Jun jujube packaging machine

A packaging machine and jujube technology, applied in packaging, transportation packaging, packaging food, etc., can solve problems such as hidden safety hazards and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

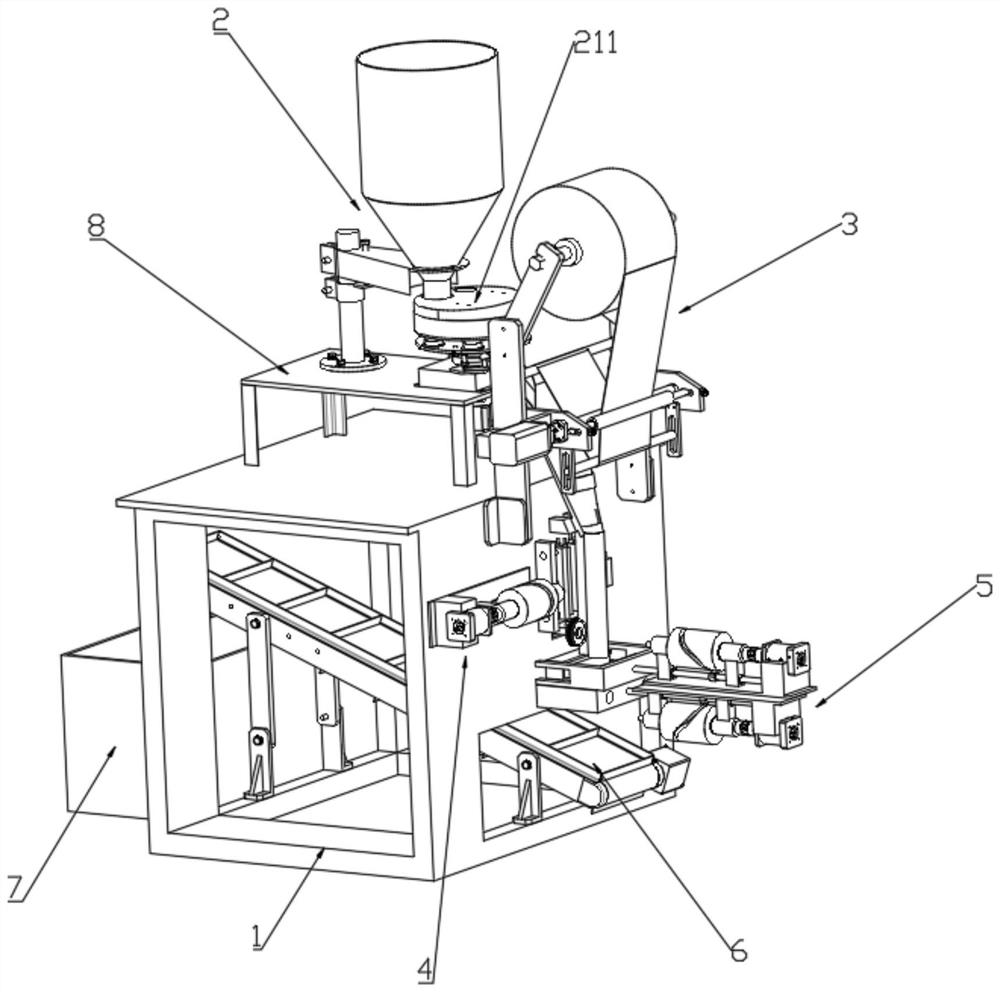

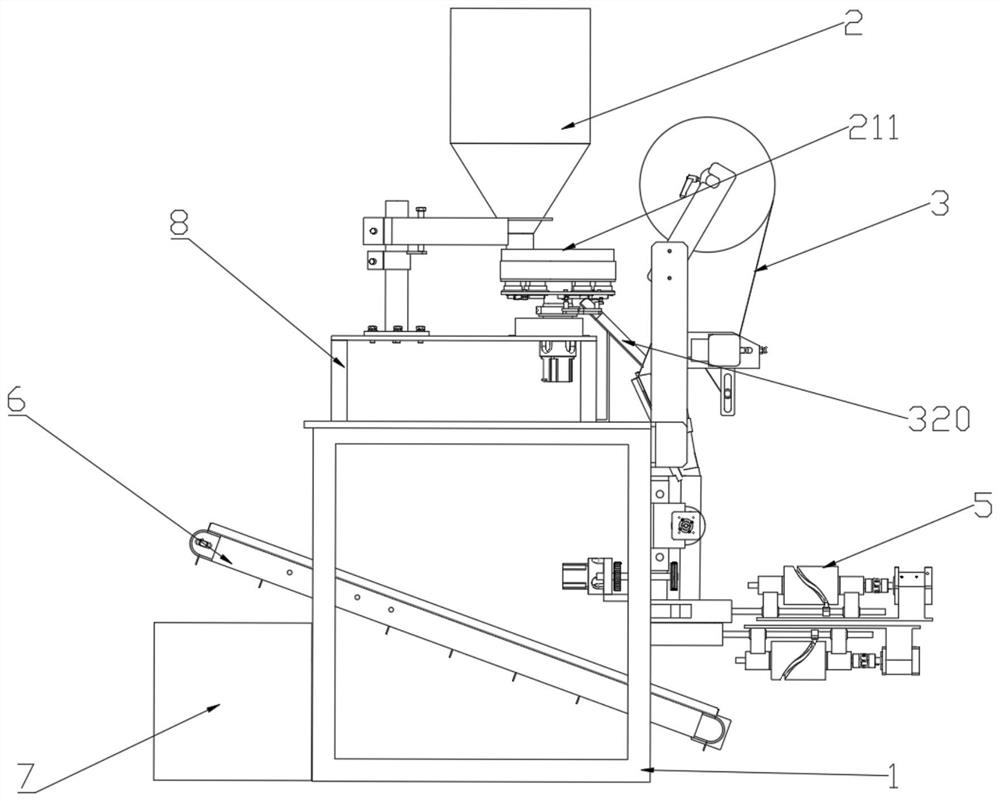

[0035] see Figure 1~2, in the embodiment of the present invention, a kind of jujube packaging machine comprises support frame 1, conveyer belt 6 and collection box 7, and collection box 7 is positioned at the left end of support frame 1, and conveyor belt 6 is positioned at the lower end of support frame 1, and the upper end of support frame 1 There is a support platform 8, the upper end of the support platform 8 is provided with a filling device 2, the filling device 2 is detachably connected with the support frame 1, the right side of the filling device 2 is provided with a film forming device 3, and the film forming device 3 is also connected to the support by bolts The frame 1 is detachably connected, the film forming device 3 and the filling device 2 are connected through a diversion channel 320, the right end of the support frame 1 is provided with a longitudinal sealing structure 4, and the right end of the support frame 1 is located below the film forming device 3. Th...

Embodiment 2

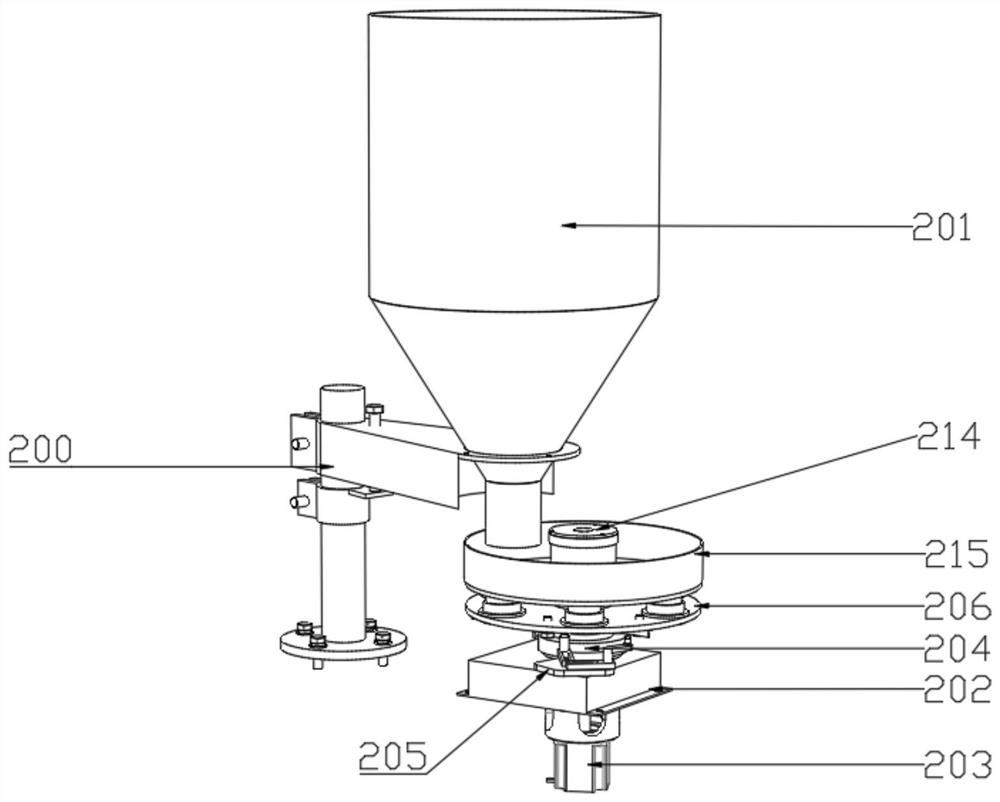

[0037] see Figure 3-7 , in combination with the basis of Embodiment 1, the packing device 2 includes a support frame 200, the support frame 200 is installed on the upper end of the support platform 8, the support frame 200 is connected with the support platform 8 through flanges and bolts, and the upper end of the support frame 200 