Knitted garment manufacturing system

A garment manufacturing and knitting technology, which is applied in the field of knitted garment manufacturing system, can solve the problems of scattered finished cloth, difficult winding, and cloth wrinkle, etc., and achieve the effect of good fixing effect, convenient inspection, and easy knitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

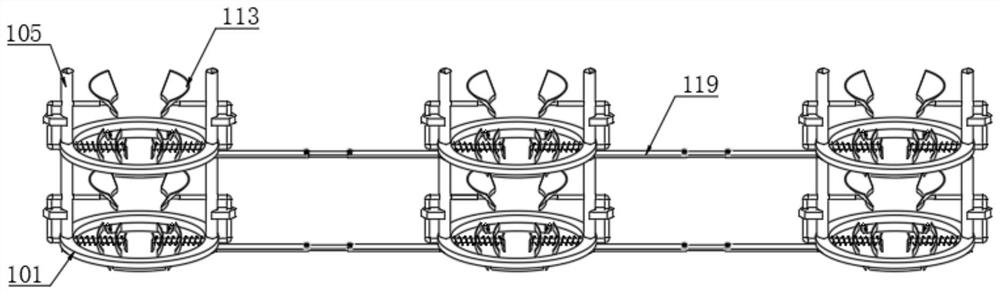

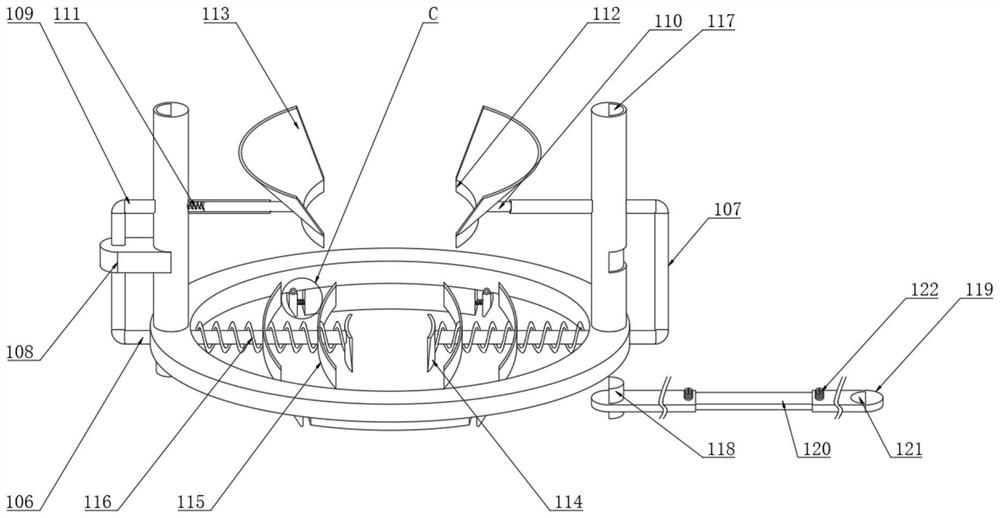

[0041] Example: such as Figure 1-4 A knitted garment manufacturing system shown includes a feeding device 100 and a manufacturing device 200. After the yarn is fed by the feeding device 100, the manufacturing device 200 performs knitting. The feeding device 100 includes a bottom ring 101, and the two ends of the bottom surface of the bottom ring 101 are All positions are welded with clamping plates 102, and the bottom ring 101 is hinged with rubber clips 103 near both ends of the clamping plate 102. Both ends of the top surface of 101 are welded with support columns 105, and the two ends of the bottom ring 101 are located at the bottom of the support column 105, and a bottom rod 106 is installed through it. The top of the bottom rod 106 is welded with a vertical rod 107, and the middle part of the vertical rod 107 is socketed There is a magnet 108, and a guide tube 109 is welded on the top of the vertical rod 107, and the guide tube 109 moves through the middle of the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com