Heat insulation and cooling conveying device of pre-dispersed master batches for rubber adhesives

A rubber adhesive, heat insulation and cooling technology, applied in the field of transmission equipment, can solve the problems of difficult transportation of bolted transportation equipment, and achieve the effects of low manufacturing cost, reasonable overall structure design, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

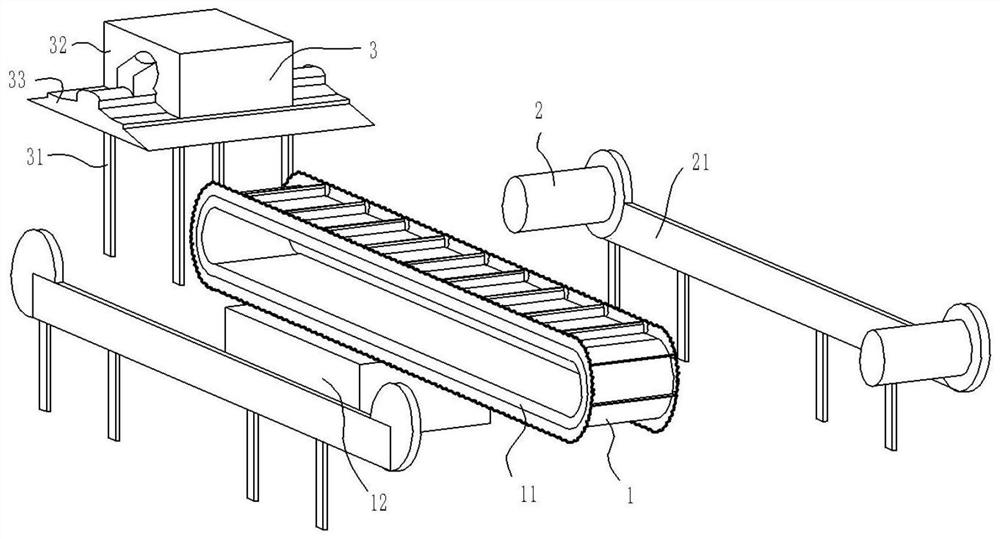

[0034] Embodiment 1: as figure 1 The shown adiabatic cooling conveying device for pre-dispersed master batches for rubber adhesives includes a transportation unit 1 for transporting pre-dispersed master batches and a second cooling unit for pre-dispersed master batches Two cooling units 3; the transport unit 1 includes a transport module 11 for transporting the pre-dispersed master batch and cooling the pre-dispersed master batch for the first time and a power module 2 for driving the transport module 11;

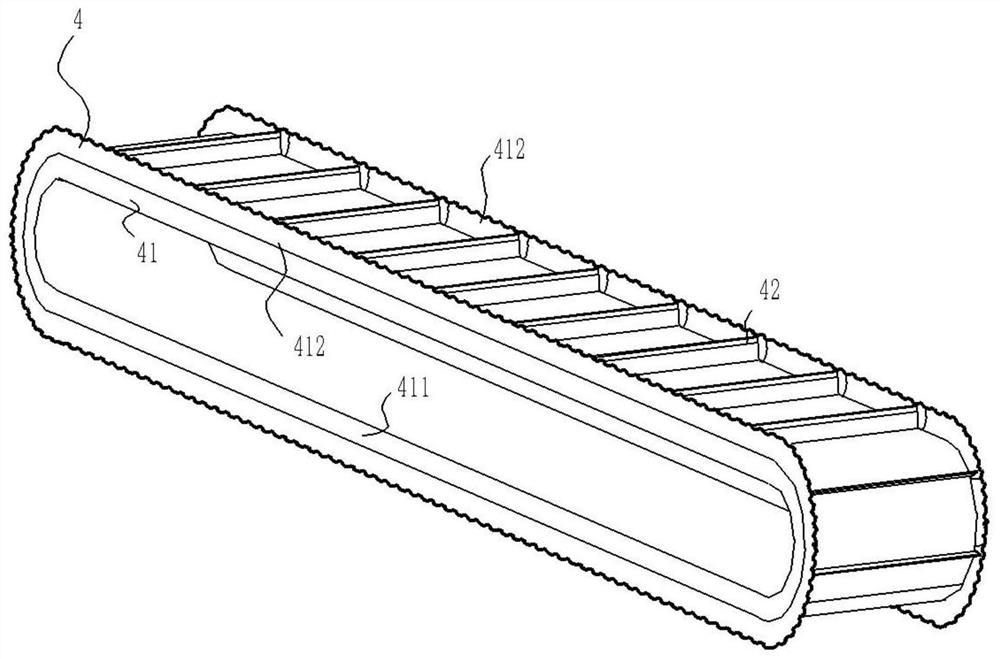

[0035] Such as figure 2 , 3 As shown, the transport module 11 adopts a cooling conveyor belt 4; the cooling conveyor belt 4 includes a conveyor belt body structure 41 and a primary cooling treatment structure 42 installed on the conveyor belt body structure;

[0036] The conveyor belt body structure 41 includes a conveyor bottom belt 411 and side wall guards 412 installed on both sides of the conveyor bottom belt 411; the conveyor bottom belt 411 includes a bottom belt b...