is provided with a stuffing bucket 201, the stuffing barrel 201 is set in a funnel shape, and a material distribution structure is provided under the stuffing barrel 201, and the material distribution structure includes an installation shell 202, which is connected to the support platform 8 through bolts, and the installation shell 202 is provided with a first Motor 203, the output shaft of the first motor 203 runs through the shell wall of the installation shell 202, the upper end of the installation shell 202 is located on the output shaft of the first motor 203, and a connecting ring 204 is sleeved, and the connecting ring 204 passes the output o...

Embodiment 3

[0039] see Figure 8 , 9 , in combination with the basis of Embodiment 1, the film forming device 3 includes two support arms 300, which are connected by bolts between the support arms 300 and the support frame 1, and a rotating roller 301 is arranged between the two supporting arms 300, and the rotating roller 301 is movable A film roll 302 is connected, and several auxiliary rollers 303 are also arranged between the two support arms 300. The front end of the front end support arm 300 is provided with a second motor 304, the output shaft of the second motor 304 runs through the support arm 300, and the second motor The output shaft of 304 is provided with a transmission roller 305, and the end of the transmission roller 305 away from the second motor 304 is rotatably connected to the other support arm 300, and the lower part of the film roll 302 is located between the two support arms 300 and a lapel former 306 is provided. The lapel forming device 306 is a circular material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com