Elevator counterweight frame assembling structure

A technology of assembly structure and frame structure, which is applied in transportation and packaging, lifting equipment in mines, etc. It can solve problems such as the difficulty of neatly installing heavy blocks into the bottom of the frame, reducing the load-bearing tension of side beams, and difficult installation of heavy blocks. , to achieve the effect of reducing handling risk, reducing labor intensity and strengthening stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

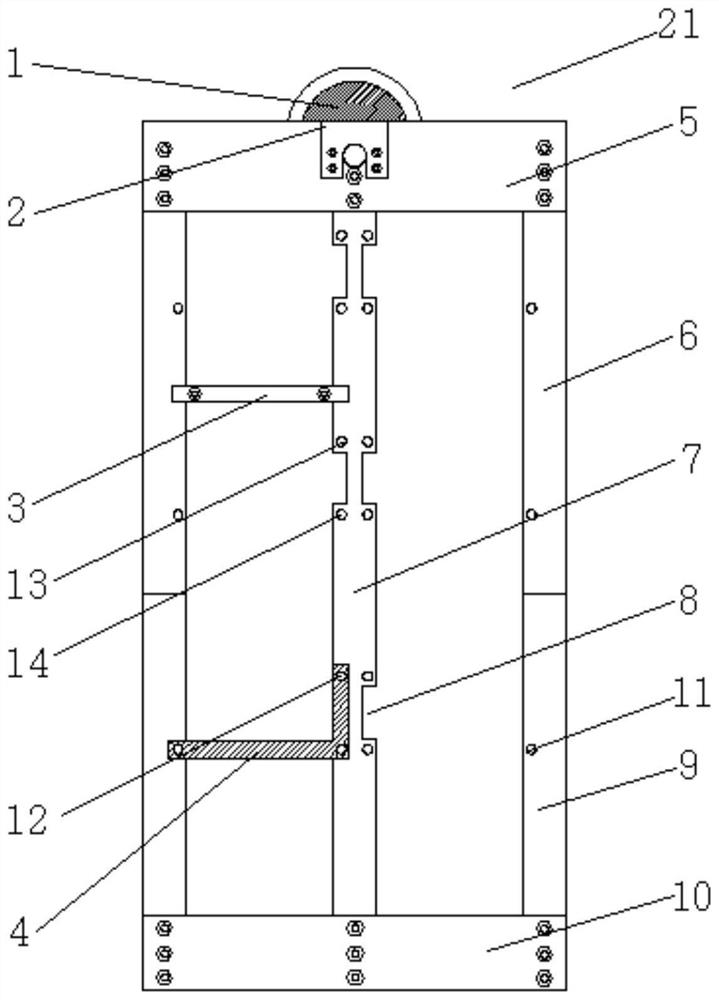

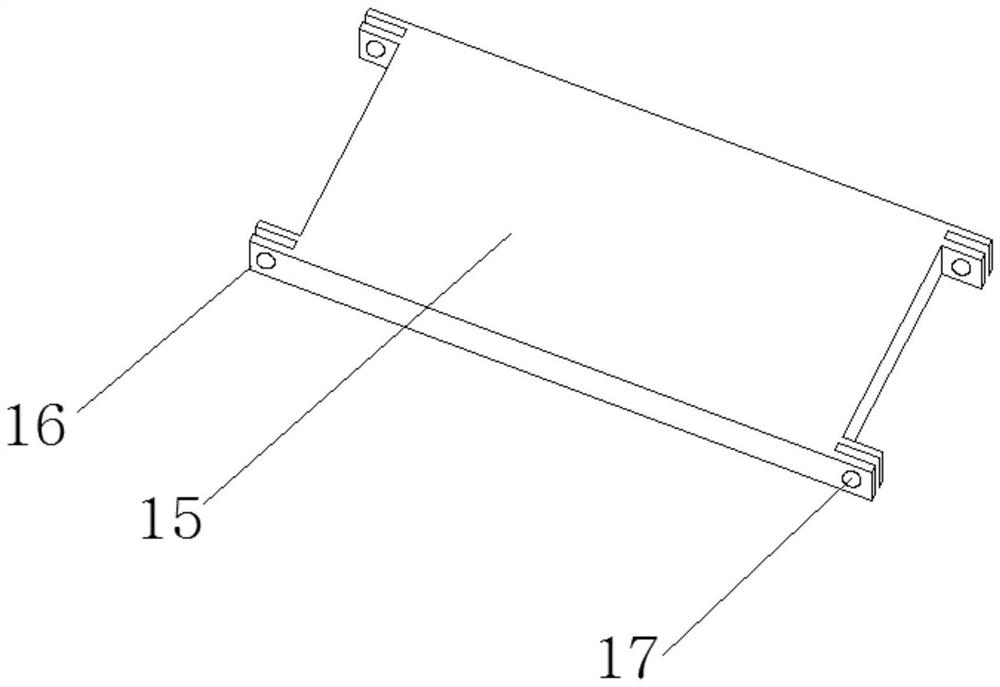

[0023] see Figure 1-5 , the present invention provides the following technical solutions: an elevator counterweight frame assembly structure, including a frame structure 21, a counterweight side fixing part 4 and a counterweight top fixing part 3, the frame structure 21 including a top beam 5, a top beam 5 Side beam assemblies are arranged on both sides, bottom beam 10 is arranged at the bottom of side beam assembly, top beam 5, side beam assembly and bottom beam 10 are all fastened by bolts, rope pulley 1 is installed inside top beam 5, side beam The middle beam 7 is fixed between the components, and the middle beam 7 is fixed between the top beam 5 and the bottom beam 10 by bolts. There is a counterweight installation opening 8 on one side of the middle beam 7, and a second counterweight installation opening 8 is opened on the top of the counterweight installation opening 8. A bolt hole 13, a second bolt hole 14 is provided at the bottom of the counterweight installation po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com