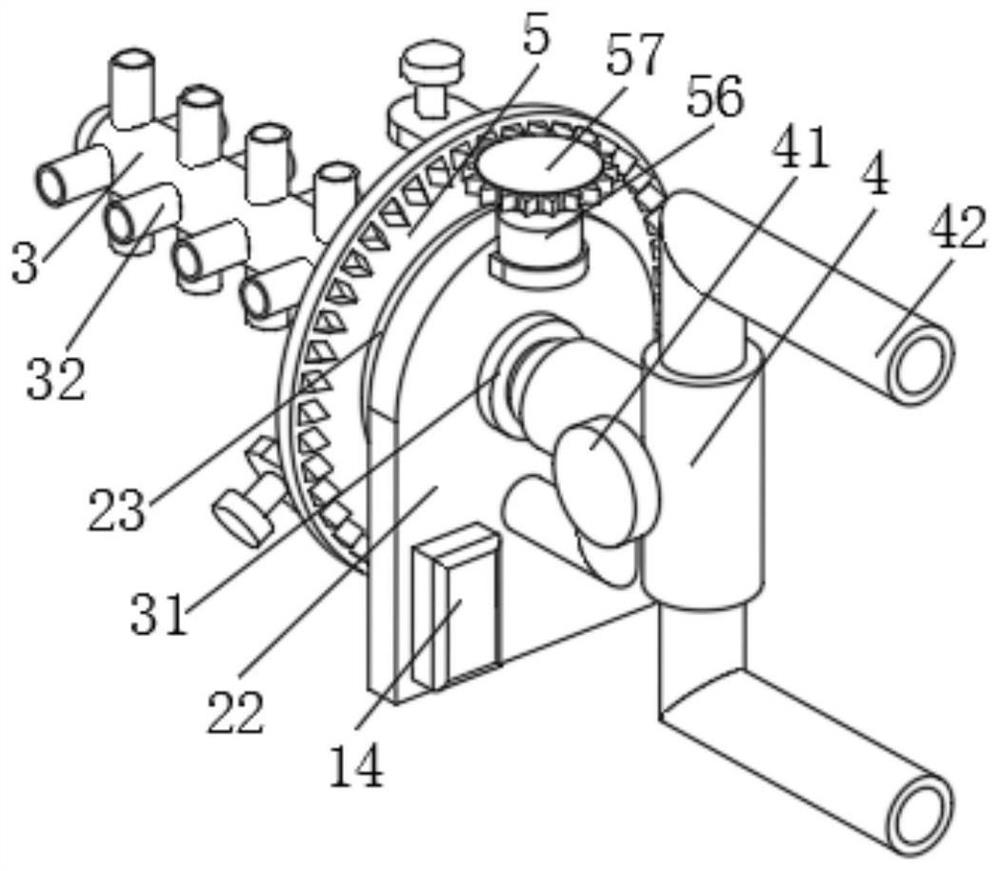

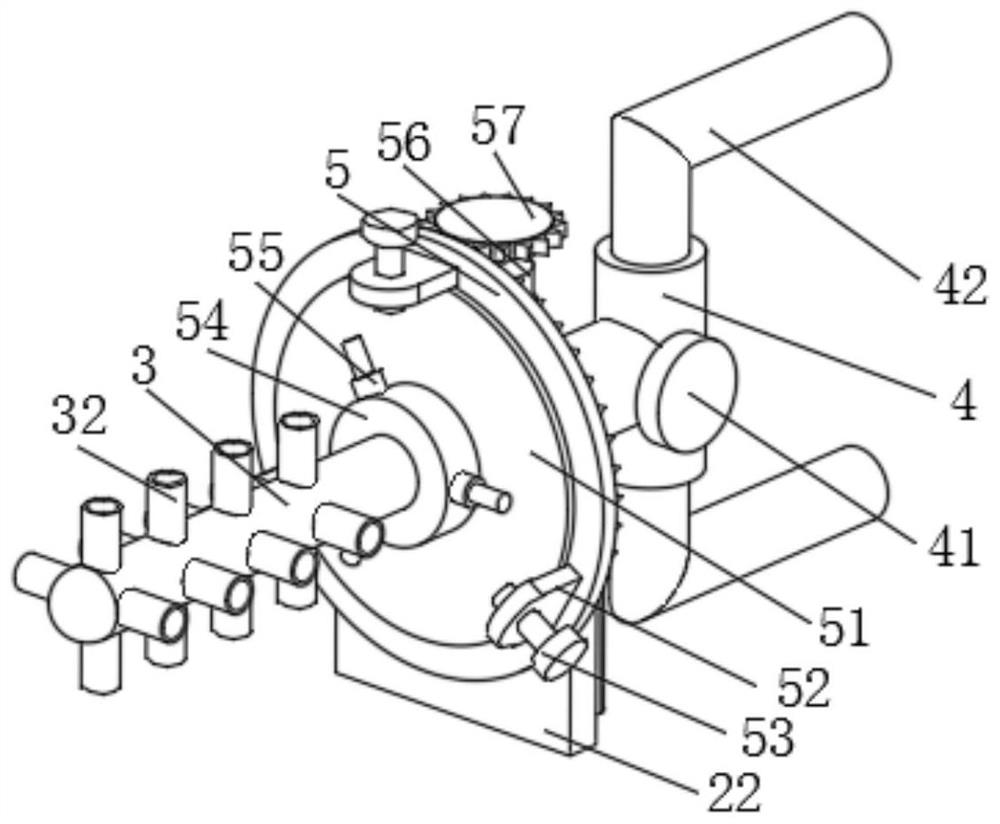

Multi-angle locating fixture for three-ball pin machining

ActiveCN112643580APlay a limiting effectEasy to operateWork holdersWork benchesStructural engineeringMachining

