Residue-free cleaning device for electronic components

A technology for cleaning devices and electronic components, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of unavoidable procedures, cleaning dead ends, easy flow into the air, etc., to facilitate subsequent processing operations , to ensure the cleaning effect and avoid the effect of falling down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

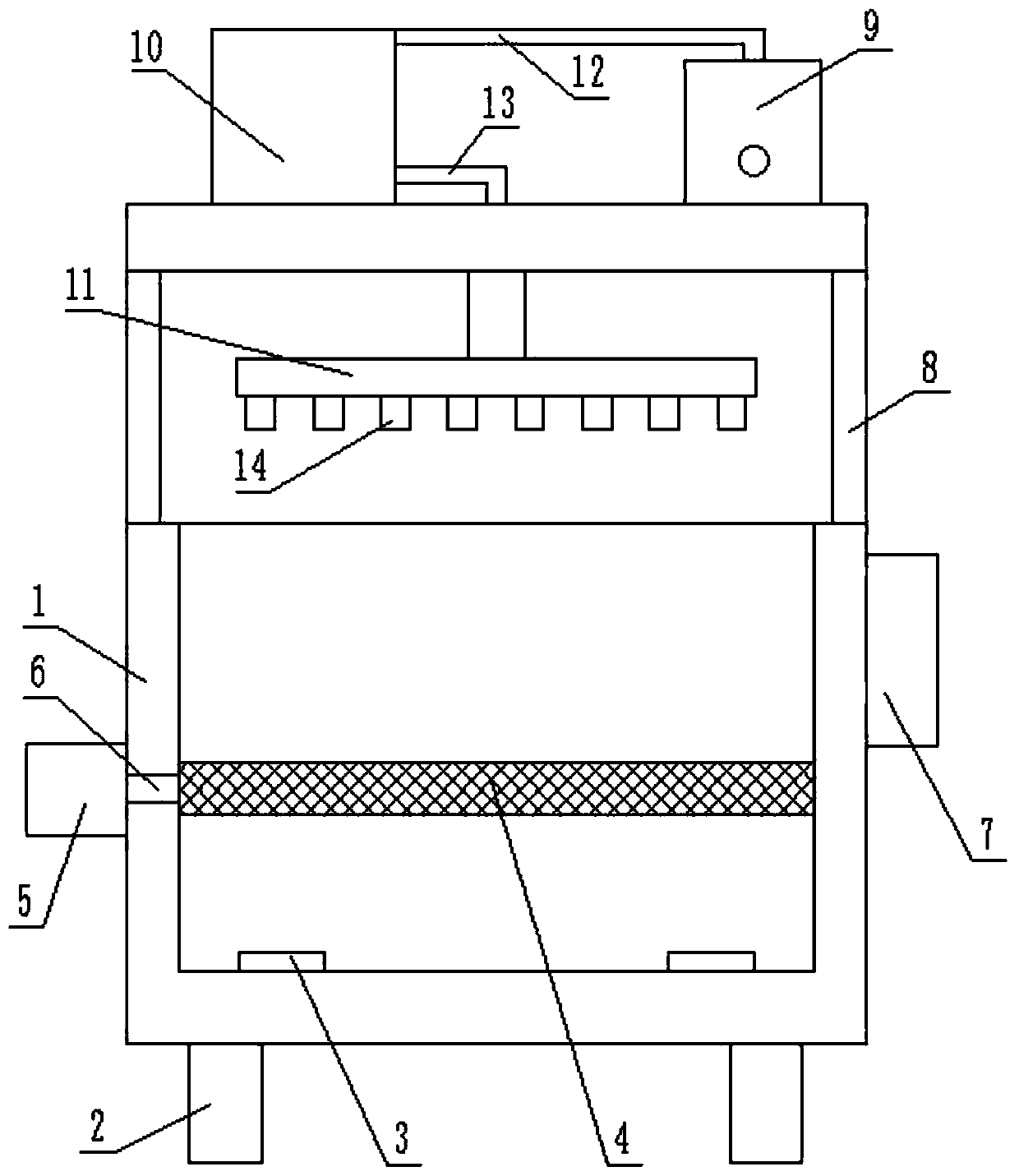

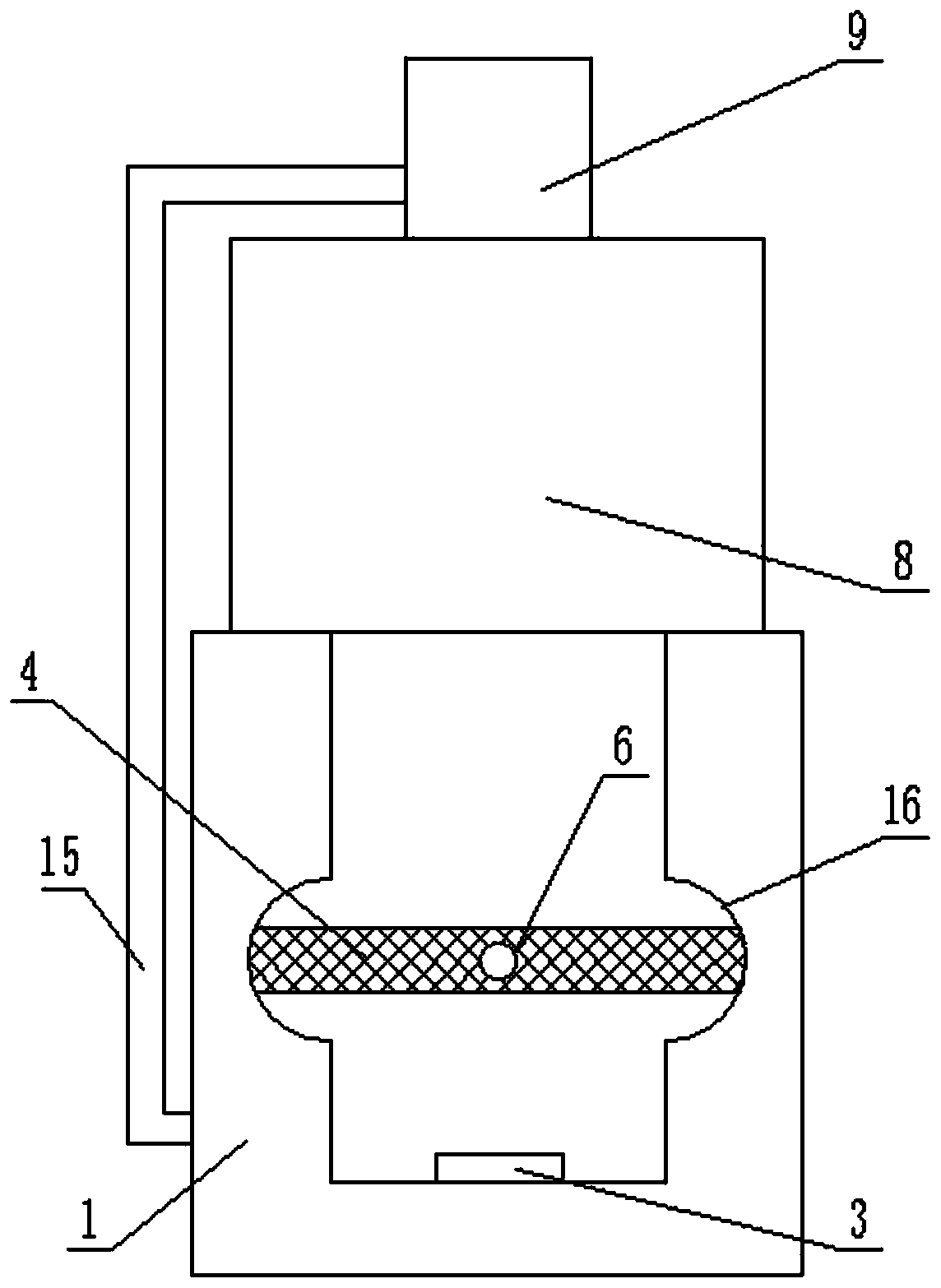

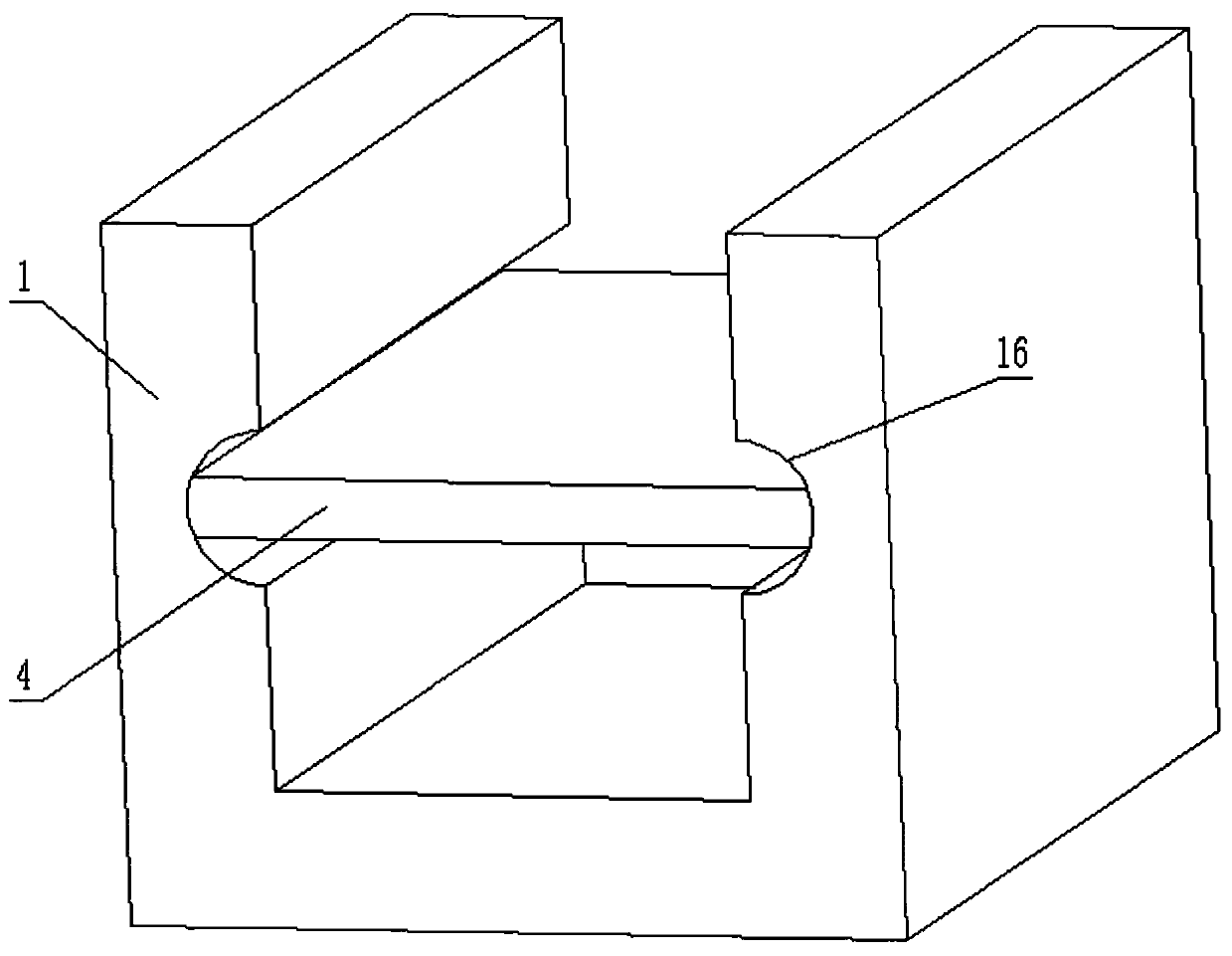

[0020] see Figure 1-3 , a device for cleaning electronic components without residue, comprising a box body 1, the bottom of the box body 1 is provided with support legs 2, the top surface of the box body 1 is open, and an ultrasonic generator 3 is arranged at the bottom of the box body 1, and in the box body 1 Also be provided with support net 4, support net 4 is used for carrying the electronic component that is put into casing 1 to be cleaned, and described support net 4 is a stainless steel net, avoids the situation such as chemical corrosion to affect the performance of electronic component; During the process, the cleaning liquid is first put into the box body 1, and then the electronic components to be cleaned are laid flat on the support net 4, and the ultrasonic generator 3 is started, and the cavitation effect and the direct flow effect of the ultrasonic wave in the liquid are used to The dirt attached to the surface of the electronic component during processing is d...

Embodiment 2

[0025] refer to Figure 4 , on the basis of Embodiment 1, the top of the transfer box 10 is open, and a filter box 17 slidingly connected to it is inserted in the transfer box 10, and vertical blocks 18 are arranged on both sides of the filter box 17, and the block 18 is used to realize the sliding connection with the transfer box 10 and maintain the fixed work of the filter box 17 after sliding down. The filter box 17 is provided with a filter screen 19, and when the cleaning liquid is transferred to the transfer box 10, it can pass through the filter box 17 The filter screen 19 on the top filters the cleaning solution to reduce the amount of dirt in the casing 1, thereby ensuring a good cleaning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com