Circulating feeding device for air spring production

A technology of feeding device and gas spring, applied in the field of gas spring processing, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

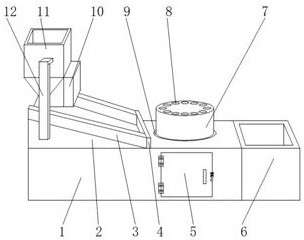

[0031] This embodiment is a circular feeding device for gas spring production.

[0032] Such as Figure 1-5 As shown, including the base 1, the left side of the outer surface of the upper end of the base 1 is fixedly installed with a sloping plate 2, one side of the upper outer surface of the swash plate 2 is provided with a hopper 11, and the outer surface of one side of the hopper 11 is fixedly installed with an auxiliary mechanism 10. The right side of the outer surface of the upper end of the base 1 is fixedly equipped with a rotating table 7, and the lower part of the rotating table 7 is provided with a circulation feeding mechanism 9, and the right outer surface of the base 1 is fixedly installed with a collection box 6. The front end of the base 1 The outer surface is provided with a protective door 5.

[0033]A mounting frame 12 is arranged between the hopper 11 and the sloping plate 2, and the outer surfaces of both sides of the hopper 11 are fixedly connected with t...

specific Embodiment 2

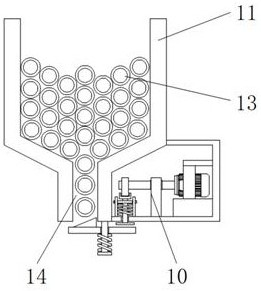

[0036] This embodiment is an embodiment of the auxiliary mechanism 10 in the circulation feeding device for gas spring production.

[0037] Such as figure 1 , 2 , As shown in 3, an auxiliary mechanism 10 for a cycle feeding device used for gas spring production, the auxiliary mechanism 10 includes a mounting box 15, a first limiting block 16, an eccentric wheel 17, a second limiting groove 18, and a fixed rod 19 , the first rotating shaft 20, the first motor 21, the support rod 22, the mounting block 23, the first guide rod 24, the slide plate 25, the first buffer spring 26, the striker 27, the strike plate 28, the first slideway 29, the second The guide rod 30, the second limit block 31, the second buffer spring 32, the through hole 33, the inclined block 34 and the movable plate 35, and the installation box 15 are fixedly installed on one side of the outer surface of the hopper 11, and the first motor 21 is installed through the The block 23 and the fixed rod 19 are fixedl...

specific Embodiment 3

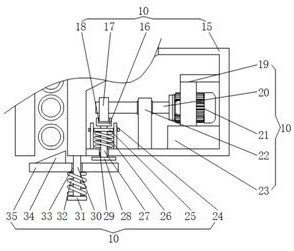

[0039] This embodiment is an embodiment of the circulation feeding mechanism 9 in the circulation feeding device used for gas spring production.

[0040] Such as figure 1 , 4 , Shown in 5, a kind of circulating feeding mechanism 9 that the circulating feeding device that gas spring is used for production, circulating feeding mechanism 9 comprises movable chamber 36, the second slideway 37, connecting plate 38, rotating disk 39, the second rotating shaft 40, the first Two motors 41, rotating disc 42, ball 43, support column 44, connecting rod 45, driving lever 46, shifting groove 47 and through groove 48, and movable chamber 36 is offered on the side of base 1 upper end outer surface, and the second slide The channel 37 is set at the bottom of the movable chamber 36, the second motor 41 is fixedly mounted on the bottom of the movable chamber 36, the second rotating shaft 40 is located on the upper outer surface of the second motor 41, and the turntable 39 is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com