The invention discloses a multi-angle locating fixture for three-ball pin machining. The fixture comprises a bottom plate, wherein supporting feet are fixedly mounted at the four corners of the lower end of the bottom plate respectively, a mounting plate is fixedly mounted in the middle of the upper end of the bottom plate, a first clamping plate is fixedly mounted at the upper end of the mounting plate, an adjusting assembly is fixedly mounted on the rear portion of the upper end of the mounting plate, a second clamping plate is arranged at the upper end of the adjusting assembly, and a semi-annular groove is formed in the middle of the upper end of the bottom plate; the end faces, away from each other, of the first clamping plate and the second clamping plate are arc-shaped faces, the ends, away from each other, of the first clamping plate and the second clamping plate are fixedly connected with a plurality of protruding strips and supporting plates at equal intervals, and two stabilizing assemblies are jointly and fixedly connected between the first clamping plate and the second clamping plate. According to the multi-angle locating fixture for three-ball pin machining, the inner side of a three-ball pin inner shaft sleeve is fixed and supported, more space is reserved, subsequent machining operation can be facilitated, and the whole fixture is simple and rapid in fixing operation and good in fixing effect.

Owner:浙江大升电子开发有限公司

A positioning tool for automobile mold processing

ActiveCN108406203BRealize omnidirectional three-dimensional controllable adjustmentRealize azimuth adjustmentWelding/cutting auxillary devicesAuxillary welding devicesBall screwGear wheel

The invention discloses a positioning tool for automobile mold processing, which comprises an adjustable positioning support column, an installation base and a servo drive unit; the adjustable positioning support column includes a positioning transmission unit and a telescopic positioning column installed on the top of the positioning transmission unit ;The positioning transmission unit includes a clamping slider and a mounting plate. A hollow support plate is installed on the upper surface of the mounting plate, and a threaded mounting groove is dug in the center. The threaded mounting groove is used to fix and install the telescopic positioning column; the lower surface of the mounting plate Inlaid with a transmission ball screw; the telescopic positioning column includes a telescopic column body and a three-way adjustable positioning tool. The telescopic column body is socketed with a hydraulic drive cylinder. The end of the telescopic column body is socketed with a transmission gear set. Connected with a rotary drive motor; the present invention can clamp and position automobile molds of different shapes, the number of clamps can be increased or decreased freely, and has automatic feedback adjustment function with high positioning accuracy and three-way adjustable height flexibility.

Owner:杭州青发科技有限公司

A special-shaped parts internal cleaning equipment

ActiveCN112917249BFacilitate subsequent processing operationsImprove stabilityEdge grinding machinesPolishing machinesStructural engineeringPipe

The invention discloses an internal cleaning device for special-shaped parts, which includes a bottom plate, a vertical plate that can move along the length direction of the bottom plate is arranged on one side of the upper surface of the bottom plate, and a conveying pipe is arranged on the upper end of the side surface of the vertical plate, and the conveying pipe is close to the bottom plate One side of the middle part is provided with evenly distributed discharge pipes, the feeding port of the conveying pipe is provided with an inlet and outlet assembly, the side of the conveying pipe is provided with a driving seal, and the side of the vertical plate is provided with a switch group. The internal cleaning equipment for special-shaped parts can be adjusted, and can clamp and position special-shaped parts. It can polish and remove rust and impurities in the special-shaped inner cavity of special-shaped parts by controlling the continuous movement of magnetic fluid and polishing sand inside the special-shaped parts. , the impurity removal effect is good, and it can also indirectly improve the strength of the parts. After the impurity removal is completed, the impurities can be extracted together with the magnetic fluid and the polishing sand, so as to avoid the impurities floating into the air and causing harm to the environment and operators. It is easy to use.

Owner:烟台晟嘉机械有限公司

Organic sludge dehydration method

The invention discloses an organic sludge dehydration method. The dehydration method comprises the steps that organic sludge and inorganic sludge containing inorganic particles are mixed, stirred andthen mechanically dehydrated, and mixed sludge with water content lower than 75% can be prepared, wherein the water content of the organic sludge and the water content of the inorganic sludge are greater than or equal to 95% respectively, and the feeding mass ratio of the inorganic sludge to the organic sludge is 5-7:1. According to the thought of "waste control by waste", the inorganic sludge inthe same sewage treatment plant is utilized to treat the organic sludge, the dehydration effect of the organic sludge is improved, and dehydration cost is lowered.

Owner:SUZHOU SUJING ENVIRONMENTAL ENG

A kind of synthetic preparation method of polybenzimidazole resin

The invention provides a method for synthesizing and preparing polybenzimidazole resin, comprising the following steps: Step 1: Add 300ml of PPA and 46g of 3,3',4,4'-tetraaminodiphenyl ether into a dry four-necked bottle , 1,4 naphthalene dicarboxylic acid or 2,6-naphthalene dicarboxylic acid 43g, crosslinking agent 2,6-pyridine dicarboxylic acid 33g; Step 2: feed nitrogen into the four-necked bottle of step 1, then slowly heat and heat up to a certain temperature and keep it warm for a period of time; step 3: then heat again, raise the temperature to a certain temperature and keep it warm for a period of time; step 4: then pour the reaction solution obtained in step 3 into deionized water, stir to precipitate a reddish-brown solid; step 5 : the reddish-brown solid obtained in step 4 is suction-filtered, then soaked with sodium bicarbonate solution for a certain period of time, then washed out with deionized water, and finally dried to obtain the polybenzimidazole resin.

Owner:常州源自然新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com