Production method of plate-seam-free molding plate roller

A production method and technology of molded plates, which are applied in printing plate preparation, printing, etc., can solve the problems that affect the stability of product quality, the processing adaptability, the demand for products that cannot meet the surface requirements, and the uneven heating of the surface of molded materials. Subsequent processing operations, small deformation, small color difference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The manufacturing method of the seamless mold embossing roller of the present embodiment comprises the following steps:

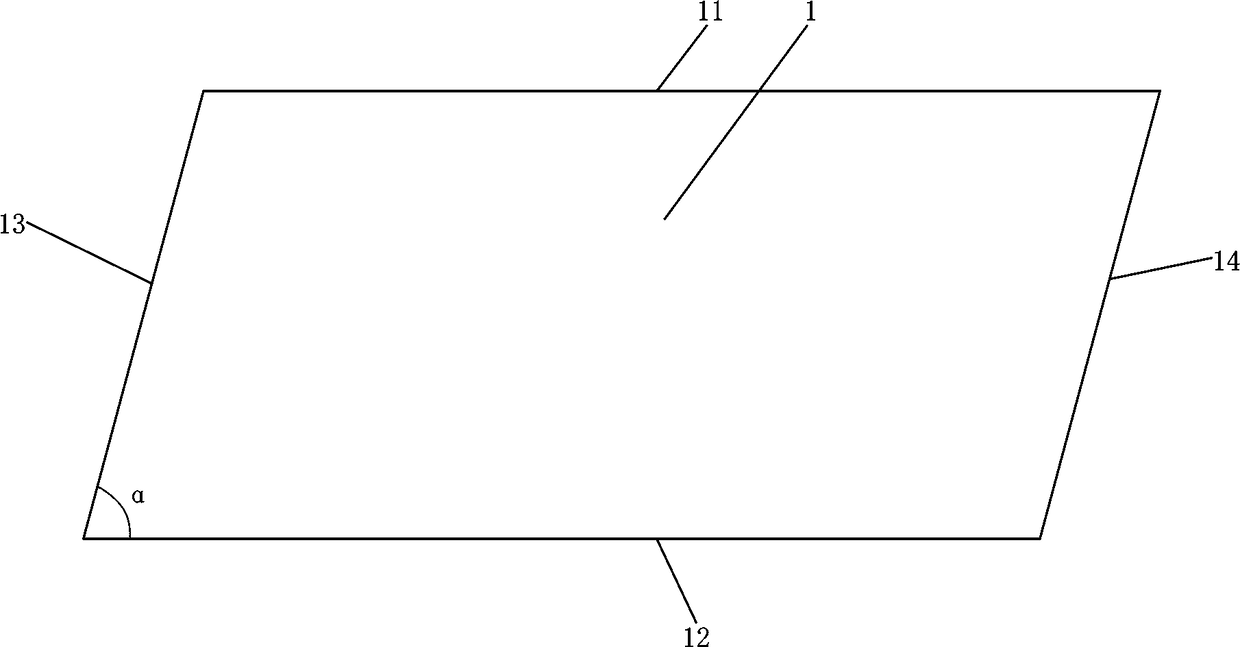

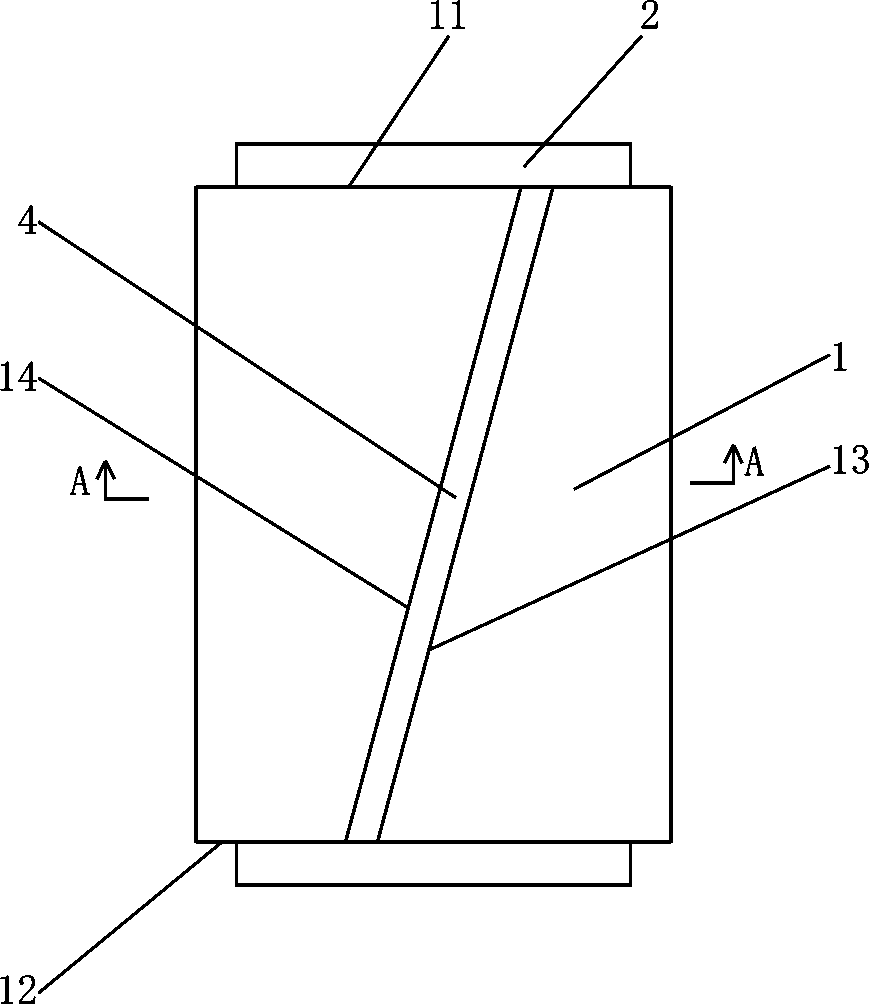

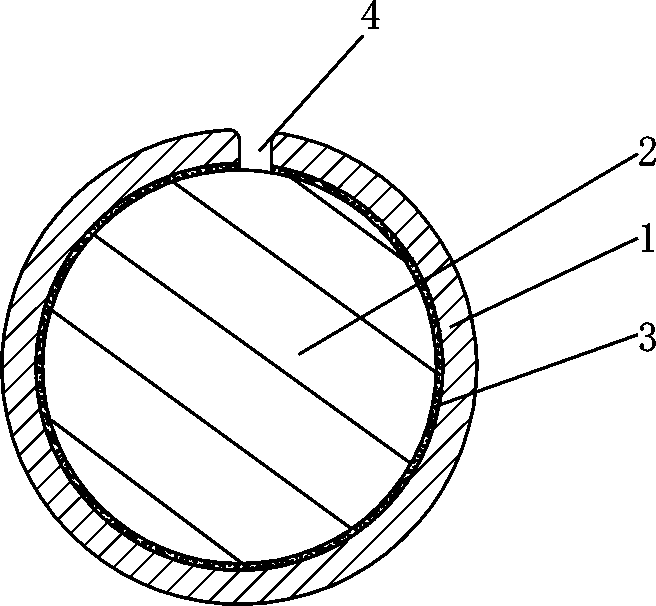

[0033] (1) Make a molded working plate 1 of a parallelogram;

[0034] In this step (1), the method for making the parallelogram-shaped molded working plate 1 is: reproduce the laser hologram text on the master plate through a laser engraving machine, and the master plate is copied into a molded working plate blank (usually Nickel plate); then use a plate cutter (the plate cutter should have a sharp knife edge and a neat incision) to cut the molded working plate blank to obtain a parallelogram molded working plate 1. Avoid burrs, nicks, etc. on the edges of the molded work when cutting. refer to figure 1 , in the parallelogram molded working version 1, the length of the first pair of opposite sides 11,12 is 1-2mm smaller than the outer circumference of the version roller body 2, and the second pair of opposite sides 13,14 is the same as the first pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com