Embodiment 2

[0042] Embodiment 2: as figure 1 The shown adiabatic cooling conveying device for pre-dispersed master batches for rubber adhesives includes a transportation unit 1 for transporting pre-dispersed master batches and a second cooling unit for pre-dispersed master batches Two cooling units 3; the transport unit 1 includes a transport module 11 for transporting the pre-dispersed master batch and cooling the pre-dispersed master batch for the first time and a power module 2 for driving the transport module 11;

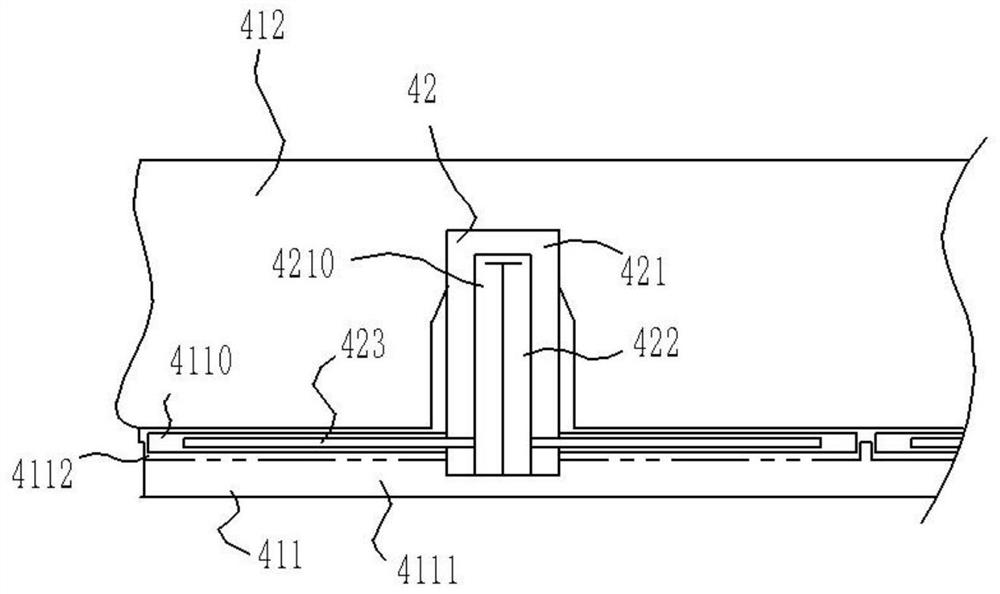

[0043] like Figure 4 , 5 , 6, the transport module 11 uses a cooling conveyor belt 4; the cooling conveyor belt 4 includes a conveyor belt body structure 41 and a first cooling treatment structure 42 installed on the conveyor belt body structure;

[0044] The conveyor belt body structure 41 includes a conveyor bottom belt 411 and side wall guards 412 installed on both sides of the conveyor bottom belt 411; the conveyor bottom belt 411 includes a bottom belt body 4111 and...

Embodiment 3

[0049] Embodiment 3: as figure 1 The shown adiabatic cooling conveying device for pre-dispersed master batches for rubber adhesives includes a transportation unit 1 for transporting pre-dispersed master batches and a second cooling unit for pre-dispersed master batches Two cooling units 3; the transport unit 1 includes a transport module 11 for transporting the pre-dispersed master batch and cooling the pre-dispersed master batch for the first time and a power module 2 for driving the transport module 11;

[0050] like Figure 7 As shown, the transport module 11 adopts a cooling conveyor belt 4; the cooling conveyor belt 4 includes a conveyor belt body structure 41 and a primary cooling treatment structure 42 installed on the conveyor belt body structure;

[0051] The conveyor belt body structure 41 includes a conveyor bottom belt 411 and side wall guards 412 installed on both sides of the conveyor bottom belt 411; the conveyor bottom belt 411 includes a bottom belt body 4111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com